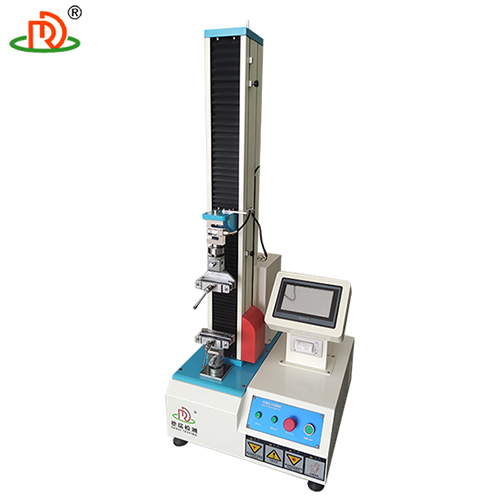

5-ton Wire Rope Tensile Testing Machine

2200.0 USD ($)/Unit

Product Details:

- Dimension (L*W*H) 450*400*1360 Millimeter (mm)

- Product Type Wire Rope Tensile Testing Machine

- Color White

- Machine Speed 50-300 mm/m

- Capacity 5 Ltr

- Application Industrial

- Weight 45 Kilograms (kg)

- Click to view more

X

5-ton Wire Rope Tensile Testing Machine Price And Quantity

- 2200.0 USD ($)/Unit

- 1 Unit

5-ton Wire Rope Tensile Testing Machine Product Specifications

- 5 Ltr

- Industrial

- 45 Kilograms (kg)

- Wire Rope Tensile Testing Machine

- 450*400*1360 Millimeter (mm)

- White

- 50-300 mm/m

5-ton Wire Rope Tensile Testing Machine Trade Information

- Cash in Advance (CID)

- 50 Unit Per Month

- 10 Days

- All India

Product Description

|

Item |

Parameters |

|

Load Capacity |

5-200kg |

|

Load cell brand |

China brand |

|

Motor |

90W OPG adjustable-speed motor |

|

Drive |

90W drive |

|

Screw |

Screw |

|

Control Way |

LED with built-in printer |

|

Speed |

Adjustable speed 50-300mm/min |

|

Max.Stroke |

900mm (including clamps) |

|

Load Resolution |

1/250,000 |

|

Load Accuracy |

0.5% |

|

Unit Switching |

gf/kgf/N//kN/LBf/T |

|

Dimension |

(L*W*H) 450*400*1360mm |

|

Weight |

Approx. 45KG |

|

Power |

1 AC 220V |

FAQs ofabout the5-ton Wire Rope Tensile Testing Machine:

-

Q: What is the maximum test load of this machine?

A: The maximum test load is 5 tons. -

Q: What types of wire rope tests is it suitable for?

A: It is suitable for tensile testing of various types of wire ropes within a specified diameter range. -

Q: Can the test speed be adjusted?

A: Yes, the test speed can be adjusted according to requirements. -

Q: What power supply does this machine require?

A: It typically requires a 220-volt power supply. -

Q: Does it come with data recording functionality?

A: Yes, some models are equipped with data recording functionality to save test results. -

Q: What is the testing accuracy?

A: The testing accuracy is high, usually within 1%. -

Q: Does it require regular calibration?

A: Yes, regular calibration is recommended to ensure testing accuracy. -

Q: Is it complicated to operate?

A: The operation is simple, usually featuring a user-friendly control interface. -

Q: Can it test other materials?

A: It is mainly used for wire ropes, but can be customized to test other materials as needed. -

Q: What are the dimensions and weight of the machine?

A: Specific dimensions and weight vary by model and should be checked in the product manual. -

Q: Does it support automated testing?

A: Some high-end models support automated testing functions. -

Q: Is it safe during testing?

A: Yes, it is equipped with multiple safety protection measures to ensure safe operation. -

Q: Are additional sensors required?

A: Sensors are usually built-in, but high-precision sensors can be added as needed. -

Q: Is the maintenance cost high?

A: The maintenance cost is low, requiring only regular cleaning and lubrication. -

Q: Is after-sales service provided?

A: Yes, most suppliers offer comprehensive after-sales service and technical support.

We hope these Q&A help you better understand the 5-ton Wire Rope Tensile Testing Machine!

Advanced Tensile Testing Technology

Our 5-ton Wire Rope Tensile Testing Machine incorporates modern engineering to deliver dependable and accurate test results. Crafted for industrial applications, it assures optimal performance and easy integration into your quality control workflow. The adjustable machine speed and efficient footprint make it suitable for diverse industrial settings.

Built for Industrial Durability

Constructed with sturdy materials and finished in white, this machine offers stability and longevity under intensive use. Its 45 kg weight ensures a solid base, while the substantial capacity and precise controls guarantee reliable operation for consistent testing, helping industries meet stringent compliance requirements.

FAQ's of 5-ton Wire Rope Tensile Testing Machine:

Q: How does the 5-ton Wire Rope Tensile Testing Machine operate?

A: The machine applies a controlled force to the wire rope, increasing tension until the breaking point is reached. The process measures the tensile strength accurately, allowing users to evaluate the reliability of their wire ropes for industrial use.Q: What are the main applications of this tensile testing machine?

A: This machine is primarily used in manufacturing and industrial settings to test the strength and durability of wire ropes, ensuring they meet safety and quality standards before deployment in critical operations.Q: When should wire ropes be tested using this machine?

A: Wire ropes should be tested periodically, particularly after manufacturing or before usage in high-stress environments, to verify their compliance with industry standards and prevent potential failures during operation.Q: Where can this machine be used most effectively?

A: It is ideal for use in quality control laboratories, production facilities, and industrial testing setups where precise tensile strength assessment of wire ropes is crucial.Q: What is the process for conducting a tensile test on this machine?

A: To perform a test, securely mount the wire rope in the machine's grips, set the desired speed (between 50 and 300 mm/m), and initiate the test. The machine records the maximum load endured by the rope before breaking, documenting tensile strength values.Q: What are the benefits of using this tensile testing machine?

A: Utilizing this machine ensures your wire ropes reliably meet quality and safety benchmarks through precise strength measurement, reducing the risk of operational failures and supporting robust industrial operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese