Cyclic Corrosion Testing Machine

3000.0 USD ($)/Unit

Product Details:

- Power Supply Electric

- Operate Method Semi Automatic

- Number of Specimens Multiple

- Usage Testing equipment

- Material Stainless Steel & PVC

- Control Mode Manual

- Click to view more

X

Cyclic Corrosion Testing Machine Price And Quantity

- 3000.0 USD ($)/Unit

- 1 Unit

Cyclic Corrosion Testing Machine Product Specifications

- Stainless Steel & PVC

- Testing equipment

- Multiple

- Semi Automatic

- Manual

- Electric

Cyclic Corrosion Testing Machine Trade Information

- Cash in Advance (CID)

- 50 Unit Per Month

- 10 Days

- All India

Product Description

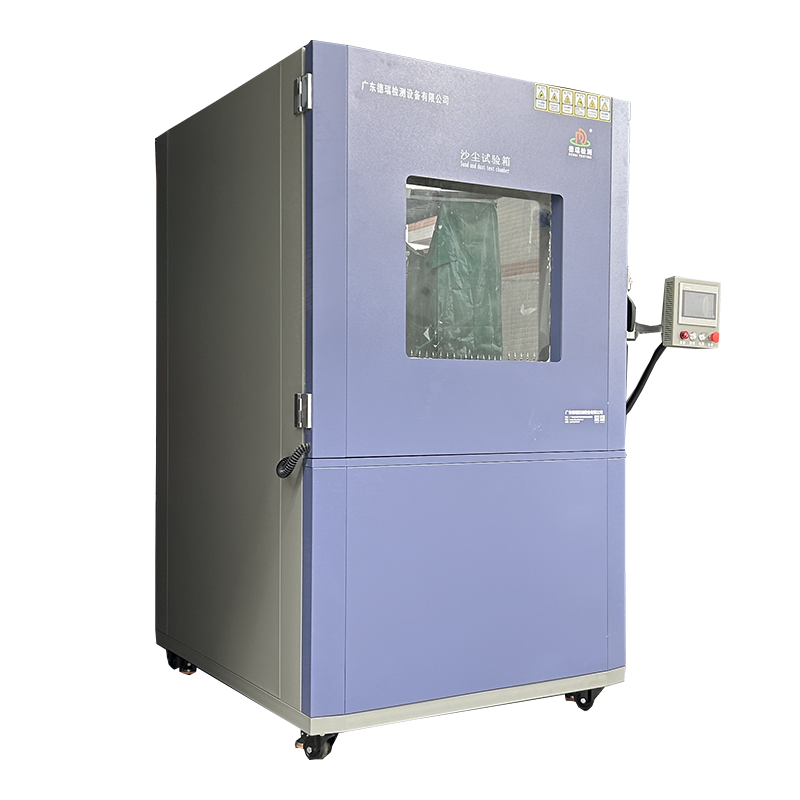

The Cyclic Corrosion Testing Machine is a reliable and efficient testing equipment that is used to evaluate the corrosion resistance of materials. This machine is made of high-quality stainless steel and PVC material, which ensures durability and long-lasting performance. The control mode of this equipment is manual, and it is designed to operate on electric power supply. With the ability to test multiple specimens at once, this machine is perfect for testing a wide range of materials. The operate method of the Cyclic Corrosion Testing Machine is semi-automatic, which makes it easy to use and provides accurate results. This machine is ideal for manufacturers, exporters, and suppliers who require a dependable testing equipment to ensure the quality of their products.

Model | DR-H304-200 |

Internal Size (W*D*H) | 2000*1000*600mm |

External Size (W*D*H) | 2700*1250*1500mm |

Equipment Material | P.V.C rigid plastic plate, thickness 8mm |

Sample tray | Diameter 10mm glass fiber rod, anti-rust V-shape plastic steel to make sure sample in 15~30 degree inclined |

Temperature Range | Room temperature ~ 55 |

Temperature Fluctuations | 0.5 |

Temperature Uniformity | 2 |

Temperature Precision | 1 |

Spraying method | Continuous and Periodic spray type |

Temperature | Salt Spray Method (NSS ACSS)351 |

Saturated air Barrel Temperature | Salt Spray Method (NSS ACSS)471 |

Brine Temperature | 351 |

Spray Quantity | 1.0~2.0 ml / 80cm2 / hr |

PH value | Salt Spray Method (NSS ACSS6.5~7.2) |

Lab Volume | 1200L |

Brine Tank Capacity | 40L |

Multiple Safety Protection Devices | Current discharge protection, over pressure protection, over temperature protection, over load fuse protection |

Accessories | Testing Salt / Measuring tank / Spray Nozzle x 1 set |

Air source | Air pump (provided by buyer) |

Test criteria | ASTM B117-08, ISO 9227... |

FAQs of Cyclic Corrosion Testing Machine:

Q: What is the Cyclic Corrosion Testing Machine used for?

A: This machine is used to evaluate the corrosion resistance of materials.Q: What materials is this machine made of?

A: The machine is made of high-quality stainless steel and PVC material.Q: What is the control mode of this equipment?

A: The control mode of this equipment is manual.Q: How many specimens can be tested at once?

A: This machine can test multiple specimens at once.Q: What is the operate method of this machine?

A: The operate method of this machine is semi-automatic.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese