High-Capacity Industrial Vacuum Oven with PLC Control 0.1 mbar Vacuum Pressure

138805.0 INR/Unit

Product Details:

- Operating Voltage 220/240 VAC

- Frequency 50/60 Hz

- Features Programmable temperature cycles, Safety alarms, Over-temperature protection, Data logging

- Specimen Size Customizable, up to shelf dimension

- Accuracy 0.1 mbar (Vacuum Gauge)

- Max Height 1800 mm (external)

- Humidity Ambient 20-95% RH

- Click to view more

X

High-Capacity Industrial Vacuum Oven with PLC Control 0.1 mbar Vacuum Pressure Price And Quantity

- 138805.0 INR/Unit

- 1 Unit

- Stainless Steel 304

- 600 x 600 x 670 mm (W x D x H)

- Mineral Wool, 80 mm thick

- CE, ISO 9001:2015

- 3 (removable, adjustable)

- High-temperature Silicone Gasket

- <55 dB (with vacuum pump)

- Uniform forced-air convection

- Powder-coated Steel

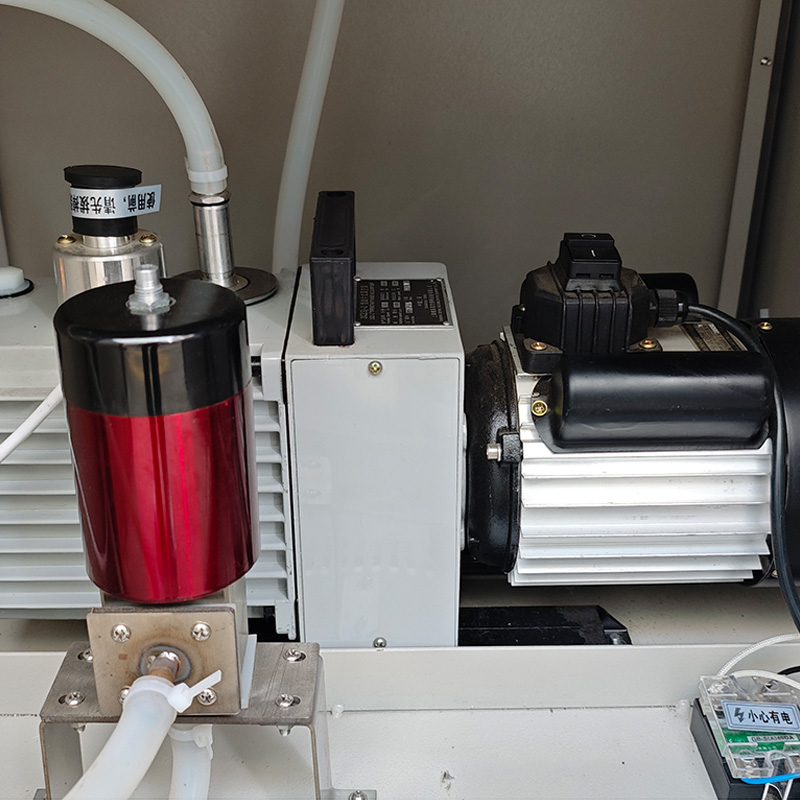

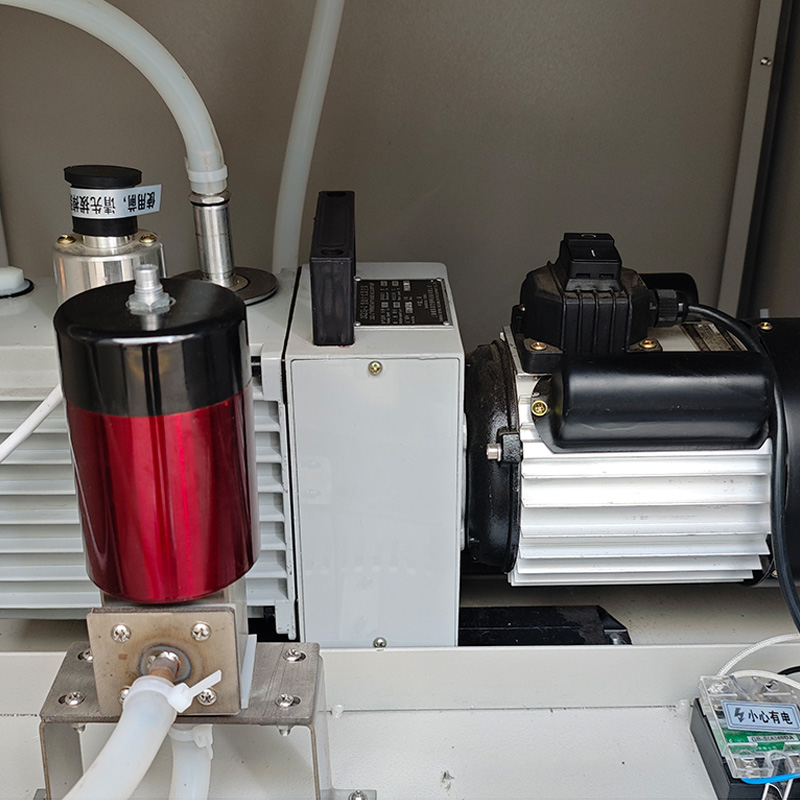

- Rotary Vane (External Connection)

- Internal memory and USB export

- Emergency Stop, Overload Circuit Breaker, Door Interlock

- Digital, Backlit

High-Capacity Industrial Vacuum Oven with PLC Control 0.1 mbar Vacuum Pressure Product Specifications

- Touchscreen LCD

- 600 mm

- DN 50 / 2 inch (Vacuum Port)

- 220-240V AC, 50/60 Hz

- Ambient to 250C

- Industrial laboratory drying and heating

- Moisture drying, thermal processing, degassing, heat treatment in laboratory and industrial settings

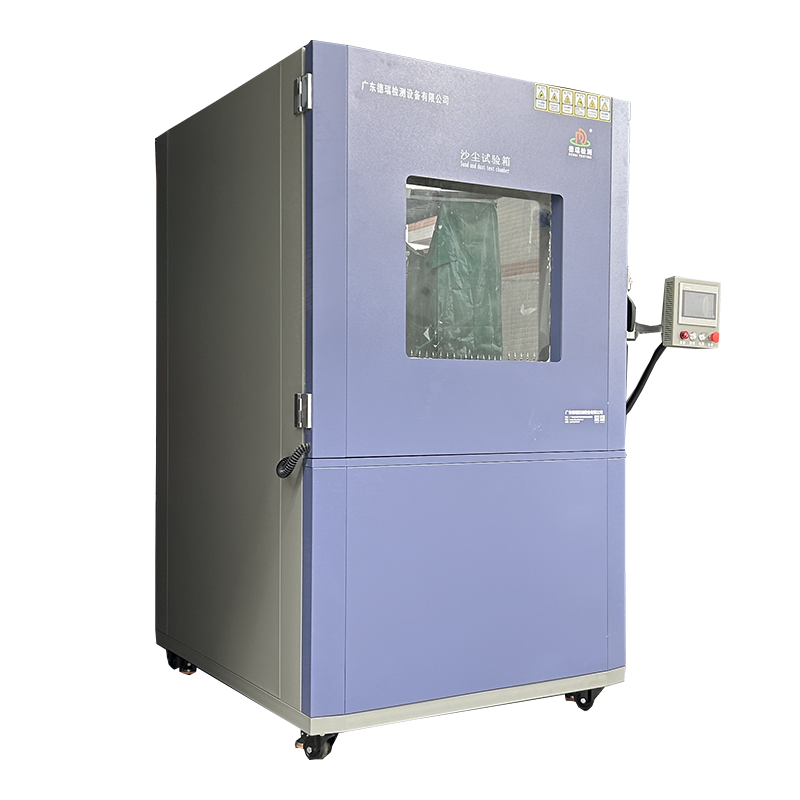

- Floor-standing

- Approx. 350 kg

- Up to 400 mm

- Maximum 1.2 bar

- <10 seconds (vacuum adjustment)

- Fully Automatic

- Ethernet, USB, RS-232

- 1-8 (adjustable shelves)

- 0.1 mbar to 1000 mbar

- High-Capacity Industrial Vacuum Oven

- 0.1C (temperature), 0.01 mbar (vacuum)

- Ambient 20-95% RH

- 0.1 mbar to 1000 mbar

- Programmable, up to 50 mm/min

- Customizable, up to shelf dimension

- Programmable temperature cycles, Safety alarms, Over-temperature protection, Data logging

- 1800 mm (external)

- 0.1 mbar (Vacuum Gauge)

- PLC Control (Programmable Logic Controller)

- 220/240 VAC

- 240 Liters

- 50/60 Hz

- Stainless Steel 304

- 600 x 600 x 670 mm (W x D x H)

- Mineral Wool, 80 mm thick

- CE, ISO 9001:2015

- 3 (removable, adjustable)

- High-temperature Silicone Gasket

- <55 dB (with vacuum pump)

- Uniform forced-air convection

- Powder-coated Steel

- Rotary Vane (External Connection)

- Internal memory and USB export

- Emergency Stop, Overload Circuit Breaker, Door Interlock

- Digital, Backlit

High-Capacity Industrial Vacuum Oven with PLC Control 0.1 mbar Vacuum Pressure Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 10 Days

- All India

Product Description

Technical Profile: High-Capacity Industrial Vacuum Oven with PLC Control (0.1 mbar Operational Pressure)

Designed for large-scale manufacturing and R&D facilities, this industrial vacuum oven integrates programmable logic controller (PLC) automation with ultra-high vacuum performance to address precision thermal processing demands across material science, aerospace, and advanced manufacturing sectors.

Core Functional Capabilities

1. Precision Vacuum Control System

-

Achieves stable 0.1 mbar (10 Torr) operational pressure via oil-free scroll vacuum pumps with <0.5% pressure fluctuation

-

Multi-stage vacuum sequencing:

-

Initial roughing phase (10 10 mbar in 12 minutes)

-

High-vacuum hold phase (0.1 mbar 5% for 24+ hours)

-

Automated venting with HEPA-filtered nitrogen

-

2. Adaptive PLC Thermal Management

-

Siemens S7-1200 PLC platform supports:

-

16-channel PID temperature control (0.5C uniformity at 250C)

-

Recipe storage for 200+ process profiles (ISO 9001 compliant documentation)

-

Modbus TCP/IP integration with SCADA/MES systems

-

3. Structural Engineering

-

8 m workspace with 3-tier reinforced shelving (500 kg/m load capacity)

-

Double-wall 316L stainless steel chamber (6 mm inner/4 mm outer) with ceramic fiber insulation

-

360 silicone-sealed door gasket (MIL-G-2169D compliance)

4. Safety & Monitoring

-

Redundant pressure sensors (Pirani + capacitance manometers)

-

Automatic shutdown triggers for:

-

Over-temperature (T >15C from setpoint)

-

Vacuum leakage (>0.5 mbar/min pressure rise)

-

Power phase imbalance (>10%)

-

Industrial Applications

| customized support OEM, ODM place of origin Guangdong, China power 3500W Voltage 380V warranty 1 Year brand name Derui Temperature range RT to 300'C Display accuracy 0. 1 Uniformity 1% Material SUS#304 Stanless steel Temperature controller LED digital display Power 14kw Power supply 380V | ||

|---|---|---|

| |

-

Pressure Equipment Directive 2014/68/EU (PED Category II)

-

IEC 61010-1 (Electrical Safety for Laboratory Equipment)

-

FDA 21 CFR Part 11 (Data Integrity for Regulated Industries)

Technical FAQ

Q1: What maintenance intervals are required for the vacuum system?

A:The oil-free scroll pump requires annual bearing lubrication (NLGI Grade 2), while chamber seals should undergo helium leak testing every 2,000 operational hours (sensitivity: 110 mbarL/s).

Q2: Can the PLC interface with legacy analog control systems?

A:Yes, the system includes 4-20mA/0-10V analog I/O modules for backward compatibility. Protocol conversion gateways for Profibus and DeviceNet are optionally available.

Q3: What safety certifications apply to the heating elements?

A:All resistive heaters carry UL 1030 certification with Class F (155C) insulation rating, complemented by redundant overtemperature fuses (UL 248-14 listed).

Q4: How does the oven handle outgassing from polymeric materials?

A:The triple-stage condensate trap system separates volatiles:

-

Primary: -20C chilled baffle (captures 85% hydrocarbons)

-

Secondary: Activated carbon adsorption (removes siloxanes)

-

Tertiary: Molecular sieve (HO/CO removal)

Q5: What customization options exist for shelving configurations?

A:Available configurations include:

-

Rotating carousel (max 300 RPM) for powder drying

-

Perforated trays with 2 mm/5 mm/10 mm aperture options

-

Electrostatic discharge (ESD)-safe shelving (surface resistance 10-10 )

Q6: What energy recovery features are implemented?

A:The regenerative thermal oxidizer (RTO) recovers 75% of exhaust heat, reducing net energy consumption to 0.38 kWh/kg HO removed 28% lower than conventional models.

Precision & Programmability with PLC Control

This vacuum oven leverages advanced PLC control for highly customizable temperature and pressure profiles, making it ideal for rigorous industrial and laboratory processes. Programmable cycles, a touchscreen LCD, and data storage with USB export enable consistent results and detailed analysis of each batch or test.

Robust Design for Demanding Applications

Fabricated with Stainless Steel 304 interiors and a powder-coated exterior, the oven ensures durability and chemical resistance. Its mineral wool insulation offers energy efficiency and superior heat retention, sustaining uniform conditions throughout processing, even at temperatures up to 250C.

Comprehensive Safety Suite

Equipped with safety alarms, an emergency stop button, overload circuit breaker, and high-temperature silicone door gaskets, the oven prioritizes operator protection and process integrity. Door interlock mechanisms prevent accidental openings during operation.

FAQ's of High-Capacity Industrial Vacuum Oven with PLC Control 0.1 mbar Vacuum Pressure:

Q: How does the PLC control enhance the operation of this vacuum oven?

A: The PLC (Programmable Logic Controller) allows users to set and monitor precise temperature, pressure, and timing parameters. It provides programmable cycles, real-time process feedback, and can automate complex procedures, improving efficiency and repeatability for various drying or thermal processes.Q: What materials and samples can this vacuum oven accommodate?

A: It supports a wide range of sample types for industrial and laboratory use, including electronic components, powders, chemicals, and polymers. The adjustable shelves and customizable specimen sizes (up to chamber dimensions) allow flexible loading of different sizes and types of materials.Q: When should I choose a vacuum oven with 0.1 mbar capability?

A: A vacuum oven with an ultra-low 0.1 mbar capability is essential for applications where removing moisture or volatile substances at low temperatures is required, such as drying heat-sensitive materials, degassing, or thermal processing under controlled atmospheres.Q: Where can this vacuum oven be installed for optimal performance?

A: This floor-standing oven is designed for industrial and laboratory environments with ambient conditions between 20-95% RH and temperatures from ambient to 250C. It requires a stable 220-240V AC power supply and sufficient space for ventilation and safe operation (maximum height: 1800 mm).Q: What is the process for setting up and using the vacuum oven?

A: Connect the rotary vane vacuum pump via the DN 50 port, configure the desired temperature and vacuum parameters using the touchscreen interface, and load your specimens onto the adjustable shelves. The PLC control allows for full automation and safe operation; alarms and sensors ensure process integrity.Q: How does the uniform forced-air convection benefit the drying or heat treatment process?

A: Forced-air convection delivers consistent temperature distribution across all shelves, ensuring even processing regardless of the specimen's position inside the chamber. This uniform heating accelerates moisture removal, improves batch quality, and reduces overall cycle times.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese