Rotary vibration testing machine

128005.0 INR/Unit

Product Details:

- Port Size 1/4 inch

- Number of Specimens 4

- Operating Voltage 220V AC

- Hardness Frame: High-strength steel

- Temperature 10C - 40C

- Humidity 20% - 80% RH

- Frequency 1-5 Hz adjustable

- Click to view more

X

Rotary vibration testing machine Price And Quantity

- 1 Unit

- 128005.0 INR/Unit

- Precision servo motor

- Programmable test duration

- < 60 dB

- Powder-coated steel

- Anti-vibration rubber feet

- Internal LED

- Enabled

- Yes

- ASTM, ISO 13002

Rotary vibration testing machine Product Specifications

- 200 mm

- 0-20 mm adjustable

- 60-300 RPM (adjustable)

- 125 kg

- 1/4 inch

- 20% - 80% RH

- 1-5 Hz adjustable

- Frame: High-strength steel

- 10C - 40C

- 4

- 220V AC

- Max load 20 kg

- LCD digital display

- Semi-Automatic

- 350 mm

- Material/component vibration fatigue testing

- 0-20 mm stroke

- 0.01 mm

- <1 second

- Digital touch panel

- 1~999999 cycles

- 1% of set value

- Automatic cycle counting, adjustable speed and stroke, overload protection

- Up to 80 mm x 80 mm

- AC 220V, 50Hz

- Rotary vibration testing machine

- RS232

- Vibration resistance testing for material or component performance evaluation

- Table top

- 0.5-0.7 MPa

- Precision servo motor

- Programmable test duration

- < 60 dB

- Powder-coated steel

- Anti-vibration rubber feet

- Internal LED

- Enabled

- Yes

- ASTM, ISO 13002

Rotary vibration testing machine Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 3 Days

- All India

Product Description

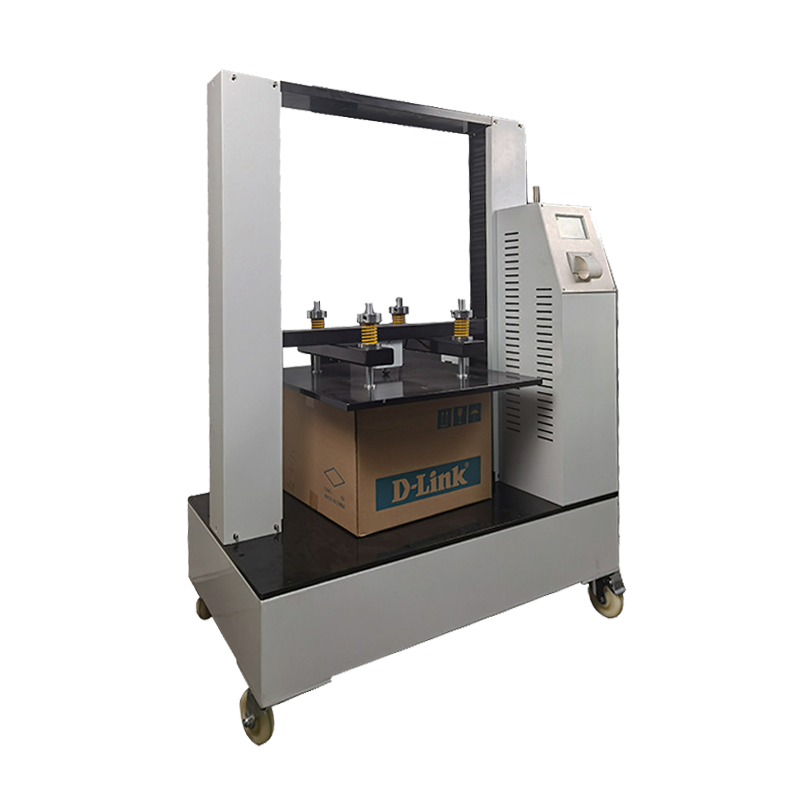

Rotary vibration tester is a widely used equipment for reliability testing of various industrial products, especially in automotive, aerospace, electronics and other fields has an indispensable position. The equipment evaluates the vibration resistance and overall reliability of products by simulating the vibration environment they may encounter during transportation and use. Its core advantage lies in its ability to provide precise vibration control and a wide frequency range, thus ensuring the accuracy and repeatability of test results.

Product Features

1.

High-precision control: The rotary vibration tester adopts an advanced servo control system, which is capable of realizing high-precision vibration frequency and amplitude control to ensure the accuracy of test conditions.

2.

Wide frequency range: the equipment supports a wide range of vibration frequencies from low to high frequencies, which can simulate the vibration environment under various practical application scenarios.

3.

User-friendly interface: Equipped with an intuitive operator interface, users can easily set and adjust the test parameters, simplifying the operation process.

4.

Multiple safety protection: Built-in multiple safety protection mechanisms, including overload protection and emergency shutdown function, to ensure the safety of the testing process.

5.

Modular design: The equipment adopts modular design, which is easy for maintenance and upgrading, and can be customized and configured according to user requirements.

Frequently Asked Questions

1. What are the main applications of rotary vibration tester?

Rotary vibration testers are widely used in automotive, aerospace, electrical and electronic, military and other fields. In these fields, products experience a variety of vibration environments during transportation and use, and the testers simulate these environments to assess the reliability and durability of the products. For example, in the automotive industry, the tester is used to test the vibration resistance of automotive parts to ensure their stability in actual driving.

2. How to choose the right vibration tester?

Selecting the right vibration tester requires consideration of a number of factors, including the range of test frequencies, load capacity, control accuracy, and the environment in which the equipment will be used. First, define the testing needs and standards; second, assess whether the performance parameters of the equipment meet the testing requirements; and finally, consider the reliability and after-sales service of the equipment. It is recommended to make detailed consultation and comparison before purchase, and choose reputable brands and suppliers.

3. What are the precautions for the maintenance of rotary vibration tester?

In order to ensure the long-term stable operation of the rotary vibration tester, regular maintenance is essential. The main precautions include: regular inspection of the mechanical components and electrical systems of the equipment to ensure that they are in good condition; keep the equipment clean to avoid dust and debris entry; regular calibration of the equipment to ensure its control accuracy; and operate in strict accordance with the operating manual to avoid improper use leading to equipment damage.

4. How are vibration tester test results analyzed?

Test results from vibration testers are usually presented in the form of graphs and data, and analyzing these results requires specialized knowledge and experience. The main analysis methods include: comparing the vibration response under different test conditions to assess the vibration resistance of the product; analyzing the impact of vibration frequency and amplitude on the product to determine the product's weak points; and evaluating the reliability of the product in the context of practical application scenarios. Through professional analysis software and tools, the test results can be more accurately interpreted to provide a basis for product improvement.

5. How is a rotary vibration tester calibrated?

Calibration of a rotary vibration tester is a critical step in ensuring the accuracy of its control and test results. The calibration process usually consists of the following: firstly, calibrate the machine using a standard vibration source; secondly, adjust the control parameters of the machine to meet the standard requirements; and finally, carry out a number of tests to verify the stability of the calibration results. It is recommended that calibration be carried out by a professional technician and rechecked on a regular basis to ensure the long-term reliability of the equipment.

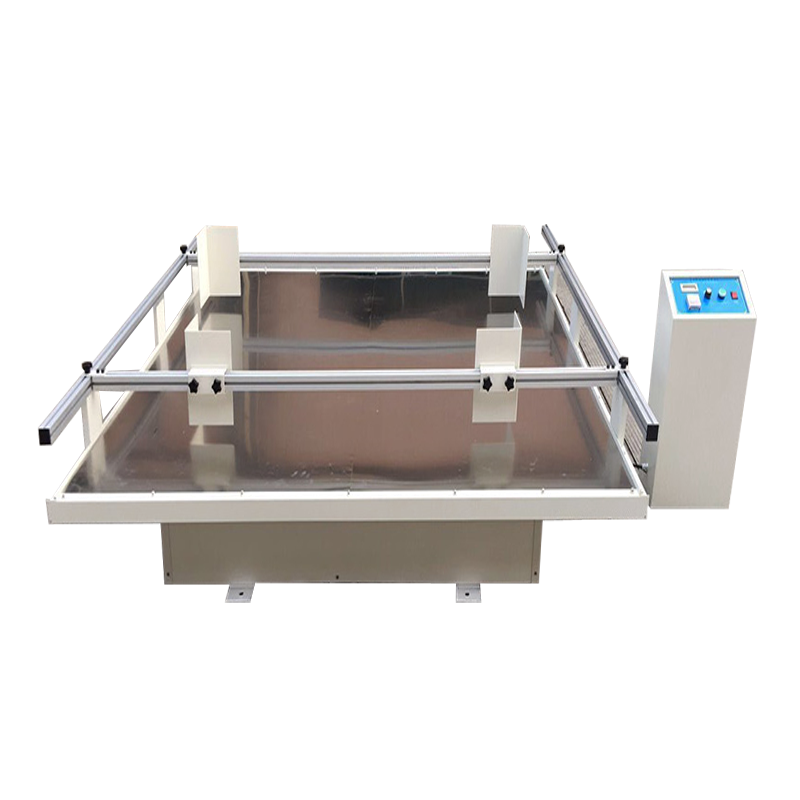

| Item | DR-B216 |

| Max. Test Load | 100kg |

| Frequency Range | 60-300rpm |

| Amplitude Range | 25.4mm (1 inch) |

| Simulation Speed | 25~40km/h |

| Vibration Mode | Roundtrip |

| Work Table Size | 1000*1200 mm ( L*W, can be customized ) |

| Outside dimension ( L*W*H ) | 1255*1070*660mm |

| Speed Mode | DC converter or AC Frequency Control |

| Power Capacity | 1 HP |

| Weight | 150kg |

| Power | 220V, 50 Hz |

| Speed Mode | DC converter or AC Frequency Control |

| Environmental Conditions | Temperature: 5~40C; Related Humidity <85% |

Precision Vibration Fatigue Testing

Designed for rigorous reliability assessment, this rotary vibration tester uses advanced servo motors and digital controls to precisely simulate real-world vibration stresses. Engineers and quality control teams benefit from highly configurable speed, stroke, and programmable test cycles, streamlining diverse material and component evaluations. Its compact, robust construction makes it a trusted choice in R&D and industrial labs alike.

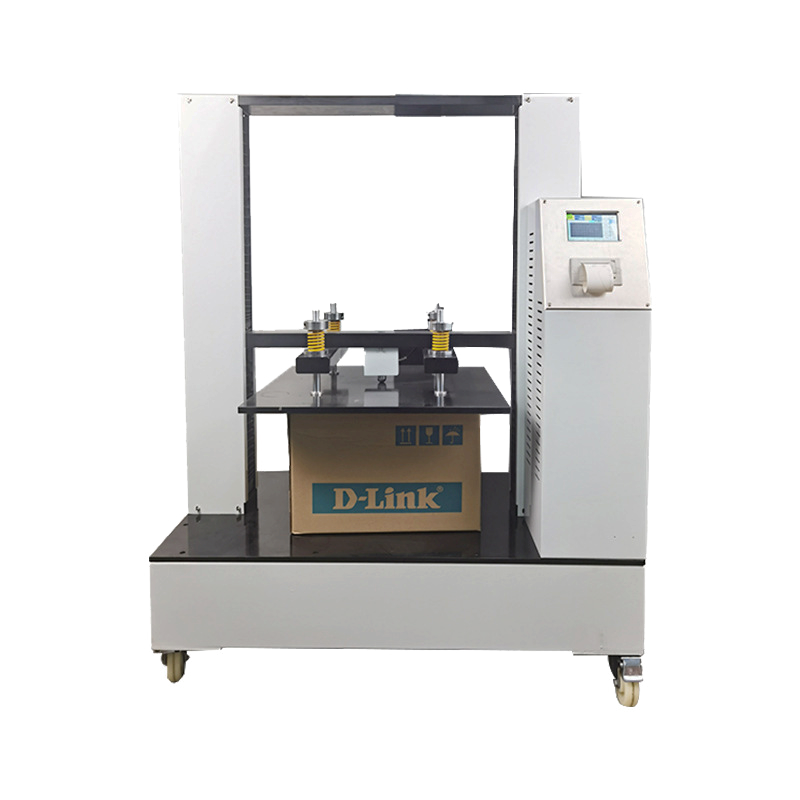

User-Friendly, Safe Operation

The digital touch panel, programmable timer, and internal LED chamber lighting ensure convenient setup and monitoring. Integrated safety interlocks, emergency stop, and overload safeguards prioritize user safety. The powder-coated enclosure, anti-vibration mounting, and low-noise operation enable stable, distraction-free testing sessions in controlled environments.

FAQ's of Rotary vibration testing machine:

Q: How can I set and monitor the vibration test parameters on this machine?

A: You can easily set test parameters such as speed (60-300 RPM), stroke (0-20 mm), and test duration using the intuitive digital touch panel. The LCD display provides clear, real-time feedback, and you can monitor progress and view cycle counts during operation.Q: What is the recommended process for initiating a test on the rotary vibration testing machine?

A: First, securely mount up to four specimens (max size: 80 x 80 mm) on the anti-vibration rubber feet. Configure test parameters with the touch panel, set the desired cycles (up to 999,999), and ensure the safety interlock and emergency stop are functional. Once ready, activate the programmable timer to commence testing.Q: When should the machine's emergency stop feature be used?

A: The emergency stop should be engaged immediately if any anomalies, unexpected noises, or unsafe conditions occur during a test. This instantly halts all motion to protect both the operator and specimens.Q: What benefits does the programmable timer and automatic cycle counting provide?

A: The programmable timer and automatic cycle counting remove the need for manual checks, reducing human error and ensuring precise, repeatable testing. Users can easily set and leave tests running, confident in consistent, accurate results.Q: Where is this rotary vibration testing machine ideally installed?

A: Designed for laboratory, quality assurance, and industrial testing facilities in India or globally, the machine's tabletop mounting, low noise level, and anti-vibration feet make it suitable for controlled indoor environments with standard AC 220V, 50Hz supply.Q: How does the safety interlock system function?

A: The safety interlock prevents operation if the chamber is improperly closed or accessed during a test. This crucial safeguard ensures operator and equipment safety by halting machine activity when the chamber is open or compromised.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese