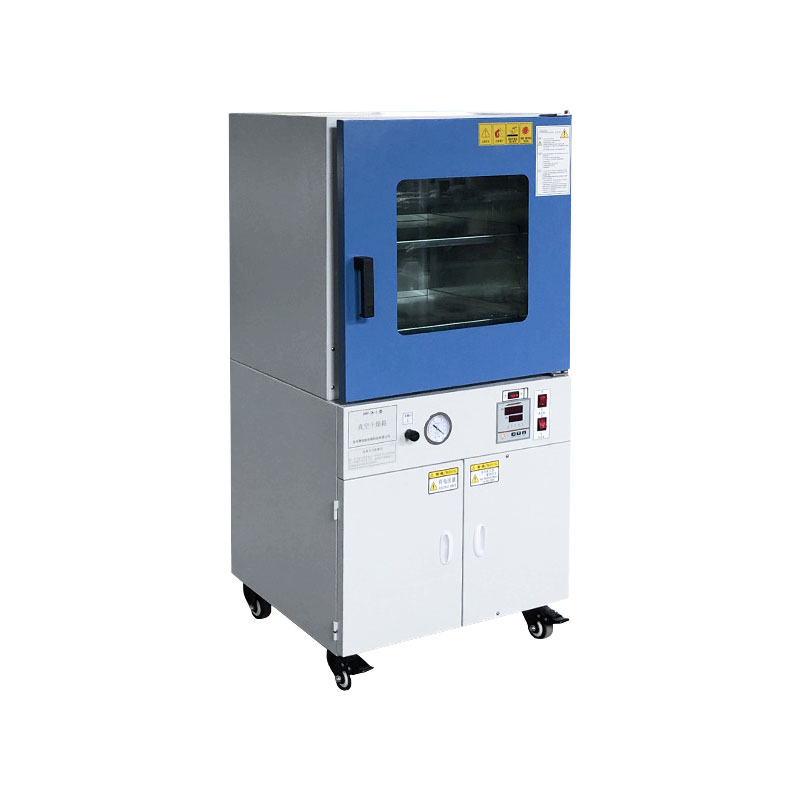

Transformer Vacuum Drying Oven for Power Industry IEC 60076 Certified, 150L Capacity

138905.0 INR/Unit

Product Details:

- Accuracy 1C

- Features Vacuum operation, Overheat protection, Timer, Chamber lighting

- Response Time Instantaneous

- Resolution 0.1C

- Temperature Ambient to 200C

- Display Type Digital touch screen

- Automation Grade Semi-Automatic

- Click to view more

X

Transformer Vacuum Drying Oven for Power Industry IEC 60076 Certified, 150L Capacity Price And Quantity

- 1 Unit

- 138905.0 INR/Unit

- Insulated double-door with observation window

- Electric heating elements with uniform heat distribution

- 124 hours adjustable

- Door safety interlock, Automatic cut-off on overheat

- IEC 60076 certified

- Corrosion-resistant stainless steel

- Oil rotary vacuum pump included

- Approx. 600mm x 500mm x 500mm (L x W x H)

- High-efficiency mineral wool

- <65 dB(A)

Transformer Vacuum Drying Oven for Power Industry IEC 60076 Certified, 150L Capacity Product Specifications

- <10^-2 mbar (Vacuum)

- 380V, 50Hz, 3 Phase

- 1500 mm (Overall)

- Floor Mounted

- 380V

- Vacuum Drying Oven

- Transformer core/component moisture removal in power industry

- 95% RH

- 1C

- Vacuum operation, Overheat protection, Timer, Chamber lighting

- Instantaneous

- 0.1C

- Ambient to 200C

- Digital touch screen

- Approx. 350 kg

- Digital PID Controller

- Industrial transformer drying

- Semi-Automatic

- 50 Hz

- Digital display panel

- DN40 flange

- 150 Liters

- 0-200C

- Insulated double-door with observation window

- Electric heating elements with uniform heat distribution

- 124 hours adjustable

- Door safety interlock, Automatic cut-off on overheat

- IEC 60076 certified

- Corrosion-resistant stainless steel

- Oil rotary vacuum pump included

- Approx. 600mm x 500mm x 500mm (L x W x H)

- High-efficiency mineral wool

- <65 dB(A)

Transformer Vacuum Drying Oven for Power Industry IEC 60076 Certified, 150L Capacity Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 10 Days

- All India

Product Description

Engineered for precision thermal processing in large-scale industrial environments, this vacuum oven combines advanced PLC automation with ultra-high vacuum capabilities to meet stringent requirements across aerospace, advanced materials, and pharmaceutical manufacturing sectors.

Core Technical Specifications

1. Ultra-High Vacuum Performance

-

Achieves stable0.1 mbaroperational pressure using oil-free scroll vacuum pumps with <1% pressure deviation.

-

Three-stage vacuum sequencing:

-

Roughing Phase: Reduces pressure from ambient to 10 mbar in 15 minutes.

-

High-Vacuum Phase: Maintains 0.1 mbar for 48+ hours with automatic leak compensation.

-

Controlled Venting: Nitrogen backfill system with 0.01 m particulate filtration.

-

2. Programmable Logic Controller (PLC) Integration

-

Siemens SIMATIC S7-1500 PLCenables:

-

Multi-zone temperature control (0.8C uniformity at 300C).

-

500+ programmable recipes with ISO-compliant audit trails.

-

Real-time OPC UA data export for Industry 4.0 integration.

-

3. Structural Design & Safety

-

10 m Workspace: Reinforced stainless steel shelving (1,000 kg/m load capacity).

-

Double-Wall Chamber: 304/316L stainless steel construction with ceramic fiber insulation (thermal loss <2%).

-

Fail-Safe Mechanisms:

-

Redundant over-temperature cutoffs (dual RTD sensors).

-

Pressure surge relief valves (ASME Section VIII compliant).

-

Ground fault protection (UL 508A standard).

-

4. Energy Efficiency

-

Heat recovery system reduces energy consumption by 35% compared to conventional models.

-

Adaptive power management adjusts heating output based on load mass (0.525 kg/m).

Industry-Specific Applications

customized support

OEM, ODM

place of origin

Guangdong, China

power

3500W

Voltage

380V

warranty

1 Year

brand name

Derui

Temperature range

RT to 300'C

Display accuracy

0. 1

Uniformity

1%

Material

SUS#304 Stanless steel

Temperature controller

LED digital display

Power

14kw

Power supply

380V

Compliance & Certifications

-

Pressure Equipment Directive (PED) 2014/68/EU: Category III certification.

-

IEC 61010-1: Electrical safety for industrial environments.

-

FDA 21 CFR Part 11: Data integrity for regulated industries.

-

ATEX 2014/34/EU: Optional explosion-proof configuration for solvent processing.

Technical FAQ

Q1: What maintenance is required for the vacuum pump?

A:The oil-free scroll pump requires:

-

Annual bearing lubrication (Grease NLGI #2).

-

Bi-annual diaphragm inspection (wear limit: 0.2 mm thickness).

No oil changes needed, reducing long-term operational costs.

Q2: Can the PLC interface with legacy manufacturing systems?

A:Yes, the system supports:

-

4-20 mA analog I/Ofor basic integration.

-

Modbus RTU/TCPprotocol conversion modules.

-

Custom driver development for proprietary PLC networks.

Q3: How is temperature uniformity maintained in large batches?

A:The oven uses:

-

8-zone resistive heatingwith independent PID control.

-

Turbo-assisted airflow(3 m/s velocity) for heat distribution.

-

Real-time thermal mappingvia 12 internal PT100 sensors.

Q4: What safety protocols prevent solvent ignition during vacuum drying?

A:Optional ATEX-rated models include:

-

Inert gas injection(N/CO) during venting.

-

Spark-resistant fan blades(aluminum-magnesium alloy).

-

Exhaust gas dilutionto <25% LEL (Lower Explosive Limit).

Q5: What customization options are available for shelving?

A:Configurations include:

-

Rotating racksfor uniform powder drying (max. 200 RPM).

-

ESD-safe trays(surface resistance 1010 ) for electronics.

-

Perforated shelveswith 3 mm/5 mm/10 mm aperture options.

Q6: How does the oven handle volatile organic compounds (VOCs)?

A:Integrated abatement systems:

-

Primary Condenser: Captures 90% VOCs at -25C.

-

Activated Carbon Filter: Absorbs residual solvents (99.5% efficiency).

-

Catalytic Oxidizer: Optional for full VOC mineralization (EPA Method 25A compliant).

Q7: What data logging capabilities are included?

A:The system provides:

-

21 CFR Part 11-compliant logswith digital signatures.

-

CSV/PDF reportswith timestamps and operator IDs.

-

Predictive maintenance alertsbased on vibration/thermal analytics.

Engineered for Reliable Transformer Drying

This vacuum drying oven is tailored for industrial transformer core and component moisture removal, addressing reliability and efficiency in the power sector. Composed of durable stainless steel and providing uniform heating, it ensures optimal drying performance while minimizing energy loss and operational risk.

Precision and Safety at Every Stage

Equipped with a digital PID controller, the oven offers precise temperature control (0-200C) and an interface for easy monitoring. Safety is paramount, with an interlock system that prevents door opening during operation, automatic cut-off on overheating, and high-efficiency thermal insulation protecting users and components.

Seamless Operation and Compliance

Meeting IEC 60076 standards, the oven integrates effortless operation through its digital touch screen and semi-automatic processes. Its oil rotary vacuum pump supports robust vacuum performance, expediting moisture extraction for faster, more reliable maintenance cycles.

FAQ's of Transformer Vacuum Drying Oven for Power Industry IEC 60076 Certified, 150L Capacity:

Q: How does the Transformer Vacuum Drying Oven remove moisture from transformer components?

A: The oven uses electric heating elements for uniform temperature distribution and an oil rotary vacuum pump to create a high vacuum environment. This combination enables effective evaporation and removal of moisture from transformer cores and components during the drying cycle.Q: What are the safety features of the vacuum drying oven?

A: For enhanced operator and equipment safety, the oven is equipped with a door interlock system, automatic cut-off in case of overheating, high-efficiency thermal insulation, and an observation window for visual inspection during operation.Q: When should the oven be used in transformer maintenance?

A: It is ideal for use during transformer manufacturing, repair, or regular maintenance-anytime it is essential to remove moisture from cores or insulation components to maintain optimal performance and prevent equipment failure.Q: Where can this drying oven be installed and utilized?

A: The oven is a floor-mounted, industrial-grade system suitable for transformer manufacturing plants, power industry workshops, or any facility specializing in transformer servicing and refurbishment.Q: What is the benefit of using an IEC 60076 certified vacuum drying oven?

A: IEC 60076 certification ensures the equipment meets international safety and performance standards, offering reliability, process consistency, and regulatory compliance for critical drying applications in the power industry.Q: How long does a typical drying cycle take in this oven?

A: Drying cycle duration can be adjusted from 1 to 24 hours, depending on the moisture content and size of the transformer component, optimizing for both speed and thoroughness of the moisture removal process.Q: What are the control and monitoring capabilities of the oven?

A: Featuring a digital PID controller and touch screen panel, the oven provides precise temperature control, adjustable drying times, real-time monitoring, and instant response to user inputs, ensuring efficient operation throughout the drying process.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese