Uv Light Accelerated Aging Test Chamber

4100.0 USD ($)/Unit

Product Details:

- Number of Specimens Multiple

- Operate Method Semi Automatic

- Power Supply Electric

- Usage Testing equipment

- Material Stainless Steel & PVC

- Control Mode Manual

- Click to view more

X

Uv Light Accelerated Aging Test Chamber Price And Quantity

- 4100.0 USD ($)/Unit

- 1 Unit

Uv Light Accelerated Aging Test Chamber Product Specifications

- Manual

- Stainless Steel & PVC

- Testing equipment

- Electric

- Semi Automatic

- Multiple

Uv Light Accelerated Aging Test Chamber Trade Information

- Cash in Advance (CID)

- 50 Unit Per Month

- 10 Days

- All India

Product Description

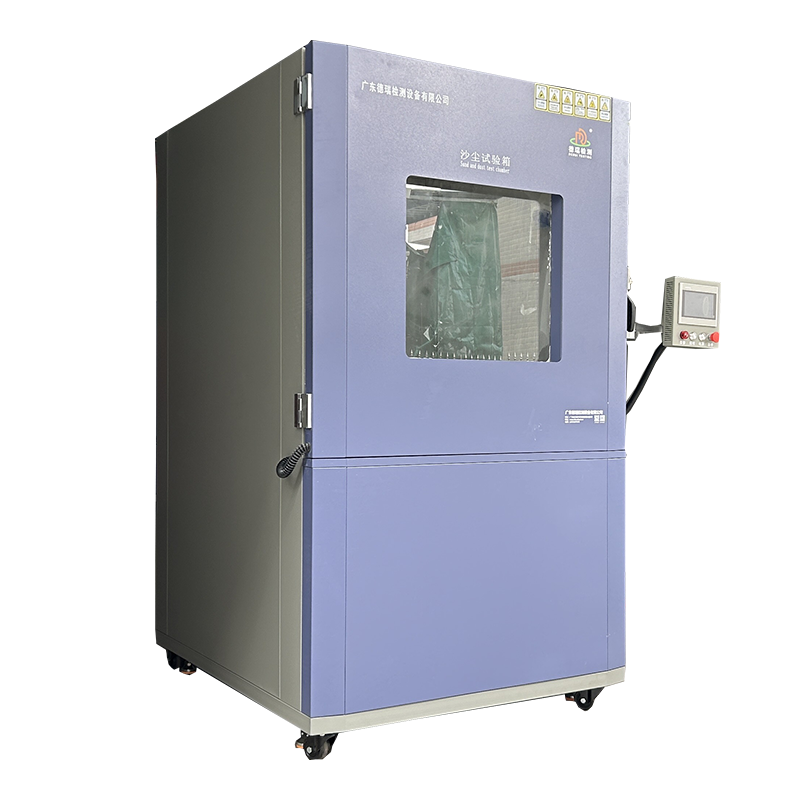

The Uv Light Accelerated Aging Test Chamber is a testing equipment designed to simulate the effects of natural weathering on various materials. This chamber operates semi-automatically and is controlled manually. It is constructed with high-quality stainless steel and PVC materials for durability. This electric-powered chamber can accommodate multiple specimens for testing purposes, making it ideal for industrial and research applications. Its features include UV light sources, temperature control, and humidity control. The Uv Light Accelerated Aging Test Chamber is designed to test the weather resistance of materials such as plastics, coatings, and textiles. It exposes the materials to UV radiation, high temperature, and humidity, accelerating the aging process. This allows the performance of materials to be evaluated efficiently and accurately. Its reliable and precise testing results make it an essential tool for manufacturers, exporters, and suppliers.

Item | Specification |

Chamber dimension (W*D*H) | 1300*500*1460mm |

Chamber material | SUS#304 stainless steel |

Temperature range | RT to 70 |

Temperature fluctuation | 1.0 |

Temperature uniformity | 3 |

Humidity range: | 75%RH |

Controller | Programmable controller, LCD touch screen |

Control mode | Balance temperature humidity control (BTHC) |

Test cycle setting | Exposure, condensation and water spray test cycle is programmable |

Water spray cycle | Spray 18mins in every 120mins / spray 12mins in every 60mins |

Water usage | 8L/day |

Distance from sample to lamp | 552mm |

Centre distance between lamps | 65~70mm |

Irradiance range | 0.45~0.90W/m2 |

UV lamps | Imported Atlas UV-A: 315-400nm (8pcs, 1600h lifetime) |

Lamp power | 40W/Piece |

Specimen Size | 75290mm (24pcs) / 75x150mm (48pcs), maximum thickness 5mm |

Testing time | 0~999H, adjustable |

Protection system | Overload short circuit protection Over temperature protection Water lacking protection Earth leakage protection Auto shut off protection |

FAQs of Uv Light Accelerated Aging Test Chamber:

Q: What is the purpose of a Uv Light Accelerated Aging Test Chamber?

A: The Uv Light Accelerated Aging Test Chamber is designed to test the weather resistance of materials such as plastics, coatings, and textiles.Q: What are the features of the Uv Light Accelerated Aging Test Chamber?

A: The features of the Uv Light Accelerated Aging Test Chamber include UV light sources, temperature control, and humidity control.Q: What materials can be tested using the Uv Light Accelerated Aging Test Chamber?

A: The Uv Light Accelerated Aging Test Chamber can test various materials such as plastics, coatings, and textiles.Q: What is the power supply of the Uv Light Accelerated Aging Test Chamber?

A: The Uv Light Accelerated Aging Test Chamber is electric-powered.Q: How many specimens can the Uv Light Accelerated Aging Test Chamber accommodate?

A: The Uv Light Accelerated Aging Test Chamber can accommodate multiple specimens for testing purposes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese