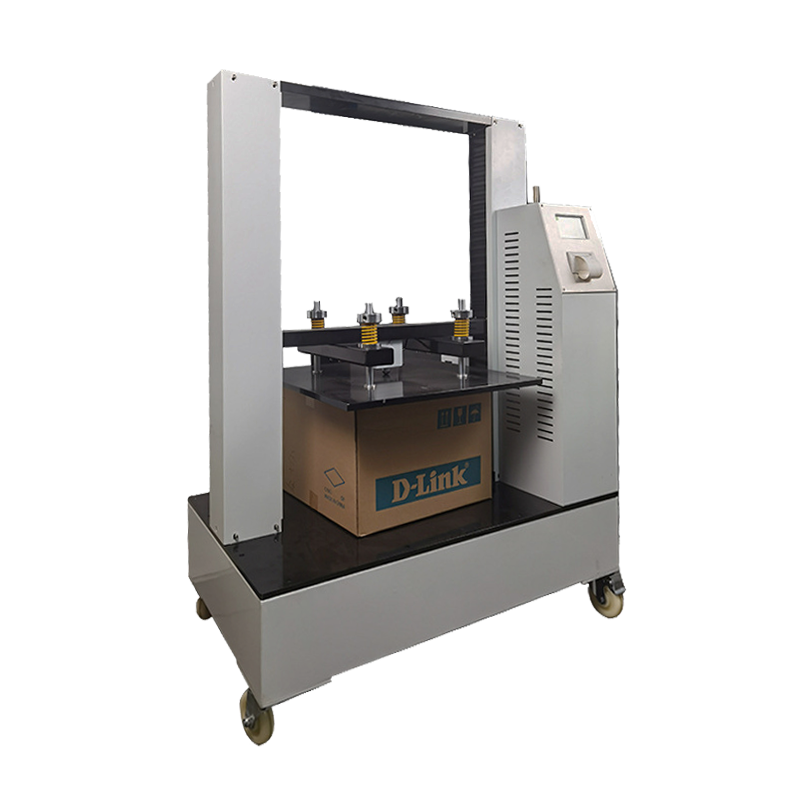

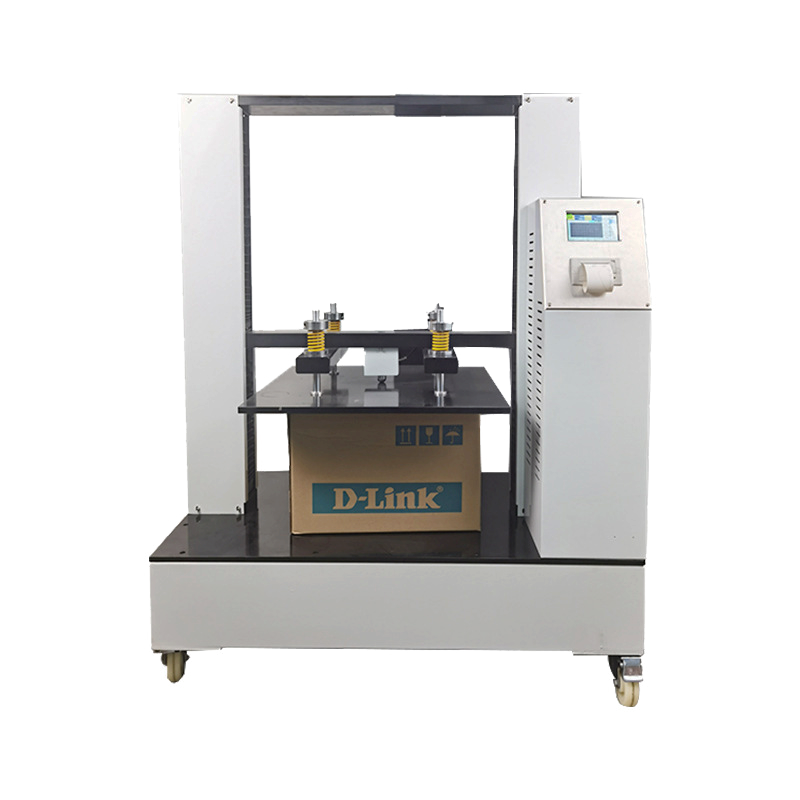

15KN range cardboard box compression testing machine

199005.0 INR/Unit

Product Details:

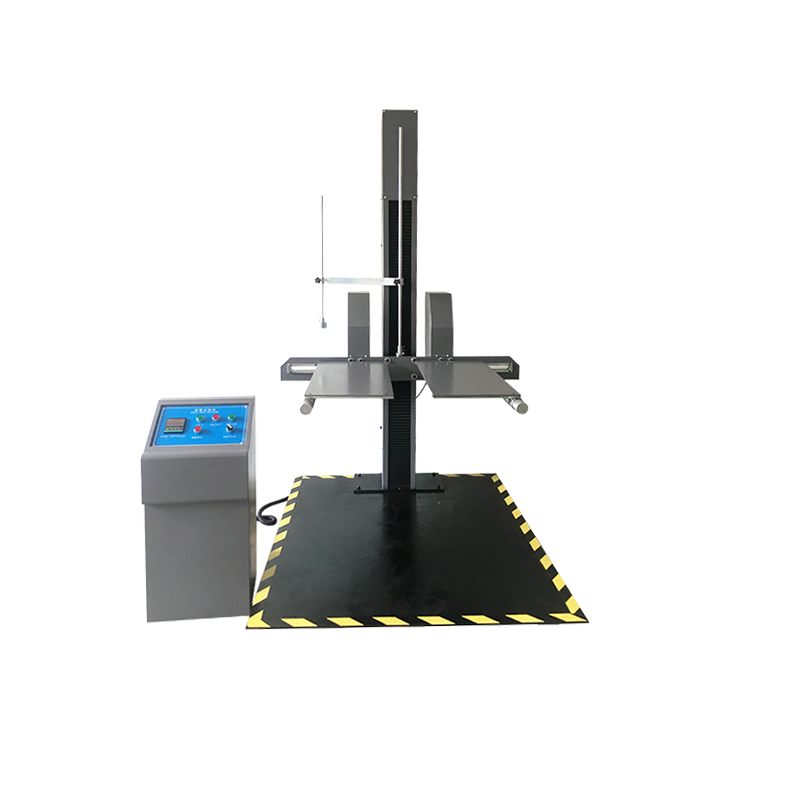

- Equipment Type Box Compression Tester

- Frequency 50 Hz

- Number of Specimens Single specimen at a time

- Operating Voltage 220V AC

- Max Height 1000 mm

- Mounting Type Floor-standing

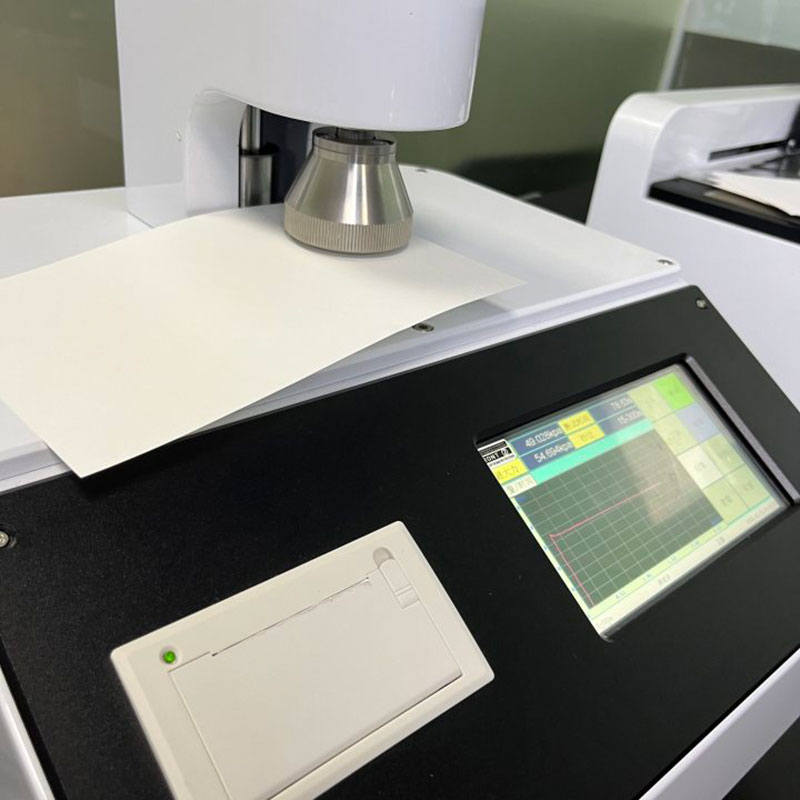

- Display Type Digital LCD Touchscreen

- Click to view more

X

15KN range cardboard box compression testing machine Price And Quantity

- 199005.0 INR/Unit

- 1 Unit

- Optional PC software for data acquisition and analysis

- 2 mm full scale

- Compression, stacking, destructive test

- High-grade steel structure with powder coating

- Emergency stop button, travel limit, overload protection

- 1 KW

- Precision servo motor

- English/Chinese

- Stores up to 100 test results

15KN range cardboard box compression testing machine Product Specifications

- 220V AC

- 1000 mm

- Floor-standing

- Digital LCD Touchscreen

- 0~15,000 N

- 1%

- Approximately 450 kg

- 10~200 mm/min (adjustable)

- 1000 mm

- 50 Hz

- Single specimen at a time

- Box Compression Tester

- 15KN

- Test plate surface HRC 602

- 0~40C

- 0.6~0.8 MPa (if applicable, for pneumatic fixtures)

- 0~15KN

- Compression strength testing for cardboard and corrugated boxes

- < 1 sec

- Laboratory and industrial quality control

- 1000 mm

- Microcomputer / Manual

- Semi-automatic

- Standard 15KN Testing Port

- Data storage, automatic reset, emergency stop, overload protection

- Max 1000 x 1000 x 1000 mm

- AC 220V, 50Hz

- RS232/USB (optional)

- 20%~80% RH

- 1 N

- Optional PC software for data acquisition and analysis

- 2 mm full scale

- Compression, stacking, destructive test

- High-grade steel structure with powder coating

- Emergency stop button, travel limit, overload protection

- 1 KW

- Precision servo motor

- English/Chinese

- Stores up to 100 test results

15KN range cardboard box compression testing machine Trade Information

- Cash in Advance (CID)

- 90 Unit Per Month

- 7 Days

- All India

Product Description

| Item | DR-B211-900 | DR-B211-1200 | DR-B211-1500 |

| Max. Force | 10KN(1000 kg ,2205lb) | 20KN(2000 kg, 4409lb) | 50KN(5000kg,11023lb) |

| Load cell | 1 load cell for highest accuracy | ||

| Control system | Dual control (Computer control with Windows mode+Touch screen control ) | ||

| Servo Motor | 400W | 750W | |

| Servo Driver | 400W | 750W | |

| Screws | Ball screws(Double ball guide rod design, high transmission accuracy, high transmission power efficiency) | ||

| Force reading | Gf, kgf, Ibf, N, KN, T etc | ||

| Load cell Resolution | 1/250,000 | ||

| Load Precision | within 0.5% | ||

| Effective test area (L x W x H) | 700x900x900mm | 1000x1200x1000mm | 1300x1500x1500mm |

| Compression Stroke | 0~900mm | 0~1000mm | 0~1500mm |

| Lift speed | 0.1~200mm/min | ||

| Software | Mtest HD-002-A(Independent R&D) | ||

| Data display | Load, displacement, speed, loading rate and elapsed time | ||

| Safety features | E-Stop Over-load protection Upper and lower limit switches Load sensor with automatic retreat | ||

| Report items | Serial number, peak value, average value, set pressure holding value, pressure holding time | ||

| Electrical Supply | 1phase, AC 220V, 500W, 50HZ | 1phase, AC 220V,550W,50HZ | 1phase, AC 220V,900W,50HZ |

| Overall Dimensions (L x W x H) | Approx.1510x1200x1645mm | Approx.1510x1200x1645mm | Approx.1865mmx1500mmx2235mm |

| Weight | Approx.350kg(772lb) | Approx.670kg(1477lb) | Approx. 1000kg(2205lb) |

| Operation Temperature and relative humidity | 10~40, 30~80% | ||

1. Equipment Overview

The 15KN range carton compression tester is a high-precision test equipment specially designed for evaluating the compressive strength, deformation performance and overall structural stability of various types of packaging cartons (such as corrugated cartons, honeycomb cardboard boxes, etc.) under vertical pressure. The maximum test force of this equipment is 15 kilonewtons (kN), which is suitable for the compression test of medium and large cartons, and can simulate the pressure of cartons in the actual transportation, storage and stacking process. The tester is widely used in packaging material manufacturing, logistics and transportation industries as well as quality control departments to ensure that packaging materials comply with relevant standards and customer requirements.

2. Main Functions

- Compressive Strength Test: Measure the maximum compressive capacity of carton in vertical direction to evaluate its load bearing capacity during stacking, transportation and storage.

- Deformation test: record the deformation of carton under pressure, evaluate its deformation degree and recovery ability.

- Stacking test: simulate the force of carton in actual stacking situation, evaluate its stacking stability and load-bearing capacity.

- Cyclic Pressure Test: Load and unload the carton for several cycles to evaluate its fatigue performance and durability.

- Data analysis and report generation: Built-in data analysis software can automatically generate detailed test reports, including maximum compressive strength, deformation, loading curve and other parameters.

3. Working Principle

1.

Specimen preparation: Place the carton to be tested between the platens of the testing machine to ensure that the position and direction of the carton is in accordance with the test requirements.

2.

Parameter setting: set the test parameters through the control panel, including loading speed, pressure range, displacement limit, etc. The range of 15KN is suitable for the compression test of medium and large cartons.

3.

Loading process: Start the testing machine, the pressure plate applies pressure to the carton at the set loading speed. The tester monitors and records the deformation of the carton and the pressure in real time.

4.

Data Acquisition and Analysis: During the testing process, the equipment automatically collects the pressure and deformation data, and generates a test report at the end of the test. The test report usually includes parameters such as maximum compressive strength, deformation amount, stacking height and so on.

4. Equipment Features

- High-precision control: Adopting advanced control system, it can accurately control parameters such as loading speed, pressure and displacement to ensure the accuracy and reliability of test results.

- Large capacity range: 15KN range design makes it able to meet the demand of compression test for medium and large cartons, applicable to various specifications of packaging materials.

- Automated operation: Fully automated operation reduces human intervention and improves test efficiency and repeatability of test results.

- Safety and Reliability: Equipped with multiple safety protection devices, such as overload protection, limit protection, emergency stop device, etc., to ensure the safety and reliability of the testing process.

- Data processing and analysis: Built-in data processing software can automatically generate test reports and provide data analysis function, which is convenient for users to analyze the results and quality control.

- Sturdy structure: made of high-strength materials, with good rigidity and stability, able to withstand large testing pressure.

5. Application field

Range 15KN Carton Compression Tester is widely used in the following fields:

- Packaging material manufacturing industry: used to evaluate the compressive strength and deformation performance of packaging materials such as corrugated cartons and honeycomb cardboard boxes.

- Logistics and transportation industry: to evaluate the load-bearing capacity and stability of packaging materials during actual transportation and stacking.

- Quality control: To carry out quality control during the production process to ensure that the packaging materials comply with relevant standards and customer requirements.

6. Frequently Asked Questions

Q1: What is the testing speed of 15KN Carton Compression Tester?

A1: The testing speed is usually between 1-500mm/min, which can be adjusted according to different testing requirements.

Q2: How does the machine ensure the accuracy of the test results?

A2: The equipment adopts advanced control system and high-precision sensors, which can accurately control the parameters of loading speed, pressure and displacement, and ensures the safety and reliability of the testing process through multiple safety protection devices to ensure the accuracy of the test results.

Q3: Is the equipment easy to operate?

A3: Yes, the equipment is equipped with user-friendly interface, simple parameter setting and easy operation. Meanwhile, the fully automated operation reduces human intervention and improves testing efficiency and repeatability of results.

Q4: What is included in the test report?

A4: The test report usually contains parameters such as maximum compressive strength, deformation, stacking height, etc. It also provides data analysis function, which is convenient for users to analyze the results and quality control.

Q5: Does the device support customized test parameters?

A5: Yes, the equipment supports the setting of different parameters such as loading speed, pressure range and displacement limit according to different materials and testing requirements to meet various testing requirements.

Efficient Compression Testing for Cardboard Boxes

This compression tester provides accurate analysis of the strength and stacking capabilities of cardboard and corrugated boxes. The precision servo motor ensures smooth and consistent operations for a wide range of test modes, including compression, stacking, and destructive testing. The machine addresses the needs of both laboratory and industrial quality control, supporting stringent standards for modern packaging requirements.

User-friendly Design with Advanced Safety Features

Operators benefit from an intuitive digital LCD touchscreen for seamless control, with English and Chinese language support enhancing accessibility. Safety is prioritized through multiple safety devices: emergency stop button, travel limit switches, and overload protection mechanisms. The robust construction and powder-coated finish ensure minimal maintenance and long-term performance.

Seamless Data Management and Analysis

Equipped with memory functions for up to 100 results, the tester offers optional PC connectivity via RS232 or USB interfaces for advanced data management. The automatic reset function increases testing convenience while ensuring data reliability. The system is ideal for manufacturers, exporters, and suppliers needing consistent, documented test results.

FAQ's of 15KN range cardboard box compression testing machine:

Q: How does the 15KN cardboard box compression testing machine operate?

A: This testing machine uses a precision servo motor to apply controlled compression forces up to 15KN on a single box specimen. Operators can adjust test speed and utilize digital touch controls or microcomputer/manual modes. The compression plate ensures parallelism within 2 mm for accurate test results.Q: What types of tests can be performed with this equipment?

A: The machine supports compression strength tests, stacking tests, and destructive tests on cardboard and corrugated boxes, helping determine the load-bearing capacity and durability of packaging materials.Q: When should I use this box compression tester?

A: Use this tester during laboratory or quality control stages in packaging production, especially when verifying carton strength before shipment, during design trials, or routine quality audits for compliance with industry standards.Q: Where is this compression tester most effectively used?

A: It is best suited for quality control laboratories, manufacturing plant testing areas, and R&D facilities within packaging, logistics, or materials supply industries.Q: What is the process for storing and analyzing test data?

A: Test results are automatically saved to the machine's memory, which can store up to 100 items. For advanced analysis, data can be exported to a PC via RS232/USB with optional software, aiding in detailed reporting and quality documentation.Q: How does the machine ensure user safety during operation?

A: The tester features an emergency stop button, travel limit switches, and overload protection to prevent operation outside safe parameters, safeguarding both the user and the equipment.Q: What are the main benefits of using this compression testing machine?

A: Major benefits include precise measurement (1% accuracy), digital data recording, adjustable test parameters, robust safety features, and support for large specimens, making it a versatile solution for reliable packaging strength evaluation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese