1000mm compression stroke testing machine

181085.0 INR/Unit

Product Details:

- Number of Specimens 1 (single test at a time)

- Accuracy 0.5% F.S.

- Operating Voltage 220V AC

- Hardness Structural frame: Q235 steel, surface hardness HRC 32-40

- Measuring Range 0-1000 mm

- Interface Type RS232/USB

- Gas Pressure 0.5-0.7 MPa

- Click to view more

X

1000mm compression stroke testing machine Price And Quantity

- 181085.0 INR/Unit

- 1 Unit

- Supports USB stick data output

- Manual clamp

- Configurable up to 99999 cycles

- 1200 mm x 850 mm

- 400 × 400 mm

- Windows-based test management software included

- High-strength steel, anti-rust treated

- Mechanical and software limit protections

- Industrial grey with blue panel

- Yes, large red button

- <70 dB

- Yes (for pneumatic components)

1000mm compression stroke testing machine Product Specifications

- PLC-based automatic & manual

- Approx. 350 kg

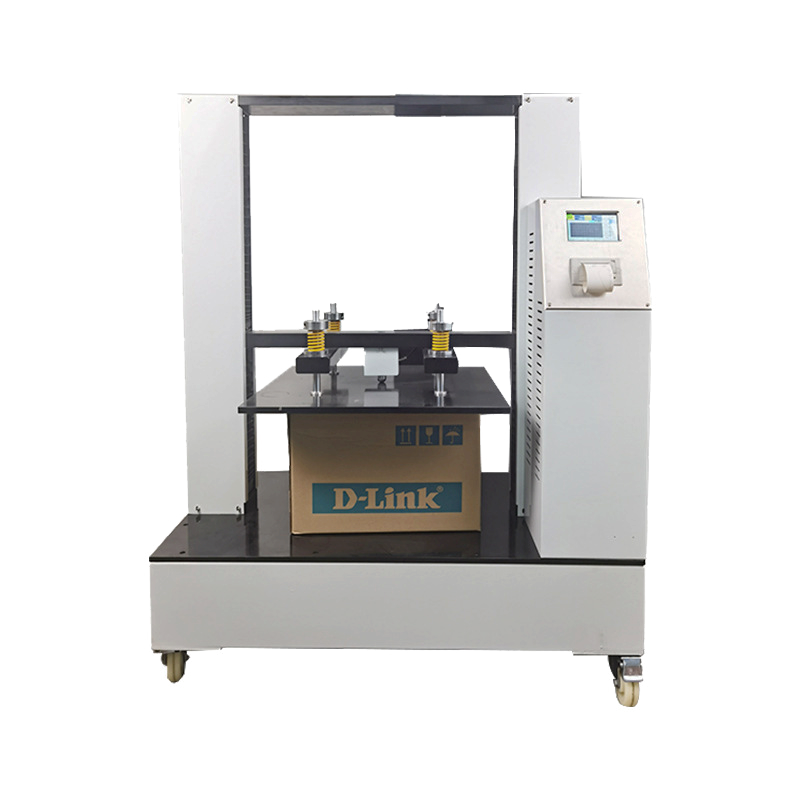

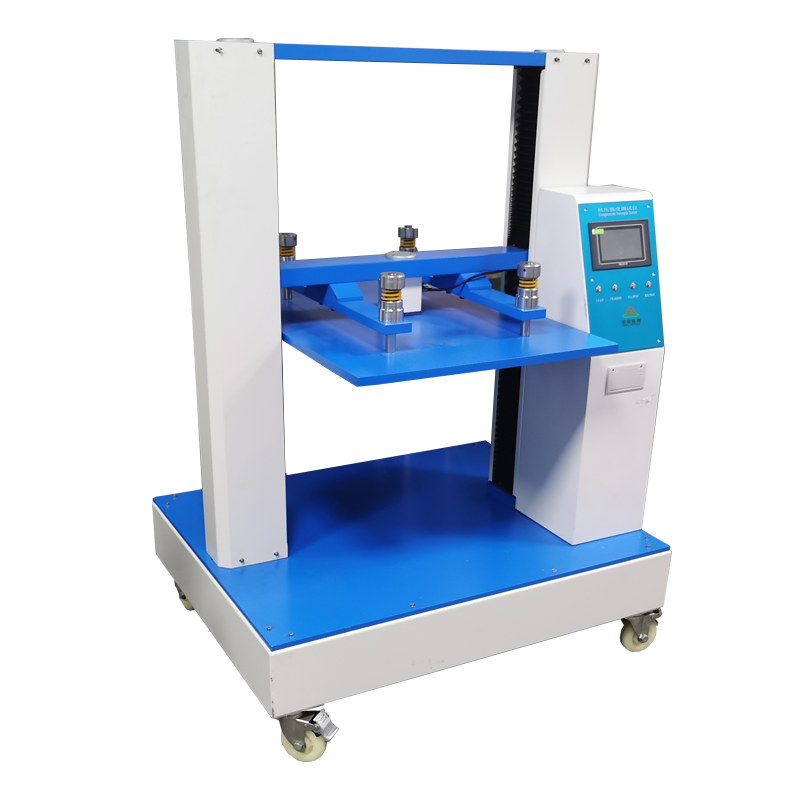

- Compression stroke testing machine

- Industrial materials testing

- 0.01 mm

- Standard 1/2-inch inlet

- Up to 50 kN

- <100 ms

- 5C - 40C

- Digital LCD display

- Semi-automatic

- C12089124525-34

- 1000 mm

- 50,000 N

- 1 (single test at a time)

- 0.5% F.S.

- Structural frame: Q235 steel, surface hardness HRC 32-40

- 220V AC

- 0-1000 mm

- RS232/USB

- 0.5-0.7 MPa

- Floor Standing

- 20% - 90% RH

- Overload protection, automatic stop, data storage, emergency switch

- 600 mm

- 50/60Hz

- 1500 mm

- Compression fatigue, stroke and lifecycle testing of samples

- Up to 1000 mm length

- AC 220V, 50Hz

- Supports USB stick data output

- Manual clamp

- Configurable up to 99999 cycles

- 1200 mm x 850 mm

- 400 × 400 mm

- Windows-based test management software included

- High-strength steel, anti-rust treated

- Mechanical and software limit protections

- Industrial grey with blue panel

- Yes, large red button

- <70 dB

- Yes (for pneumatic components)

1000mm compression stroke testing machine Trade Information

- Cash in Advance (CID)

- 120 Unit Per Month

- 7 Days

- All India

Product Description

1. Equipment Overview

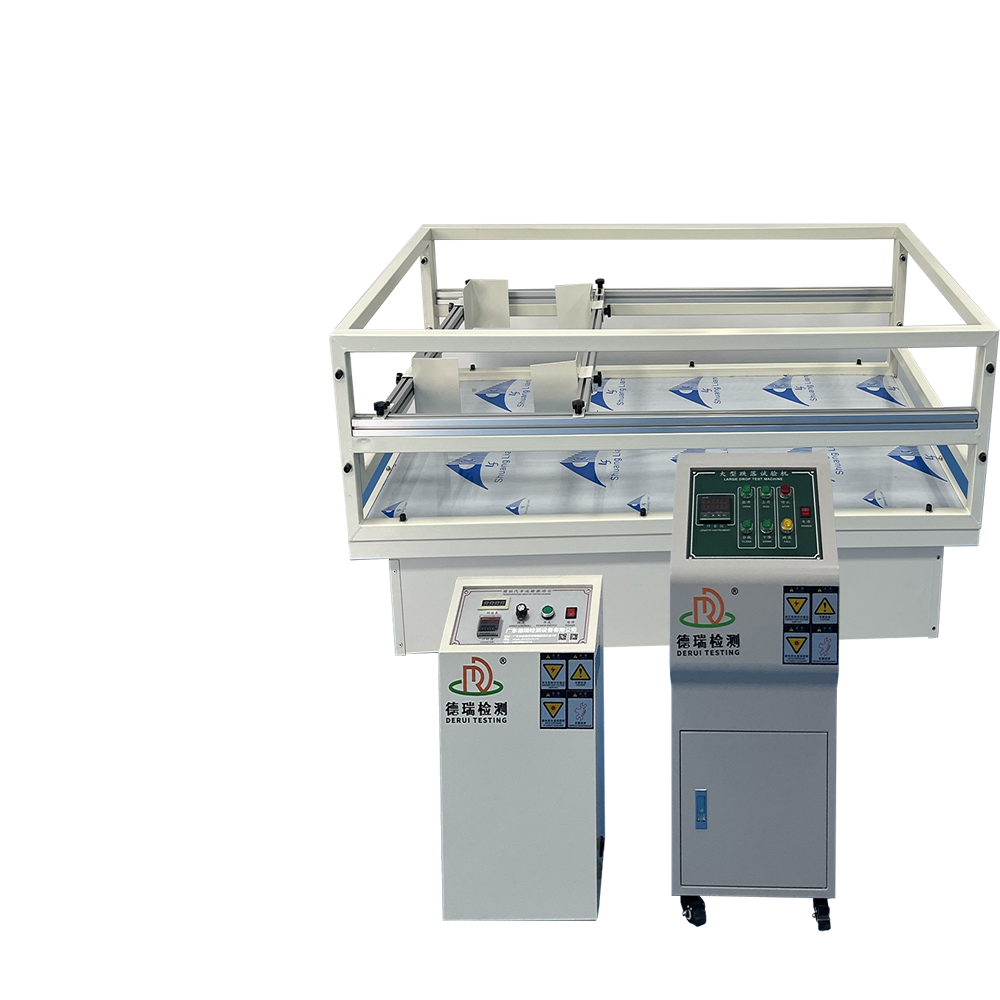

1000mm Compression Stroke Tester is a high-precision, large-stroke testing equipment, mainly used to evaluate the performance of various materials and products under compression load. With a compression stroke of up to 1000mm, the machine is able to meet the needs of compression testing of large-sized materials or products, which are widely used in packaging materials, automotive parts, construction materials, furniture, electronic products and other fields. The tester can simulate the compression load in the actual use environment to evaluate the compression strength, deformation characteristics and overall structural stability of the material.

2. Main Functions

Compression strength test: Measure the maximum bearing capacity of the material under compression load, and evaluate its compression bearing performance in actual use.

Deformation test: Record the deformation of the material in the compression process, assess the degree of deformation and recovery ability.

Cyclic compression test: Compress and release the material for several cycles to assess its fatigue performance and durability.

Displacement Control and Measurement: Accurately control the compression stroke and measure the deformation displacement of the material in real time to ensure the accuracy and repeatability of the test.

Data analysis and report generation: Built-in data analysis software can automatically generate detailed test reports, including maximum compression force, deformation, loading curve and other parameters.

3. Working Principle

1.

Specimen Preparation: Place the material or product to be tested between the compression plates of the testing machine to ensure that the position and direction of the specimen is in accordance with the test requirements.

2.

Parameter setting: Set the test parameters through the control panel, including compression speed, load range, displacement limit, etc. The 1000mm stroke range can meet the test requirements of large-size specimens.

3.

Loading process: Start the testing machine, the compression plate applies compression load to the specimen at the set speed. The equipment monitors and records the deformation of the specimen and the load in real time.

4.

Data Acquisition and Analysis: During the testing process, the equipment automatically collects load and deformation data and generates a test report at the end of the test. The report usually includes parameters such as maximum compression force, deformation, loading curve and so on.

4. Equipment Features

Large Stroke Design: 1000mm compression stroke design enables it to test large-size materials or products and meet various complex testing needs.

High-precision control: Adopting advanced control system, it can accurately control the parameters of compression speed, load and displacement to ensure the accuracy and reliability of the test results.

Automated operation: fully automated operation reduces human intervention and improves testing efficiency and repeatability of test results.

Safety and Reliability: Equipped with multiple safety protection devices, such as overload protection, limit protection, emergency stop device, etc., to ensure the safety and reliability of the testing process.

Data processing and analysis: Built-in data processing software can automatically generate test reports and provide data analysis function, which is convenient for users to analyze the results and quality control.

Sturdy structure: made of high-strength materials, with good rigidity and stability, able to withstand large test loads.

5. Application Areas

1000mm Compression Stroke Tester is widely used in the following fields:

Packaging material manufacturing industry: used to evaluate the compression strength and deformation performance of large packaging materials (e.g. large cartons, trays, etc.).

Automobile parts: To test the compression performance and durability of automobile interior parts, seats, instrument panels, etc.

Building materials: Evaluate the compressive strength and deformation properties of building materials (e.g. concrete slabs, bricks, etc.).

Furniture: Test the compression performance and comfort of furniture components (e.g. sofas, mattresses, etc.).

Electronic products: Evaluate the compression performance and compression resistance of electronic product housings and internal structures.

6. Frequently Asked Questions

Q1: What is the test speed of the 1000mm compression stroke tester?

A1: The test speed is usually between 0.01-500mm/min, which can be adjusted according to different test requirements.

Q2: How does the machine ensure the accuracy of the test results?

A2: The equipment adopts advanced control system and high-precision sensors, which can accurately control the parameters of compression speed, load and displacement, and ensures the safety and reliability of the testing process through multiple safety protection devices to ensure the accuracy of the test results.

Q3: Is the device easy to operate?

A3: Yes, the equipment is equipped with user-friendly interface, simple parameter setting and easy operation. Meanwhile, the fully automated operation reduces human intervention and improves testing efficiency and repeatability of results.

Q4: What is included in the test report?

A4: The test report usually contains parameters such as maximum compression force, deformation, loading curve, etc. It also provides data analysis function, which is convenient for users to analyze the results and quality control.

Q5: Does the device support customized test parameters?

A5: Yes, the equipment supports setting different parameters such as compression speed, load range and displacement limit according to different materials and test requirements to meet various test requirements.

| Item | DR-B211-900 | DR-B211-1200 | DR-B211-1500 |

| Max. Force | 10KN(1000 kg ,2205lb) | 20KN(2000 kg, 4409lb) | 50KN(5000kg,11023lb) |

| Load cell | 1 load cell for highest accuracy | ||

| Control system | Dual control (Computer control with Windows mode+Touch screen control ) | ||

| Servo Motor | 400W | 750W | |

| Servo Driver | 400W | 750W | |

| Screws | Ball screws(Double ball guide rod design, high transmission accuracy, high transmission power efficiency) | ||

| Force reading | Gf, kgf, Ibf, N, KN, T etc | ||

| Load cell Resolution | 1/250,000 | ||

| Load Precision | within 0.5% | ||

| Effective test area (L x W x H) | 700x900x900mm | 1000x1200x1000mm | 1300x1500x1500mm |

| Compression Stroke | 0~900mm | 0~1000mm | 0~1500mm |

| Lift speed | 0.1~200mm/min | ||

| Software | Mtest HD-002-A(Independent R&D) | ||

| Data display | Load, displacement, speed, loading rate and elapsed time | ||

| Safety features | E-Stop Over-load protection Upper and lower limit switches Load sensor with automatic retreat | ||

| Report items | Serial number, peak value, average value, set pressure holding value, pressure holding time | ||

| Electrical Supply | 1phase, AC 220V, 500W, 50HZ | 1phase, AC 220V,550W,50HZ | 1phase, AC 220V,900W,50HZ |

| Overall Dimensions (L x W x H) | Approx.1510x1200x1645mm | Approx.1510x1200x1645mm | Approx.1865mmx1500mmx2235mm |

| Weight | Approx.350kg(772lb) | Approx.670kg(1477lb) | Approx. 1000kg(2205lb) |

| Operation Temperature and relative humidity | 10~40, 30~80% | ||

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese