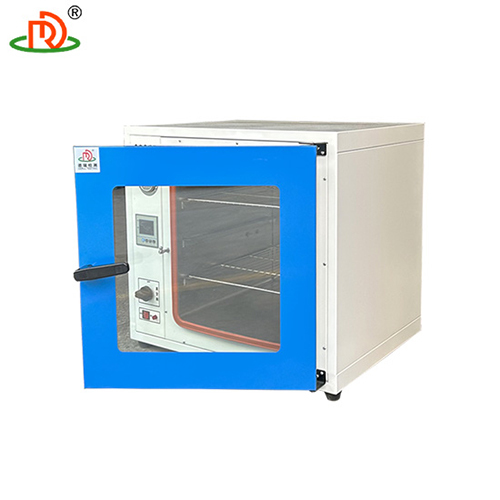

360 degree rotating sample holder ozone box

338005.0 INR/Unit

Product Details:

- Condition New

- Power Source Electric

- Usage Industrial

- Product Type ozone box

- Color White

- Surface Finish Painted

- Click to view more

X

360 degree rotating sample holder ozone box Price And Quantity

- 338005.0 INR/Unit

- 1 Unit

360 degree rotating sample holder ozone box Product Specifications

- ozone box

- New

- Painted

- Industrial

- Electric

- White

360 degree rotating sample holder ozone box Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 7 Days

- All India

Product Description

Standard Features

| Item | Specification |

| Internal dimension | 450W*450D*500Hmm (100L) |

| Temperature range | RT+10~ 60 (suggest to use 402) |

| Temperature Fluctuation | 1 |

| Ozone concentration | 50~1000 pphm, adjustable (suggest to use 50pphm) |

| Ozone concentration deviation | 10% |

| Sample holder rotation | 360 degree rotation |

| Sample holder | 2pcs removable sample tray, SUS#304 stainless steel |

| Temperature controller | Programmable touch screen controller |

| Ozone concentration analysis | Concentration analysis meter |

| Ozone generator | High pressure silence discharge type |

| Protection system | Leakage, short circuit, over temperature, over heat |

. The Scientific Nature of Dynamic Cycling: The Leap from Linear to Nonlinear

1. Limitations of Traditional Cyclic Testing

-

Timing curing: preset fixed temperature and humidity - ozone concentration cycling curve (e.g. ASTM D1149 standard cycle), unable to simulate the real environment random fluctuations;

-

Decoupling distortion: there is a time lag between ozone concentration changes and temperature and humidity adjustments (usually >30 seconds), leading to multifactor synergistic effect bias;

-

Data silos: cycling parameters and material response data are fragmented, making it impossible to optimize test paths in real time.

Technological leap forward goal:

Construct an intelligent cycling system with the ability of environment sensing - dynamic decision-making - instantaneous regulation, and realize quantum-level synchronization between ozone attack and material damage.

II. Dynamic ozone concentration field generation system

2.1 Superfluidic ozone transport technology

-

Microchannel matrix:

A MEMS process is used to fabricate honeycomb ozone microchannels (cell size 100 m 100 m) to achieve millisecond gradient distribution of ozone concentration from 0-2000 pphm;

Support spatially programmed concentration fields (e.g., 500 pphm on the surface/200 pphm inside) to simulate ozone penetration differences under heterogeneous structure of materials.

-

Dynamic gas mixing algorithms:

Real-time optimization of ozone/air mixing ratio based on Computational Fluid Dynamics (CFD) with concentration fluctuation accuracy 3pphm (@1000pphm).

2.2 Closed-loop adaptive control engine

-

Material response sensing:

Embedded fiber grating sensor array to monitor material strain, temperature, ozone penetration depth (spatial resolution 0.1mm);

Terahertz spectrometer to capture molecular chain break signals online (e.g. characteristic peaks of C=C bond breaks in NR rubber).

-

Intelligent decision modeling:

Reinforcement learning algorithm dynamically adjusts cyclic parameters based on real-time damage data (e.g., automatically triggers ozone concentration pulses to 1200 pphm when crack extension rate > 1 m/min is detected);

Generate asymmetric cycling curves (e.g. ozone concentration rise time < 1/5 of the fall time) to accelerate weak link failure.

III. Multi-physics field spatio-temporal coupling technique

3.1 Four-dimensional environmental loading matrix

Physical Field

Dynamic range

Switching speed

Synergy mode

Ozone concentration

0-2000pphm

<100ms

Non-linear coupling with temperature and humidity

Temperature

-70~+150

10/sec

Ozone adsorption coefficient with temperature dynamic compensation

Humidity

10%~98%RH

15%RH/sec

Condensation phase change triggers ozone dissolution attack

Mechanical Stress

Multi-axis vibration (0-2000Hz)

0.1ms response

Strain rate controlled ozone diffusion path

3.2 Quantum level synchronization control

-

Time crystal architecture:

FPGA-based time slicing technique to partition the 1-hour test into 3.6 10 10-s control cycles, each cycle independently performing environmental parameter calculations and actuator control;

Ozone concentration field refresh rate of 1 kHz, which exceeds the response speed of material molecular motion (rubber chain segment relaxation time 1 ms).

. Industry 4.0 Intelligent Testing Ecology

4.1 Digital twin generation

-

Material digital passport:

Integrate material genomic data (chemical structure, filler distribution, process history) to generate high fidelity digital twins;

Preview trillions of ozone molecule attack paths in virtual space to guide the optimization of test protocols for physical devices.

4.2 Autonomous Evolutionary Test Protocols

-

Swarm optimization algorithm:

Hundreds of devices are networked to share test data and discover the optimal cyclic parameter combinations through swarm intelligence;

Automatically generates customized test standards for special scenarios such as new energy vehicle seals and photovoltaic backsheets.

4.3 Zero Contact Arbitration System

-

Blockchain depository:

Real-time uploading of test process data (including raw sensor signals) to ensure military-grade data tamperability;

AI arbitrator automatically compares data differences between different labs and locates equipment calibration deviations (accuracy up to 0.5pphm).

Optimized Ozone Treatment

Experience enhanced precision with the 360-degree rotating sample holder ozone box. The electric-powered rotation mechanism ensures samples receive a uniform ozone exposure, maximizing treatment quality and reliability. The painted, corrosion-resistant surface protects the equipment, supporting long-term industrial use.

Industrial Reliability and Versatility

Built for new-age industrial standards, this sample holder ozone box is engineered to handle high-demand environments. Its durable design couples with easy operation, making it suitable for laboratories, research facilities, and manufacturing lines requiring consistent ozone application to various samples.

FAQ's of 360 degree rotating sample holder ozone box:

Q: How does the 360-degree rotating sample holder ozone box function?

A: The box features an electrically powered rotating holder that spins samples 360 degrees. This movement ensures all surfaces of the sample are uniformly exposed to ozone, enhancing the effectiveness and consistency of ozone treatment.Q: What are the primary industrial uses of this ozone box?

A: This ozone box is mainly used in laboratories, manufacturing, and research settings for sterilizing, oxidizing, or treating various industrial samples with ozone. Its rotating mechanism improves the uniformity of ozone exposure across samples.Q: When should the ozone sample holder box be used?

A: The device should be used whenever uniform and effective ozone treatment is required, particularly when processing sensitive materials or when consistent exposure is crucial for reliable results.Q: Where is this product manufactured and supplied from?

A: This 360-degree rotating sample holder ozone box is manufactured, exported, and supplied by a company based in China, offering global distribution for various industrial clients.Q: What is the process for operating the ozone box?

A: Operation is straightforward: place the sample in the painted, rotating holder, close the enclosure, set the desired ozone treatment parameters, and activate the electric mechanism. The device will then rotate the sample throughout the ozone exposure period.Q: What are the benefits of using a rotating holder for ozone treatment?

A: A rotating holder ensures that every part of the sample receives equal ozone exposure, reducing treatment inconsistencies and improving processing efficiency compared to stationary holders.Q: How does the surface finish contribute to the product's durability?

A: The painted surface finish provides added resistance to corrosion and wear, which is essential for longevity in industrial environments where the equipment may be exposed to harsh chemicals or continuous use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese