Battery Fire Test Machine

3800.0 USD ($)/Unit

Product Details:

- Material PVC & Metal

- Usage Testing equipment

- Operate Method Semi Automatic

- Power Supply Electric

- Control Mode Manual

- Click to view more

X

Battery Fire Test Machine Price And Quantity

- 3800.0 USD ($)/Unit

- 1 Unit

Battery Fire Test Machine Product Specifications

- Testing equipment

- Semi Automatic

- PVC & Metal

- Manual

- Electric

Battery Fire Test Machine Trade Information

- Cash in Advance (CID)

- 50 Unit Per Month

- 10 Days

- All India

Product Description

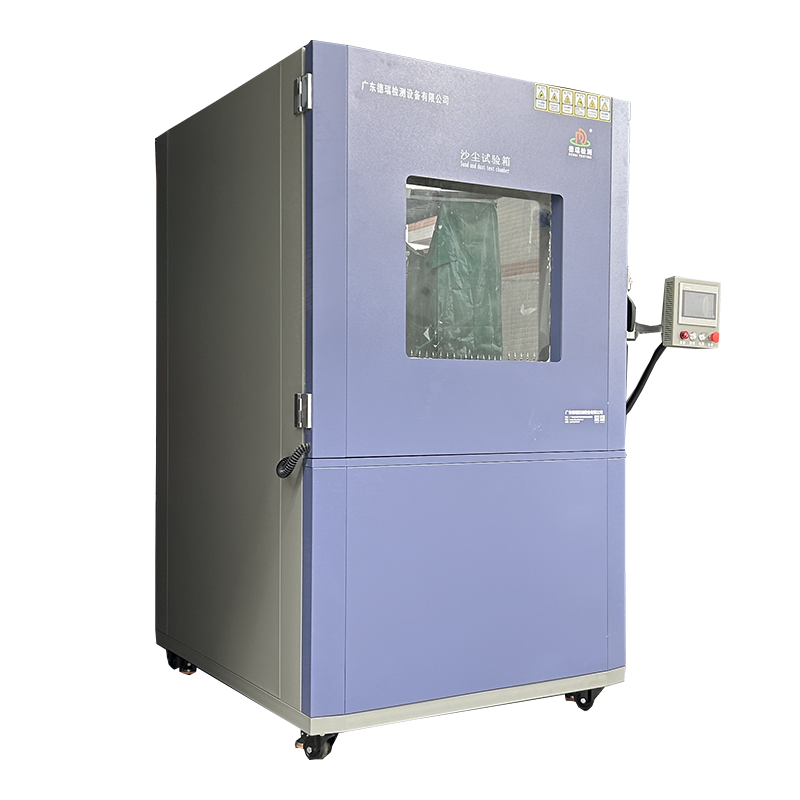

The Battery Fire Test Machine is an essential testing equipment for all battery manufacturers. This machine is designed to test the safety of batteries under various conditions. It is made of high-quality PVC and metal materials, ensuring durability and sustainability. This machine operates on electric power and has a manual control mode with a semi-automatic operate method. The battery fire test machine can perform various tests, including overcharge test, short-circuit test, thermal shock test, crush test, and puncture test. This testing machine is a reliable and efficient tool that helps ensure the safety of batteries before they reach the market. It is easy to use and can be operated by anyone with basic training. With its accurate and consistent results, the Battery Fire Test Machine is the perfect investment for all battery manufacturers who prioritize safety and quality.

Item | Specification |

Control method | push button or PLC touch screen |

Burner | Bunsen burner, the inner diameter of the nozzle is 9.5mm, and the length is about 100 mm |

Flame application time | 0 ~ 999.9 seconds ± 0.1 seconds |

Test round hole surface diameter | 102mm |

Test mesh sieve | woven from stainless steel wire with a diameter of 0.43mm (0.017inch) into a US inch mesh screen with 20 grids |

Flame height | 38mm |

Inside dimension | 750*750*500mm |

Outside dimension | 900*900*1300mm |

Combustion gas | methane or liquefied petroleum gas (customer-owned) |

Power supply | 1-phase, 220V, 50Hz |

Internal chamber material | 1.2mm thick stainless steel plate with Teflon; strong corrosion resistance and flame retardant |

External chamber material | 1.5 mm thick A3 cold plate paint treatment |

Observation window | Two-layer vacuum tempered glass observation window with size 250*250mm |

Exhaust port | Diameter: 100mm; it start work once when machine operate |

Door safety device | Open and power off threshold switch |

Test hole | A test hole with a diameter of 50 mm on the left side of the machine |

FAQs of Battery Fire Test Machine:

Q: What is the material used in the Battery Fire Test Machine?

A: The Battery Fire Test Machine is made of high-quality PVC and metal materials.Q: What is the power supply of the Battery Fire Test Machine?

A: The Battery Fire Test Machine operates on electric power.Q: What is the control mode of the Battery Fire Test Machine?

A: The Battery Fire Test Machine has a manual control mode.Q: What is the operate method of the Battery Fire Test Machine?

A: The Battery Fire Test Machine has a semi-automatic operate method.Q: What tests can the Battery Fire Test Machine perform?

A: The Battery Fire Test Machine can perform various tests, including overcharge test, short-circuit test, thermal shock test, crush test, and puncture test.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese