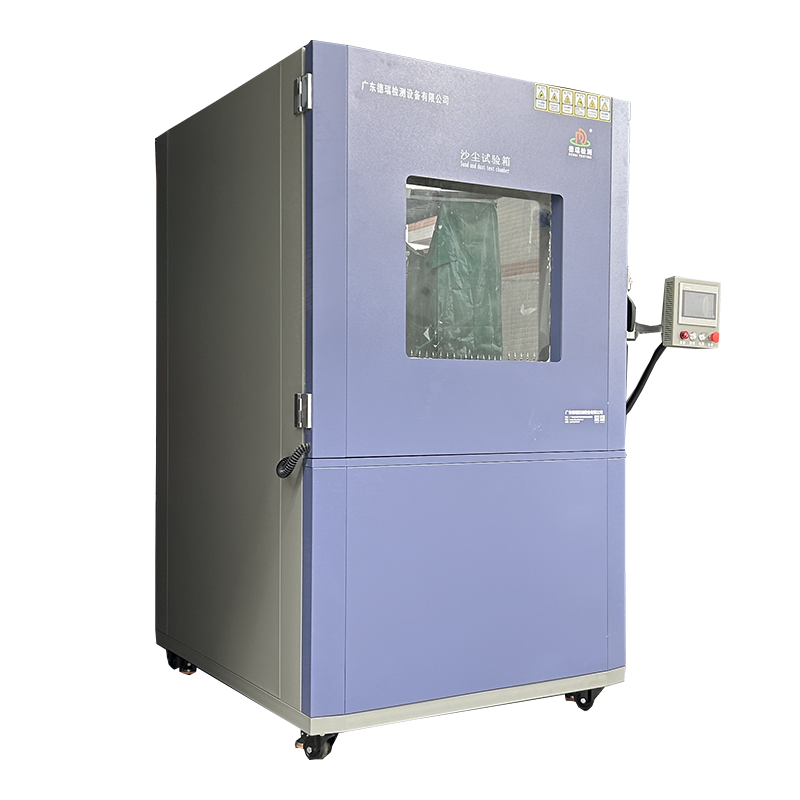

Battery module sand and dust testing system

268005.0 INR/Unit

Product Details:

- Features Programmable cycle, Overload protection

- Equipment Type Sand and Dust Testing System

- Test Range Battery module or pack

- Frequency Cycle adjustable 1~99 times

- Power Supply AC 220V 10% 50 Hz

- Interface Type RS232/USB

- Automation Grade Automatic

- Click to view more

X

Battery module sand and dust testing system Price And Quantity

- 1 Unit

- 268005.0 INR/Unit

- 65 dB(A)

- -10C to 70C

- Complies with IEC 60529, GB/T 4208

- Tempered glass large side window

- LED observation window illumination

- Emergency stop button & Leakage protection

- ISO Fine Arizona dust

- Automatic tray removal

- 200~1100 m/h adjustable

- 304 stainless steel

- High-grade silicone seals for dust protection

- Integrated for battery enclosure pressure drop

Battery module sand and dust testing system Product Specifications

- Max 500 x 400 x 300 mm

- RS232/USB

- Automatic

- 2 inch

- Battery module or pack

- Sand and Dust Testing System

- Programmable cycle, Overload protection

- Cycle adjustable 1~99 times

- AC 220V 10% 50 Hz

- 0.01 g/m

- Ambient to 60C

- Digital LCD display

- 1~8 Km/h adjustable

- 220V

- Laboratory / Industrial IP testing

- Up to 70 liters test chamber

- PLC + Touch Screen

- 3 sec

- Floor standing

- 1%

- 20~90% RH adjustable

- 0.6 MPa

- 1800 mm

- 380 Kg

- 1500 mm

- Battery module ingress protection tests

- Dust concentration 0.1~5 g/m

- Test dust hardness Mohs 6~7

- 1~4 specimens adjustable

- 600 mm

- 65 dB(A)

- -10C to 70C

- Complies with IEC 60529, GB/T 4208

- Tempered glass large side window

- LED observation window illumination

- Emergency stop button & Leakage protection

- ISO Fine Arizona dust

- Automatic tray removal

- 200~1100 m/h adjustable

- 304 stainless steel

- High-grade silicone seals for dust protection

- Integrated for battery enclosure pressure drop

Battery module sand and dust testing system Trade Information

- Cash in Advance (CID)

- 90 Unit Per Month

- 5 Days

- All India

Product Description

Dust Test Chamber Parameter

| Item | Specification |

| Internal dimension | 800W*800D*800Hmm |

| External dimension | 1300W*1000D*1700Hmm |

| Test sample | Size W20cm- L30cm-D15cm, weight 0.5kg |

| Chamber material | SUS304 Stainless steel |

| Specifications of square mesh sieve | Mesh hole 75um, mesh metal wire diameter 50um |

| Talcum powder amount | 2kg/ m |

| Airflow speed | No more than 2m/s |

| Door | Left open door with tempered glass door |

| Controller | PLC Touch Screen controller, programmable to set as below cycle: a. Blowing dust time (Stop/Blow) m/s b. Cycle time: can be adjusted c. Pre-set test time: 0s ~99m99s |

| Vacuum system | Pressure gauge, air filter, Pressure regulating FRL, connecting pipe, Vacuum pump |

| Vacuum pump capacity | 60-600 L/H |

| Fan | Centrifugal fan |

| Safety protection devices | Meter over-temperature function, Phase shortage protection, Power short-circuit protection |

Battery module sand and dust testing system Typical Application Scenarios

Electric vehicle battery packs:

Verify the protection level of the module under sandstorm environment (e.g. IP67/IP69K) to ensure no thermal runaway caused by dust intrusion.

Energy storage power station battery cabinet:

Simulate the long-term erosion of industrial dust on outdoor cabinets to evaluate sealing and heat dissipation efficiency.

Mining electric equipment:

Test the explosion-proof performance of battery modules in coal mine dust environments (in accordance with IEC 60079-11).

Drone Battery Modules:

Test the safety and range stability of UAV batteries flying in desert environment.

The test standards of the battery module sand and dust test system mainly include the following aspects:

1. International Standards

- IEC 60529: This standard specifies the enclosure protection level (IP code), including IP5X and IP6X dust test methods

The IP5X test allows for limited dust ingress, while the IP6X test requires complete dust protection.

- ISO 12103-1: This standard specifies environmental conditions and test methods for road vehicles, including specific requirements for sand and dust testing

MIL-STD-810G.

- MIL-STD-810G: US military standard covering environmental engineering considerations and laboratory test methods, including sand and dust testing

MIL-STD-810G: US military standard covering environmental engineering considerations and laboratory test methods, including sand and dust testing 2 6.

2. National standards

- GB/T 2423.37-2006: Chinese national standard that specifies the method of sand and dust test for environmental testing of electrical and electronic products.

GB 4208-2008: This standard is similar to IEC 60529.

- GB 4208-2008: This standard is similar to IEC 60529 and specifies the test methods for the enclosure protection level (IP code)

GB 10485-2007: This standard specifies the test method for dust protection.

- GB 10485-2007: This standard specifies the test methods for dust protection.

GB 10485-2007: This standard specifies the dustproof test method 1.

3. Industry standards

- SAE J2464: This standard applies to safety and abuse testing of charging and storage systems for electric and hybrid electric vehicles, including testing in a sand and dust environment.

UL 1642: This standard applies to the safety and abuse testing of lithium ion.

- UL 1642: This standard applies to the safety testing of lithium batteries and covers the requirements for environmental testing.

UL 1642: This standard applies to the safety testing of lithium batteries and covers environmental testing requirements 8.

- UN 38.3: United Nations Standard for the Transportation of Dangerous Goods contains requirements for testing batteries under various environmental conditions, including sand and dust.

UN 38.3: United Nations Standard for the Transportation of Dangerous Goods.

4. Other relevant standards

- ASTM D1735: Standard developed by the American Society for Testing and Materials (ASTM) covering specific methods and equipment for sand and dust testing, applicable to a wide range of materials and products.

IEC 62133: This standard covers specific methods and equipment for sand and dust testing.

- IEC 62133: This standard applies to the safety standard for secondary lithium-ion batteries for electric vehicles and covers tests such as temperature cycling and thermal abuse

GB/T 31467.1-201

- GB/T 31467.1-2015, GB/T 31467.2-2015, GB/T 31467.3-2015: These standards apply to the testing of lithium-ion power battery packs and systems for electric vehicles, covering high power applications, high energy applications and safety performance requirements

.

5. Overview of test procedures

1.Initial Test: Under standard environmental conditions, the battery module is subjected to initial tests on appearance, basic functions, and electrical performance.

2.Sample Placement: Place the battery module in the test chamber to ensure that it is in normal working condition.

3.Setting Parameters: Set the parameters such as dust concentration, airflow speed, temperature, humidity, test time, etc. according to the test standard or customer's requirement.

4.Start the test: Start the test chamber and begin the sand and dust test.

5.

Continuous monitoring: During the test, monitor the performance and status of the battery module regularly and record the relevant data.

6.End of test: After the test, take out the samples, carry out appearance and function check, and evaluate the test results.

6. Evaluation Criteria

- Appearance Inspection: Check whether there is any dust deposition on the surface of the battery module and whether there is any dust entry in the sealed part.

- Function test: Test whether the functions of the battery module are normal and whether it is affected by sand and dust.

- Sealing test: Evaluate the sealing performance of the battery module to ensure that dust will not enter the interior and affect its normal operation.

- Electrical performance: Test whether the electrical performance of the battery module is affected, such as voltage, current, internal resistance and so on.

- Safety performance: Test the safety performance of the battery module to ensure that no short circuit, overheating, explosion and other safety problems will occur in the sand and dust environment.

7. Precautions

- Safe Operation: Operators should wear protective equipment, such as dust masks and protective glasses.

- Equipment Maintenance: Regularly check and maintain the equipment to ensure its normal operation, especially the sand dust generator and airflow control system.

- Dust Recycling: Recycle dust after use to avoid environmental pollution.

- Temperature and humidity control: Ensure the uniformity of temperature and humidity in the test chamber to avoid localized overheating or overhumidity.

- Environmental control: Keep the test environment clean to avoid external dust affecting the test results.

Advanced Observation and Illumination

Featuring a large, tempered glass window and powerful LED internal lighting, operators can monitor testing in real time without interrupting the test process. The illuminated window enhances visibility, aiding in precise assessments of particle behavior and battery module integrity during sand and dust exposure cycles.

Strict Compliance and Control

The system fully meets IEC 60529 and GB/T 4208 standards, making it suitable for formal ingress protection certifications. With PLC-based touch screen controls, users can easily set test parameters such as airflow, dust concentration, and test speed, ensuring repeatable and accurate results regardless of application.

Efficient Cleaning and Safety

Automatic tray removal streamlines cleaning between tests, minimizing operator intervention. Built-in safety protocols, including an emergency stop and leakage protection, ensure user safety at all stages, particularly important for high-volume laboratory or industrial environments handling sensitive battery packs.

FAQ's of Battery module sand and dust testing system:

Q: How does the sand and dust testing system enhance the accuracy of ingress protection tests for battery modules?

A: The system utilizes ISO Fine Arizona dust and a precise control of dust concentration (0.1-5 g/m3 with 0.01 g/m3 resolution and 1% accuracy), automated airflow regulation, and integrated vacuum for pressure drop testing. This setup, combined with programmable test cycles, ensures highly reproducible and compliant results for battery ingress protection evaluation.Q: What safety features are integrated into the system to protect users and equipment during testing?

A: It includes an emergency stop button, leakage protection, and overload safeguards, all designed to immediately halt operation in case of emergency or malfunction. The high-grade silicone seals further prevent dust leakage, keeping the laboratory environment safe and clean.Q: When is this testing system typically used within battery module development and certification?

A: The sand and dust testing system is employed during stages requiring qualification of battery modules according to ingress protection standards (such as IEC 60529). It's crucial in R&D, pre-certification, and quality assurance processes to verify device durability and enclosure integrity under harsh environmental conditions.Q: Where can the battery module sand and dust testing system be installed?

A: This floor-standing unit is suitable for laboratory and industrial environments engaged in battery module or pack IP testing. Its robust construction and adjustable parameters support a wide range of applications, from manufacturing quality control labs to research institutions.Q: What benefits does the observation window with LED illumination provide during the test process?

A: The large tempered glass observation window paired with LED lighting allows detailed, unobstructed monitoring of test specimens while tests are ongoing. This design promotes safety, minimizes test interruptions, and ensures accurate visual inspection of dust ingress and specimen behavior.Q: How does the system manage cleaning and specimen switching between tests?

A: Automatic tray removal simplifies and speeds up the cleaning process, allowing quick dust disposal and efficient preparation for subsequent tests. This automation reduces manual labor and turnaround time between test cycles, enhancing laboratory productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese