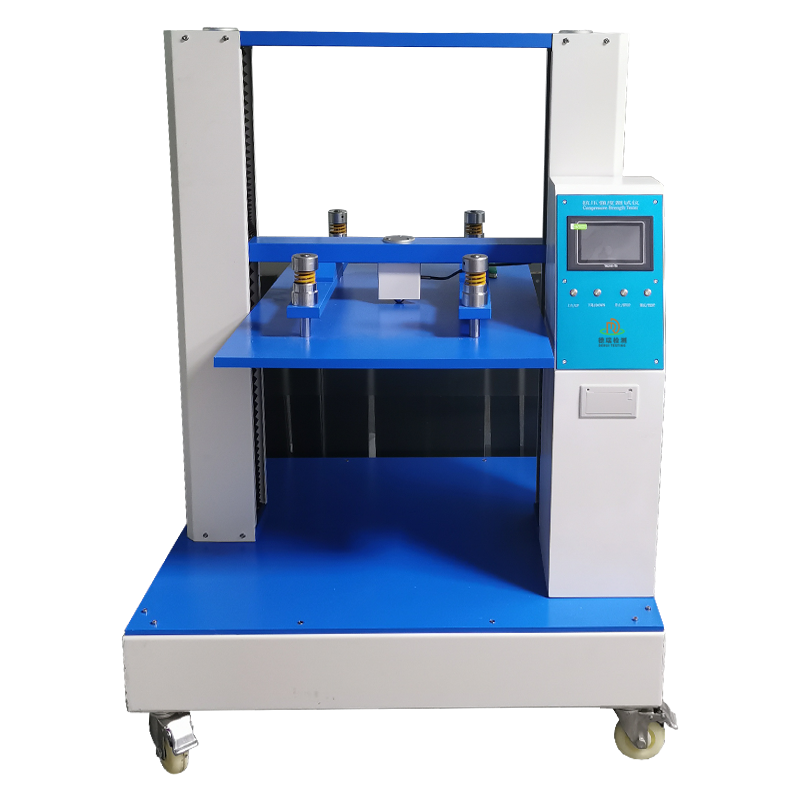

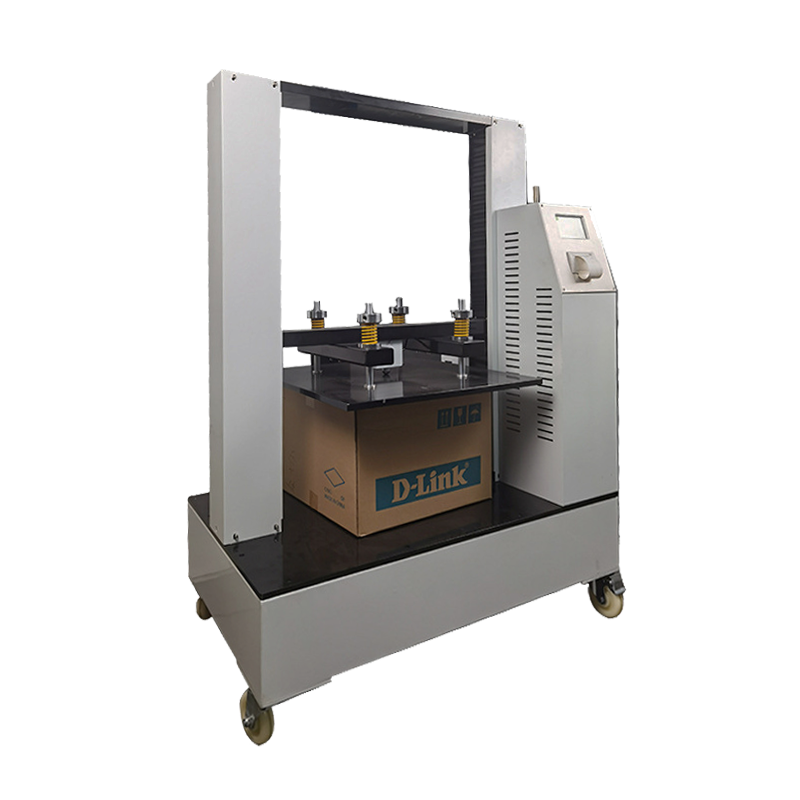

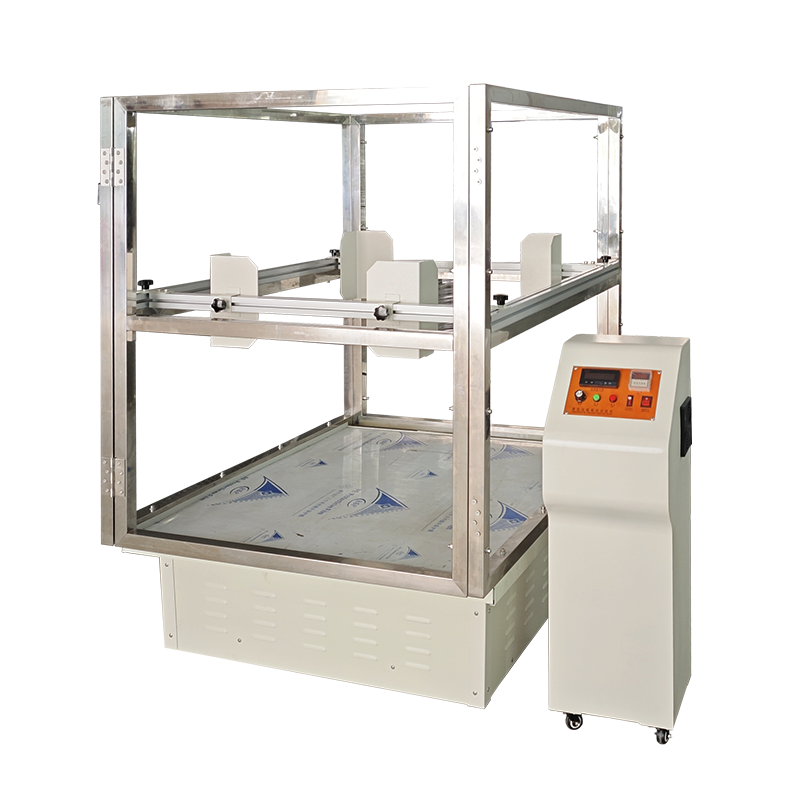

Compression testing machine for irregular packaging boxes

158005.0 INR/Unit

Product Details:

- Humidity 85% RH

- Interface Type RS232, USB

- Hardness High-strength steel frame

- Equipment Type Compression Testing Machine

- Specimen Size Irregular packaging boxes up to 700 x 700 mm

- Temperature 10C~40C

- Application Compression strength test of irregular packaging boxes

- Click to view more

X

Compression testing machine for irregular packaging boxes Price And Quantity

- 1 Unit

- 158005.0 INR/Unit

- 500 test results

- Heavy-duty caster wheels

- Automatic and manual

- On-site training and remote support available

- High precision strain gauge

- Hardened stainless steel

- Enabled via software

- Proprietary analysis software included

- 60 x 60 mm

- Irregular, corrugated, multi-layered

- Multi-language display

- 70 kg

- English/Chinese

- 650 W

- Natural air circulation

- <65 dB

- Manual and programmable cycles

- Emergency stop switch

- Password protected access

- Up to 1000 lux

- Epoxy powder coated steel

Compression testing machine for irregular packaging boxes Product Specifications

- Digital LCD display

- 50/60 Hz

- 1 at a time

- 50 kN

- 2 seconds

- 600 mm

- AC 220V, 50/60Hz

- 0-50 kN

- Real-time data processing, Overload protection, Adjustable speed

- 0.1-50 kN

- Semi-automatic

- 0.6 MPa

- Floor standing

- 760 mm

- 6 mm

- Microcomputer control / manual control

- RS232, USB

- 85% RH

- Laboratory and industrial packaging box testing

- High-strength steel frame

- 600 mm

- 280 kg

- 0.5-500 mm/min adjustable

- Compression strength test of irregular packaging boxes

- Irregular packaging boxes up to 700 x 700 mm

- 10C~40C

- Compression Testing Machine

- 1% of reading

- 0.01 kN

- AC 220 V

- 500 test results

- Heavy-duty caster wheels

- Automatic and manual

- On-site training and remote support available

- High precision strain gauge

- Hardened stainless steel

- Enabled via software

- Proprietary analysis software included

- 60 x 60 mm

- Irregular, corrugated, multi-layered

- Multi-language display

- 70 kg

- English/Chinese

- 650 W

- Natural air circulation

- <65 dB

- Manual and programmable cycles

- Emergency stop switch

- Password protected access

- Up to 1000 lux

- Epoxy powder coated steel

Compression testing machine for irregular packaging boxes Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 5 Days

- All India

Product Description

| Item | DR-B211-900 | DR-B211-1200 | DR-B211-1500 |

| Max. Force | 10KN(1000 kg ,2205lb) | 20KN(2000 kg, 4409lb) | 50KN(5000kg,11023lb) |

| Load cell | 1 load cell for highest accuracy | ||

| Control system | Dual control (Computer control with Windows mode+Touch screen control ) | ||

| Servo Motor | 400W | 750W | |

| Servo Driver | 400W | 750W | |

| Screws | Ball screws(Double ball guide rod design, high transmission accuracy, high transmission power efficiency) | ||

| Force reading | Gf, kgf, Ibf, N, KN, T etc | ||

| Load cell Resolution | 1/250,000 | ||

| Load Precision | within 0.5% | ||

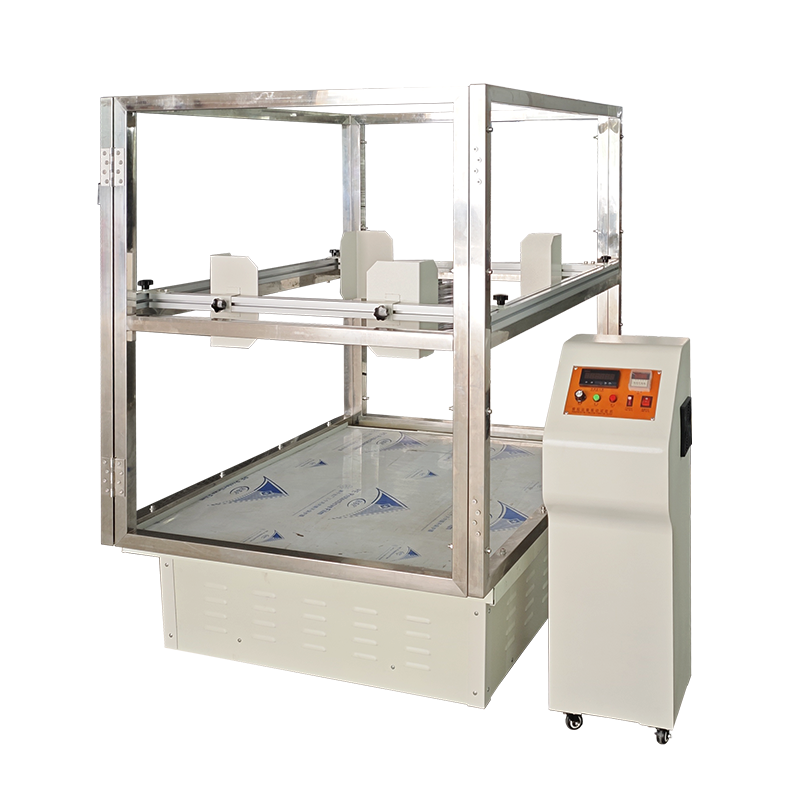

| Effective test area (L x W x H) | 700x900x900mm | 1000x1200x1000mm | 1300x1500x1500mm |

| Compression Stroke | 0~900mm | 0~1000mm | 0~1500mm |

| Lift speed | 0.1~200mm/min | ||

| Software | Mtest HD-002-A(Independent R&D) | ||

| Data display | Load, displacement, speed, loading rate and elapsed time | ||

| Safety features | E-Stop Over-load protection Upper and lower limit switches Load sensor with automatic retreat | ||

| Report items | Serial number, peak value, average value, set pressure holding value, pressure holding time | ||

| Electrical Supply | 1phase, AC 220V, 500W, 50HZ | 1phase, AC 220V,550W,50HZ | 1phase, AC 220V,900W,50HZ |

| Overall Dimensions (L x W x H) | Approx.1510x1200x1645mm | Approx.1510x1200x1645mm | Approx.1865mmx1500mmx2235mm |

| Weight | Approx.350kg(772lb) | Approx.670kg(1477lb) | Approx. 1000kg(2205lb) |

| Operation Temperature and relative humidity | 10~40, 30~80% | ||

1. Main functions

Compressive strength test: Measure the maximum compressive capacity of the shaped packing box in the vertical direction according to the relevant standards or customer requirements, and assess its load-bearing capacity during stacking, transportation and storage.

Deformation test: Record the deformation of the box under compression load, assess the degree of deformation and recovery ability, and ensure that the box can still maintain its structural integrity and appearance after being subjected to pressure.

Stacking test: simulate the force on the boxes in the actual stacking situation, assess their stacking stability and load-bearing capacity, and ensure that no collapse or damage occurs when multiple layers are stacked.

Cyclic compression test: The box is loaded and unloaded for several cycles to assess its fatigue performance and durability, to ensure that the box still maintains good compression resistance after repeated handling and transportation.

Customized fixture design: Design and use customized fixtures according to the special shapes and sizes of the shaped boxes to ensure the stability of the boxes during the test and the accuracy of the test results.

Data analysis and report generation: Built-in data analysis software can automatically generate detailed test reports, including maximum compressive strength, deformation, loading curve and other parameters to help quality control departments carry out strict quality assessment.

Equipment Features

- Flexibility and customization: capable of adapting to various shapes and sizes of shaped boxes, providing customized fixtures and test solutions.

- High-precision control: Adopting advanced control system, it can accurately control parameters such as compression speed, load and displacement to ensure the accuracy and reliability of test results.

- Safety and Reliability: Equipped with multiple safety protection devices, such as overload protection, limit protection, emergency stop device, etc., to ensure the safety and reliability of the testing process.

- Data processing and analysis: Built-in data processing software can automatically generate test reports that meet the standards and provide data analysis functions, which is convenient for quality control personnel to carry out strict quality assessment.

- Sturdy structure: Made of high-strength materials with good rigidity and stability, it can withstand large testing pressure and ensure the reliability of the equipment in long-time use.

When using the shaped box compression tester for testing, common misconceptions mainly include the following points:

Improper sample selection and processing:

Misunderstanding: When selecting carton samples, we have not ensured that the size, material, structure and other parameters of the carton are consistent, or we have not made the moisture of the carton reach a dynamic equilibrium state in the pretreatment process.

Consequence: This may result in inaccurate test results that do not truly reflect the carton's compressive properties.

Suggestion: Ensure that the selected carton samples are consistent in terms of size, material, structure, etc., and that they are pretreated for 24 hours under the standard test condition, so that the moisture in the carton reaches a dynamic equilibrium state.

The test parameters are set unreasonably:

Mistake: When setting test parameters, not adjusted according to the specifications and test requirements of the carton, or set too high pressure range and loading rate.

Consequence: It may lead to excessive damage or destruction of the carton during the test, affecting the accuracy of the test results.

Suggestion: Set the appropriate pressure range and loading rate according to the specifications and test requirements of the carton to simulate the stress situation in the actual transportation environment.

Improper operation during testing:

Misconceptions: During the testing process, the carton samples are not placed in strict accordance with the testing requirements, or the changes in the testing data and the operation status of the equipment are not closely monitored.

Consequence: It may lead to inaccurate test data or even equipment damage.

Suggestion: During the testing process, place the carton samples in strict accordance with the testing requirements to ensure the stability and accuracy of the testing process. At the same time, pay close attention to the changes in the test data and the operating status of the equipment, if you find any abnormalities or equipment failure, you should immediately stop the test and ask the professionals to check and repair.

Neglect the safety operation procedures:

Misconceptions: Failure to wear protective gloves, eyeglasses and other safety items during operation, or the operator's hands and other body parts are close to the moving parts of the equipment during the operation of the equipment.

Consequence: May result in injury to the operator or damage to the equipment.

Suggestion: Observe the safety operating procedures of the equipment and wear protective gloves, glasses and other safety items to ensure the safety of the operation process.

By avoiding these misunderstandings, you can ensure that the test results of the shaped box compression tester are accurate and reliable, thus providing an effective guarantee for product quality.

High-Precision Testing for Irregular Boxes

Engineered to handle the complexities of irregular, corrugated, and multi-layered packaging, this compression tester delivers consistent and accurate measurement. The high precision strain gauge and hardened stainless steel plates ensure reliable results for boxes of varied shapes and strengths.

User-Friendly and Secure Operation

Equipped with password-protected access and an emergency stop switch, the machine prioritizes operator safety and data security. The large digital LCD display, English/Chinese interface, and multi-language support simplify operations, while automatic or manual calibration enhances user flexibility.

Comprehensive Data and Remote Monitoring

Easily store and manage up to 500 test results with proprietary analysis software. Real-time data processing, RS232/USB connectivity, and remote monitoring capabilities empower users to control tests and access reports from different locations, streamlining the quality assurance process.

FAQ's of Compression testing machine for irregular packaging boxes:

Q: How does the compression testing machine accommodate irregular packaging boxes?

A: This machine features an adjustable test width up to 760 mm, and supports packaging boxes with irregular shapes up to 700 x 700 mm, making it suitable for a wide variety of non-standard packaging types, including multi-layered and corrugated boxes.Q: What is the process for calibrating the compression tester?

A: Calibration is conducted via both automatic and manual modes. Users may initiate the automatic calibration sequence through the software, or perform manual adjustments as needed, ensuring precise force measurement and maintaining accuracy throughout testing.Q: Where can I access and store test results from the machine?

A: Test results are stored internally with a capacity of up to 500 individual results. Data can be exported using RS232 or USB interfaces, and comprehensive analysis is available through the included proprietary software, which also supports remote monitoring.Q: When is it safe to operate this equipment?

A: Operation is safe within an ambient temperature range of 10C to 40C and humidity levels below 85% RH. The emergency stop switch and overload protection system ensure immediate shutdown in case of unexpected events, enhancing safety during use.Q: What benefits does the machine offer for laboratory and industrial testing?

A: For both laboratory and industrial settings, the machine delivers high-accuracy, repeatable results for compression strength testing. The durable epoxy powder coated steel frame, real-time data processing, remote monitoring, and multiple language support enhance operational efficiency and productivity.Q: How is user access controlled on this device?

A: User authentication is password-protected, restricting access to authorized personnel only. This prevents unintentional changes to test parameters and safeguards sensitive test data.Q: Which test modes are available and how can I select them?

A: The equipment supports both programmable and manual test cycles. Selection is easily made via the microcomputer control panel or the proprietary software, allowing users to customize tests according to specific packaging requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese