Drop Test Chamber Free Fall Analyzer

148605.0 INR/Unit

Product Details:

- Measuring Range 0-1000 mm

- Display Type Digital/LED

- Application Package drop testing, Impact resistance analysis

- Hardness Industrial-grade steel construction

- Test Range Up to 1000 mm drop height

- Features Adjustable drop height, Digital display, Durable construction

- Specimen Size Max 800 x 800 x 1000 mm

- Click to view more

X

Drop Test Chamber Free Fall Analyzer Price And Quantity

- 1 Unit

- 148605.0 INR/Unit

- Single and multiple drop modes

- Powder-coated steel

- < 70 dB

- Emergency stop, Safety interlock

- ISTA, ASTM D5276

- Indoor use only

- Electromagnetic release

- Approx. 1500 x 1200 x 2200 mm

Drop Test Chamber Free Fall Analyzer Product Specifications

- 10-40C

- Push Button / Digital panel

- Digital / PLC Control

- 50/60 Hz

- 1 per cycle

- 320 kg

- Adjustable, Up to 2 m/s

- 1000 mm

- Drop Test Chamber Free Fall Analyzer

- 85% RH

- 220 V

- Instantaneous

- 1 mm

- Standard

- Floor standing

- Laboratory, Quality control, Industrial testing

- 0-1000 mm

- Up to 800 mm

- Digital/LED

- 0-1000 mm

- Industrial-grade steel construction

- Package drop testing, Impact resistance analysis

- Adjustable drop height, Digital display, Durable construction

- Up to 1000 mm drop height

- Up to 80 kg

- Max 800 x 800 x 1000 mm

- Semi-automatic

- 1 mm

- AC 220V, 50/60 Hz

- Single and multiple drop modes

- Powder-coated steel

- < 70 dB

- Emergency stop, Safety interlock

- ISTA, ASTM D5276

- Indoor use only

- Electromagnetic release

- Approx. 1500 x 1200 x 2200 mm

Drop Test Chamber Free Fall Analyzer Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 3 Days

- All India

Product Description

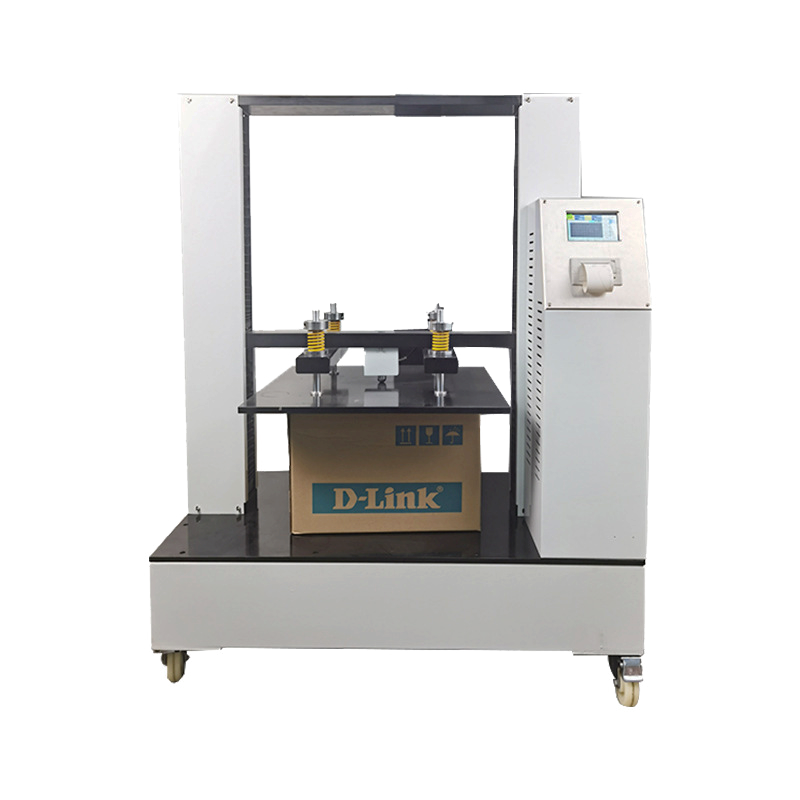

Specifications:

| Item | Description |

| Drop height | 400-1500mm (can be customized) |

| Display method | Digital display |

| Max. weight of sample | 60kg (can be customized) |

| Max. size of sample | (L*W*H) 800*800*800mm |

| Drop panel area | 1400x1200mm (material is Solid steel plate) |

| Control box dimension | (L*W*H) 350*350*1100mm |

| Deviation of drop horizon | Less than 1 |

| Machine size | (L*W*H)1400*1200*2200mm |

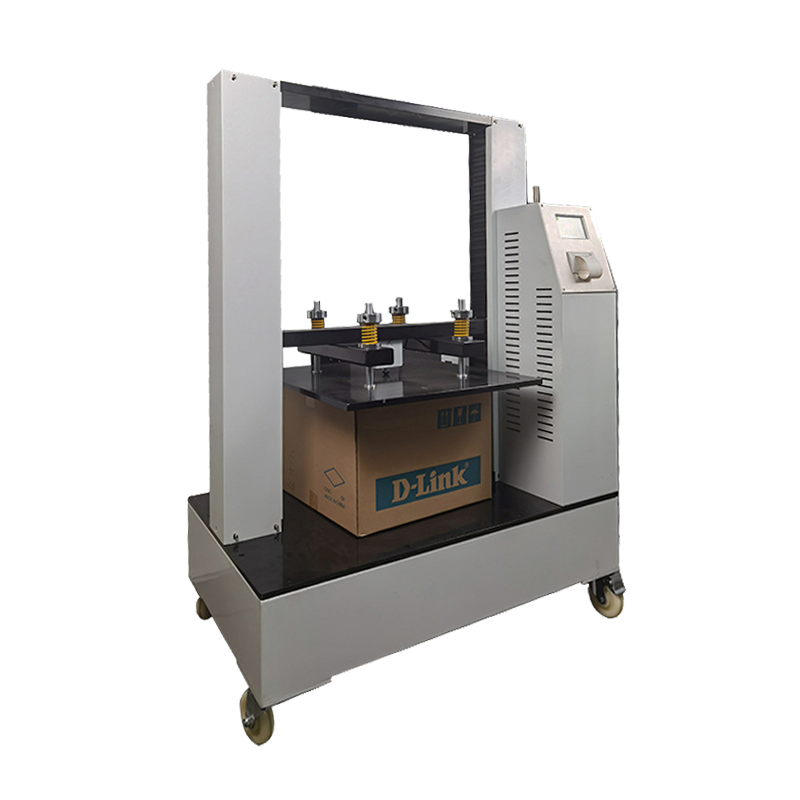

In the competitive landscape of product manufacturing and quality assurance, the Drop Test Chamber Free Fall Analyzeremerges as a crucial instrument for evaluating product durability and reliability. This sophisticated equipment is designed to simulate free-fall scenarios, providing manufacturers with critical data on how their products withstand various drop conditions. In this article, we will explore the features, functionalities, installation process, and usage precautions of the Drop Test Chamber Free Fall Analyzer, ensuring a comprehensive understanding of its capabilities.

Key Features and Functionalities

1.

Free Fall Simulation:

The primary function of the Drop Test Chamber Free Fall Analyzeris to simulate free-fall conditions. This is achieved through a controlled release mechanism that allows products to fall from varying heights, accurately replicating real-world drop scenarios. This feature is essential for assessing the impact resistance and structural integrity of products.

2.

Adjustable Drop Height:

One of the standout characteristics of this analyzer is its adjustable drop height, ranging from 1 to 200 cm. This flexibility enables manufacturers to test products under different drop conditions, ensuring that they can evaluate the durability of their products across a wide spectrum of potential scenarios. The adjustable height feature is particularly beneficial for products that are likely to experience drops from different elevations during their lifecycle.

3.

Precision Control System:

The analyzer is equipped with a precision control systemthat ensures accurate and repeatable drop tests. This system allows for precise positioning of the product before release, ensuring that each test is conducted under identical conditions. This level of control is crucial for obtaining reliable and consistent data, which can be used to make informed decisions about product design and manufacturing processes.

4.

High-Speed Data Capture:

The Drop Test Chamber Free Fall Analyzer is equipped with advanced sensors and data capture technology. This enables the analyzer to record high-speed data during the drop test, providing detailed insights into the impact forces and the product's response. This data is invaluable for identifying potential weaknesses and areas for improvement in product design.

5.

User-Friendly Interface:

The analyzer features an intuitive user interface that simplifies the testing process. With clear controls and a straightforward setup, users can easily configure the test parameters and initiate the drop sequence. This user-friendly design reduces the learning curve for new users and ensures that testing can be conducted efficiently and effectively.

Installation and Setup

Installing the Drop Test Chamber Free Fall Analyzeris a straightforward process, but it requires careful attention to ensure optimal performance:

1.

Location Selection:

Choose a stable and level surface for the analyzer. The location should be free from vibrations and other external disturbances that could affect the test results.

2.

Assembly:

Follow the manufacturer's instructions for assembling the analyzer. This typically involves attaching the drop mechanism, securing the base, and connecting the control unit.

3.

Calibration:

Once assembled, calibrate the analyzer to ensure accurate test results. This may involve adjusting the drop height, verifying the release mechanism, and confirming the data capture settings.

4.

Safety Checks:

Conduct a series of safety checks to ensure that the analyzer is functioning correctly. This includes testing the emergency stop function and verifying that all safety interlocks are operational.

Usage Precautions

To ensure the safe and effective operation of the Drop Test Chamber Free Fall Analyzer, consider the following precautions:

Regular Maintenance:

Perform regular maintenance checks to ensure that the analyzer remains in good working condition. This includes inspecting the drop mechanism, checking the sensors, and verifying the calibration.

Proper Product Positioning:

Ensure that the product is positioned correctly before each test. This ensures that the drop is consistent and that the data captured accurately reflects the product's response to the impact.

Environmental Conditions:

Be mindful of the environmental conditions in which the analyzer is operated. Extreme temperatures, humidity, and other factors can affect the performance of the analyzer and the test results.

Training:

Provide adequate training for all users of the analyzer. This ensures that they understand how to operate the equipment safely and effectively, reducing the risk of accidents and ensuring reliable test results.

Advanced Control and Precision

The Drop Test Chamber Free Fall Analyzer boasts advanced digital/PLC control and an electromagnetic release system, offering accurate and repeatable drop tests for packages of various sizes. With digital/LED display and an accuracy of 1 mm, users can confidently conduct impact resistance analysis under standardized conditions for reliable test outcomes.

Enhanced Safety and User Experience

Designed for safe, effortless operation, the chamber features emergency stop and safety interlock systems, ensuring operator protection. Its noise level remains below 70 dB, providing a quiet testing environment. The push button or digital panel interface allows intuitive operation, making it suitable for laboratory and industrial quality control applications.

Robust Construction and Versatile Application

Constructed from powder-coated, industrial-grade steel, this floor-standing analyzer supports weights up to 80 kg and is compatible with specimen sizes up to 800 x 800 x 1000 mm. Its adjustable drop height and speed settings make it suitable for various package testing needs, including compliance with international standards like ISTA and ASTM D5276.

FAQ's of Drop Test Chamber Free Fall Analyzer:

Q: How does the drop mechanism function in the Free Fall Analyzer?

A: The drop mechanism employs an electromagnetic release, ensuring precise and consistent package release for reproducible drops within the 0-1000 mm range.Q: What type of materials can be tested using this chamber, and what are the specimen size and weight limits?

A: You can test packages or products up to 80 kg in weight, with maximum specimen dimensions of 800 x 800 x 1000 mm, making it suitable for a diverse range of packaging formats.Q: When should I use the single versus multiple drop test modes?

A: Single drop mode is ideal for general impact tests, while multiple drop mode is used for assessing repeated shock resilience, both selectable per your testing requirements.Q: Where is the recommended location for installing this drop test chamber?

A: The chamber is designed exclusively for indoor use, preferably in laboratories or industrial environments meeting ambient conditions of 10-40C and humidity up to 85% RH.Q: What is the process for operating the chamber and adjusting test parameters?

A: Operation is simple via a digital/LED panel or push button interface. Users can set the drop height, speed, and quantity through digital/PLC controls with instantaneous response, ensuring flexible and efficient testing.Q: How does the equipment ensure operator safety during testing?

A: It incorporates an emergency stop and safety interlock mechanism that halts operation instantly if a safety risk is detected, protecting both operators and devices.Q: What are the main benefits of using this Drop Test Chamber for quality control?

A: The analyzer provides accurate, standardized drop testing to international standards, supporting precise analysis of package impact resistance, improving packaging reliability, and ensuring product safety during transit.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese