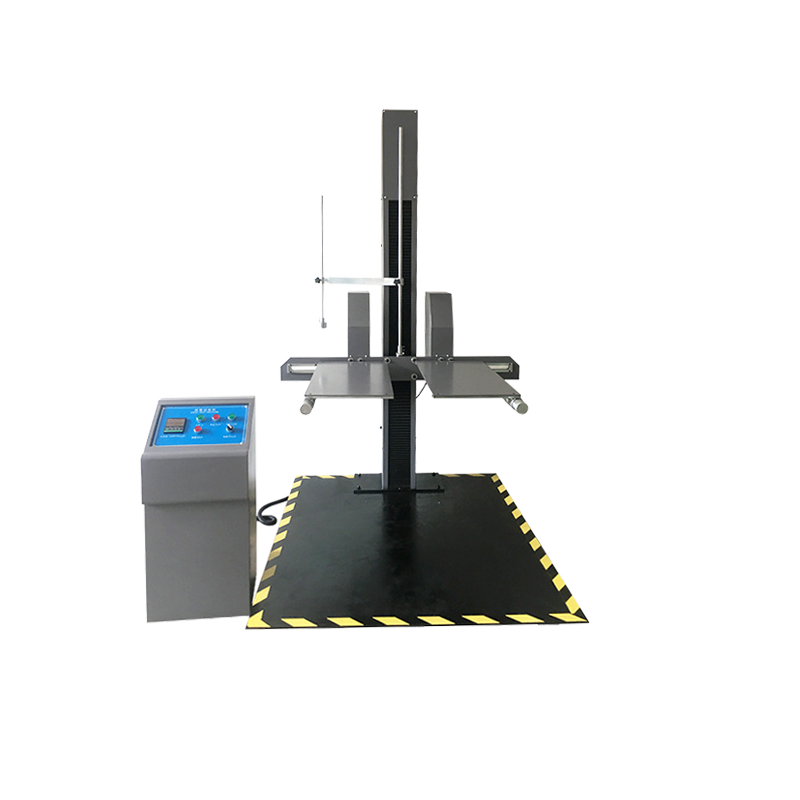

Custom Drop Test Machine Design Services

198005.0 INR/Unit

Product Details:

- Resolution 1 mm

- Port Size Standard / Customizable

- Measuring Range 0.5 to 2.0 m drop height

- Features Auto-lift, Emergency Stop, Adjustable Drop Height

- Application Drop impact testing of packages, materials, and components

- Accuracy 2 mm on drop height

- Frequency Manual or per test cycle

- Click to view more

X

Custom Drop Test Machine Design Services Price And Quantity

- 198005.0 INR/Unit

- 1 Unit

- High-grade Steel Structure with Powder Coating

- Factory Calibrated with Certificate

- Indoor Use Only

- Onsite/Remote Technical Support

- Manual/Mechanical Loading Arm

- Emergency Stop, Protective Guard, Sensor Interlock

- Supported on request (specimen size, drop height, etc.)

- CE Certified / ISO 17025-compatible

- Protective Export Packing Included

- Adjustable Clamp Platform

- Approx. 400 Kg (with crate)

- 68 dB

Custom Drop Test Machine Design Services Product Specifications

- Drop Test Machine

- Semi-automatic / Fully Automatic

- Up to 1200 mm

- Approx. 350 Kg

- 01500 mm

- Customizable, typically 2.5 m/s to 3.0 m/s

- Instantaneous ( 1 sec)

- 230V AC, 50 Hz

- 0C to 50C

- Floor Mounted

- 1 per cycle

- PLC Based / Manual

- 2000 mm

- Max 1000mm x 1000mm x 600mm

- Touchscreen/Manual Interface

- 230V AC

- 2 mm on drop height

- Up to 200 Kg

- 1 mm

- Standard / Customizable

- 0.5 to 2.0 m drop height

- Drop impact testing of packages, materials, and components

- Auto-lift, Emergency Stop, Adjustable Drop Height

- Manual or per test cycle

- 0.5m to 2.0m adjustable

- Digital Display

- 10%90% RH

- Industrial, Laboratory

- High-grade Steel Structure with Powder Coating

- Factory Calibrated with Certificate

- Indoor Use Only

- Onsite/Remote Technical Support

- Manual/Mechanical Loading Arm

- Emergency Stop, Protective Guard, Sensor Interlock

- Supported on request (specimen size, drop height, etc.)

- CE Certified / ISO 17025-compatible

- Protective Export Packing Included

- Adjustable Clamp Platform

- Approx. 400 Kg (with crate)

- 68 dB

Custom Drop Test Machine Design Services Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 5 Days

- All India

Product Description

Introduction:

The pursuit of product excellence hinges on meticulous testing procedures that accurately gauge durability under diverse conditions. At TradeIndia, we stand at the confluence of innovation and precision, offering unmatched custom drop test machine engineering services. Our mission is to collaborate with forward-thinking businesses to design, engineer, and deliver testing machines that redefine industry standards. By focusing on bespoke solutions, we enable our clients to fortify their quality control frameworks, ensuring that their products not only meet but surpass consumer expectations.

Unrivalled Custom Drop Test Machine Engineering Services:

-

Bespoke Design Philosophy: We believe that one-size-fits-all solutions fall short in addressing the nuanced testing needs of modern products. Our custom design philosophy revolves around creating machines that are intricately aligned with the unique specifications and testing parameters of each client. This approach ensures that every drop test machine we design is a testament to precision and purpose-built functionality.

-

State-of-the-Art Technology Integration: Leveraging the latest advancements in testing technology, our engineers infuse each custom drop test machine with cutting-edge features. From advanced impact sensors to sophisticated data analysis software, our machines are engineered to deliver results with unparalleled accuracy and reliability.

-

Superior Craftsmanship and Durability: Constructed using the finest materials and adhering to stringent manufacturing standards, our custom drop test machines are built to endure the rigors of continuous use. This commitment to quality ensures that our clients receive testing equipment that stands the test of time, providing consistent performance year after year.

-

Client-Centric Collaboration: Our design process is rooted in collaboration and transparency. We engage in open dialogue with our clients throughout the project lifecycle, from the initial concept phase to the final installation and beyond. This ensures that every aspect of the custom drop test machine meets and exceeds client expectations.

-

Comprehensive Support and Training: Understanding that the effectiveness of a testing machine is intrinsically linked to its operation, we provide comprehensive training and support to our clients. Our team equips users with the knowledge and skills required to harness the full potential of their custom drop test machine, ensuring optimal utilization and test result integrity.

Navigating the Future of Product Testing:

As industries evolve and product complexity increases, the demand for sophisticated and adaptable testing solutions has never been greater. By choosing TradeIndia's custom drop test machine engineering services, businesses can future-proof their quality control processes. Our bespoke machines are designed to accommodate evolving testing requirements, ensuring that our clients remain at the forefront of innovation and quality assurance.

Specifications:

| Item | Description |

| Drop height | 400-1800mm (can be customized) |

| Display method | Digital display |

| Max. weight of sample | 60kg (can be customized) |

| Max. size of sample | (L*W*H) 800*800*800mm |

| Drop panel area | 1400x1200mm (material is Solid steel plate) |

| Control box dimension | (L*W*H) 350*350*1100mm |

| Deviation of drop horizon | Less than 1 |

| Machine size | (L*W*H)1400*1200*2200mm |

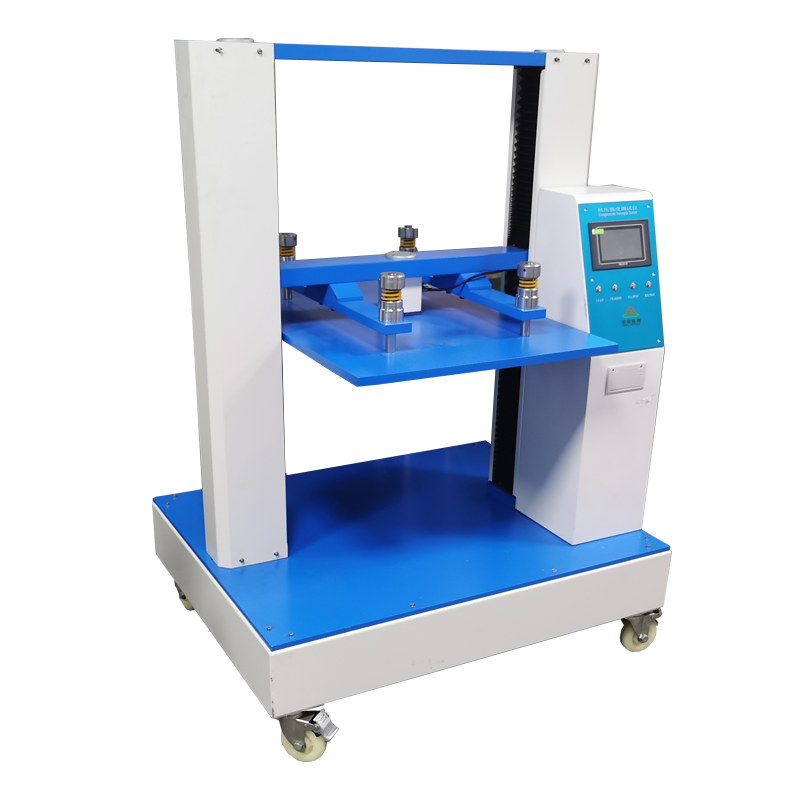

Advanced Construction and Safety Features

The drop test machine is engineered with a high-grade steel structure and powder coating for durability in demanding laboratory and industrial environments. Key safety features include emergency stop, protective guards, and sensor interlock systems. The design supports low operating noise (68 dB), making it suitable for indoor use with minimal disruption. Comprehensive protective export packaging ensures the equipment arrives safely at your destination.

Flexible Test Parameters and Customization

Our solution accommodates a range of test requirements with an adjustable clamp platform and both manual and mechanical sample loading options. Drop height can be set anywhere from 0.5m to 2.0m (2 mm accuracy), and the system supports customizable test speeds, widths (up to 1200 mm), and specimen dimensions. Customization is available to match your specific product and testing needs upon request.

Certified Accuracy and Reliable Performance

Each drop test machine is factory calibrated and delivered with a calibration certificate. The equipment is compatible with CE and ISO 17025 standards, ensuring accurate, consistent results with a digital readout that delivers instantaneous response (1 sec). With a robust design and PLC/manual controls, the machine supports both semi-automatic and fully automatic operations for reliable drop impact testing.

FAQ's of Custom Drop Test Machine Design Services:

Q: How does the drop test machine ensure accurate and repeatable results?

A: The machine uses factory calibration (certificate provided) and digital display systems with 2 mm accuracy on drop height and 1 mm resolution. PLC-based or manual control modes guarantee precise, repeatable drop testing cycles for every specimen.Q: What safety mechanisms are incorporated in the machine's design?

A: The drop test machine features an emergency stop button, protective guard, and sensor interlock to ensure operator safety during use. These systems help prevent accidental operation and provide immediate intervention in any emergency situation.Q: When is customization of the drop test machine recommended or required?

A: Customization is ideal if your specimens exceed standard dimensions, need specific drop heights, or require unique test speeds or mounting solutions. Our service supports modifications for test height, width, clamp type, interface, and automation level on request.Q: Where can this drop test machine be installed and utilized?

A: Designed for indoor environments, the drop test machine is suitable for installation in laboratories, manufacturing sites, and quality assurance facilities thanks to its sturdy construction, compact footprint, and low noise output.Q: What is the typical process for operating the drop test machine?

A: Place the specimen on the adjustable clamp platform using the manual or mechanical arm, set the drop height via the digital interface, and initiate the test. The machine automatically lifts and releases the sample with instant digital feedback and precise measurement.Q: How does service support and maintenance work for this equipment?

A: We provide both onsite and remote technical support, ensuring prompt assistance for installation, user training, calibration, and troubleshooting. Comprehensive service plans are available to maintain optimal machine performance throughout its lifecycle.Q: What are the primary benefits of using this drop test machine?

A: Key benefits include highly accurate and customizable drop testing, robust construction for long-term operation, comprehensive safety features, wide testing range, and compliance with CE and ISO 17025 standards. Users benefit from factory calibration, flexible operation modes, and reliable on-site/export support.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese