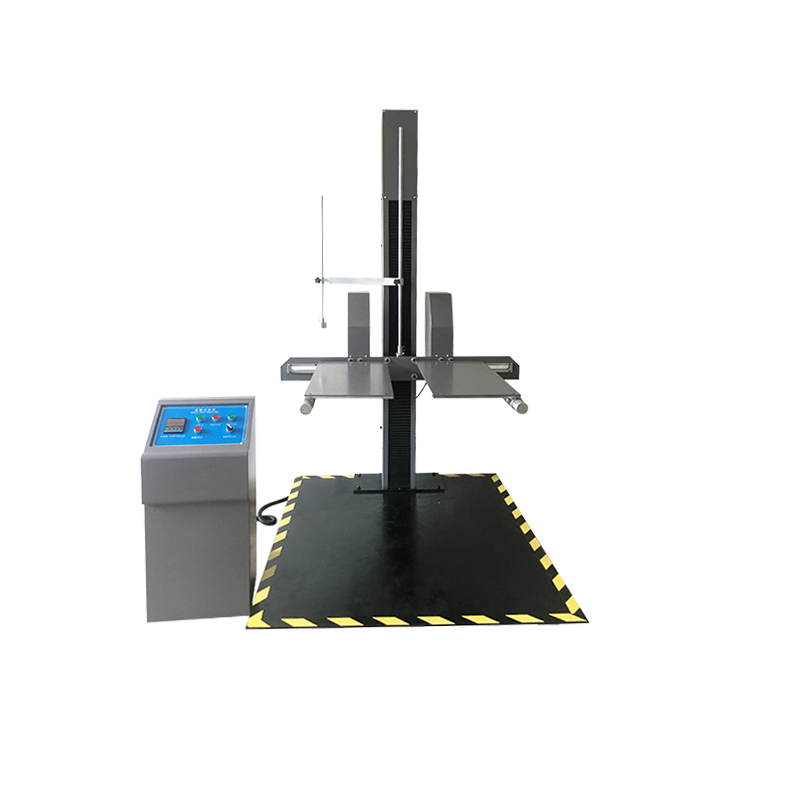

Drop Test Machine for 1.8m Free Fall Simulation

168005.0 INR/Unit

Product Details:

- Features Heavy Duty Steel Frame, Quick Release Mechanism, Adjustable Forks

- Interface Type Push Button & Emergency Stop

- Resolution 1 mm

- Equipment Type Drop Test Machine for 1.8m Free Fall Simulation

- Measuring Range 0~1800 mm (Drop Height)

- Frequency Single operation per drop

- Operating Voltage 220V/50Hz

- Click to view more

X

Drop Test Machine for 1.8m Free Fall Simulation Price And Quantity

- 168005.0 INR/Unit

- 1 Unit

- Industrial Grey/Blue

- 1 Set

- Electric Motor Powered Lifting Arm

- Emergency Stop, Locking system

- Approx. 1700 mm x 1400 mm x 2300 mm (L x W x H)

- <70 dB

- Electromagnetic Quick Release

- ISO 2248, ASTM D5276, ISTA Standards

- Flat, Edge, and Corner Drop Possible

- Powder Coated Steel

Drop Test Machine for 1.8m Free Fall Simulation Product Specifications

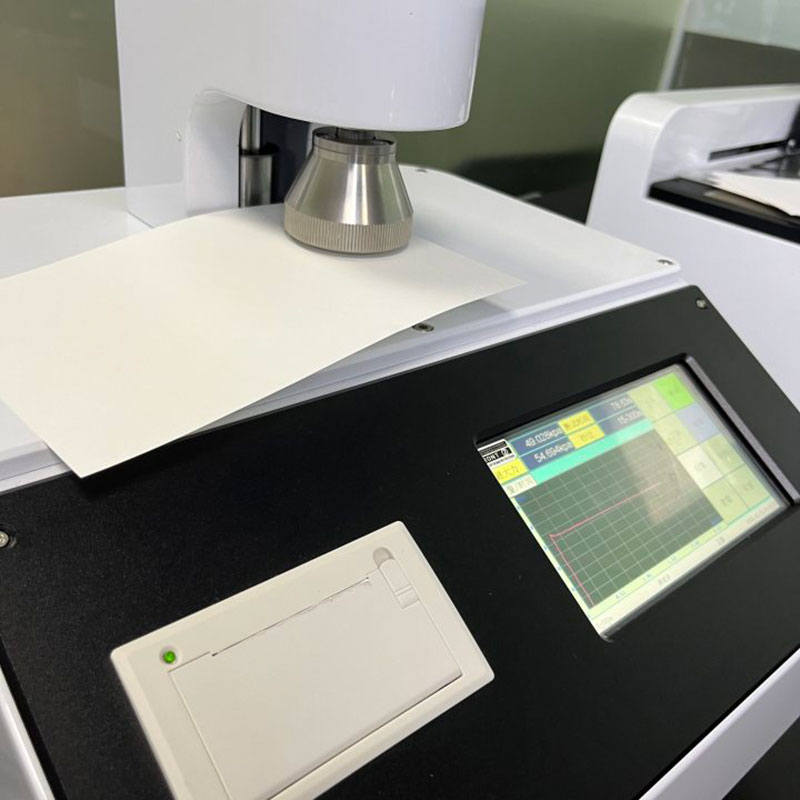

- Digital Display

- 1800 mm

- 0~40C

- Free fall (Gravity Acceleration)

- 1 per test

- Hardened release arms, Industrial Grade

- 85% RH

- Standard (customizable based on requirement)

- Up to 1.8 meters drop height

- Semi-Automatic

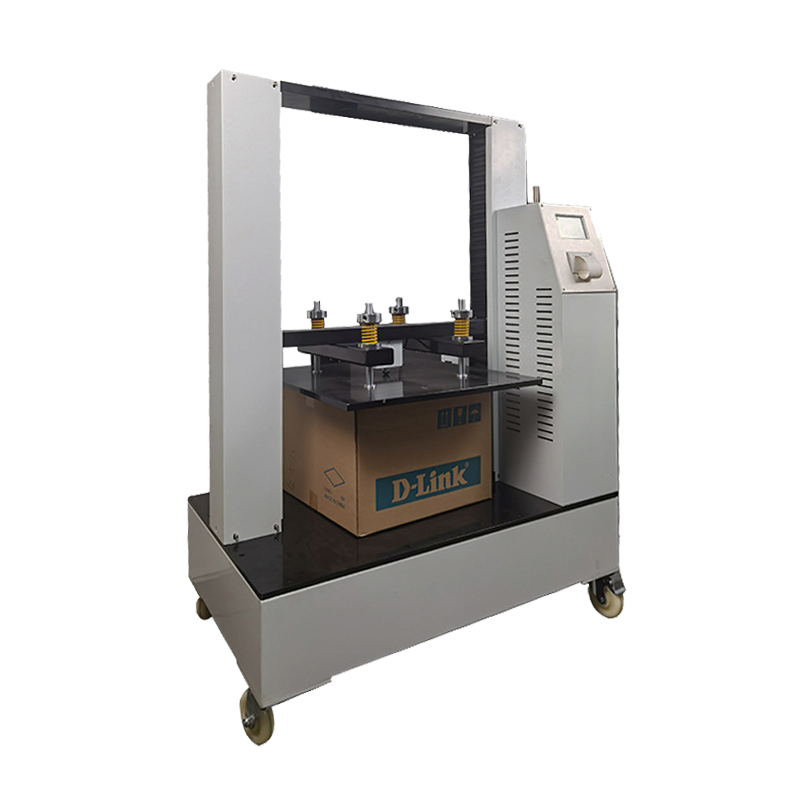

- Carton, Packaging & Container Free Fall Drop Test

- Up to 80 kg specimen

- Max 1200 x 1200 mm

- Package Impact Drop Testing

- Approx. 350 kg

- Floor standing

- AC 220V, 50Hz

- Instantaneous Release (<0.05 s)

- Drop Test Machine for 1.8m Free Fall Simulation

- Adjustable up to 1800 mm

- Up to 1200 mm

- Single operation per drop

- 0~1800 mm (Drop Height)

- 220V/50Hz

- Electric / Manual

- 1 mm

- Heavy Duty Steel Frame, Quick Release Mechanism, Adjustable Forks

- 1 mm

- Push Button & Emergency Stop

- Industrial Grey/Blue

- 1 Set

- Electric Motor Powered Lifting Arm

- Emergency Stop, Locking system

- Approx. 1700 mm x 1400 mm x 2300 mm (L x W x H)

- <70 dB

- Electromagnetic Quick Release

- ISO 2248, ASTM D5276, ISTA Standards

- Flat, Edge, and Corner Drop Possible

- Powder Coated Steel

Drop Test Machine for 1.8m Free Fall Simulation Trade Information

- Cash in Advance (CID)

- 80 Unit Per Month

- 5 Days

- All India

Product Description

Specifications:

| Item | Description |

| Drop height | 400-1500mm (can be customized) |

| Display method | Digital display |

| Max. weight of sample | 60kg (can be customized) |

| Max. size of sample | (L*W*H)800*800*800mm |

| Drop panel area | 1400x1200mm(material is Solid steel plate) |

| Control box dimension | (L*W*H) 350*350*1100mm |

| Deviation of drop horizon | Less than 1 |

| Machine size | (L*W*H)1400*1200*2200mm |

In the competitive landscape of product manufacturing, ensuring durability and reliability is paramount. Our Drop Test Machine for 1.8m Free Fall Simulation is engineered to deliver precision testing that mimics real-world conditions, providing invaluable insights into product performance.

Key Features and Benefits:

-

1.8m Free Fall Simulation:This drop test machine is specifically designed to simulate a 1.8m free fall, accurately replicating the impact forces that products may encounter during handling and transportation. The 1.8m free fall simulation is a critical test to ensure product resilience.

-

Advanced Technology:Equipped with cutting-edge technology, our drop test machine offers precise control and consistent results. The machines advanced sensors and automated systems ensure that each test is conducted with unparalleled accuracy, enhancing the reliability of your product testing.

-

Versatile Applications:Whether youre testing electronics, packaging, or other consumer goods, our drop test machine is versatile enough to meet a wide range of testing needs. The 1.8m free fall simulation is particularly useful for assessing the durability of products that are prone to drops from heights.

-

User-Friendly Interface:Designed with the user in mind, our drop test machine features an intuitive interface that simplifies the testing process. Operators can easily set up and execute tests, saving time and reducing the risk of human error.

-

Compliance and Safety:Our drop test machine is built to comply with international testing standards, ensuring that your products meet the required safety and quality benchmarks. The 1.8m free fall simulation is a key component in achieving compliance for various industries.

Why Choose Our Drop Test Machine:

- Enhanced Product Quality:By subjecting your products to a 1.8m free fall simulation, you can identify potential weaknesses and make necessary improvements, leading to higher quality products.

- Cost-Effective Testing:Our drop test machine offers a cost-effective solution for product testing, reducing the need for expensive field testing and potential product recalls.

- Data-Driven Insights:The precise data generated from each 1.8m free fall simulation provides valuable insights into product performance, enabling better decision-making and product development.

Versatile Drop Testing for Packaging Integrity

This machine enables comprehensive drop tests-flat, edge, and corner-simulating accidental falls during shipping and handling. The adjustable release height (up to 1800 mm) and heavy-duty steel frame accommodate diverse packaging formats, ensuring robust evaluation of product protection during transit.

Advanced Control and Safety Features

Equipped with electric and manual operation modes, the drop test machine features an electromagnetic quick release, digital display, push button interface, and emergency stop system. Its locking mechanism enhances operator safety, while the noise level remains under 70 dB for a quieter testing environment.

FAQ's of Drop Test Machine for 1.8m Free Fall Simulation:

Q: How does the drop test machine simulate free-fall drops?

A: The machine uses an electric motor-powered lifting arm to raise the test specimen to the desired height (up to 1.8 meters) and then releases it instantly using an electromagnetic quick release system, allowing for accurate simulation of gravity-driven, free-fall impact.Q: What safety features are included in the drop test machine design?

A: This equipment incorporates multiple safety mechanisms, including an emergency stop button, locking system, hardened release arms, and a powder-coated steel frame to protect operators and maintain stable, secure testing conditions.Q: When is it necessary to use a drop test machine for packaging evaluation?

A: Drop test machines should be used during product development, quality control, or before shipping to ensure that packages, cartons, and containers can withstand accidental drops, meeting both regulatory compliance and customer requirements.Q: Where should the drop test machine be installed for optimal performance?

A: The machine is floor standing and should be installed on a flat, stable floor in a controlled environment with humidity not exceeding 85% RH and temperatures between 0~40C to ensure accurate and consistent testing results.Q: What is the process for conducting a drop test on this equipment?

A: To conduct a test, secure the specimen on the adjustable forks, set the drop height using the digital controls, lift the specimen with the electric arm, and initiate the quick release. The specimen will then drop freely under gravity, and results can be observed and recorded.Q: How is the drop test machine beneficial for manufacturers and exporters?

A: This machine provides reliable data on packaging durability and compliance with ISO 2248, ASTM D5276, and ISTA standards. It helps manufacturers ensure product safety during transportation, reduce damage claims, and meet international export requirements.Q: What types of specimens can be tested with this drop test machine?

A: It supports cartons, packaging, and containers up to 1200 x 1200 mm in size and up to 80 kg in weight, making it suitable for a wide range of packaging impact and drop resistance tests for different industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese