Lithium ion battery pack short circuit testing machine

198005.0 INR/Unit

Product Details:

- Features Automatic data recording, real-time monitoring, programmable parameters, overload protection

- Measuring Range 0-1000A

- Gas Pressure 0.6-0.8 MPa

- Automation Grade Automatic

- Power Supply AC 220V, 50Hz

- Response Time 1ms

- Specimen Size Max 250mm 250mm

- Click to view more

X

Lithium ion battery pack short circuit testing machine Price And Quantity

- 1 Unit

- 198005.0 INR/Unit

- Built-in memory, USB export

- Battery Pack Short Circuit Tester

- Up to 1000A continuous

- 0-99min adjustable

- Natural air cooling

- Stainless steel and insulation layer

- External contactor automatic or manual

- Over-current, over-temperature, fuse cut-off

- 5m

- UN38.3, IEC62133, GB/T31485

- Industrial grey

- Yes, with door protection

Lithium ion battery pack short circuit testing machine Product Specifications

- AC 220V, 50Hz

- 1ms

- 50-300 mm

- 100Ah batteries

- Automatic data recording, real-time monitoring, programmable parameters, overload protection

- 0-1000A

- Automatic

- 0.6-0.8 MPa

- Battery pack safety short-circuit testing

- 0.1-500mm/s adjustable

- 220V AC

- PLC + Touch Screen

- 0.1A

- 600 mm

- 0-40C

- 1% F.S.

- 10 mm

- 125 kg

- 20-80% RH

- Lithium-ion battery pack safety testing

- 0-1000A

- Floor Standing

- Max 250mm 250mm

- 220 mm

- 1 specimen per test

- Touch Screen Display

- 50Hz

- RS232/USB

- Built-in memory, USB export

- Battery Pack Short Circuit Tester

- Up to 1000A continuous

- 0-99min adjustable

- Natural air cooling

- Stainless steel and insulation layer

- External contactor automatic or manual

- Over-current, over-temperature, fuse cut-off

- 5m

- UN38.3, IEC62133, GB/T31485

- Industrial grey

- Yes, with door protection

Lithium ion battery pack short circuit testing machine Trade Information

- Cash in Advance (CID)

- 99 Unit Per Month

- 5 Days

- All India

Product Description

Lithium ion battery pack short circuit testing machine Main Functions

Short-circuit simulation: Create short-circuits inside or outside the battery pack by mechanical or electrochemical means to simulate short-circuit failures in actual use.

Thermal runaway assessment: real-time monitoring of the temperature change of the battery pack during the short-circuit process, assessing its thermal runaway risk and thermal runaway behavior.

Safety testing: Evaluate the safety performance of the battery pack under short-circuit conditions, including whether smoke, fire, explosion and other dangerous situations will occur.

Data Acquisition and Analysis: Real-time acquisition of temperature, voltage, current and other data of the battery pack and generation of detailed test reports to help analyze the thermal runaway characteristics and safety performance of the battery pack.

Multiple safety protection: Equipped with multiple safety protection devices, such as explosion-proof box, explosion-proof door, pressure relief device, fire extinguishing system and emergency stop device, to ensure the safety of the testing process.

Environmental control: It can simulate short circuit under different environmental conditions (e.g. temperature, humidity) to evaluate the safety performance of battery packs in different environments.

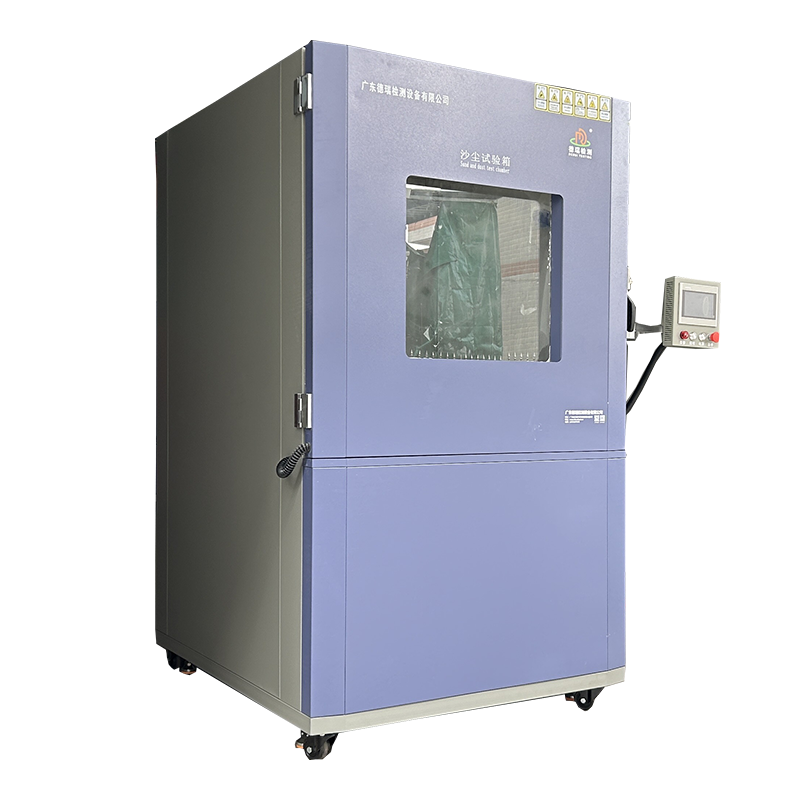

| Model | DR-D201 |

| Inner box size | 500x500x500mm (width x depth x height); |

| Equipment dimensions | 700x800x1530mm (width x depth x height); |

| Internal material | SUS201 stainless steel plate, thickness 1.2mm, with Teflon affixed; |

| External material | 1.5mm thick cold-rolled steel plate with paint treatment; |

| Observation window | The size is 250x250mm two-layer tempered glass, the transparent window is equipped with stainless steel mesh; |

| Smoke outlet | 100mm in diameter, located at the back of the box; |

| Pressure relief port | The size of the opening is 200x200mm, located on the back side of the box. When the sample explodes, the pressure relief port will pop open to relieve the pressure; |

| Box door | The single door opens to the left, the box door is equipped with a safety limit switch, and the side is equipped with an explosion-proof chain. The device can be operated only when the box door is closed to ensure the safety of personnel; |

| Test hole | There are 2 test holes with a diameter of 50mm on the left side of the device, which are convenient for putting in the collection lines of temperature, voltage, current, etc.; |

| Lighting device | It is convenient to observe the state of the tested sample; |

| Temperature collection range | RT-1000; |

| Temperature acquisition channel | 1 channel; |

| Temperature display accuracy | 0.5; |

| Voltage acquisition range | 0-100V; |

| Voltage acquisition channel | 1 channel; |

| Voltage display accuracy | 0.5%; |

| Maximum short-circuit current | 1000A; |

| Current acquisition channel | 1 channel; |

| Current display accuracy | 0.5%; |

| The internal resistance of the device loop | 8020m; |

| Equipment movement | There are four universal casters at the bottom of the equipment, which can be moved freely; |

| Control method | PLC touch screen control; |

| Equipment weight | 85Kg |

| Power supply | AC220V;50Hz/60Hz |

Analysis of differences in test results of testers under different environmental conditions (e.g., high and low temperatures)

When conducting tests such as compression resistance and short-circuit testing of batteries or packaging materials, environmental conditions (e.g., high and low temperatures) have a significant impact on the test results. The following is a detailed analysis of the test results under different environmental conditions:

1. Test results under high temperature environment

1.1 Battery test equipment (e.g. lithium battery short-circuit tester, power battery short-circuit explosion-proof test chamber, etc.)

-

Increased risk of thermal runaway:

In a high temperature environment, the chemical reaction speed inside the battery is accelerated, resulting in the battery being more likely to reach a thermal runaway state. Test results show that the rate of temperature rise and the maximum temperature of the battery are usually higher at high temperatures than at room temperature.

For example, at 60C, the internal chemical reaction rate of a lithium-ion battery may be several times higher than at 25C, resulting in a shorter thermal runaway time.

-

Reduced safety:

At high temperatures, the battery's diaphragm and electrolyte materials may soften or decompose, further increasing the risk of short-circuit and thermal runaway.

The probability of the battery smoking, catching fire or exploding at high temperatures during testing increases, and the passing rate of the safety test decreases.

-

Performance degradation:

High temperatures accelerate the aging process of batteries, leading to a decrease in battery capacity and cycle life. Test results show that the capacity retention rate of batteries after cyclic charging and discharging at high temperature is low.

1.2 Testing equipment for packaging materials (e.g. carton compression tester, plastic container compression tester, etc.)

-

Material softening:

Under high temperature environment, the rigidity and strength of packaging materials such as plastics and rubbers will be reduced, resulting in a decrease in their compression resistance.

For example, the compressive strength of HDPE plastic drums at 60C may be reduced by more than 20% compared to that at 25C. - Material softening.

-

Increased deformation:

High temperature will make packaging materials more prone to plastic deformation, resulting in increased deformation under the same pressure.

Test results show that the deformation of carton at high temperature is usually more than 10% higher than that at room temperature.

-

Decreased stacking stability:

The stacking stability of packaging materials decreases under high temperature environment, and it is easy to collapse or deform during the stacking process.

2. Test results under low temperature environment

2.1 Battery test equipment

-

Battery performance decreases:

Low temperatures reduce the chemical reaction rate of the battery, resulting in a decrease in battery capacity and discharge performance.

For example, at temperatures as low as -20C, the capacity of a lithium-ion battery may be only about 70% of that at room temperature.

-

Increased internal resistance:

At low temperatures, the internal resistance of the battery increases, resulting in lower power output and efficiency.

Tests have shown that the internal resistance of batteries at low temperatures is typically more than 50% higher than at room temperature.

-

Increased safety:

Low temperatures slow down the rate of chemical reactions within the battery, reducing the risk of thermal runaway.

At low temperatures, the probability of thermal runaway is reduced and the safety test pass rate is increased.

Compliant and Reliable Safety Testing

Built to meet major international standards, including UN38.3 and IEC62133, this battery pack short circuit testing machine guarantees accurate and safe validation for lithium-ion batteries. Its rigorous safety interlocks and alarm functionality safeguard both users and specimens during high current testing up to 1000A.

Automated Control and Real-time Monitoring

The equipment employs PLC control and a responsive touchscreen display, providing intuitive access to adjustable parameters and immediate monitoring of test status. Automated data recording and real-time export options facilitate secure analysis and record management for every battery pack tested.

Customizable Test Parameters for Diverse Needs

Operators can flexibly configure the testing process, adjusting test time, stroke, speed, and specimen dimensions. These features, paired with stainless steel and insulated fixtures, enable the safe examination of battery packs up to 100Ah and 250mm 250mm in size.

FAQ's of Lithium ion battery pack short circuit testing machine:

Q: How does the short circuit resistance of 5m benefit battery pack testing?

A: A low short circuit resistance of 5m allows the tester to replicate real-life short circuit conditions more accurately, ensuring precise and effective evaluation of a battery pack's safety and protection mechanisms.Q: What safety features are incorporated in the testing machine?

A: The machine includes multiple safety features such as an over-current and over-temperature alarm system, a fuse cut-off mechanism, safety interlock with door protection, and overload protection to prevent operator hazards and equipment damage.Q: Where is the data from each test stored and how can it be accessed?

A: Test data is automatically recorded in the machine's built-in memory. Users can export this data conveniently using a USB drive or access it through the RS232 interface, providing robust traceability and analytical functionality.Q: What is the process for conducting a short circuit test with this equipment?

A: The testing process involves securely mounting the battery specimen in the fixture, configuring parameters-such as current, time, and stroke-via the touchscreen, and initiating the test. The machine will then automatically manage the short circuit mode, collect real-time data, and activate alarms if any danger is detected.Q: When should lithium-ion battery manufacturers use this tester?

A: Manufacturers should utilize this tester during qualification and safety certification stages, routinely before market release, or whenever compliance with international safety standards is required for lithium-ion battery packs.Q: How does the natural air cooling system contribute to the device's operation?

A: Natural air cooling efficiently dissipates heat generated during high-current testing, ensuring stability and extending equipment life without the need for complex mechanical cooling systems.Q: What are the key benefits of using a PLC + touch screen control mode?

A: PLC + touch screen control streamlines operation, offers high precision in parameter adjustments, enables easy monitoring, and simplifies data management for efficient and user-friendly battery pack safety testing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese