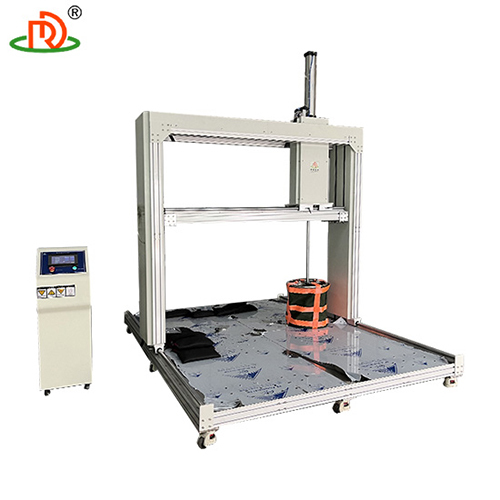

Mattress Rolling And Firmness Durability Tester

8000.0 USD ($)/Unit

Product Details:

- Usage Testing equipment

- Power Supply Electric

- Number of Specimens Multiple

- Operate Method Semi Automatic

- Material Stainless Steel

- Control Mode Manual

- Click to view more

X

Mattress Rolling And Firmness Durability Tester Price And Quantity

- 8000.0 USD ($)/Unit

- 1 Unit

Mattress Rolling And Firmness Durability Tester Product Specifications

- Manual

- Stainless Steel

- Semi Automatic

- Testing equipment

- Electric

- Multiple

Mattress Rolling And Firmness Durability Tester Trade Information

- Cash in Advance (CID)

- 50 Unit Per Month

- 10 Days

- All India

Product Description

The Mattress Rolling and Firmness Durability Tester is an essential testing equipment for mattress manufacturers, exporters, and suppliers. Made of high-quality stainless steel, this testing machine is built to last and withstand long hours of operation. It can test multiple specimens at once, making it a cost-effective solution for large-scale operations. The control mode is manual, but the operate method is semi-automatic, which makes it user-friendly and easy to operate. Its electric power supply ensures reliable and consistent performance. The Mattress Rolling and Firmness Durability Tester tests the firmness and durability of mattresses by simulating real-world conditions. It applies a rolling load on the mattress to test its ability to withstand wear and tear. The machine measures the firmness of the mattress by applying pressure on its surface and analyzing the indentation left behind. With this testing equipment, mattress manufacturers can ensure that their products meet industry standards and are of high quality.

Maximum size of mattress | 2mx2m |

Cylinder wood barrel | 140kg,length 1000mm,Diameter 300mm |

Test stroke | EN 1957:250mm on either side of the longitudinal centre line |

Test speed | 0-16r/min |

Hexagonal wood barrel | 109kg,Length 363in(91575mm),Diameter of roller (flat to flat)171in(43025mm) |

Test stroke | ASTM 1566:No less than 70%of the width of mattress,or 38 in(965mm),whichever is smaller. |

Test speed | 0-16r/min |

Firmness and Height loss test | High servo measure system |

Power | 3f, AC380V,5kW |

Test standard | EN1957GB/T26706-2011QB/T1952.2-2011ASTM F1566-2009 |

The PLC controller provides easy control and setting. | |

FAQs of Mattress Rolling And Firmness Durability Tester:

Q: What is the material of the Mattress Rolling and Firmness Durability Tester?

A: The Mattress Rolling and Firmness Durability Tester is made of stainless steel, which ensures durability and longevity.Q: How many specimens can be tested at once?

A: The Mattress Rolling and Firmness Durability Tester can test multiple specimens at once, making it a cost-effective solution for large-scale operations.Q: What is the control mode of this testing machine?

A: The control mode of the Mattress Rolling and Firmness Durability Tester is manual, but the operate method is semi-automatic.Q: What is the purpose of this testing equipment?

A: The Mattress Rolling and Firmness Durability Tester tests the firmness and durability of mattresses by simulating real-world conditions.Q: What is the power supply of this machine?

A: The Mattress Rolling and Firmness Durability Tester has an electric power supply, which ensures reliable and consistent performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese