Microcomputer controlled compressive strength tester

298005.0 INR/Unit

Product Details:

- Temperature 10C~35C

- Test Range 10 N 5000 N

- Application Compressive strength testing of materials like boxes, cartons, foams, etc.

- Frequency 50/60 Hz

- Operating Voltage 220 V

- Measuring Range 10 N 5000 N (expandable on request)

- Automation Grade Automatic

- Click to view more

X

Microcomputer controlled compressive strength tester Price And Quantity

- 1 Unit

- 298005.0 INR/Unit

- Overload and over-run protection

- Built-in printer & PC connectivity

- Statistical calculation, result printout, curve display, report export

- 400 mm x 400 mm

- Precision screw drive

- Supports storage of up to 100 test results

- CCT, RCT, ECT, FCT compatible

- High-precision load cell

Microcomputer controlled compressive strength tester Product Specifications

- Automatic

- LCD Digital Display / Computer Interface

- 1% of reading

- AC 220V 10%, 50 Hz

- 700 mm

- 0.1 N

- Peak hold, automatic return, programmable tests, data storage

- Not applicable (electromechanical system)

- 5~300 mm/min (adjustable)

- Floor Mounted

- Max 400 x 400 x 400 mm

- Standard Compression Plate: 150 mm x 150 mm

- Microcomputer Control, Automatic Operation

- Single Specimen at a Time

- Microcomputer Controlled Compressive Strength Tester

- USB & RS232 Serial Port

- Laboratory, Industrial Material Testing

- <1 s

- 20~80% RH (non-condensing)

- 5000 N (standard)

- 10C~35C

- 260 mm

- 10 N 5000 N

- 50/60 Hz

- Compressive strength testing of materials like boxes, cartons, foams, etc.

- 220 V

- 10 N 5000 N (expandable on request)

- Up to 700 mm

- Approximately 110 kg

- Overload and over-run protection

- Built-in printer & PC connectivity

- Statistical calculation, result printout, curve display, report export

- 400 mm x 400 mm

- Precision screw drive

- Supports storage of up to 100 test results

- CCT, RCT, ECT, FCT compatible

- High-precision load cell

Microcomputer controlled compressive strength tester Trade Information

- Cash in Advance (CID)

- 90 Unit Per Month

- 7 Days

- All India

Product Description

| Item | DR-B211-900 | DR-B211-1200 | DR-B211-1500 |

| Max. Force | 10KN(1000 kg ,2205lb) | 20KN(2000 kg, 4409lb) | 50KN(5000kg,11023lb) |

| Load cell | 1 load cell for highest accuracy | ||

| Control system | Dual control (Computer control with Windows mode+Touch screen control ) | ||

| Servo Motor | 400W | 750W | |

| Servo Driver | 400W | 750W | |

| Screws | Ball screws(Double ball guide rod design, high transmission accuracy, high transmission power efficiency) | ||

| Force reading | Gf, kgf, Ibf, N, KN, T etc | ||

| Load cell Resolution | 1/250,000 | ||

| Load Precision | within 0.5% | ||

| Effective test area (L x W x H) | 700x900x900mm | 1000x1200x1000mm | 1300x1500x1500mm |

| Compression Stroke | 0~900mm | 0~1000mm | 0~1500mm |

| Lift speed | 0.1~200mm/min | ||

| Software | Mtest HD-002-A(Independent R&D) | ||

| Data display | Load, displacement, speed, loading rate and elapsed time | ||

| Safety features | E-Stop Over-load protection Upper and lower limit switches Load sensor with automatic retreat | ||

| Report items | Serial number, peak value, average value, set pressure holding value, pressure holding time | ||

| Electrical Supply | 1phase, AC 220V, 500W, 50HZ | 1phase, AC 220V,550W,50HZ | 1phase, AC 220V,900W,50HZ |

| Overall Dimensions (L x W x H) | Approx.1510x1200x1645mm | Approx.1510x1200x1645mm | Approx.1865mmx1500mmx2235mm |

| Weight | Approx.350kg(772lb) | Approx.670kg(1477lb) | Approx. 1000kg(2205lb) |

| Operation Temperature and relative humidity | 10~40, 30~80% | ||

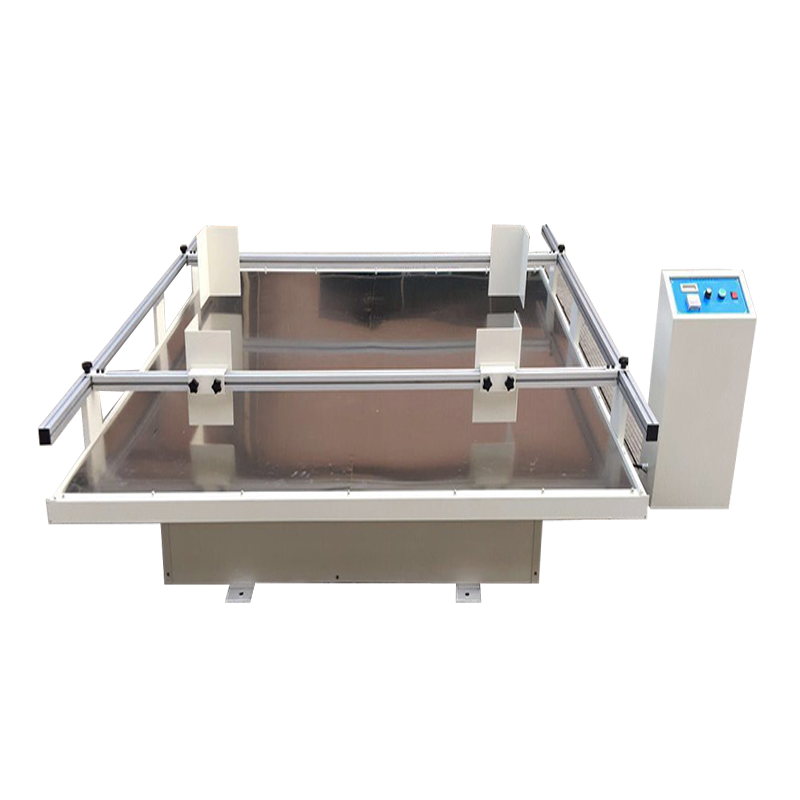

Microcomputer Control Compressive Strength Tester

1. Equipment Overview

Microcomputer-controlled compressive strength tester is a high-precision, intelligent equipment, mainly used to test the compressive strength of various materials. It is widely used in quality control and product development in packaging materials, construction materials, paper, cardboard, plastics, ceramics and other fields. With precise sensors and microcomputer control system, this equipment is able to monitor and record the pressure and deformation of the material in the process of compression in real time, and generate detailed test reports automatically.

2. Main Functions

Compressive strength test: Evaluate the maximum compressive capacity of the material in the vertical direction and test its load-bearing capacity and stability in actual use.

Deformation test: Record the deformation of the material under pressure and evaluate its deformation degree and recovery ability.

Cyclic Pressure Test: Load and unload the material for several cycles to assess its fatigue performance and durability.

Data Acquisition and Analysis: Real-time acquisition of pressure and deformation data and automatic generation of test reports to provide data analysis functions.

3. Working Principle

1.

Specimen preparation: Place the material to be tested between the pressure plates of the tester to ensure that the position and direction of the specimen are in accordance with the test requirements.

2.

Parameter setting: Set the test parameters through the microcomputer control panel, including loading speed, pressure range, displacement limit, etc.

3.

Loading process: Start the tester, the platen applies pressure to the material at the set loading speed. The tester monitors and records the pressure and deformation of the material in real time.

4.

Data Acquisition and Analysis: During the testing process, the device automatically collects pressure and deformation data and generates a test report at the end of the test. The test report usually includes parameters such as maximum compressive strength, deformation and loading curve.

4. Equipment Features

High-precision control: Adopting advanced microcomputer control system, it can accurately control parameters such as loading speed, pressure and displacement, ensuring the accuracy and reliability of test results.

Automatic operation: fully automatic operation, reducing human intervention, improving test efficiency and test result repeatability.

Safety and Reliability: Equipped with multiple safety protection devices, such as overload protection, limit protection, emergency stop device, etc., to ensure the safety and reliability of the testing process.

Data processing and analysis: Built-in data processing software can automatically generate test reports and provide data analysis function, which is convenient for users to analyze the results and quality control.

Sturdy structure: Made of high-strength materials, it has good rigidity and stability and can withstand large testing pressure.

User-friendly interface: friendly operation interface, simple parameter setting and convenient operation.

5. FAQ

Q1: What types of materials can the Microcomputer Controlled Compressive Strength Tester test?

A1: The equipment can test a wide range of materials, including but not limited to packaging materials (e.g. cartons, cardboard), construction materials (e.g. concrete, bricks), plastic and rubber products, ceramics and glass products.

Q2: How does the equipment ensure the accuracy of the test results?

A2: The equipment adopts advanced microcomputer control system and high-precision sensors, which can accurately control the parameters of loading speed, pressure and displacement, and ensure the safety and reliability of the testing process through multiple safety protection devices to ensure the accuracy of the test results.

Q3: What does the test report contain?

A3: The test report usually contains parameters such as maximum compressive strength, deformation, loading curve, etc. It also provides data analysis function, which is convenient for users to analyze the results and quality control.

Q4: Is the equipment easy to operate?

A4: Yes, the equipment is equipped with a user-friendly interface with simple parameter setting and easy operation. Meanwhile, the fully automated operation reduces human intervention and improves testing efficiency and repeatability of results.

Q5: How to maintain the equipment?

A5: Maintenance and servicing of the equipment should be carried out in accordance with the operation manual provided by the manufacturer, including regular inspection and calibration of sensors, cleaning of equipment surfaces, checking of safety protection devices, etc. The maintenance and servicing of the equipment should be carried out in accordance with the operation manual provided by the manufacturer. It is recommended that maintenance and servicing be carried out by a specialized technician.

Q6: Does the device support customized test parameters?

A6: Yes, the equipment supports the setting of different parameters such as loading speed, pressure range and displacement limit according to different materials and testing requirements to meet various testing requirements.

Room.

Advanced Control and Automation

Harnessing the reliability of microcomputer technology, this compressive strength tester delivers precise, fully-automated testing. The intuitive interface and programmable parameters ensure consistent, repeatable results, ideal for quality assurance in both research and production environments. Automatic return, peak hold, and safety features minimize manual intervention and operational risk.

Comprehensive Data Handling

With built-in storage for 100 results, embedded statistical analysis, and an integrated printer, this tester makes data management seamless. USB and RS232 ports facilitate effortless transfer to PCs for further processing, while curve display and report export ensure thorough documentation for record-keeping and review.

Versatile Testing for Various Materials

Engineered for flexibility, this tester accommodates diverse specimens up to 400 400 400 mm, supporting industry-standard tests like CCT, RCT, ECT, and FCT. Its wide measuring and speed ranges, combined with a sturdy floor-mounted design, make it an indispensable tool for laboratories and manufacturing facilities.

FAQs of Microcomputer controlled compressive strength tester:

Q: How does the microcomputer control enhance the testing process?

A: The integrated microcomputer enables fully automatic operation, precise control over testing parameters, and real-time data processing. This ensures accurate, consistent results while minimizing manual adjustments and operator error.Q: What types of materials can be tested using this compressive strength tester?

A: This tester is designed for the compressive strength analysis of materials such as boxes, cartons, foams, and similar packaging substrates, supporting major test methods like CCT, RCT, ECT, and FCT.Q: When should overload and over-run protection features be utilized?

A: These built-in safety features automatically engage whenever the applied force or stroke exceeds preset limits, preventing damage to the tester and ensuring operator safety during daily testing operations.Q: Where can the test results be output and stored?

A: Test results can be printed directly using the built-in printer, viewed and exported via the LCD digital display or through PC connectivity using USB or RS232 ports. The device also stores up to 100 results internally for later review.Q: What is the typical process for conducting a test?

A: A single specimen is placed on the test plate, and parameters are set via the microcomputer interface. The automatic program initiates the compression, records data, displays the force curve, and exports or prints the final report upon completion.Q: How does this equipment benefit laboratory and industrial environments?

A: Its automation, high precision, robust safety mechanisms, and comprehensive data management reduce operational time, eliminate manual errors, and facilitate thorough material evaluation, enhancing overall efficiency and reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese