Drop Test Chamber for ASTM D4169 Packaging

148005.0 INR/Unit

Product Details:

- Temperature Ambient

- Measuring Range Drop Height & Impact

- Accuracy 2 mm

- Automation Grade Semi-Automatic / Automatic

- Hardness NA (not applicable for equipment body)

- Mounting Type Floor-standing

- Number of Specimens 1 per cycle

- Click to view more

X

Drop Test Chamber for ASTM D4169 Packaging Price And Quantity

- 1 Unit

- 148005.0 INR/Unit

- Adjustable to specimen size

- Provided

- Flat, Edge, and Corner Drop Tests

- Approx. 2 kW

- Yes

- Emergency Stop, Protective Mesh

- < 65 dB(A)

- Electro-Mechanical Motorized System

- ASTM D4169, IS:7028 (Part IV)

- High-Strength Powder-Coated Steel

Drop Test Chamber for ASTM D4169 Packaging Product Specifications

- Floor-standing

- Controlled Manual / Automated Release

- NA (not applicable for equipment body)

- Up to 200 kg

- 2 mm

- Semi-Automatic / Automatic

- Packaging Drop Strength and Impact Performance

- Drop Height & Impact

- Ambient

- Programmable Drop Height, Sturdy Steel Frame, Safety Interlock

- 50 Hz

- Digital Display

- Instantaneous

- Drop Height: 3002000 mm

- Ambient

- ASTM D4169 Packaging Test

- Standard Customizable

- Buttons / Digital Panel

- Up to 1000 x 1000 x 1000 mm

- 0 2000 mm

- 220V

- Up to 1200 mm

- 1 mm

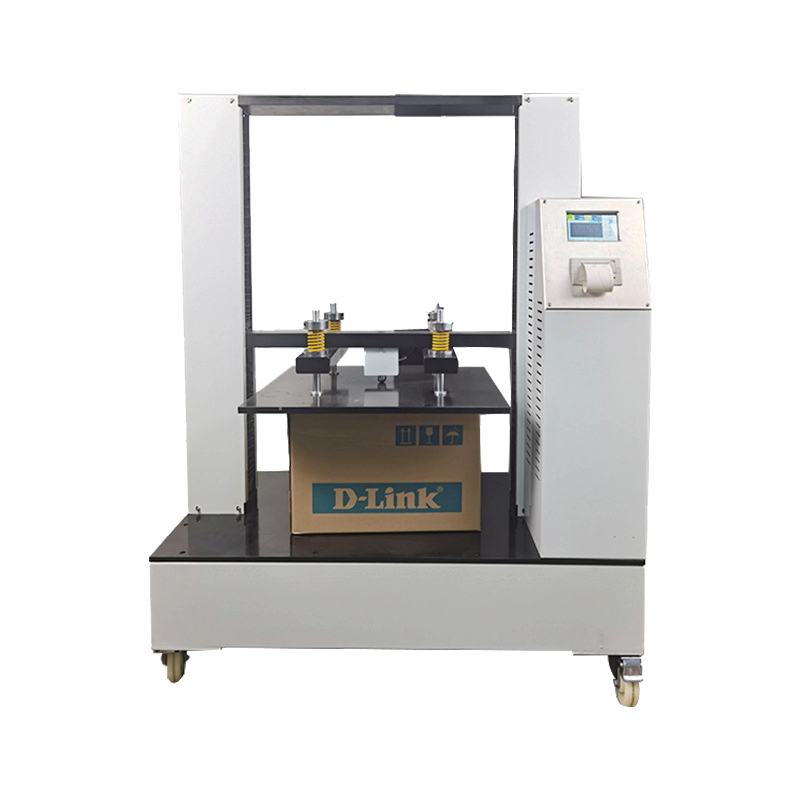

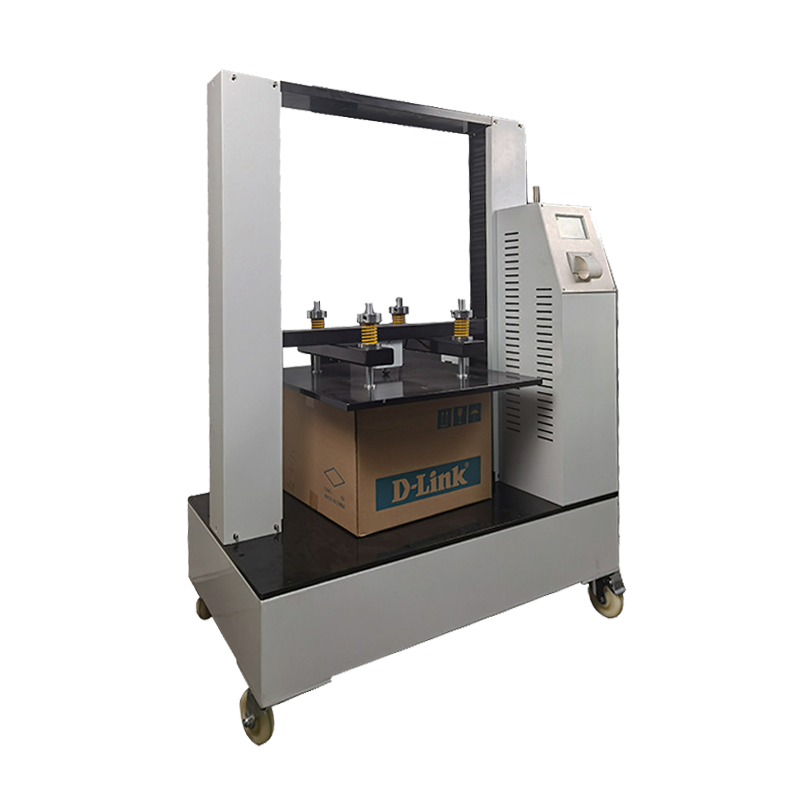

- Drop Test Chamber

- Approx. 600 kg

- Digital Control Panel

- 1 per cycle

- 2000 mm

- 220V AC, 50 Hz

- Adjustable to specimen size

- Provided

- Flat, Edge, and Corner Drop Tests

- Approx. 2 kW

- Yes

- Emergency Stop, Protective Mesh

- < 65 dB(A)

- Electro-Mechanical Motorized System

- ASTM D4169, IS:7028 (Part IV)

- High-Strength Powder-Coated Steel

Drop Test Chamber for ASTM D4169 Packaging Trade Information

- Cash in Advance (CID)

- 80 Unit Per Month

- 5 Days

- All India

Product Description

Specifications:

| Item | Description |

| Drop height | 400-1500mm (can be customized) |

| Display method | Digital display |

| Max. weight of sample | 60kg (can be customized) |

| Max. size of sample | (L*W*H) 800*800*800mm |

| Drop panel area | 1400x1200mm (material is Solid steel plate) |

| Control box dimension | (L*W*H) 350*350*1100mm |

| Deviation of drop horizon | Less than 1 |

| Machine size | (L*W*H)1400*1200*2200mm |

A Drop Test Chamber for ASTM D4169 Packaging is a vital testing tool that simulates the physical forces packaging may encounter during transport. This specialized chamber is essential for manufacturers seeking to test the durability and reliability of packaging in accordance with ASTM D4169 standards. By reproducing various drop scenarios, the chamber ensures that packaging designs are capable of protecting products from damage during handling and shipping.

Functions of the Drop Test Chamber for ASTM D4169 Packaging

The Drop Test Chamber for ASTM D4169 performs a critical role in evaluating packagings resistance to impact, which is essential for preventing damage to products during transit. The primary functions include:

-

Simulated Drop Testing: The chamber allows manufacturers to simulate a wide range of drop scenarios that packaging might encounter during distribution, testing for factors such as height, angle, and surface type. This helps predict real-world packaging performance under various impact conditions.

-

Compliance with ASTM D4169 Standards: ASTM D4169 outlines standardized test methods for packaging, ensuring consistent, repeatable results. The drop test chamber is built to meet these specific requirements, offering a precise means for manufacturers to verify their packaging's protective qualities.

-

Protection Assessment: By subjecting packaging materials to drops from different heights and angles, the chamber helps to identify design flaws or weaknesses in packaging structures. This testing gives companies valuable insight into how their packaging performs, helping to minimize the risk of product damage during transit and reduce the costs associated with returns or damaged goods.

-

Efficiency and Precision: The chamber's automated system provides consistency in testing. With pre-programmed drop sequences, it removes human error from the process, ensuring high-quality, repeatable tests that accurately reflect packagings resilience.

Features of the Drop Test Chamber for ASTM D4169 Packaging

-

Adjustable Drop Heights: The drop test chamber is equipped with an adjustable height feature, enabling manufacturers to test packaging at varying drop distances. This flexibility allows testing from low-impact to high-impact drops, ensuring packaging can withstand different levels of shock typically encountered during transportation.

-

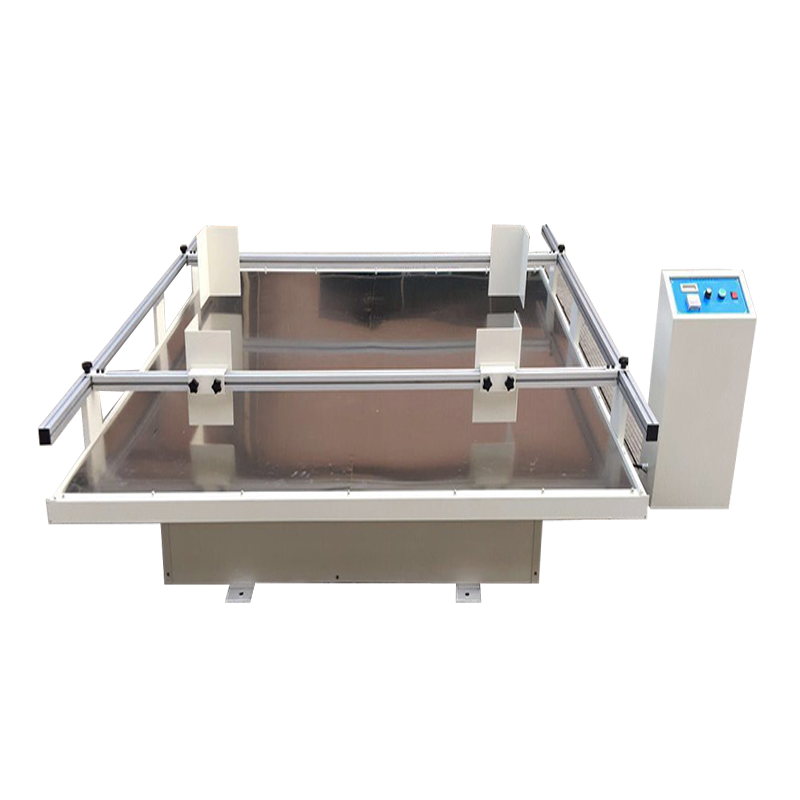

Multiple Drop Surfaces: The chamber is designed with a variety of impact surfacessuch as flat, corrugated, or angularmimicking the different conditions a package may experience during shipment. Testing on these diverse surfaces helps assess how packaging materials react to different environmental factors, such as rough handling or dropping onto hard concrete versus softer surfaces like carpeted areas.

-

High-Precision Control System: The user-friendly control panel provides accurate adjustments for drop height, drop frequency, and angle. This precise control ensures that each test is performed under exact conditions, allowing manufacturers to replicate the real-world scenarios they need to simulate in their packaging tests.

-

Durable and Robust Construction: Constructed with high-strength steel and corrosion-resistant materials, the chamber is designed to withstand long-term, heavy-duty use. Its durability ensures the longevity of the system, making it a reliable investment for manufacturers engaged in continuous testing and quality assurance.

-

Realistic Drop Angles and Impact Variability: To better simulate the conditions of real-world handling and transportation, the chamber offers the ability to vary drop angles, including vertical and angled drops. This feature is especially important for testing packaging systems that may be subjected to non-vertical impacts, like those that might occur when boxes are dropped from a height or fall off shelves at an angle.

-

Automated Data Collection and Analysis: With the built-in data logging and analysis system, the chamber can track key metrics like impact force, drop angle, and packaging damage, providing manufacturers with in-depth reports. This data is critical for optimizing packaging design and ensuring compliance with industry standards.

Installation and Setup of the Drop Test Chamber

Proper installation is essential to ensure the optimal performance of the Drop Test Chamber for ASTM D4169 Packaging. Here are the steps to follow for setting up the chamber correctly:

-

Prepare the Testing Area: Choose a clean, spacious, and stable area for installation. Ensure that the flooring is flat and free from vibrations that could influence the accuracy of testing. If possible, choose an area with easy access to power outlets and ventilation to ensure smooth operation.

-

Assemble the Drop Test Chamber: Most chambers come with comprehensive assembly instructions. Ensure that all components, including the drop platform, control panel, and safety barriers, are securely installed. Take your time during the assembly process to avoid errors that could affect the test results.

-

Install Power and Control Systems: Connect the chamber to a stable power source that meets the manufacturer's voltage and current requirements. Verify that the control panel is calibrated correctly, ensuring that the system is ready for use. This system is the core of the chamber, as it controls settings like drop height, speed, and frequency.

-

Position Packaging Correctly: Before starting any tests, ensure that the test sample is correctly positioned within the chamber. Packaging should be placed so that it is properly aligned with the drop path, ensuring consistent and accurate results with each test. Improper placement can lead to inconsistent outcomes, so double-check before starting the test.

-

Calibrate the Test Chamber: Calibration ensures that the system is performing to exact standards. Check the drop height settings, control angles, and surface configurations before initiating any tests. Calibration should be done regularly to ensure that the chamber remains compliant with ASTM D4169 standards and delivers reliable, repeatable results.

Important Considerations When Using the Drop Test Chamber

-

Test Multiple Samples for Reliability: For consistent and reliable results, it is essential to test multiple packaging samples under the same conditions. This helps account for any variations in the packaging material or design and provides a comprehensive view of how the packaging will perform across different shipments.

-

Follow ASTM D4169 Guidelines Strictly: Adhering to the ASTM D4169 guidelines ensures that tests are conducted properly and results are standardized. These standards specify the proper drop heights, angles, and impact conditions required for reliable results. Deviating from these standards could result in inaccurate testing outcomes.

-

Evaluate Various Packaging Materials: The Drop Test Chamber for ASTM D4169 Packaging can be used to evaluate different types of packaging, such as corrugated cardboard, plastic wraps, bubble wraps, and foam inserts. Testing various materials allows manufacturers to compare the strengths and weaknesses of different packaging systems and make informed decisions on the best protective solutions.

-

Monitor and Record Test Results: Always document the results from each test, including drop height, surface type, damage sustained, and any other relevant data. This information is essential for identifying trends, pinpointing packaging vulnerabilities, and making necessary improvements to packaging designs.

-

Perform Regular Maintenance: A well-maintained drop test chamber ensures continued high performance and accuracy. Regularly clean the chamber, check for wear and tear, and recalibrate settings as needed. A proactive maintenance plan ensures longevity and consistent results throughout the lifecycle of the test chamber.

Precision-Oriented Drop Testing for Packaging

This drop test chamber enables manufacturers and quality engineers to conduct drop tests according to global packaging standards. It simulates real-world fall scenarios including flat, edge, and corner impacts, evaluating package durability efficiently. The digital display with 2 mm accuracy and 1 mm resolution provides instant feedback for reliable results.

Robust Build and User-Friendly Operation

Engineered for longevity, the chamber features a high-strength powder-coated steel frame and a sturdy, floor-standing design. A digital control panel, emergency stop, safety interlock, and programmable features make operation intuitive and safe, while the adjustable lifting platform accommodates varied specimen sizes for broad usability.

FAQ's of Drop Test Chamber for ASTM D4169 Packaging:

Q: How does the Drop Test Chamber simulate real packaging drop scenarios?

A: The chamber performs flat, edge, and corner drop tests, simulating typical drops encountered during handling and transportation of packaged products. It meets ASTM D4169 and IS:7028 (Part IV) standards, ensuring results match industry requirements for packaging impact resistance.Q: What is the process for conducting a drop test using this chamber?

A: To perform a test, place the specimen on the adjustable lifting platform, set the desired drop height using the digital control panel, and select either manual or automated release. The chamber can test heights ranging from 300 mm to 2000 mm, and records drops via the cycle counter for reproducibility.Q: When should I use this drop test chamber for my packaging?

A: This chamber is suitable any time a packaging design needs to be validated for impact performance, such as during product development, quality assurance, or prior to product shipment, ensuring packaging integrity and compliance with international standards.Q: Where can the Drop Test Chamber be installed?

A: Designed as a floor-standing unit, it can be installed in quality control laboratories, production floors, or R&D centers. Its robust construction and standard/com customizable port size allow it to fit seamlessly into various industrial environments.Q: What safety features are included with the Drop Test Chamber?

A: Safety is ensured with an emergency stop button, protective mesh around moving parts, and a safety interlock system. These features protect users during testing and prevent accidental activation during specimen placement or setup.Q: How is the drop height measured and displayed?

A: Drop height is digitally set and displayed with high accuracy (2 mm), and a 1 mm resolution on the control panel. The real-time height ensures precision in every test, contributing to the reliability and repeatability of results.Q: What are the key benefits of using this drop test chamber for packaging tests?

A: Using this chamber ensures your packaging meets international safety and durability standards. Benefits include programmable drop heights, digital control and measurement, safe operation, and reliable performance assessment, helping reduce product damage claims and enhance customer satisfaction.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese