OEM UV Test Equipment for Bulk Adhesive Shear Strength Testing in Textiles

361800.0 INR/Unit

Product Details:

- Specimen Size (L)100 mm (W)25 mm

- Max Height 550 mm

- Hardness Standard tool steel

- Power Supply 220V/50Hz

- Temperature 1540C

- Equipment Type OEM UV Test Equipment

- Humidity 3090% RH

- Click to view more

X

OEM UV Test Equipment for Bulk Adhesive Shear Strength Testing in Textiles Price And Quantity

- 1 Unit

- 361800.0 INR/Unit

- Quick-release dual clamp system

- High intensity UV lamp

- Stores up to 1000 test results

- UV shielding door, emergency stop

- 365405 nm

- Integrated LED lights for sample visualization

- PC connectivity for data analysis

- Shear, peel, tensile

- Programmable 1999 sec

- Touchscreen with multi-language support

- Stainless steel body with anodized aluminum fixtures

- Auto calibration/self-check

OEM UV Test Equipment for Bulk Adhesive Shear Strength Testing in Textiles Product Specifications

- OEM UV Test Equipment

- 3090% RH

- RS232

- 250 mm

- 1-200 mm/min adjustable

- 05000 N

- AC 220V/50Hz

- 0.1 N

- (L)100 mm (W)25 mm

- 550 mm

- Standard tool steel

- 220V/50Hz

- 1540C

- 6 mm

- High precision, user-friendly controls, UV exposure chamber

- 50/60 Hz

- 0.6 MPa

- 05000 N

- 50 kN

- 6

- Textile adhesive shear strength analysis

- Semi-automatic

- Digital LCD

- 0.6 s

- Bulk adhesive shear strength testing in textiles

- Bench-top

- 100 mm

- 1%

- 42 kg

- Digital/Manual

- Quick-release dual clamp system

- High intensity UV lamp

- Stores up to 1000 test results

- UV shielding door, emergency stop

- 365405 nm

- Integrated LED lights for sample visualization

- PC connectivity for data analysis

- Shear, peel, tensile

- Programmable 1999 sec

- Touchscreen with multi-language support

- Stainless steel body with anodized aluminum fixtures

- Auto calibration/self-check

OEM UV Test Equipment for Bulk Adhesive Shear Strength Testing in Textiles Trade Information

- Cash in Advance (CID)

- 80 Unit Per Month

- 10 Days

- All India

Product Description

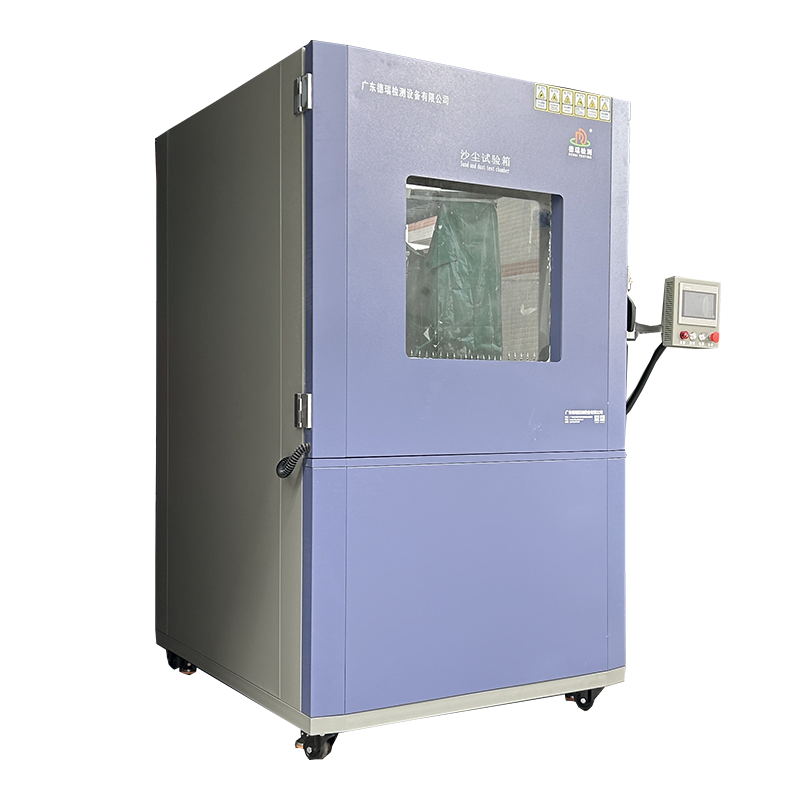

The UV Test Equipment for Adhesive Bond Strength is a cutting-edge laboratory system designed to evaluate the durability and performance of adhesives under prolonged ultraviolet (UV) exposure, temperature fluctuations, and humidity cycles. Compliant with ASTM D904, ISO 4892-3, and BIS standards, this equipment simulates real-world environmental stressors to ensure adhesives maintain bond integrity in demanding applications, from automotive assembly to aerospace manufacturing. Tailored for Indias industrial sector, it addresses critical quality control needs while enhancing product reliability.

Technical Specifications

-

UV Light Source & Spectral Control

-

UVA-340 Lamps: Simulate solar UV wavelengths (295365 nm) with adjustable irradiance (0.51.5 W/m @ 340 nm).

-

Spectral Filters: Quartz filters ensure precise UV-A dominance, minimizing infrared (IR) interference.

-

-

Environmental Controls

-

Temperature Range:

-

Ambient: 10C to 80C (1C accuracy).

-

Bond Surface Temperature: Up to 120C (1.5C) for high-stress adhesive testing.

-

-

Humidity Control: 10%98% RH (3% stability) with cyclic condensation for monsoon-like conditions.

-

-

Bond Strength Testing

-

Integrated Load Cell: Measures tensile/shear strength (05000 N) with 0.5% accuracy.

-

Test Fixtures: Customizable grips for lap shear, peel, and cleavage tests (ASTM D1002, D1876).

-

-

Chamber Design

-

Sample Capacity: Benchtop (50L) to industrial (500L), accommodating bonded specimens up to 30cm x 30cm.

-

Material: Corrosion-resistant stainless steel interior, UV-transparent quartz windows.

-

Safety Features: Overload protection, emergency stop, and leakage detection.

-

-

Automation & Data Management

-

Programmable Test Cycles: Pre-set UV/thermal/humidity profiles for ASTM D904 compliance.

-

Touchscreen Interface: Real-time monitoring of bond strength, UV irradiance, and environmental parameters.

-

Data Export: Generate compliance reports (CSV/PDF) with failure modes, load curves, and YI (yellowing index).

-

Key Applications

-

Automotive Adhesives:

-

Validate UV resistance of structural bonds in body panels, trim, and EV battery housings.

-

-

Aerospace Components:

-

Test epoxy and acrylic adhesives for composite bonding under high-altitude UV exposure.

-

-

Electronics Manufacturing:

-

Assess adhesive degradation in PCB encapsulation and display lamination.

-

-

Construction Materials:

-

Evaluate sealants and adhesives for faade panels under tropical UV/humidity stress.

-

Compliance & Certifications

-

ASTM D904: Standard Practice for Exposure of Adhesive Specimens to Artificial Light.

-

ISO 4892-3: PlasticsExposure to Fluorescent UV Lamps.

-

Indian Standards: BIS-compatible testing (IS 16046) and NABL-accredited calibration.

-

Certifications: CE, RoHS, ISO 9001:2015.

Advantages for Indian Industries

-

High Precision:

-

0.5% load cell accuracy ensures reliable bond strength measurements.

-

-

Climate Adaptability:

-

Simulate Indias extreme conditions (e.g., desert UV, coastal humidity).

-

-

Energy Efficiency:

-

Inverter-driven systems reduce power consumption by 25% versus traditional models.

-

-

Localized Support:

-

Service hubs in Mumbai, Delhi, and Chennai provide installation, training, and spare parts.

-

FAQs (UV Test Chamber Condensation Cycle Testing)

Q1: How does UV exposure affect adhesive bond strength?

A: UV radiation degrades polymer chains, causing brittleness and bond failure; this equipment quantifies such effects under controlled conditions.

Q2: Can it test UV-curable adhesives?

A: Yescustom profiles simulate curing and post-cure UV exposure for hybrid adhesives.

Q3: What is the typical test duration?

A: Tests range from 48500 hours, depending on adhesive type and irradiance settings.

Q4: How to maintain load cell accuracy?

A: Calibrate quarterly using NIST-traceable weights; avoid overloading beyond 80% capacity.

Q5: Does it comply with BIS standards?

A: Yespre-set profiles align with IS 16046 for industrial adhesives.

High-Performance UV Shear Strength Testing for Textiles

Engineered for the demands of textile adhesive testing, the OEM UV Test Equipment delivers precision and reliability. Featuring a high-intensity UV lamp within 365-405 nm, programmable exposures, and an industrial-grade body, it accommodates up to 6 specimens simultaneously. Digital/Manual controls and an adjustable test speed allow flexibility, while integrated safety systems protect users throughout the process.

Comprehensive Data Management and User-Focused Design

Beyond robust testing, this equipment provides advanced data storage for up to 1000 results and PC connectivity through RS232. The touchscreen interface supports multi-language operation and intuitive workflows. With integrated LED lighting and a quick-release clamp system, sample handling and visualization are straightforward, making the system suitable for global textile labs and quality control.

FAQ's of OEM UV Test Equipment for Bulk Adhesive Shear Strength Testing in Textiles:

Q: How does the OEM UV Test Equipment ensure accurate bulk adhesive shear strength testing in textiles?

A: This equipment delivers high-precision measurements with a resolution of 0.1 N and 1% accuracy. Auto calibration/self-check functions ensure test reliability, while programmable UV exposure times and user-friendly controls guarantee consistent, repeatable results every test cycle.Q: What are the main benefits of using a high-intensity UV lamp with a wavelength range of 365-405 nm for adhesive shear testing?

A: The high-intensity UV lamp accelerates adhesive curing, simulating real-world bonding conditions. The defined wavelength range targets textile adhesives effectively, ensuring accurate strength assessment and improving product quality evaluations.Q: When and where is this UV test equipment most suitable for application?

A: It is ideal for textile R&D laboratories, quality control departments, and production lines where bulk adhesive shear strength is critical. The equipment is designed for bench-top mounting and operates efficiently in environments with 30-90% RH and temperatures from 15-40C.Q: What is the process for testing adhesive shear strength using this equipment?

A: After mounting up to six specimens with the quick-release dual clamps, users program the test parameters via the touchscreen panel. The UV exposure, followed by mechanical testing (shear, peel, tensile), is automatically conducted, and results are stored digitally for later analysis or export.Q: How does the equipment support data analysis and result management?

A: With memory for up to 1000 test results and RS232 PC connectivity, users can analyze, back up, and share data effectively. The digital LCD display enables immediate review, and data can be accessed for extended statistical analysis or compliance reporting.Q: What safety features are included in the UV test equipment?

A: The equipment includes a UV shielding door and emergency stop button to protect users from accidental UV exposure. Automatic interlocks and clearly marked digital/manual controls further enhance operational safety during testing.Q: Why choose this OEM UV Test Equipment for bulk adhesive shear strength testing in textiles?

A: It combines high accuracy, automation, and robust data management with user-friendly features and advanced safety. Its sturdy build, versatile testing modes, and compliance with laboratory environments make it a comprehensive solution for manufacturers, exporters, and quality assurance specialists.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese