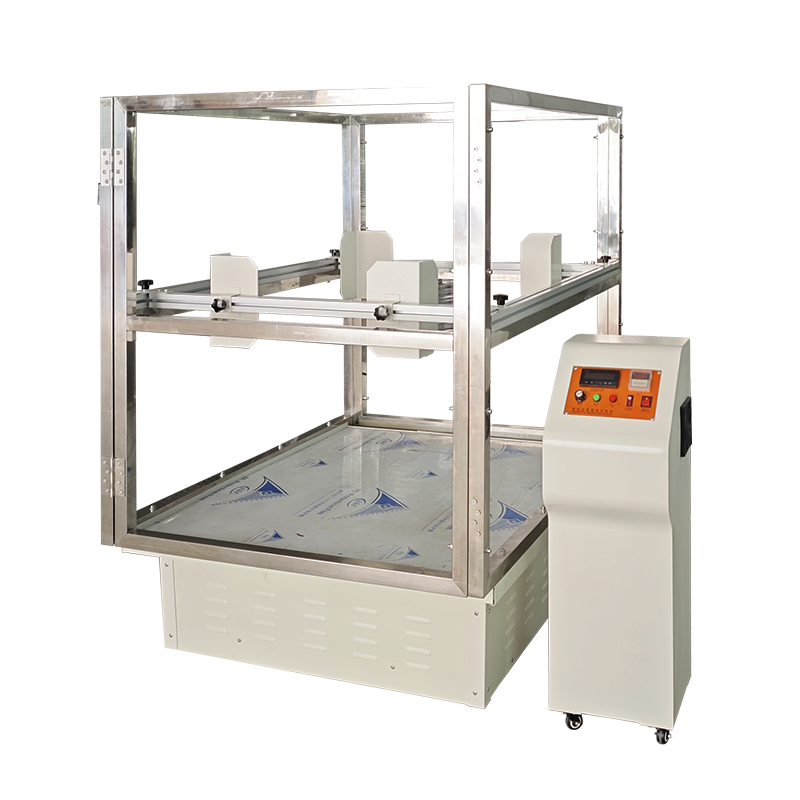

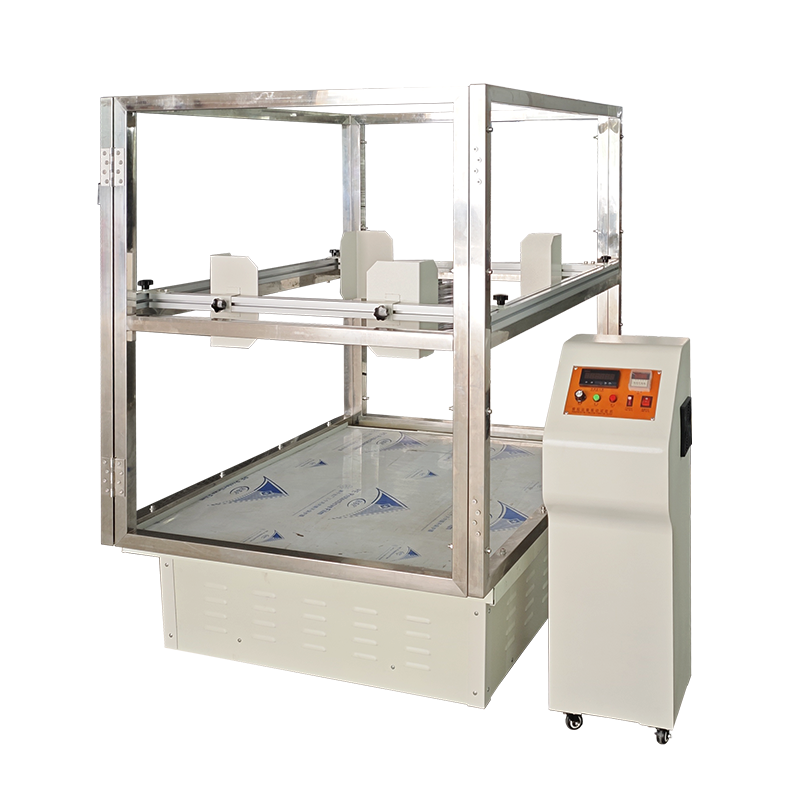

Random Vibration Tester for Transportation Simulation

138005.0 INR/Unit

Product Details:

- Response Time Instantaneous

- Temperature Room Temperature (10C - 40C)

- Interface Type RS232/USB

- Frequency 5 - 150 Hz (random vibration)

- Port Size Standard

- Application Transportation simulation for packaging, product shock and vibration analysis

- Power Supply AC 220V, 50/60Hz

- Click to view more

X

Random Vibration Tester for Transportation Simulation Price And Quantity

- 138005.0 INR/Unit

- 1 Unit

- Emergency Stop Switch, Overload Alarm

- Stainless Steel

- 0-999 minutes

- Random Sine, Classical Shock

- Included for Mobility

- 70 dB

- Vertical

- Microprocessor Based

Random Vibration Tester for Transportation Simulation Product Specifications

- 0.1g - 5g

- Floor Standing

- Packaging testing, vibration simulation

- LCD Digital Display

- 1.2 m

- Digital Control

- Programmable frequency, over-load protection, automatic shutdown

- 30% - 85% RH

- 1 pc

- 5%

- Industrial Grade

- 0.5g - 5g

- 25 mm

- 220V

- 100 kg Max

- 5 - 150 Hz (random vibration)

- Standard

- Transportation simulation for packaging, product shock and vibration analysis

- Instantaneous

- Room Temperature (10C - 40C)

- 200 kg

- RS232/USB

- 0.01g

- Max 600 x 600 mm

- Semi-Automatic

- 60-300 rpm/min

- AC 220V, 50/60Hz

- Random Vibration Tester

- 600 mm

- Emergency Stop Switch, Overload Alarm

- Stainless Steel

- 0-999 minutes

- Random Sine, Classical Shock

- Included for Mobility

- 70 dB

- Vertical

- Microprocessor Based

Random Vibration Tester for Transportation Simulation Trade Information

- Cash in Advance (CID)

- 80 Unit Per Month

- 5 Days

- All India

Product Description

| Item | DR-B216 |

| Max. Test Load | 100kg |

| Frequency Range | 60-300rpm |

| Amplitude Range | 25.4mm (1 inch) |

| Simulation Speed | 25~40km/h |

| Vibration Mode | Roundtrip |

| Work Table Size | 1000*1200 mm ( L*W, can be customized ) |

| Outside dimension ( L*W*H ) | 1255*1070*660mm |

| Speed Mode | DC converter or AC Frequency Control |

| Power Capacity | 1 HP |

| Weight | 150kg |

| Power | 220V, 50 Hz |

| Speed Mode | DC converter or AC Frequency Control |

| Environmental Conditions | Temperature: 5~40C; Related Humidity <85% |

1. Overview

A Random Vibration Tester simulates real-world vibrations experienced during transportation to assess product durability. Unlike sinusoidal vibration, it uses a broad frequency spectrum simultaneously, replicating unpredictable conditions encountered in road, rail, air, or maritime transport.

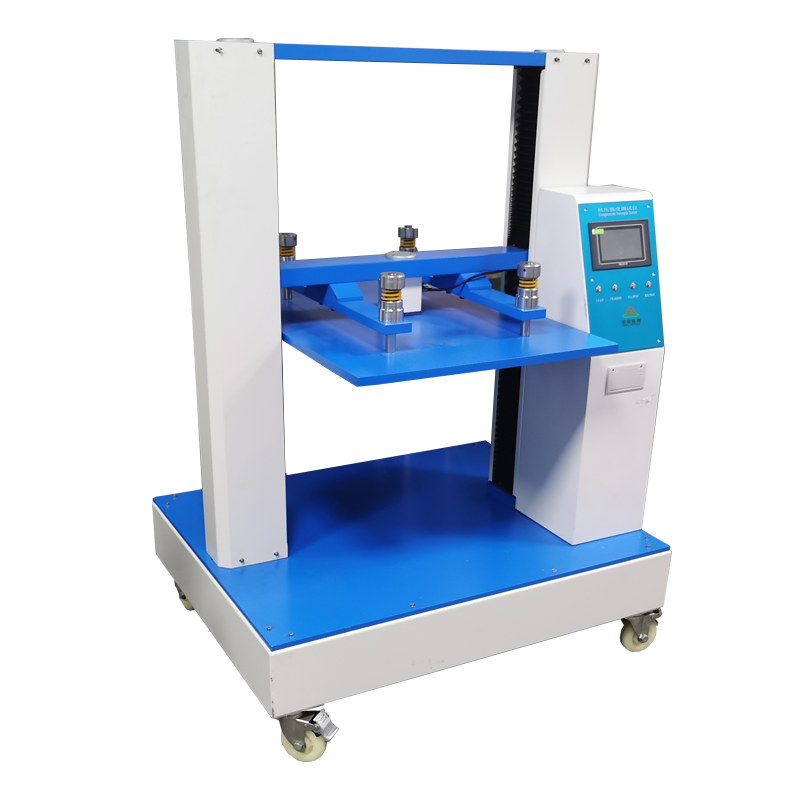

2. Key Components

-

Vibration Exciter (Shaker):

-

Type: Electrodynamic shakers are preferred for high-frequency ranges (up to 2 kHz) and precise control. Hydraulic shakers may be used for heavy payloads but are limited to lower frequencies.

-

Specifications: Must support required displacement (e.g., 25 mm), velocity, and acceleration (e.g., 100 g) based on test standards.

-

-

Controller:

-

Generates random signals matching a target Power Spectral Density (PSD) profile, which defines vibration energy distribution across frequencies.

-

Utilizes real-time feedback from accelerometers to adjust output, ensuring accuracy.

-

Features notching filters to dampen resonance frequencies in the test specimen.

-

-

Sensors:

-

Piezoelectric accelerometers for high sensitivity and wide frequency range.

-

Data acquisition systems for capturing vibration response.

-

-

Software:

-

Creates/imports PSD profiles (e.g., ISO 13355, ISTA 3A).

-

Simulates transport modes (truck, ship, etc.) and includes data logging, analysis, and reporting tools.

-

-

Power Amplifier: Drives the electrodynamic shaker, converting control signals into high-power output.

3. Design Considerations

-

Frequency Range: Typically 52000 Hz for road transport; lower for maritime (1100 Hz).

-

Payload Capacity: Match shaker force (e.g., 10 kN for medium loads) to product weight.

-

Fixture Design: Securely mounts specimens without introducing damping/resonance (e.g., aluminum alloy fixtures).

-

Safety: Emergency stop, overload protection, and isolation pads to prevent external interference.

4. Testing Standards

-

ISTA: Procedures for packaging (e.g., ISTA 3E for truck transport).

-

ASTM: Standards like ASTM D4728 for shipping container testing.

-

MIL-STD-810G: Military equipment robustness.

5. Applications

-

Electronics: Validate PCB durability under truck vibrations.

-

Automotive: Test component fatigue in engine-mounted parts.

-

Packaging: Assess cushioning material performance using ISTA profiles.

6. Challenges

-

PSD Compliance: Ensuring accurate profile matching, especially at high frequencies.

-

Resonance Management: Automated notching to prevent specimen damage.

-

Cost vs. Performance: Balancing budget with high-frequency capability and payload needs.

7. Calibration & Maintenance

-

Regular calibration using reference accelerometers (e.g., ISO 16063-21).

-

Amplifier and sensor checks to maintain signal integrity.

8. Conclusion

A well-designed random vibration tester integrates precise control, robust hardware, and adaptive software to simulate real-world conditions. By adhering to industry standards and addressing challenges like resonance, it ensures reliable product validation for transportation durability.

Example Configuration:

-

Shaker: 15 kN electrodynamic, 52000 Hz.

-

Controller: 24-bit DSP with real-time PSD adjustment.

-

Software: Custom profiles for maritime (180 Hz) and aerospace (102000 Hz).

This system enables accelerated life testing, reducing time-to-market while ensuring compliance with global transportation standards.

Simulate Real-World Transport Conditions

This Random Vibration Tester rigorously reproduces vibrations experienced during packaging transit, ensuring products meet stringent shipping standards. Programmable frequency and classical shock modes allow the user to tailor tests for unique packaging or product requirements. The vibration direction is vertical, covering a frequency range from 5 to 150 Hz to simulate various transportation scenarios.

Precise Control and Reliable Safety Features

Equipped with a microprocessor-based digital controller, the tester offers programmable settings for timer, speed, and waveform. Safety is enforced by an emergency stop switch, overload alarms, and a stainless steel base for maximum stability. The LCD digital display provides real-time feedback, enhancing user confidence throughout the testing process.

Versatile Application and Convenient Usage

The tester accommodates specimens up to 600 x 600 mm and 100 kg, making it suited for a wide array of packaging and shock analysis applications. Its mobility (transport wheels included) and semi-automatic operation streamline integration into laboratory or manufacturing environments. The unit's USB/RS232 interface ensures seamless data transfer for further analysis.

FAQ's of Random Vibration Tester for Transportation Simulation:

Q: How does the Random Vibration Tester simulate transportation conditions?

A: The tester generates programmable random, sine, and shock waveforms in a vertical direction, mimicking vibrations experienced during real-world shipping and transit. By adjusting frequency, amplitude, and cycle time, it closely replicates conditions your packaging or products will face in distribution.Q: What types of specimens and packaging can be tested on this equipment?

A: This machine supports single specimens up to 600 x 600 mm in size and a maximum weight of 100 kg. It's suitable for various packaging forms, electronic products, and components needing simulation of transport-induced vibration and shock.Q: When should I use the emergency stop or expect overload alarms?

A: Use the emergency stop switch in case of any unexpected interruption or hazard during operation. Overload alarms automatically activate if specimen weight or vibration force exceeds set safe limits, protecting both operator and equipment.Q: Where can this tester be used most effectively?

A: Its floor-standing design and transport wheels make it ideal for use in quality control laboratories, manufacturing plants, and R&D departments focused on packaging and product reliability testing.Q: What is the process for adjusting test parameters like duration and frequency?

A: You can digitally program the desired vibration duration (0-999 minutes), test speed (60-300 rpm/min), frequency (5-150 Hz), and waveform directly from the LCD control interface. All settings are stored and managed by the microprocessor-based controller for ease and accuracy.Q: How does the tester benefit product development and packaging?

A: By simulating genuine transport stresses, it helps optimize packaging design, reduce shipping damage risks, and validate product durability, ultimately enhancing product reliability and customer satisfaction.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese