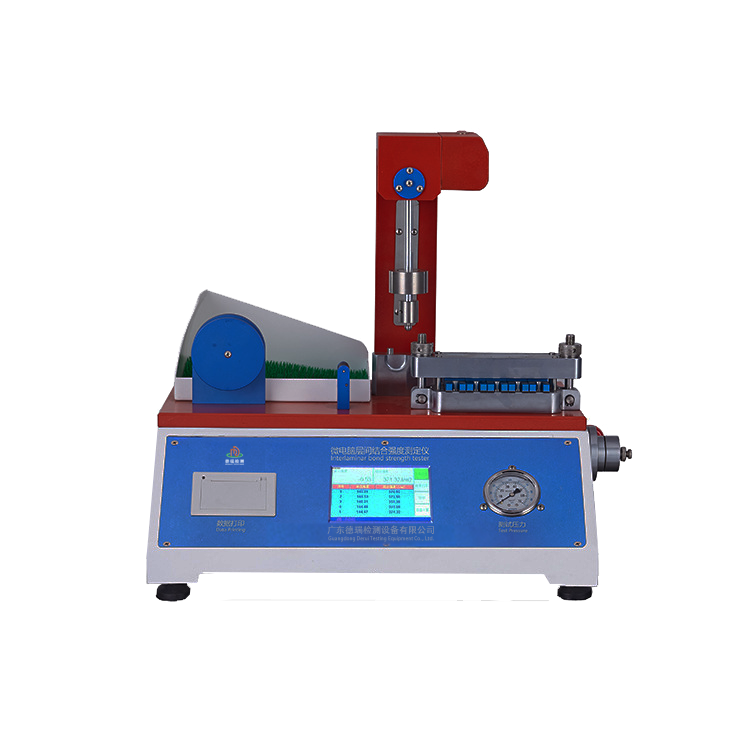

Automatic Interlayer Adhesion Tester Machine for Packaging & Film Industries

28000.0 INR/Unit

Product Details:

- Measuring Range 0.0130 N

- Features Automatic test, data storage, real-time display, programmable

- Power Supply 220V AC 10%, 50Hz

- Frequency 50 Hz

- Gas Pressure 0.4~0.7 MPa

- Temperature 1035C (operating)

- Equipment Type Automatic Interlayer Adhesion Tester

- Click to view more

X

Automatic Interlayer Adhesion Tester Machine for Packaging & Film Industries Price And Quantity

- 28000.0 INR/Unit

- 1 Unit

- 180°/90° peel test modes

- Overload and emergency stop protection

- Printer output supported, USB export

- ASTM D1876, GB/T 2790, ISO 8510

- 520 mm × 380 mm × 260 mm

- English, Chinese

- Up to 1000 test results

- Adhesion clamps, Calibration weights, Power cord

Automatic Interlayer Adhesion Tester Machine for Packaging & Film Industries Product Specifications

- 150 mm

- 1035C (operating)

- 100 mm/min (adjustable)

- Automatic Interlayer Adhesion Tester

- 30 N

- 50 Hz

- 0.4~0.7 MPa

- Automatic test, data storage, real-time display, programmable

- 35 kg

- Microprocessor based automatic control

- 220V AC 10%, 50Hz

- 15 mm, 25 mm (customizable)

- 0.0130 N

- Automatic

- Material interlayer adhesion assessment

- RS232, USB

- Digital LCD touch screen

- 0.01N

- 300 mm

- 220V

- 1 specimen per test

- 030 N (standard)

- Bench-top

- 4080% RH (operating)

- 1% FS

- 150 mm 15/25 mm

- 6 mm (air inlet)

- Packaging & film industries adhesion measurement

- <100 ms

- 180°/90° peel test modes

- Overload and emergency stop protection

- Printer output supported, USB export

- ASTM D1876, GB/T 2790, ISO 8510

- 520 mm × 380 mm × 260 mm

- English, Chinese

- Up to 1000 test results

- Adhesion clamps, Calibration weights, Power cord

Automatic Interlayer Adhesion Tester Machine for Packaging & Film Industries Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 10 Days

- All India

Product Description

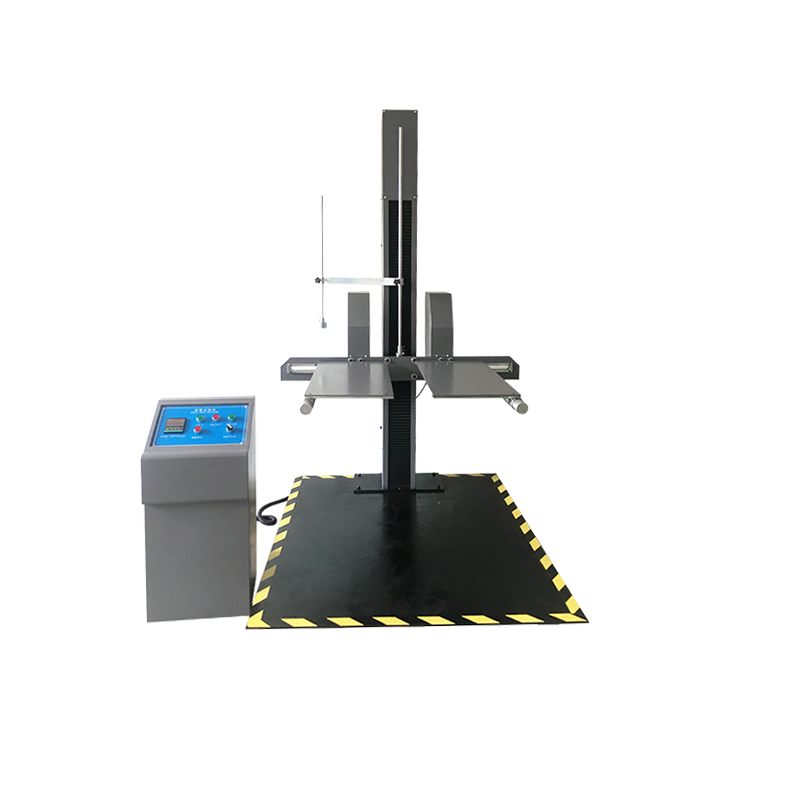

Product introductionThe interlayer bonding strength tester is a testing instrument used to detect the interlayer bonding strength (between paper layers, and within paper) of paper and cardboard. This interlayer bonding strength can also be used to detect the internal bonding strength of sheet materials such as paper composite materials, film composite materials, etc. Widely used in packaging enterprises, papermaking enterprises, quality inspection centers, inspection and quarantine units, etc.

application area

Packaging companies, paper companies, quality inspection centers, inspection and quarantine

Product Features

Equipped with a 5-inch color touch screen, simple, convenient and easy to use, the system supports Chinese English conversion, and a completely self-designed operating interface

Detect and calculate test results through microcomputers and optical encoders

Electromagnetic pendulum release reduces vibration and displacement, improves accuracy, and can be automatically calibrated for easy maintenance

Replaceable pendulum weights for measuring different ranges

Technical parameter

1Measurement range: A range (0~500) J/M2 B range (500~1000) J/M2

2Indication error: A level 1J/M2; B gear 2J/M 2

3Resolution: Data acquisition resolution of 0.001 lbf/in , 5000 pulse high-precision encoder

4Sample parallelism: less than 0.1mm

5Maximum sampling thickness: 1.5mm

6Common sample pressure: (690 21) kPa

7Sample clamping force: The sample clamping range is 0~600N (adjustable)

8Impact angle: Standard impact energy release angle of 90

9Secondary gravity structure: Secondary gravity overlaps to ensure the accuracy of secondary measurement results

10Release method: fully automatic release

11Double sided adhesive condition: The adhesive force of the double-sided adhesive to stainless steel is greater than 486 N/m

12Protective cover: Comes with a protective cover, safe and reliable

13Full range oil system: equipped with an independent refueling window, can quickly complete refueling work

FAQs for "Interlayer Bonding Strength Testing Machine

1. What is an Interlayer Bonding Strength Testing Machine?

An interlayer bonding strength testing machine measures the adhesive force between layers of materials like laminates, composites, or packaging films. It ensures quality control in industries such as flexible packaging, automotive interiors, and medical device manufacturing.

2. How Does an Interlayer Bond Strength Tester Work?

The machine applies controlled tensile or peel force to separate bonded layers, recording peak force (in Newtons or lbf) via load cells. Advanced models include digital displays, auto-stop features, and compliance with ASTM D903 or ISO 8510 standards.

3. Why is Testing Interlayer Bond Strength Critical?

Poor bonding causes delamination, product failure, or safety risks. Testing ensures material durability, compliance with industry regulations, and consistency in multi-layer products like food pouches or composite panels.

4. What Materials Can Be Tested with This Machine?

It supports:

Plastic films (PE, PET, BOPP)

Metal-polymer laminates

Adhesive tapes

Composite materials (carbon fiber, fiberglass)

Ensure the machines grip design matches your sample thickness and texture.

5. What Standards Do These Testers Comply With?

Top machines meet ASTM F904, ISO 527-3, and TAPPI T569. Compliance is essential for industries like medical packaging (ISO 11607) or aerospace composites.

6. How to Calibrate an Interlayer Bond Tester?

Use certified weights or reference materials annually. Digital models often include self-calibration software and traceable NIST certificates. Always follow the manufacturers calibration protocol.

7. What Features Differentiate High-Quality Bond Strength Testers?

Look for:

Programmable test modes (peel, shear, tensile)

Real-time graphs and data export (Excel/PDF)

Adjustable speed (1500 mm/min)

Multi-language interface for global operations

8. Can This Machine Test High-Strength Industrial Adhesives?

Yes, heavy-duty testers handle bond strengths up to 5,000 N with precision (0.5% accuracy). Confirm the load cell capacity matches your adhesives maximum force requirements.

Advanced Precision Design

This machine delivers unmatched accuracy (1% FS) in assessing the adhesion between layers of packaging films. Its robust construction, adjustable test speeds, and customizable test widths make it suitable for diverse applications within film and packaging industries. The strong bench-top mounting and safety mechanisms, including overload and emergency stop protection, ensure both operator safety and test integrity.

Comprehensive Data Management

With a memory capable of storing up to 1000 test results, the tester supports both real-time display and data output through printer and USB export. Multi-language support (English and Chinese) enables international applicability, while the system's programmable features streamline testing processes and ensure compliance with global standards.

Seamless Operation & Versatility

Offering fully automatic operation via a user-friendly digital LCD touch screen, this tester facilitates easy setup, test selection, and result retrieval. Adjustable parameters such as test speed, width, and stroke accommodate various specimen sizes. Provided accessories and simple connectivity (RS232, USB) further enhance operational convenience for quality control laboratories and production settings.

FAQ's of Automatic Interlayer Adhesion Tester Machine for Packaging & Film Industries:

Q: How does the Automatic Interlayer Adhesion Tester perform adhesion measurements?

A: The tester evaluates interlayer adhesion by conducting standardized 180 or 90 peel tests, measuring the required force to separate specimen layers. It is controlled automatically via a microprocessor for consistent and repeatable results.Q: What types of films and packaging materials can be tested with this equipment?

A: This machine is designed for assessing adhesion strength in a range of packaging films used in the packaging and film industries, including flexible laminates and multilayer films, using specimen sizes of 150 mm 15/25 mm.Q: When and where is it recommended to use this adhesion tester?

A: The tester is ideal for use in quality control laboratories, production lines of packaging manufacturers, and research institutes. It is suitable in any application requiring adherence to international testing standards for film and packaging materials.Q: What is the process for preparing and testing a specimen?

A: Prepare the specimen to the specified dimensions, mount it using the supplied adhesion clamps, select the required test mode and parameters on the LCD touch screen, and initiate the test. Results are displayed in real time and stored automatically.Q: What are the key usage benefits of this adhesion tester?

A: Benefits include automatic operation, high accuracy, programmable test modes, rapid response, data storage, and extensive safety features. These attributes enhance productivity, ensure compliance, and minimize operator intervention.Q: How are test results output and stored for review or reporting?

A: Test results are displayed on the digital LCD screen and may be exported via printer or USB device. The system stores up to 1000 results for future retrieval, enabling efficient quality documentation and traceability.Q: What safety features are incorporated in this testing machine?

A: The tester is equipped with overload protection and an emergency stop function to safeguard users and equipment during operation. These ensure a secure testing environment and protect against accidental damage or injury.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese