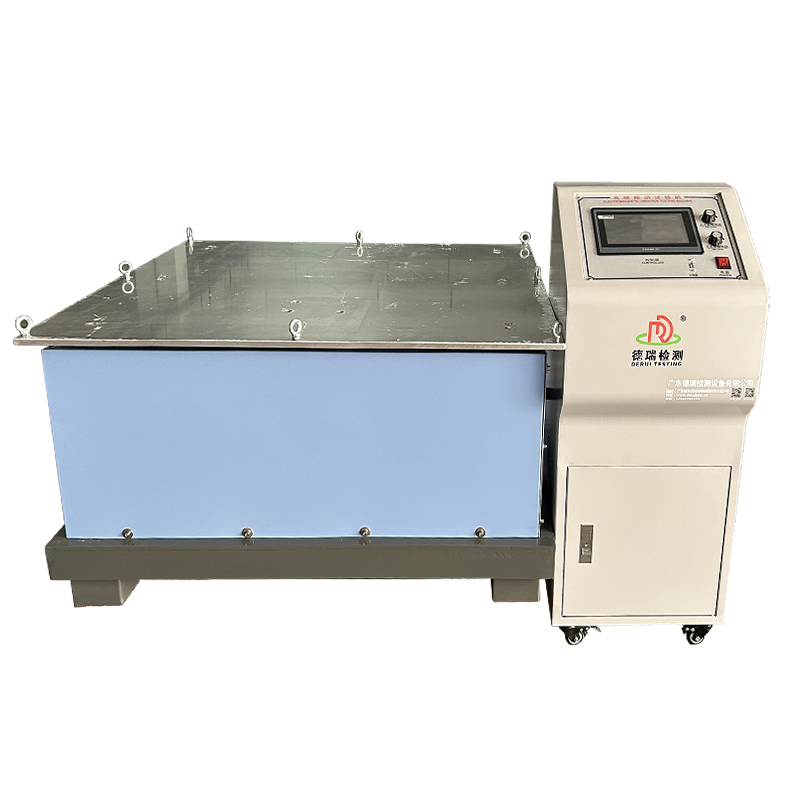

Random Vibration Testing Table for Logistics Simulation

138005.0 INR/Unit

Product Details:

- Application Testing & Measurement

- Usage Measuring Tools

- Power Supply Electric

- Product Type Random Vibration Testing Table

- Material Mild Steel

- Voltage 220 Volt (v)

- Features Efficient

- Click to view more

X

Random Vibration Testing Table for Logistics Simulation Price And Quantity

- 1 Unit

- 138005.0 INR/Unit

Random Vibration Testing Table for Logistics Simulation Product Specifications

- Electric

- Measuring Tools

- Testing & Measurement

- 220 Volt (v)

- Mild Steel

- Random Vibration Testing Table

- 150 Kilograms (kg)

- 1 Horsepower (HP)

- Efficient

- White

- Free Stand

- Random Vibration Testing Table

Random Vibration Testing Table for Logistics Simulation Trade Information

- Cash in Advance (CID)

- 90 Unit Per Month

- 4 Days

- All India

Product Description

| Item | DR-B216 |

| Max. Test Load | 100kg |

| Frequency Range | 60-300rpm |

| Amplitude Range | 25.4mm (1 inch) |

| Simulation Speed | 25~ 40km/h |

| Vibration Mode | Roundtrip |

| Work Table Size | 1000*1200 mm ( L*W, can be customized ) |

| Outside dimension ( L*W*H ) | 1255*1070*660mm |

| Speed Mode | DC converter or AC Frequency Control |

| Power Capacity | 1 HP |

| Weight | 150kg |

| Power | 220V, 50 Hz |

| Speed Mode | DC converter or AC Frequency Control |

| Environmental Conditions | Temperature: 5~40C; Related Humidity <85% |

In the complex process of logistics and transportation, every step of a product's journey from factory to consumer is full of challenges. The Random Vibration Test Bench is a precision instrument designed to meet these challenges. It not only simulates the vibration during transportation, but is also dedicated to reproducing those unpredictable vibration patterns in logistics. In this article, we will discuss the features, applications and data behind this equipment from multiple perspectives to help readers understand its key role in improving product toughness and optimizing logistics processes.

Core Functions and Features

1.

Subtle design for multi-axis vibration simulation

The most remarkable feature of the Random Vibration Test Bed is its multi-axis vibration simulation capability. It is capable of simultaneously reproducing complex vibration patterns during transportation in the vertical, transverse and longitudinal directions. This multi-dimensional vibration reproduction is not a simple stack of features, but is based on an in-depth understanding of the actual vibration environment in the logistics process. Through this simulation, manufacturers can more accurately identify the weak points of their products under different transportation conditions and thus make targeted improvements.

2.

Programmable vibration modes

The test bench is equipped with a highly flexible programmable control system that allows users to customize vibration patterns according to different transportation scenarios (e.g., air, sea, land). This highly customizable test solution allows the user to simulate a wide range of vibration scenarios from slight bumps to severe shocks. This flexibility is essential to fully evaluate the vibration resistance of a product.

3.

High Frequency Vibration and Precision Control

The test stand supports high-frequency vibration simulation up to 2000Hz or more, which is particularly important for capturing subtle vibrations that are easily overlooked in traditional tests. High-frequency vibration often leads to fatigue damage and microscopic cracks in materials, which may gradually appear after the product is put into use. The test stand can effectively identify these potential problems through accurate frequency control and acceleration adjustment, providing valuable data to support product design.

4.

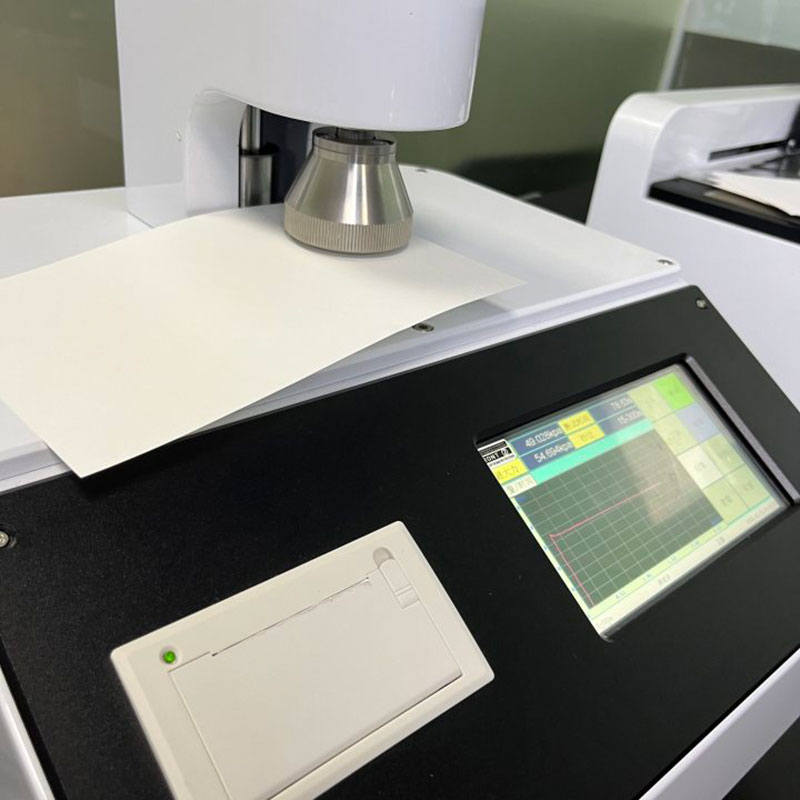

Real-time data monitoring and high-fidelity recording

Equipped with advanced sensor arrays and high-fidelity data recording systems, the test bench is able to monitor various parameters in the vibration process in real time, such as acceleration, displacement and frequency changes. The data is not only voluminous but also highly accurate, providing detailed first-hand information for analyzing product performance under different vibration conditions. This data-driven testing approach makes product improvement more targeted and scientific.

5.

User-friendly operation interface

Despite the complexity of its functions, the user interface of the test bench is designed to be extremely user-friendly. Operators can easily set test parameters, start and stop tests, and view data reports in real time through the intuitive control panel. This simple and efficient design lowers the threshold of use, enabling even users without a deep technical background to get started quickly.

Application Scenarios and Practical Benefits

Random vibration test benches have a wide range of applications in logistics and manufacturing, and the practical benefits they bring are obvious:

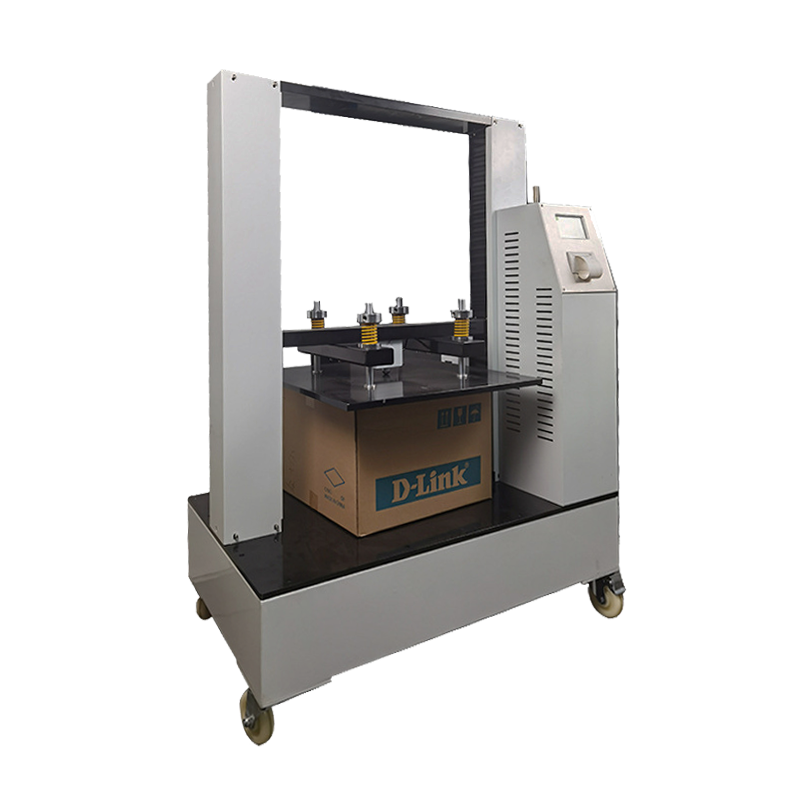

Product Reliability Improvement

By simulating real transportation vibrations, test benches help manufacturers identify and solve potential problems before products leave the factory. This not only improves product reliability, but also reduces returns and customer complaints due to transportation damage.

Cost Control and Risk Avoidance

Test benches help companies reduce repair and replacement costs by effectively predicting and preventing damage that may occur during transportation. At the same time, by identifying and resolving product defects in advance, companies can avoid legal risks and reputation losses due to product quality issues.

Compliance and Standardization

In global trade, product transportation standards are becoming increasingly stringent. Test benches help companies ensure that their products comply with various international and domestic transportation standards, thus successfully passing all kinds of compliance reviews.

Logistics Process Optimization

By analyzing vibration data, logistics experts can optimize packaging design and transportation solutions to better protect products. This not only improves logistics efficiency, but also reduces transportation costs.

Installation and Operation Points

To fully utilize the advantages of a random vibration test bed, the following installation and operation points should not be overlooked:

Environment Selection

The test bench should be installed in an environment far away from external vibration sources to avoid external interference affecting the accuracy of test results. A stable test environment is the basis for obtaining reliable data.

Regular Calibration and Maintenance

The sensors and actuators of the test stand require regular calibration and maintenance to ensure their accuracy and reliability. This continuous maintenance is the key to ensuring the consistency of test results.

Safe Operating Procedures

Operators must strictly follow safety procedures to ensure the safety of personnel and equipment during testing. This is not only for the protection of personnel, but also for the guarantee of the service life of the equipment.

Professional training and knowledge accumulation

The operation of the test bench requires a certain amount of specialized knowledge. Providing systematic training and continuous knowledge accumulation is crucial for operators, which can help them better understand and use this precision instrument.

Reliable Simulation for Logistics

Designed specifically for logistics simulation, this Random Vibration Testing Table ensures your packaging and products can withstand real-world transportation stresses. The precise control of vibrations allows for thorough assessment, reducing risk and improving product durability before shipping.

Strong Construction and Efficient Performance

Constructed with mild steel and weighing 150 kg, this testing table is robust and stable during high-frequency operations. Its 1 HP electric power ensures consistent vibration output, making it suitable for heavy-duty industrial settings requiring reliable testing results.

Flexible Installation and User-Friendly Operation

With a free-standing design and standard 220V power supply, this equipment is easy to set up in diverse industrial environments. User-centered controls and safety features mean that technicians can operate it with confidence and efficiency, directly contributing to improved workflow and reduced downtime.

FAQ's of Random Vibration Testing Table for Logistics Simulation:

Q: How does the Random Vibration Testing Table benefit logistics simulation?

A: The Random Vibration Testing Table replicates the vibration conditions encountered during transportation, helping manufacturers identify potential weaknesses in packaging or products before shipping. This proactive approach reduces damage, saves costs, and improves customer satisfaction.Q: What materials are used in constructing the Random Vibration Testing Table?

A: This equipment is constructed using mild steel, offering excellent durability and stability during rigorous testing scenarios, which is ideal for industrial environments.Q: When should I use a Random Vibration Testing Table?

A: The table should be employed during the development or quality control stages to ensure products and packaging can endure vibrations experienced in transit, thereby minimizing risks of shipment damage.Q: Where is this testing table typically used?

A: It is most commonly used in industrial facilities, quality assurance labs, and manufacturing plants where testing and measurement of logistics and packaging reliability are critical.Q: What is the process for conducting a test on this equipment?

A: Simply mount the product or package onto the free-standing table, set the desired vibration profile via the controls, and monitor the performance. The equipment's efficient electric motor ensures consistent vibration throughout the testing process.Q: How user-friendly is the installation and operation of this table?

A: Thanks to its free-standing design and standard voltage requirement (220V), the table is straightforward to install. The intuitive controls ensure that technicians can quickly learn and safely operate the system.Q: What are the efficiency features of this Random Vibration Testing Table?

A: With a robust 1 HP electric motor and stable mild steel construction, the table delivers reliable, efficient vibration testing, helping streamline quality control processes while maintaining testing accuracy.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese