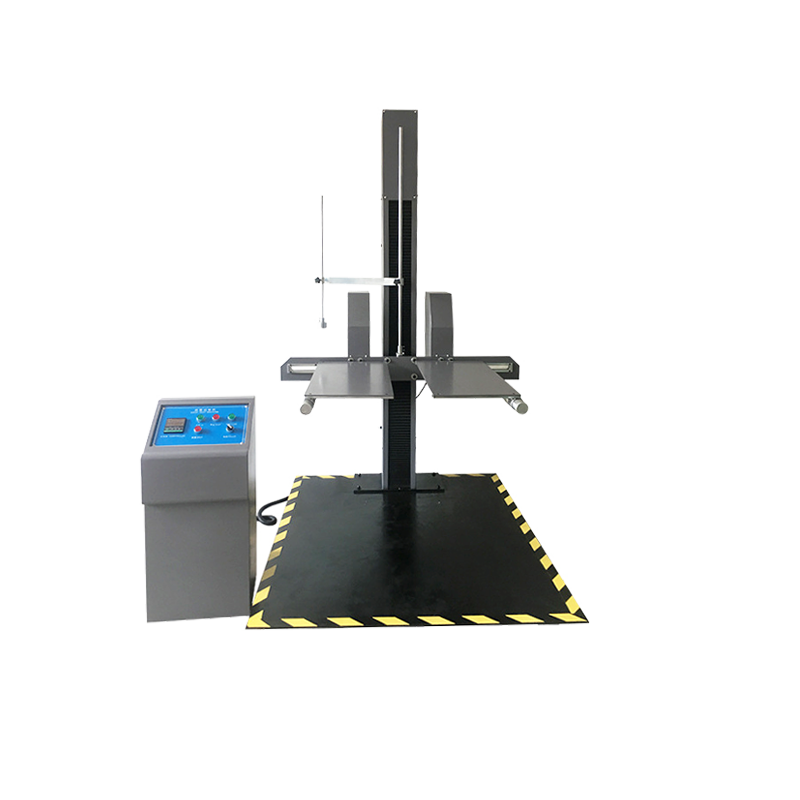

Drop Test Chamber with Data Logging Software

148005.0 INR/Unit

Product Details:

- Automation Grade Semi-Automatic

- Equipment Type Drop Test Chamber with Data Logging

- Operating Voltage 220V AC

- Power Supply 220V AC, 50Hz

- Hardness Drop platform made of hardened steel

- Test Range 1 kg to 100 kg

- Response Time <1 second

- Click to view more

X

Drop Test Chamber with Data Logging Software Price And Quantity

- 1 Unit

- 148005.0 INR/Unit

- Windows 7/8/10

- Factory calibrated with certificate

- Powder-coated mild steel

- Motorized precision lead screw

- <70 dB

- Up to 100 test records

- Flat, Edge, and Corner

- Emergency stop, Drop Area Guard Railings

Drop Test Chamber with Data Logging Software Product Specifications

- Up to 100 kg

- Standard 200 mm

- Single specimen per cycle

- Approx. 250 kg

- Max. 800 mm 800 mm

- Up to 80% RH, non-condensing

- 1 mm (drop height)

- Up to 800 mm

- Testing physical integrity of packaging

- 0 1200 mm (drop height)

- Packaging and Material Drop Testing

- 1 mm

- Programmable cycles, Data storage, Emergency stop

- Adjustable up to 2 m/s

- Floor mounted

- Microprocessor based with Data Logging Software

- USB & RS232

- <1 second

- 1 kg to 100 kg

- Drop platform made of hardened steel

- 220V AC, 50Hz

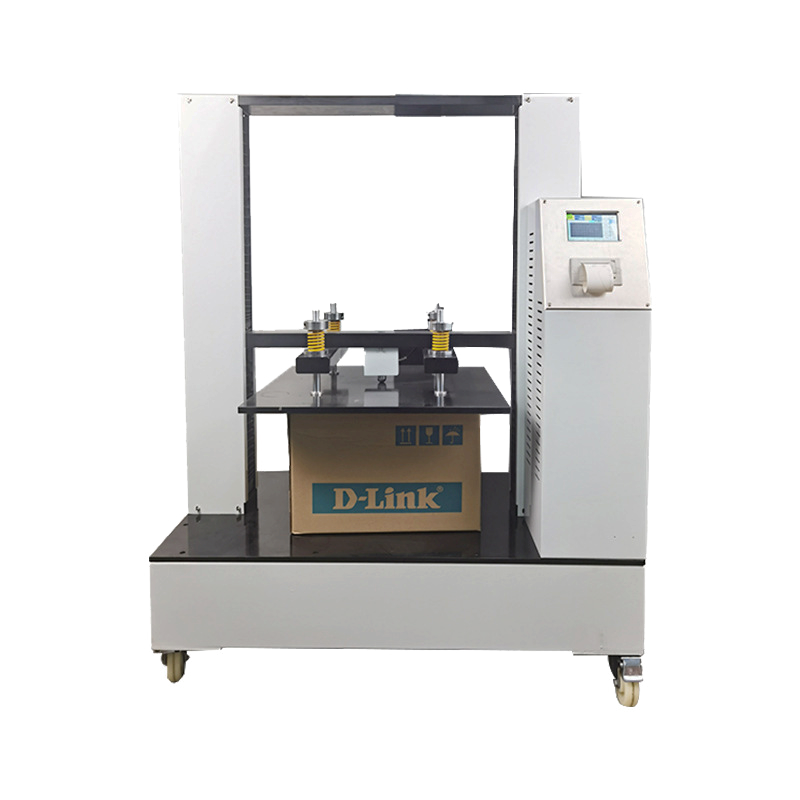

- Drop Test Chamber with Data Logging

- 220V AC

- Semi-Automatic

- 0 1200 mm

- 1200 mm

- 10C to 40C

- Digital LCD Display

- Single Drop/Repeat Cycle

- Windows 7/8/10

- Factory calibrated with certificate

- Powder-coated mild steel

- Motorized precision lead screw

- <70 dB

- Up to 100 test records

- Flat, Edge, and Corner

- Emergency stop, Drop Area Guard Railings

Drop Test Chamber with Data Logging Software Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 3 Days

- All India

Product Description

Introduction

In todays competitive manufacturing landscape, ensuring product resilience during transportation and handling is non-negotiable. A Drop Test Chamber with Data Logging Software offers a cutting-edge solution for industries aiming to validate product durability while adhering to global quality standards. This article explores how this advanced testing equipment optimizes reliability assessments through precise data capture and analysis.

Key Features & Benefits

-

Automated Data Logging for Precision

Unlike traditional drop testers, this chamber integrates intelligent software that automatically records impact force, velocity, and deformation metrics. The data logging software generates real-time reports, eliminating manual errors and streamlining compliance documentation. -

Customizable Testing Protocols

Tailor drop heights, angles, and surface materials to simulate real-world scenariosfrom warehouse handling to international shipping. The systems modular design supports testing for electronics, packaging, automotive components, and more. -

Enhanced Traceability & Compliance

Meet ISO 2248 and ASTM D5276 standards effortlessly. The Drop Test Chamber archives test results securely, enabling manufacturers to trace quality benchmarks and address design flaws proactively. -

User-Friendly Interface

Engineers can configure tests in minutes via an intuitive dashboard. The software exports data in CSV or PDF formats, simplifying collaboration between R&D and quality assurance teams.

Why Choose This Solution?

- Cost Efficiency: Reduce product failure risks and recalls by identifying weaknesses early.

- Scalability: Adaptable for small batches or high-volume production lines.

- Sustainability: Minimize material waste through data-driven design improvements.

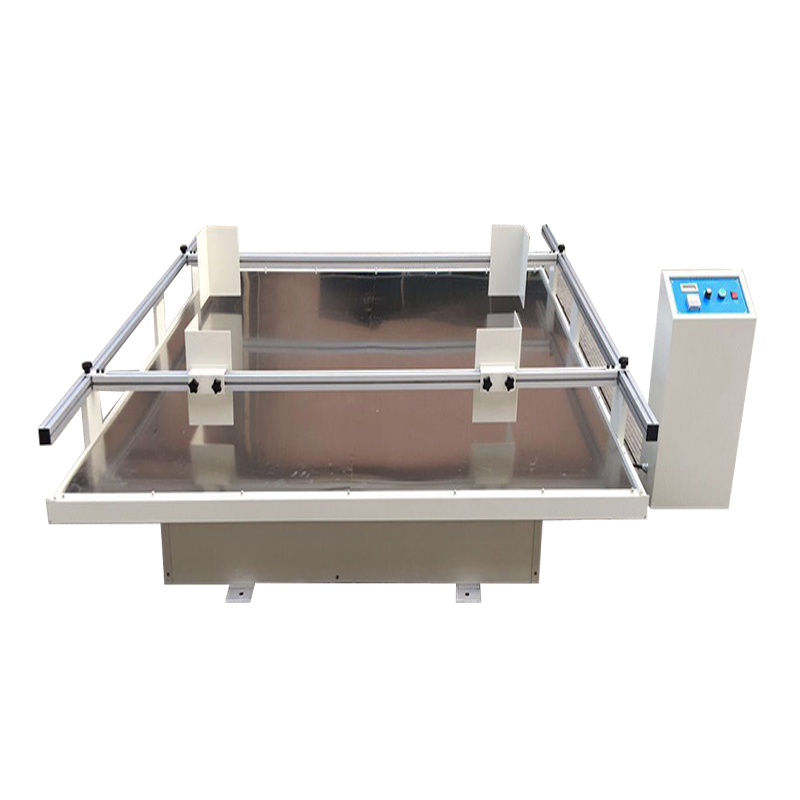

Applications Across Industries

- Electronics: Validate smartphone or laptop durability against accidental drops.

- Logistics: Optimize packaging designs to withstand rough handling.

- Automotive: Test component integrity under extreme stress conditions.

- Specifications:

Item

Description

Drop height

400-1500mm (can be customized)

Display method

Digital display

Max. weight of sample

60kg (can be customized)

Max. size of sample

(L*W*H) 800*800*800mm

Drop panel area

1400x1200mm (material is Solid steel plate)

Control box dimension

(L*W*H) 350*350*1100mm

Deviation of drop horizon

Less than 1

Machine size

(L*W*H)1400*1200*2200mm

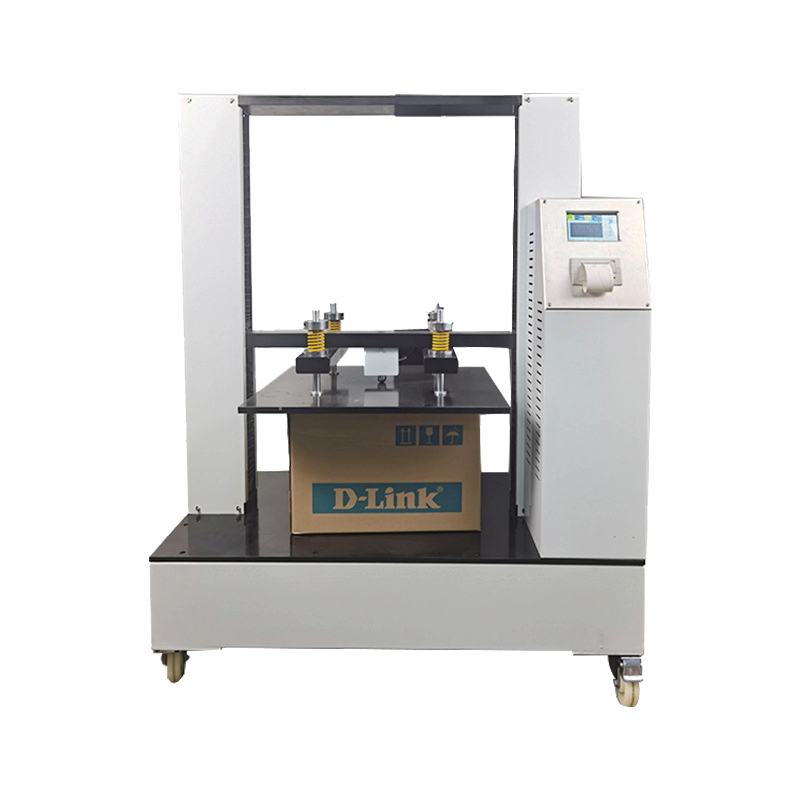

Efficient and Accurate Drop Testing

With automated lift mechanisms and microprocessor-based controls, the Drop Test Chamber delivers accurate, repeatable results for a wide range of packaging and materials. Users can easily adjust test speeds, drop heights, and modes to suit different testing standards while benefiting from rapid response and high measurement accuracy.

Comprehensive Data Logging and Traceability

Equipped with advanced Data Logging Software, the chamber lets users store, retrieve, and analyze up to 100 test records. Compatibility with Windows 7/8/10 ensures seamless integration with existing systems, supporting export and review of results for in-depth analysis and long-term quality assurance.

Enhanced Safety and User-Friendly Design

Safety is ensured through features like emergency stop, guard railings in the drop area, and stable floor-mounted design. The digital LCD display and intuitive interface provide clear visibility and straightforward operation, making it easy to set up, monitor, and control each test cycle.

FAQ's of Drop Test Chamber with Data Logging Software:

Q: How does the data logging functionality work with the Drop Test Chamber?

A: The chamber's data logging software records test parameters and results for up to 100 test records. Data can be exported via USB or RS232 to compatible Windows (7/8/10) systems, enabling users to analyze and archive test outcomes for traceability and compliance.Q: What types of tests can be performed with this Drop Test Chamber?

A: You can conduct flat, edge, and corner drop tests to assess the physical integrity and durability of packaging materials and products within a measuring range of 0 - 1200 mm and weight capacities of 1 - 100 kg.Q: When is it necessary to recalibrate the Drop Test Chamber?

A: The chamber is delivered factory calibrated with a certificate. It is advisable to recalibrate periodically as per internal quality protocols or after extensive use to maintain accuracy within 1 mm.Q: Where should the Drop Test Chamber be installed for optimal performance?

A: Install the chamber on a stable, flat floor in a temperature-controlled environment (10C-40C) with humidity below 80% RH (non-condensing) to ensure accurate and consistent results.Q: What is the process for operating a drop test with programmable cycles?

A: Select the desired drop mode, adjust drop height (up to 1200 mm) and speed (up to 2 m/s), and place the specimen on the reinforced steel platform. Use the digital LCD to set test cycles; data logging software will automatically record each drop's data.Q: How does the chamber ensure operator safety during testing?

A: Safety is enforced through emergency stop buttons, drop area guard railings, and a secure motorized lead screw lift drive. These features minimize risks during operation and test setup.Q: What are the key benefits of using a Drop Test Chamber with Data Logging?

A: You gain precise, repeatable test results, comprehensive record-keeping, automated operation, enhanced safety, and efficient analysis, leading to improved packaging design, quality control, and regulatory compliance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese