Static tensile ozone aging test chamber

368005.0 INR/Unit

Product Details:

- Test Range 101000 ppm ozone

- Gas Pressure 0.40.7 MPa

- Mounting Type Floor standing type

- Specimen Size Standard: 30 3 100 mm

- Features Programmable temperature, humidity, and ozone control

- Resolution 0.1 ppm

- Port Size 1/4 inch

- Click to view more

X

Static tensile ozone aging test chamber Price And Quantity

- 368005.0 INR/Unit

- 1 Unit

- Large double-layer tempered glass

- Cold-rolled steel with powder coating

- Interior LED lamp

- 0999 h

- Silent discharge

- Multi-directional forced convection

- Air cooling

- Over-temperature and leakage protection

- SUS304 Stainless Steel

- USB/Printer port

- Ambient temp 5~35C, humidity 85% RH

Static tensile ozone aging test chamber Product Specifications

- 25 L

- Material aging and ozone resistance evaluation

- 6

- RS232

- Rubber, elastomer, polymer tensile ozone resistance testing

- AC 220V, 50Hz

- Automatic

- Digital LCD

- 4090% RH

- Ozone measurement: 01000 ppm

- Max. 300 mm

- Room temperature to 90C

- 2% F.S.

- Programmable digital controller

- 600 mm

- 10500 mm/min

- 220V 10%

- Floor standing type

- 0.40.7 MPa

- 101000 ppm ozone

- 60 mm

- Approx 150 kg

- 50/60 Hz

- <10 sec

- 1/4 inch

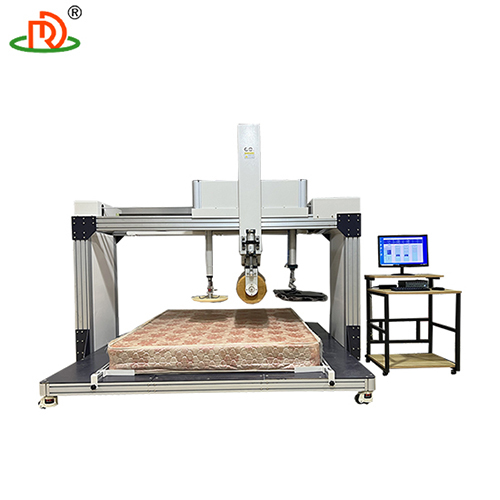

- Static tensile ozone aging test chamber

- Programmable temperature, humidity, and ozone control

- Standard: 30 3 100 mm

- 0.1 ppm

- Large double-layer tempered glass

- Cold-rolled steel with powder coating

- Interior LED lamp

- 0999 h

- Silent discharge

- Multi-directional forced convection

- Air cooling

- Over-temperature and leakage protection

- SUS304 Stainless Steel

- USB/Printer port

- Ambient temp 5~35C, humidity 85% RH

Static tensile ozone aging test chamber Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 7 Days

- All India

Product Description

I. Core Functions and Features

Compound environment simulation

Static Tensile + Ozone Aging Dual Mode Testing: Supports ozone exposure experiments for materials under fixed tensile stress.

Simultaneous control of tensile force (0-50 N/m), ozone concentration (20-500 ppm), temperature and humidity (10-60C, 30-90% RH). -90% RH).

Precise control and safety design

High-precision servo motor: tensile displacement control accuracy up to **0.1 mm**, supports preset multi-stage tensile program.

Dual safety interlock: automatic shutdown and alarm in case of over-temperature, over-pressure, ozone leakage or abnormal stretching force.

Data monitoring and analysis

Built-in touch screen real-time display of tensile stress curve, ozone concentration trend and material deformation data.

Support data export (Excel/PDF) and cloud synchronization for long-term tracking and comparison.

Modularized design

UV assisted aging or dust spraying module can be selected to expand the multi-factor aging test capability.

Typical Technical Parameters

Parameter Example Value/Description

Tensile force range 0-50 N/m (higher loads can be customized)

Tensile accuracy 0.1% FS

Ozone concentration range 20-500 ppm (1 ppm control accuracy)

Temperature control 10-60C (0.5C accuracy)

Humidity control 30-90% RH (2% accuracy)

Working mode Timer operation, gradient cycle, program customization

Power requirements AC 220V/50Hz, power 800-1200W

Inner box size 600400350mm (customized design)

III. Application Scenarios

Material durability test

Rubber products (tires, seals) in long-term tensile stress under the ozone cracking performance assessment.

Aging failure analysis of plastics and paints under dynamic stress and ozone together.

Verification of automotive parts

Reliability testing of automotive wiring harnesses and seals under simulated outdoor ozone and vibration environments.

Electronic Materials Research

Anti-aging performance of silicone and wire insulation under static stretching and ozone exposure.

Product development and quality control

Aging life prediction of new composite materials (e.g. EPDM, fluoroelastomer).

IV. Suggestions for Purchase

Matching test requirements

Basic version: meets the regular tensile-ozone synergistic test (e.g. 0-20 N/m load).

Premium version: add multi-axial tensile, fatigue cycle or low temperature (-40C) test module.

Sensor selection

Ozone sensor: Electrochemical type is preferred (high immunity to interference, long life).

Tensile sensors: High resolution (0.05% FS) S-type strain gauges are recommended.

Compliance Standards

Confirm that the equipment complies with international standards such as ASTM G154 (UV aging) and ISO 11343 (ozone aging).

Maintenance Costs

Pay attention to the replacement cycle of the ozone generator (generally 5000-8000 hours) and the cost of consumables.

V. Maintenance Precautions

Regular Calibration

Calibrate the ozone concentration sensor and tension sensor every 6 months.

Seal check

Check the sealing strip of the box before experiment to avoid ozone leakage or entry of external pollutants.

Lubrication Maintenance

The guide rails of the tensioning mechanism need to be lubricated with high temperature grease regularly (quarterly is recommended).

Software Updates

Regularly update the control software to optimize algorithms and add new functions.

Standard Features

| Item | Specification |

| Internal dimension | 450W*450D*500Hmm (100L) |

| Temperature range | RT+10~ 60 (suggest to use 402) |

| Temperature Fluctuation | 1 |

| Ozone concentration | 50~1000 pphm, adjustable (suggest to use 50pphm) |

| Ozone concentration deviation | 10% |

| Sample holder rotation | 360 degree rotation |

| Sample holder | 2pcs removable sample tray, SUS#304 stainless steel |

| Temperature controller | Programmable touch screen controller |

| Ozone concentration analysis | Concentration analysis meter |

| Ozone generator | High pressure silence discharge type |

| Protection system | Leakage, short circuit, over temperature, over heat |

Comprehensive Ozone Aging Simulation

This test chamber offers programmable control over ozone concentration (101000 ppm), humidity (4090% RH), and temperature (room temperature to 90C), meeting a wide spectrum of testing requirements. Featuring a silent discharge ozone generator and multi-directional forced convection air circulation, it simulates real-world aging conditions for reliable results.

Sturdy Construction and User Convenience

The chambers interior is crafted from SUS304 stainless steel, delivering excellent durability and corrosion resistance. The large double-layer tempered glass observation window and built-in LED lighting enable clear specimen observation without interrupting the testing process.

Advanced Control and Data Management

A programmable digital controller offers precise test parameter regulation and automation. Data can be easily exported via USB, printer port, or RS232 interface, ensuring comprehensive documentation for quality control and research.

FAQs of Static tensile ozone aging test chamber:

Q: How does the static tensile ozone aging test chamber generate ozone?

A: The chamber utilizes a silent discharge method to generate ozone, ensuring stable and uniform ozone concentration (101000 ppm) within the test environment. This method is reliable, energy-efficient, and minimizes disturbance during material testing.Q: What materials can be tested using this chamber?

A: This equipment is designed primarily for testing rubber, elastomers, and polymer materials. It evaluates their resistance to ozone-induced aging, making it ideal for use in research, development, and quality assurance in relevant industries.Q: What is the specimen capacity, and what are the size requirements?

A: The chamber can accommodate up to 6 specimens simultaneously. The standard specimen size is 30 3 100 mm, and the test width is 60 mm with a maximum height of 600 mm and a test stroke of up to 300 mm.Q: How is test data recorded and exported from the chamber?

A: Test data can be conveniently recorded and exported through USB or printer port for analysis. Additionally, an RS232 interface is available for external communication and integration with laboratory data management systems.Q: When is over-temperature and leakage protection activated during operation?

A: The chambers safety protection system continuously monitors internal conditions. Over-temperature and leakage protection are automatically triggered if the pre-set safety thresholds are exceeded, ensuring safe and reliable test operation at all times.Q: Where should the chamber be installed for optimal performance?

A: For best results, the chamber should be installed in an environment with an ambient temperature between 5C and 35C and humidity 85% RH. Placing it on a stable floor in a well-ventilated lab space is recommended.Q: What are the main benefits of using this ozone aging test chamber?

A: The primary benefits include highly accurate, programmable environmental simulation, robust safety features, convenient observation, and versatile data management. These advantages lead to improved efficiency, compliance with testing standards, and reliable evaluation of material durability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese