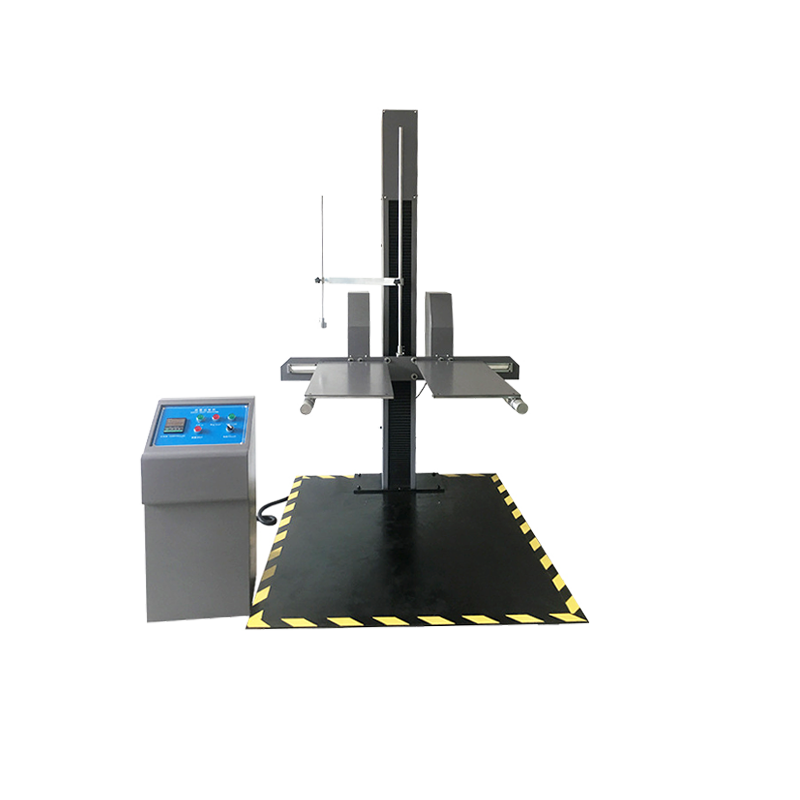

Toy Drop Test Machine for Safety Standards

Product Details:

Toy Drop Test Machine for Safety Standards Price And Quantity

- 156005.0 INR/Unit

- 1 Unit

Toy Drop Test Machine for Safety Standards Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 5 Days

- All India

Product Description

The Toy Drop Test Machine for Safety Standards is an essential tool designed to test the resilience and safety of toys under various conditions. Specifically developed to comply with international safety standards, this machine simulates real-world impacts and conditions to ensure that toys can withstand handling during shipping, retail display, and usage. By utilizing this drop test machine, manufacturers can verify the durability and safety of their products, safeguarding both the quality of toys and the well-being of consumers.

Key Features of the Toy Drop Test Machine

-

Simulates Real-World Impact Conditions

The Toy Drop Test Machine replicates the physical forces toys are likely to encounter during transport and use. With adjustable drop heights and various impact surfaces, it provides manufacturers with the flexibility to test toys under different conditions. This ensures that toys meet safety standards and can withstand any mishandling or rough usage. -

Compliance with Safety Standards

This drop test machine is designed to meet stringent safety regulations for toys, such as those set by ASTM F963, EN71, and other international safety standards. By performing drop tests, manufacturers can demonstrate that their products are safe for children, ensuring that they pass required safety certifications and comply with industry guidelines. -

Durable Construction and Reliability

Built with high-quality materials, the Toy Drop Test Machine is durable enough to handle repeated testing over long periods. The machine is designed for efficiency, ensuring consistent and reliable testing results that are critical for product approval and safety compliance. -

Customizable Drop Configurations

The machine allows users to customize drop heights and angles, testing toys under multiple impact scenarios. This versatility makes it suitable for a wide range of toy types and sizes, from soft plush toys to hard plastic items. The ability to vary drop configurations ensures comprehensive testing that closely mirrors real-world conditions. -

Data Collection and Reporting

The Toy Drop Test Machine is equipped with advanced data logging features, enabling manufacturers to collect detailed information on each test, such as impact force, drop height, and the resulting damage to the toy. This data is invaluable for product analysis and improving the design of toys to prevent safety issues in the future.

Benefits of Using the Toy Drop Test Machine

-

Ensures Toy Safety: By simulating accidental drops and impacts, the test machine helps identify weaknesses in toy design, such as small parts that may become detached or areas that may break easily. This early detection of safety hazards can prevent injuries and ensure compliance with safety standards.

-

Cost-Effective Quality Control: Investing in a Toy Drop Test Machine allows manufacturers to conduct thorough testing without relying on external testing labs, saving time and money in the product development and quality control process.

-

Enhances Product Durability: Toys that pass rigorous drop testing are less likely to suffer damage during transport or everyday play. This contributes to greater consumer satisfaction and reduces the number of returns due to product defects.

Applications of the Toy Drop Test Machine

The Toy Drop Test Machine for Safety Standards is widely used in the toy manufacturing industry, particularly by companies that need to ensure their products meet strict regulatory requirements. It is used for testing:

-

Soft Toys and Stuffed Animals

Soft toys, often made with plush materials and delicate parts, need to undergo drop testing to ensure that they do not pose choking hazards or other risks when dropped. -

Plastic Toys

Hard plastic toys, which can break into sharp pieces when impacted, are tested to determine their durability and to check if any small parts could detach during impact. -

Electronic Toys

Toys with built-in electronics must undergo drop testing to ensure that the electronics are safely contained and that no hazardous materials are exposed during an impact.

How the Toy Drop Test Machine Works

The Toy Drop Test Machine operates by lifting the toy to a predefined height and releasing it onto a specific surface. The drop height, surface type, and angle can be adjusted based on the specific testing requirements. Each test provides valuable data on how the toy reacts to the drop, allowing manufacturers to assess whether the product is fit for the market. The results also help to pinpoint areas of design that may need improvement to pass safety standards.

| Item | Description |

| Drop height | 400-1500mm (can be customized) |

| Display method | Digital display |

| Max. weight of sample | 60kg (can be customized) |

| Max. size of sample | (L*W*H) 800*800*800mm |

| Drop panel area | 1400x1200mm (material is Solid steel plate) |

| Control box dimension | (L*W*H) 350*350*1100mm |

| Deviation of drop horizon | Less than 1 |

| Machine size | (L*W*H)1400*1200*2200mm |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese