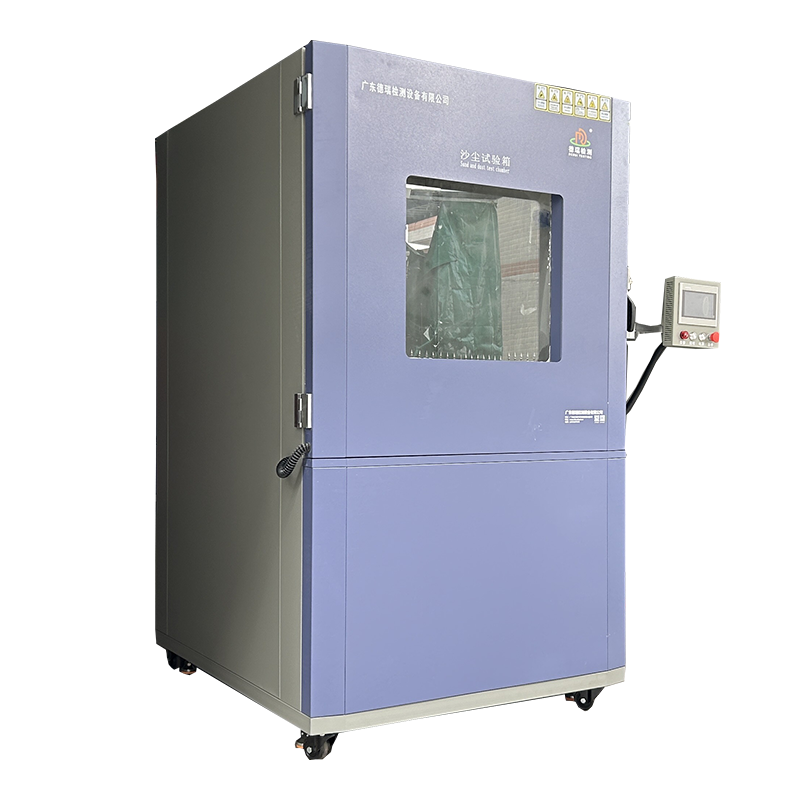

Vertical circulating airflow sand and dust box

268005.0 INR/Unit

Product Details:

- Interface Type RS232, USB

- Port Size 150 mm diameter

- Humidity 20%-80% RH adjustable

- Gas Pressure 0.5-0.8 MPa

- Temperature Room temperature to 60 adjustable

- Power Supply AC 220V, 50Hz

- Test Range Simulates natural sand and dust environmental conditions

- Click to view more

X

Vertical circulating airflow sand and dust box Price And Quantity

- 1 Unit

- 268005.0 INR/Unit

- 1 min 99 hr

- Vertical airflow with filtration

- < 150 micron

- IEC 60068-2-68, MIL-STD-810F

- 50 mm PU foam

- Overload, over-temperature, leakage protector

- Adjustable/removable racks

- Double-layer silicone rubber gasket

- < 65 dB(A)

- Provided for cables/measurement

- Up to 30 cycles/hour

- Optional (air cooled)

- LED illumination

- Caster wheels with brakes

- 250 x 300 mm

- SUS304 stainless steel interior, powder-coated steel exterior

Vertical circulating airflow sand and dust box Product Specifications

- Floor standing

- Fully automatic

- Immediate adjustment within 5 seconds

- Standard environmental sand and dust standards

- Max 300 x 300 x 300 mm

- LCD digital display

- 220V AC

- Programmable electronic control

- Up to 6 specimens per test

- N/A (Not applicable to equipment chamber)

- 0.1 / 0.1% RH

- 2% RH (humidity), 1 (temperature)

- 1000 mm

- Stainless steel interior, clear observation window, automated cycling

- AC 220V, 50Hz

- Simulates natural sand and dust environmental conditions

- 1800 mm (external)

- Industrial laboratory testing

- 20%-80% RH adjustable

- 0.5-0.8 MPa

- Room temperature to 60 adjustable

- 150 mm diameter

- 800 mm

- RS232, USB

- Vertical circulating airflow sand and dust test box

- Approximately 350 kg

- Dust and sand resistance testing for electronics, automotive and industrial components

- 0.5-1.5 m/s adjustable

- 50Hz

- Test chamber volume 1000 L

- 1 min 99 hr

- Vertical airflow with filtration

- < 150 micron

- IEC 60068-2-68, MIL-STD-810F

- 50 mm PU foam

- Overload, over-temperature, leakage protector

- Adjustable/removable racks

- Double-layer silicone rubber gasket

- < 65 dB(A)

- Provided for cables/measurement

- Up to 30 cycles/hour

- Optional (air cooled)

- LED illumination

- Caster wheels with brakes

- 250 x 300 mm

- SUS304 stainless steel interior, powder-coated steel exterior

Vertical circulating airflow sand and dust box Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 5 Days

- All India

Product Description

Dust Test Chamber ParameterC12089124525-34

| Item | Specification |

| Internal dimension | 800W*800D*800Hmm |

| External dimension | 1300W*1000D*1700Hmm |

| Test sample | Size W20cm- L30cm-D15cm, weight 0.5kg |

| Chamber material | SUS304 Stainless steel |

| Specifications of square mesh sieve | Mesh hole 75um, mesh metal wire diameter 50um |

| Talcum powder amount | 2kg/ m |

| Airflow speed | No more than 2m/s |

| Door | Left open door with tempered glass door |

| Controller | PLC Touch Screen controller, programmable to set as below cycle: a. Blowing dust time (Stop/Blow) m/s b. Cycle time: can be adjusted c. Pre-set test time: 0s ~99m99s |

| Vacuum system | Pressure gauge, air filter, Pressure regulating FRL, connecting pipe, Vacuum pump |

| Vacuum pump capacity | 60-600 L/H |

| Fan | Centrifugal fan |

| Safety protection devices | Meter over-temperature function, Phase shortage protection, Power short-circuit protection |

Vertical circulating airflow sand and dust box is a kind of experimental equipment that simulates the natural wind and sand environment, which is mainly used to test the durability and protection performance of materials, coatings, electronic devices, etc. under the action of wind and sand. The following are its key information and points:

1. Working Principle

Vertical Airflow Circulation: The top and bottom high-efficiency fans form an up-and-down bidirectional airflow circulation to simulate the dynamic distribution of real wind and sand.

Sand and Dust Control: Built-in vibrating screening system or dosing device ensures that sand and dust are evenly suspended and maintained at a set concentration (e.g. ISO 9227 standard).

Temperature and humidity control: optional heating/cooling module to control the temperature and humidity of the experimental environment (applicable to high cold/desert extreme conditions).

2. Core application areas

Automotive industry: testing the corrosion resistance of paint, seals and sensors in wind and sand.

Building materials: Evaluate the resistance of exterior paints and glass curtain walls to abrasion by wind and sand.

Electronic products: Verify the dustproof sealing level (IP protection) of outdoor equipment (e.g. drones, communication base stations).

Military equipment: simulate the erosive effects of wind and sand on equipment in the battlefield.

3. Suggestions for equipment selection

Select by test object:

Small samples: desktop or compact units.

Large components: industrial grade floor standing chamber.

By Standards Compliance:

Compliance with ISO 9227-2 (dry sand method), GB/T 2423.37 (Chinese national standard), etc.

Additional Functional Requirements:

Equipped with camera to observe the test effect in real time.

Data acquisition system (record wind speed, temperature and humidity curve).

4. Precautions for use

Safe operation:

Check the sealing before the experiment to avoid sand and dust leakage.

Regularly clean the filter and fan dust accumulation.

Sample Preparation:

Samples need to be fixed firmly to avoid displacement or collision.

Initial state record (e.g. quality, surface morphology).

Maintenance cycle:

Weekly cleaning of internal residual grit.

Calibrate the wind speed sensor and temperature and humidity meter every six months.

5. Typical Problem Solving

Dust settles too quickly: Check airflow stability or add agitation device.

Unstable temperature control: Make sure the heating/cooling power matches the chamber volume.

Equipment rattling: Check fan bearing lubrication or foreign matter blockage.

Advanced Environmental Simulation

This test box provides precision-controlled simulation of sand and dust environments. With adjustable air circulation up to 30 cycles per hour and programmable settings for humidity and temperature, you can replicate a wide range of real-world conditions. The instruments stainless steel construction and robust sealing ensure accurate and repeatable testing, ideal for evaluating component durability and ingress protection.

User-Friendly Design and Operation

A large observation window with internal LED lighting allows easy monitoring of specimens during testing. Access ports support measurement and cable integration, while caster wheels facilitate mobility. The digital LCD display ensures all parameters are visible at a glance, and the programmable electronic control system provides an intuitive user experience for both routine and complex testing cycles.

Comprehensive Safety and Compliance

Safety mechanisms include overload, over-temperature, and leakage protection, ensuring secure operation in laboratory and industrial environments. The equipment is manufactured to meet leading international standards (IEC 60068-2-68, MIL-STD-810F), supporting consistent, valid results that stand up to regulatory requirements.

FAQs of Vertical circulating airflow sand and dust box:

Q: How does the vertical circulating airflow system function in this sand and dust test box?

A: The system utilizes vertical airflow to evenly distribute sand and dust particles throughout the chamber, enhancing the uniformity of environmental exposure. Integrated filtration ensures effective recirculation, maintaining consistent test conditions while safely containing dust during operation.Q: What types of objects or specimens can be tested with this equipment, and what are the size limits?

A: You can test up to six specimens simultaneously, with each specimen measuring up to 300 x 300 x 300 mm. The chamber is designed for electronics, automotive, and industrial components, providing versatility for various durability and ingress protection assessments.Q: When should I use this sand and dust test box in my product development process?

A: This equipment is ideal during the validation and quality assurance phases of product development, ensuring your products meet required sand and dust resistance standards before market release, especially for items intended for harsh environments.Q: Where is the best location to install the test chamber in a facility?

A: The chamber is floor-standing and mounted on caster wheels for easy transport. It should be installed in a well-ventilated laboratory or testing area with access to AC 220V power and a stable surface to support its 350 kg weight and ensure safe operation.Q: What is the testing process and how can parameters be adjusted?

A: Testing involves placing specimens on adjustable racks, sealing the chamber, and configuring test conditions (airflow, humidity, temperature, timer) through the LCD display. All parameters can be tailored using the programmable electronic control, with immediate response to adjustments in under five seconds.Q: How does this equipment benefit my testing or manufacturing operations?

A: It streamlines sand and dust resistance testing, providing fast, reproducible results that support compliance with international standards. Automated cycling, robust safety features, and user-friendly controls enhance efficiency and reduce manual supervision, ultimately improving product reliability and quality assurance workflows.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese