Waterproof material ozone testing machine

398005.0 INR/Unit

Product Details:

- Power Supply AC 220V, 50Hz

- Accuracy 2% F.S.

- Response Time 10 s

- Humidity 40-85% RH

- Test Range 0-200 ppm ozone concentration

- Measuring Range 0-200 ppm

- Equipment Type Ozone Testing Machine

- Click to view more

X

Waterproof material ozone testing machine Price And Quantity

- 1 Unit

- 398005.0 INR/Unit

- 0-9999 min

- Uniform forced air convection

- Leakage protection, Over-temperature cutoff

- SUS304 Stainless steel

- 700 × 750 × 1100 mm

- Tempered glass with anti-fogging

- Built-in, silent operation

- 145 kg

- Electrochemical

Waterproof material ozone testing machine Product Specifications

- 0-200 ppm ozone concentration

- 40-85% RH

- 0-200 ppm

- AC 220V, 50Hz

- 150 mm

- 60 mm

- 10 s

- 2% F.S.

- DN15

- Waterproof materials, rubber, plastics

- 6

- Automatic

- 8 L

- Ozone Testing Machine

- 350 mm

- Floor standing

- Touch screen PLC control

- Programmable test cycles, High and low alarm, Overload protection

- 0-100 mm/min adjustable

- 120 kg

- Room temperature to 80C

- AC 220V

- Waterproof material aging and durability test

- Digital/LED display

- 50 Hz

- 0.1 ppm

- RS232/USB

- 0.1~0.5 MPa

- 150 mm 50 mm

- 0-9999 min

- Uniform forced air convection

- Leakage protection, Over-temperature cutoff

- SUS304 Stainless steel

- 700 × 750 × 1100 mm

- Tempered glass with anti-fogging

- Built-in, silent operation

- 145 kg

- Electrochemical

Waterproof material ozone testing machine Trade Information

- Cash in Advance (CID)

- 90 Unit Per Month

- 7 Days

- All India

Product Description

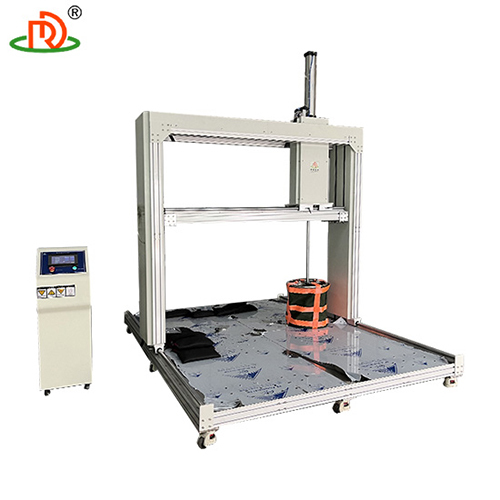

Waterproof material ozone tester is a special equipment used to simulate the ozone environment in the atmosphere and conduct aging test on waterproof material. The following is detailed information about Waterproof Material Ozone Tester:

1. Equipment Overview

Waterproof Material Ozone Tester is mainly used to simulate and enhance the ozone environment in the atmosphere, to conduct accelerated aging test on waterproof materials to assess their ozone resistance and durability under actual use conditions.

This equipment is widely used in the fields of building materials, waterproofing membranes, coatings, etc. By simulating the aging process under the ozone environment, it can quickly identify and evaluate the ozone aging resistance of the materials.

2. Main applications

The ozone tester for waterproof materials is mainly used in the following fields:

Waterproofing membrane: such as asphalt waterproofing membrane, polymer waterproofing membrane, etc., to evaluate its weathering resistance and durability under ozone environment.

Paints and coatings: for ozone resistance testing of coating materials such as paints, coatings, powder coatings, etc., to assess their weathering resistance in the atmospheric environment.

Sealing materials: such as rubber seals, sealants, etc., to assess their aging performance and sealing performance in ozone environment.

Other waterproof materials: such as waterproof coatings, waterproofing agents, etc., to assess their aging resistance and service life under ozone environment.

3. Working Principle

The working principle of the ozone tester for waterproof materials includes the following steps:

1.

Ozone generation: high-voltage discharge method or ultraviolet irradiation method to generate ozone. High-voltage discharge method using high-voltage alternating current to make the oxygen molecules in the air decomposition and recombination to generate ozone; UV irradiation method is the use of specific wavelengths of ultraviolet light to irradiate the oxygen, so that the oxygen molecules absorb the light energy decomposition to produce ozone.

2.

Environmental control: The temperature inside the test chamber is regulated by the heating system and refrigeration system to keep it within the set temperature range. At the same time, humidifier or dehumidifier is used to control the humidity inside the chamber to meet the humidity requirements of different test standards.

3.

Gas circulation: Equipped with a fan or circulating air duct to evenly distribute the ozone gas inside the chamber to ensure consistent ozone concentration around the test pieces. The gas in and out is controlled through the ventilation system to maintain the stability of ozone concentration inside the chamber.

4. Equipment features

High-precision control: Adopting advanced control system, it can accurately control the ozone concentration, temperature and humidity to ensure the stability and consistency of the test conditions.

Safe and reliable: Equipped with multiple safety protection devices, such as over-temperature protection, overload protection, power supply short circuit protection, etc., to ensure the safety and reliability of the test process.

Convenient observation: usually equipped with a transparent observation window, which is convenient to observe the changes of materials in the test process.

Energy-saving and environmental protection: adopting energy-saving design with low energy consumption and efficient heat exchange system to improve test efficiency and save energy.

Standard Features

| Item | Specification |

| Internal dimension | 450W*450D*500Hmm (100L) |

| Temperature range | RT+10~ 60 (suggest to use 402) |

| Temperature Fluctuation | 1 |

| Ozone concentration | 50~1000 pphm, adjustable (suggest to use 50pphm) |

| Ozone concentration deviation | 10% |

| Sample holder rotation | 360 degree rotation |

| Sample holder | 2pcs removable sample tray, SUS#304 stainless steel |

| Temperature controller | Programmable touch screen controller |

| Ozone concentration analysis | Concentration analysis meter |

| Ozone generator | High pressure silence discharge type |

| Protection system | Leakage, short circuit, over temperature, over heat |

Precision Ozone Resistance Testing

This machine is specifically designed to simulate and evaluate the aging process of waterproof materials, rubber, and plastics under controlled ozone exposure. With a test range up to 200 ppm and high-precision electrochemical sensing, it provides reliable data for quality assurance and research purposes.

Smart Features and User Safety

Equipped with a PLC touch screen control and programmable test cycles, the system ensures easy operation and flexible adjustments. Enhanced safety mechanisms, including leakage protection, over-temperature cutoff, and clear anti-fog viewing, help maintain a secure testing environment.

Robust and Versatile Construction

Manufactured with SUS304 stainless steel and tempered glass, the machine is durable yet approachable. Uniform forced air convection, adjustable test speeds, and multi-specimen capacity make it adaptable for a range of industries, from manufacturers to research facilities.

FAQ's of Waterproof material ozone testing machine:

Q: How does the ozone testing machine ensure uniform ozone exposure during tests?

A: The machine utilizes a uniform forced air convection system, ensuring each specimen receives the same concentration of ozone throughout the test cycle for accurate and repeatable results.Q: What types of materials can be tested with this ozone testing machine?

A: It is suitable for waterproof materials, rubber, plastics, and other similar products that require assessment of ozone resistance, aging, and durability.Q: When should I use ozone testing for my materials?

A: Ozone testing is ideal during the development phase of products, routine quality assurance, or when validating material performance for environments exposed to ozone and oxidative stress.Q: Where is the best environment to install this testing machine?

A: The machine should be installed in a laboratory or quality control area that meets standard safety requirements and accommodates floor-standing equipment with a power supply of AC 220V.Q: What is the process of conducting a test using this equipment?

A: Users prepare up to six specimens, place them in the chamber, set parameters via the touch screen PLC, and initiate programmable test cycles. The system monitors temperature, humidity, and ozone concentration automatically, ensuring precise testing conditions.Q: How is user safety managed during ozone testing operations?

A: The machine features built-in leakage protection, an over-temperature cutoff, high and low alarms, and an anti-fog tempered glass viewing window, providing comprehensive operational safety.Q: What are the key benefits of using this ozone testing machine?

A: By automating the ozone exposure and monitoring process, users gain precise, reproducible results. The robust build, safety features, and programmable settings make it efficient for industrial, research, and quality assurance applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese