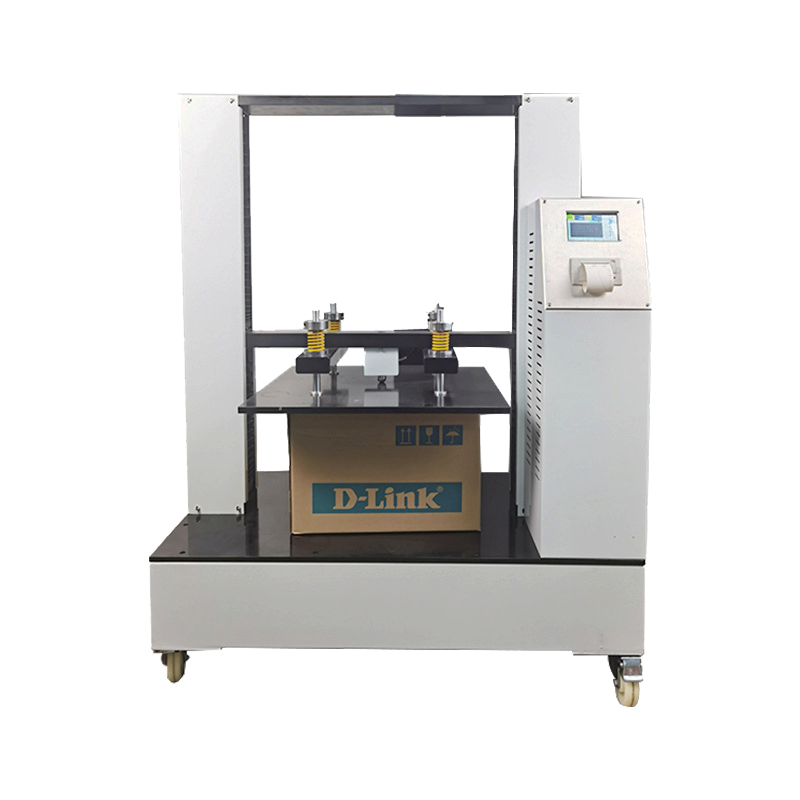

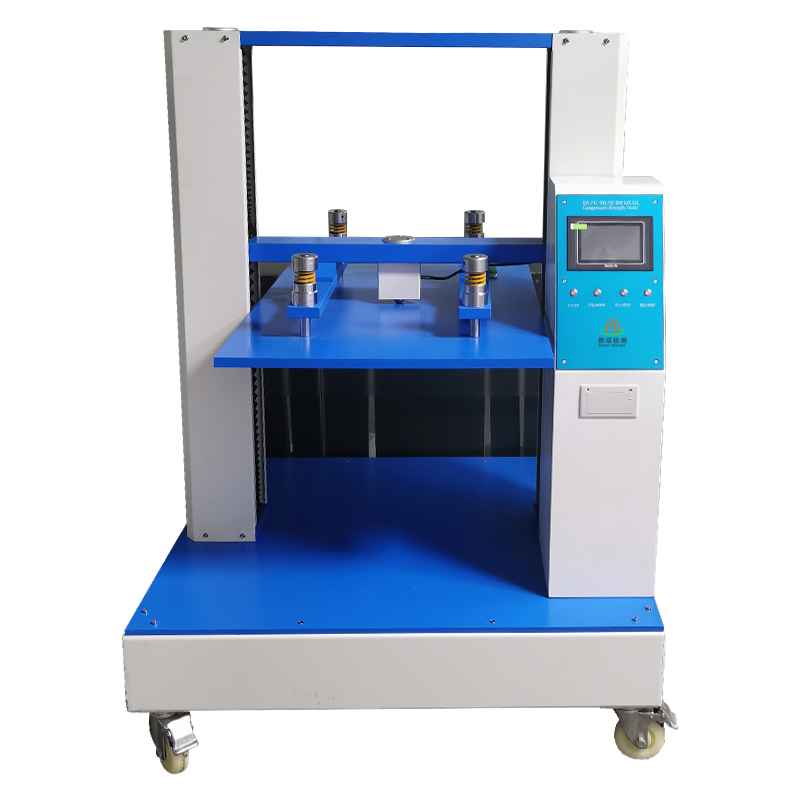

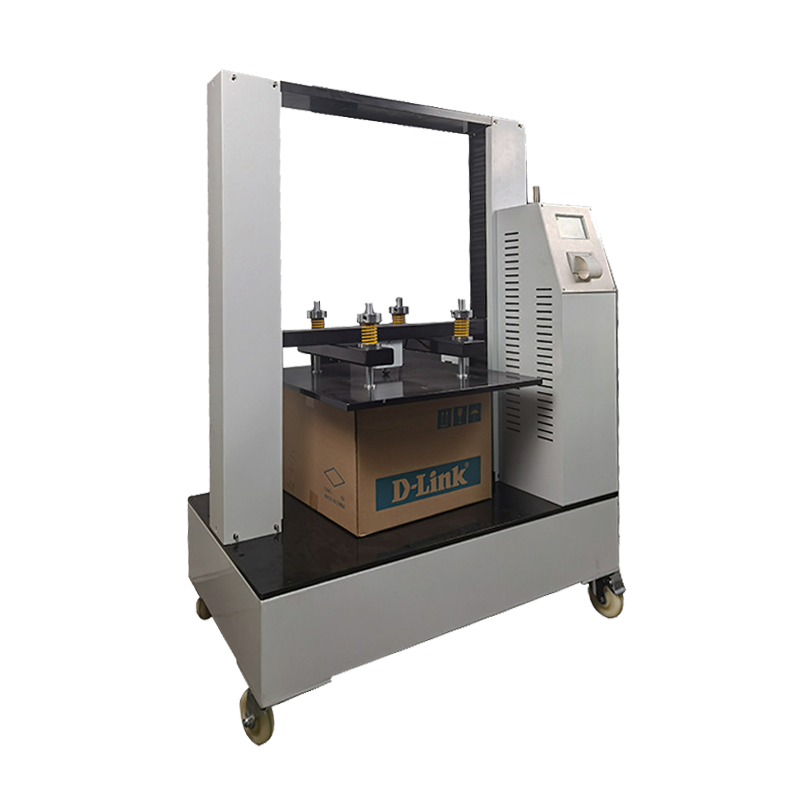

ASTM D642 cardboard compression test box

168005.0 INR/Unit

Product Details:

- Frequency 50 Hz

- Test Range Max 50 kN

- Mounting Type Floor-mounted

- Power Supply AC 220V 7% 50Hz

- Measuring Range 0~50,000 N

- Accuracy 7% of indication

- Temperature 15~356C (operating environment)

- Click to view more

X

ASTM D642 cardboard compression test box Price And Quantity

- 1 Unit

- 168005.0 INR/Unit

- Emergency stop, overload sensor, movement limiters

- AC Servo Motor

- Heavy-duty steel structure with powder coating

- Professional analysis software included

- 1000 x 1000 mm

- Constant speed, load, displacement, auto return

- Approx. 1600 x 1400 x 2000 mm

- ASTM D642, ISO 12048, TAPPI T804

- Less than 60 dB(A) during operation

- Electronic calibration system

ASTM D642 cardboard compression test box Product Specifications

- Microcomputer control

- 50 kN (adjustable types available)

- 0~1200 mm (adjustable)

- Min 100 x 100 mm, Max 1000 x 1000 mm

- AC 220V

- Digital LCD

- 1200 mm

- For standard ASTM D642 box compression testing

- Over-travel protection, auto return, limit protection, microcomputer digital display

- s

- Cardboard/carton/box compressive strength testing

- 1000 mm

- Box Compression Tester

- RS232 (optional USB)

- Customizable on request

- Single specimen per test

- 30%~85% RH (operating environment)

- Automatic

- 7% of indication

- 15~356C (operating environment)

- 1 N

- 0~50,000 N

- AC 220V 7% 50Hz

- Max 50 kN

- 50 Hz

- Approx. 450 kg

- Floor-mounted

- 10 7 3 mm/min

- Emergency stop, overload sensor, movement limiters

- AC Servo Motor

- Heavy-duty steel structure with powder coating

- Professional analysis software included

- 1000 x 1000 mm

- Constant speed, load, displacement, auto return

- Approx. 1600 x 1400 x 2000 mm

- ASTM D642, ISO 12048, TAPPI T804

- Less than 60 dB(A) during operation

- Electronic calibration system

ASTM D642 cardboard compression test box Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 7 Days

- All India

Product Description

| Item | DR-B211-900 | DR-B211-1200 | DR-B211-1500 |

| Max. Force | 10KN(1000 kg ,2205lb) | 20KN(2000 kg, 4409lb) | 50KN(5000kg,11023lb) |

| Load cell | 1 load cell for highest accuracy | ||

| Control system | Dual control (Computer control with Windows mode+Touch screen control ) | ||

| Servo Motor | 400W | 750W | |

| Servo Driver | 400W | 750W | |

| Screws | Ball screws(Double ball guide rod design, high transmission accuracy, high transmission power efficiency) | ||

| Force reading | Gf, kgf, Ibf, N, KN, T etc | ||

| Load cell Resolution | 1/250,000 | ||

| Load Precision | within 0.5% | ||

| Effective test area (L x W x H) | 700x900x900mm | 1000x1200x1000mm | 1300x1500x1500mm |

| Compression Stroke | 0~900mm | 0~1000mm | 0~1500mm |

| Lift speed | 0.1~200mm/min | ||

| Software | Mtest HD-002-A(Independent R&D) | ||

| Data display | Load, displacement, speed, loading rate and elapsed time | ||

| Safety features | E-Stop Over-load protection Upper and lower limit switches Load sensor with automatic retreat | ||

| Report items | Serial number, peak value, average value, set pressure holding value, pressure holding time | ||

| Electrical Supply | 1phase, AC 220V, 500W, 50HZ | 1phase, AC 220V,550W,50HZ | 1phase, AC 220V,900W,50HZ |

| Overall Dimensions (L x W x H) | Approx.1510x1200x1645mm | Approx.1510x1200x1645mm | Approx.1865mmx1500mmx2235mm |

| Weight | Approx.350kg(772lb) | Approx.670kg(1477lb) | Approx. 1000kg(2205lb) |

| Operation Temperature and relative humidity | 10~40, 30~80% | ||

1. Equipment overview

The ASTM D642 Carton Compression Chamber is a precision test equipment designed to evaluate the compressive strength and deformation properties of cartons, corrugated boxes, and other packaging containers under static compression loads. The equipment is designed and operated in strict accordance with the ASTM D642 standard established by the American Society for Testing and Materials (ASTM) to ensure the accuracy and international applicability of the test results. The tester is widely used in packaging material manufacturing industry, logistics and transportation industry as well as quality control departments to ensure the safety and reliability of packaging materials in actual use.

2. Main Functions

Compressive Strength Test: Measure the maximum compressive capacity of carton in vertical direction according to ASTM D642 standard, and evaluate its load-bearing capacity during stacking, transportation and storage.

Deformation test: Record the deformation of carton under compression load, evaluate its deformation degree and recovery ability.

Stacking test: simulate the force of carton in actual stacking situation, evaluate its stacking stability and load-bearing capacity.

Cyclic compression test: Load and unload the carton for several cycles to evaluate its fatigue performance and durability.

Data analysis and report generation: Built-in data analysis software can automatically generate test reports in accordance with ASTM D642 standards, including maximum compressive strength, deformation, loading curve and other parameters.

Selecting the right model of carton compression tester requires consideration of a number of factors to ensure that the equipment will meet the testing requirements and provide accurate test results. Below are some key steps and considerations to help you select the right carton compression tester:

1. Determine the test criteria

First, identify the test standards you need to follow. Different countries and regions may have different standards, for example:

International standards: ASTM D642 (American Society for Testing and Materials), ISO 12048 (International Organization for Standardization)

National standards: GB/T 4857 (Chinese National Standard), JIS Z0212 (Japanese Industrial Standard)

Ensure that the selected equipment is capable of meeting your desired test standards.

2. Determine the size of the test sample

According to the size of the carton you need to test, choose the right model of test chamber. Common carton sizes include:

Small carton: e.g. 300mm 300mm 300mm

Medium-sized carton: e.g. 600mm 600mm 600mm

Large cartons: e.g. 1200mm 1200mm 1200mm

Ensure that the testing space of the chamber can accommodate your maximum carton size.

3. Determine the test force range

According to the expected load-bearing capacity of the carton, select the appropriate force range. Common test force ranges include:

Low range: e.g. 5kN for small cartons or lightweight packaging

Medium range: e.g. 15kN for medium-sized cartons

High range: e.g. 50kN or more for large cartons or heavy duty packaging.

4. Consider test speed and control accuracy

Test speed and control accuracy directly affect the accuracy of the test results. Common test speeds range from 1-500mm/min. Ensure that the equipment selected provides sufficient control accuracy, for example:

Displacement accuracy: 0.5mm

Pressure accuracy: 1%.

5. Automation and ease of operation

Selecting equipment with automated operation will improve test efficiency and reduce human error. Consider the following factors:

User interface: whether it is intuitive and easy to use

Parameter setting: whether it is simple and convenient

Data processing: whether the data analysis software is built-in, whether the test report can be generated automatically

6. Safety and reliability

Ensure that the equipment is equipped with multiple safety protection devices, such as:

Overload protection

Limit protection

Emergency stop device

These protections ensure the safety of the testing process and the long-term reliability of the equipment.

7. Brand and after-sales service

Choosing a well-known brand and a supplier with good after-sales service can ensure the quality of the equipment and follow-up support. Consider the following factors:

Brand reputation: choose a brand with a good reputation

After-sales service: including installation, training, repair and maintenance services

Warranty policy: understand the warranty coverage and duration of the equipment

8. Budget and cost-effectiveness

Choose cost-effective equipment according to your budget. The price of different brands and models of equipment may vary greatly, comprehensively consider the performance of the equipment, brand reputation and after-sales service, choose the most suitable equipment.

9. Additional functions and accessories

Select additional functions and accessories according to needs, e.g:

Environmental control: e.g. temperature and humidity control

Special fixtures: choose the right fixture according to different types of cartons

Data export: e.g. USB interface or network connection for easy data transfer and analysis

Advanced Testing Capabilities

This box compression tester supports a diverse range of test modes, including constant speed, load, and displacement, with an adjustable test stroke up to 1200 mm and capacity up to 50 kN. The professional analysis software enables detailed data evaluation, and the electronic calibration system ensures high accuracy, making it ideal for quality assurance in packaging industries.

Reliable, Safe, and Efficient Operation

Incorporating safety features like emergency stop functions, overload sensors, and movement limiters, this machine guarantees operational safety. The automatic, digital LCD interface provides intuitive control and monitoring. With a low ambient noise operation (under 60 dB(A)) and floor-mounted design, it offers a convenient and efficient solution for any test facility.

FAQ's of ASTM D642 cardboard compression test box:

Q: How does the ASTM D642 Box Compression Tester ensure accurate measurement during tests?

A: The tester employs an electronic calibration system and features a high-resolution digital LCD display, providing accuracy within 7% of the indicated value. The included professional analysis software further aids in delivering precise data analysis.Q: What is the recommended process for conducting a compression test on a cardboard box using this equipment?

A: Place a single specimen (minimum 100 x 100 mm, maximum 1000 x 1000 mm) on the compression plate, select the desired test mode (constant speed, load, or displacement), and initiate the test via the digital control interface. The machine will automatically conduct the test and provide results for analysis.Q: When should I use this box compression tester?

A: Use the box compression tester whenever you need to determine the compressive strength of cardboard, carton, or packaging boxes according to ASTM D642, ISO 12048, or TAPPI T804 standards, typically in product development, quality control, and batch inspection phases.Q: Where can this equipment be installed and what are its environmental requirements?

A: The tester is floor-mounted and should be installed in a laboratory or production area with stable power (AC 220V, 50 Hz), ambient temperatures between 15-35C, and relative humidity from 30% to 85% RH, ensuring optimal operating conditions.Q: What are the primary safety features included with this compression tester?

A: Key safety elements include an emergency stop button, overload sensors, movement limiters, over-travel protection, and limit protection, ensuring safe operation for users.Q: What are the benefits of using microcomputer control and digital display in this tester?

A: Microcomputer control and a digital LCD display enhance ease of use, ensure testing repeatability, and streamline data collection and analysis for higher productivity and more reliable results.Q: How can the port size and machine capacity be adjusted to meet specific requirements?

A: Port sizes and machine capacity can be customized upon request, accommodating different testing needs for various carton or box sizes and strengths.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese