Automatic Offset Ink Proofing Press with Digital Control - Lab & Industrial Use

28000.0 INR/Unit

Product Details:

- Accuracy High Repeatability (0.2 mm)

- Mounting Type Benchtop

- Resolution Digital Precision Control

- Response Time Immediate (Digital)

- Measuring Range Full Sheet Coverage

- Temperature 10C35C

- Automation Grade Automatic

- Click to view more

X

Automatic Offset Ink Proofing Press with Digital Control - Lab & Industrial Use Price And Quantity

- 1 Unit

- 28000.0 INR/Unit

- 750 mm x 380 mm x 490 mm

- Offset, UV, Flexo Inks

- Adjustable: 02 mm

- <65 dB

- Plug & Use No Complex Setup Required

- Quick Release for Roller Cleaning

- Emergency Stop Button and Overload Protection

- Technical Service & Calibration Available

- Special Alloy with Rubber Coating

Automatic Offset Ink Proofing Press with Digital Control - Lab & Industrial Use Product Specifications

- 350 mm

- 8 mm

- 0.50.7 MPa

- Manual Feed, Up to 150 sheets/hour

- Digital Control

- 210 mm

- Automatic Offset Ink Proofing Press

- Universal Ink Types

- 20%85% RH

- Offset Ink Proofing and Performance Testing

- Maximum 220 mm x 320 mm

- Single or Multiple

- Automatic, Consistent Proofing, Easy Cleaning, Speed Adjustment

- Digital LED Display

- 220V

- Lab & Industrial Ink Testing/Proofing

- Approx. 60 Kg

- Up to 220 mm

- Benchtop

- High Repeatability (0.2 mm)

- 10C35C

- Immediate (Digital)

- Full Sheet Coverage

- Digital Precision Control

- 220V AC, 50 Hz

- 50 Hz

- Automatic

- Digital Touch Panel

- Industrial Grade Rollers

- Variable, up to 150 sheets/hour

- 750 mm x 380 mm x 490 mm

- Offset, UV, Flexo Inks

- Adjustable: 02 mm

- <65 dB

- Plug & Use No Complex Setup Required

- Quick Release for Roller Cleaning

- Emergency Stop Button and Overload Protection

- Technical Service & Calibration Available

- Special Alloy with Rubber Coating

Automatic Offset Ink Proofing Press with Digital Control - Lab & Industrial Use Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 10 Days

- All India

Product Description

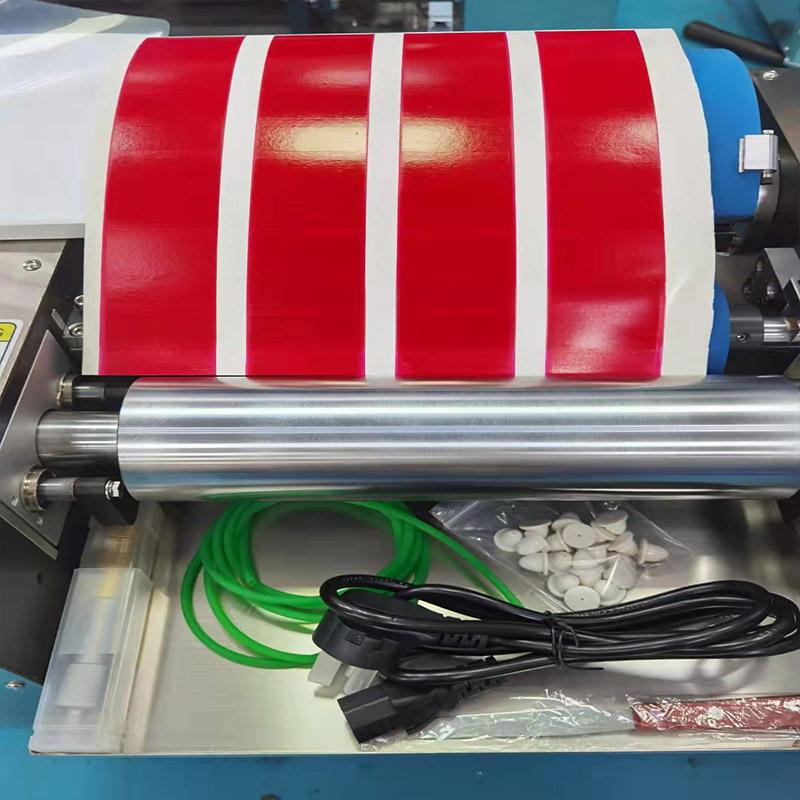

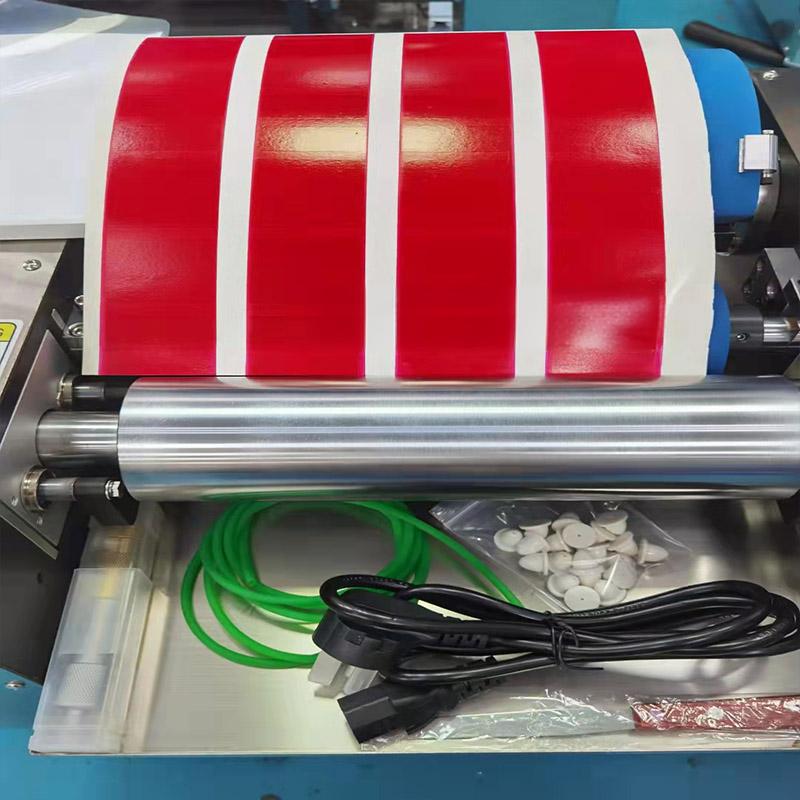

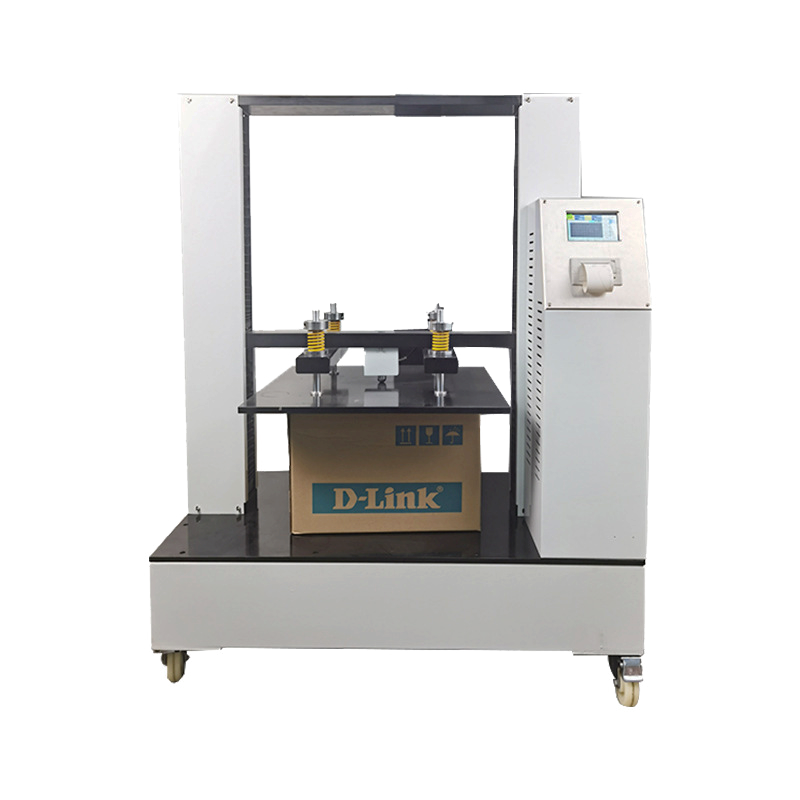

The offset ink spot color proofing machine is designed and produced by imitating the working principle of printing machines. The proofing machine has adjustable pressure and a wide range of substrates, and is suitable for use in packaging printing production, paper production enterprises, ink production enterprises, scientific research institutions and other departments. Accurately predict the color of ink through standard sampling. By constantly comparing the colors with the standard sample, the correct ink ratio is determined. After the spot color is correctly mixed, it is then mass-produced on the printing machine according to this ratio, turning the color matching work into pre press work.Suitable for ink offset printing with regular ink, UV ink, relief ink, UV flexographic ink

One printing roller comes standard with the factory, suitable for ordinary or UV ink

Sampling areas of 45 200mm (4 pieces), 60 200mm (3 pieces), and 106 200mm (2 pieces) are optional

Paper size 250 260mm

The ink mixing mode is automatic and can be switched manually

Automatic color display mode

Ink mixing speeds of 550, 700, and 900 revolutions per minute, with direct speed control in three levels, and can be infinitely variable frequency speed controlled within the equipment

Color display speeds of 10, 16, and 22 revolutions per minute, with direct speed control in three levels, and can be infinitely variable frequency speed controlled within the equipment

The ink mixing time can be adjusted from 1 to 200 seconds

Printing pressure is adjusted digitally according to the thickness of the printing material ( 0-800g)

Uniform ink pressure is adjusted externally according to the usage of the rubber roller

Control system PLC control system and touch screen

Instrument appearance 550 450 330mm

Instrument power 380W

Instrument voltage AC220V 50HZ

The total weight of the machine is 85KG

characteristic:

1. The whole machine adopts microcomputer automatic control, high-definition LCD screen display, and detailed parameter information of each function is displayed on the screen, making the operation more user-friendly and intuitive.

2. Built in three ink blending modes for personalized settings, meeting different operating habits and special situations.

Positioning in series, intermittent engagement, fixed engagement, both time and speed can be freely set (each level can set ink mixing time from 1 to 200 seconds, and speed can be set to high, medium, and low levels).

The soft start function can be set to not move in the middle, reducing uneven color development on the left and right sides and preventing ink flying.

3. Equipped with a high-precision synchronous motor, the interface accurately displays the current color pressure value. With just a simple press, it can automatically adjust to the desired color pressure.

4. Suitable color development pressure can be obtained for different thicknesses of materials, with a wide range of adjustable pressure (negative 1-40, positive 1-80) mm.

5. The color display speed can be pre-set in the mode (with adjustable high, medium, and low speeds).

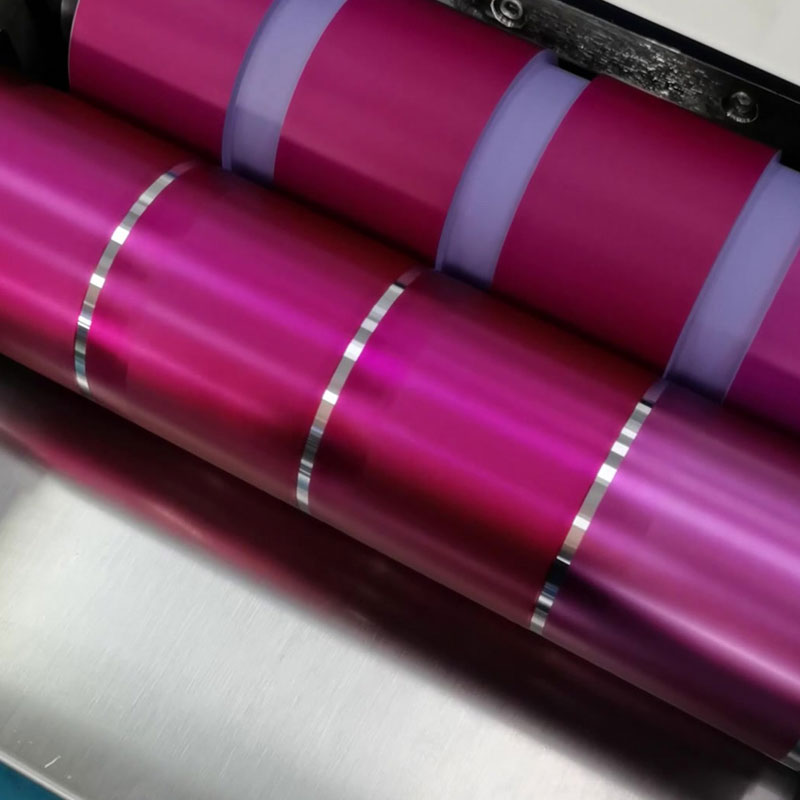

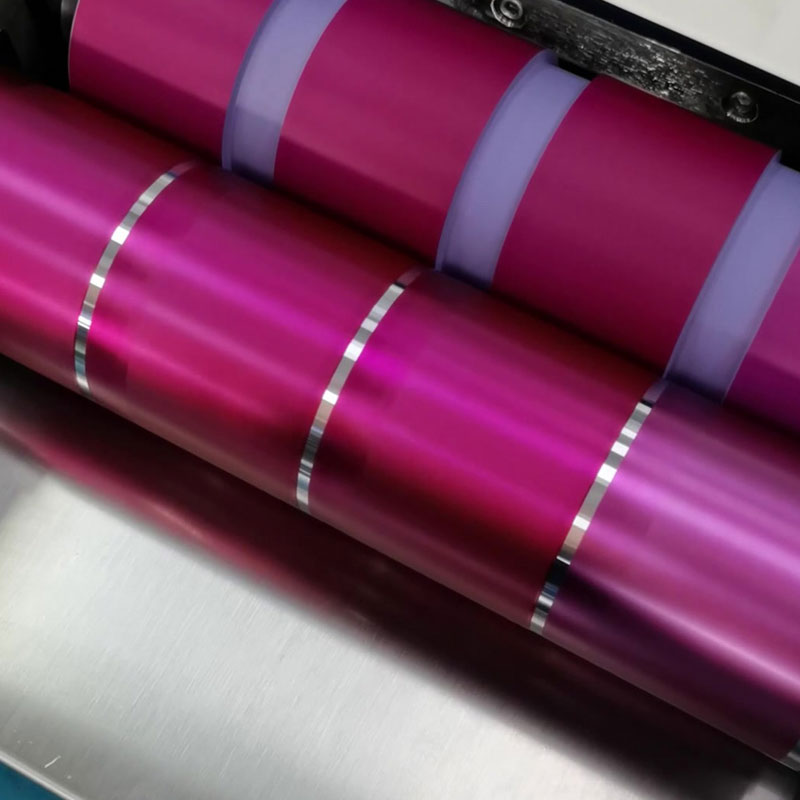

6. Personalized customization of two-color, three color, and four-color printing rollers is available to fully meet the needs of various practical usage situations, facilitating more intuitive analysis of the comparison and accuracy of current ink color samples.

7. Ordinary ink rollers and UV ink rollers can be selected according to actual needs, covering substrates such as news paper, offset paper, copperplate paper, brochure paper, writing paper, kraft paper, gold card, silver card, etc.

8. In cleaning mode, the metal roller can move separately or move together with the ink roller (cleaning separation, cleaning combination).

9. The cleaning speed is divided into high, medium, and low gears, and can be set at low, medium, and high speeds according to the level of proficiency, making the operation more convenient, safe, and fast.

Advanced Digital Control for Reliable Ink Testing

Achieve consistent and repeatable results with the press's digital touch panel, which allows precise adjustments for print layer thickness and speed. The digital LED display ensures real-time status monitoring, making every test accurate, regardless of operator experience. Its rapid response time and high-resolution controls streamline lab workflows and industrial testing.

Versatile and Efficient Proofing

Designed to handle multiple ink types-including offset, UV, and flexo inks-this press is compatible with universal ink testing processes. Its manual feed system accommodates single or multiple specimens, making it suitable for high-throughput applications. With sheet coverage up to 220 mm width and up to 150 sheets per hour, it's optimal for both research and production environments.

Easy Operation and Maintenance

Installation is as simple as plug and use-there's no need for complex setup or calibration. The quick-release cleaning system minimizes downtime, while industrial-grade rollers and a safety system (emergency stop and overload protection) ensure both durability and user safety. Technical service and calibration support are readily available for peace of mind.

FAQ's of Automatic Offset Ink Proofing Press with Digital Control - Lab & Industrial Use:

Q: How do I set up and operate the Automatic Offset Ink Proofing Press?

A: The press features a plug-and-use design, requiring only a standard 220V AC, 50Hz power supply. After plugging in the unit, use the digital touch panel to control and adjust print settings. Manual feed allows you to test single or multiple sheets up to 220 mm x 320 mm without complicated setup.Q: What types of ink can be tested with this equipment?

A: This proofing press supports a broad range of ink types, including offset, UV, and flexo inks. Its universal ink compatibility is ideal for various laboratory and industrial applications.Q: When is technical support and calibration service available?

A: Technical support and calibration services are available upon request for ongoing maintenance and optimal performance, ensuring your press always delivers high accuracy and repeatability.Q: Where is the best environment to use the press?

A: The ideal operating environment is a laboratory or industrial setting with humidity between 20%-85% RH and temperature from 10C-35C, on a stable benchtop surface.Q: What is the process for cleaning the rollers after usage?

A: The press has a quick-release system, enabling fast and easy removal of rollers for cleaning. Regular cleaning, especially after ink changes, ensures accurate and consistent results.Q: How does the press benefit ink quality and proofing workflows?

A: With high repeatability (0.2 mm), immediate digital response, and adjustable layer thickness, the press delivers consistent proofing results, enhancing quality control and expediting development in both research and manufacturing contexts.Q: Can the press handle high testing volume?

A: Yes, the machine features variable speed settings and can process up to 150 sheets per hour, making it suitable for both small-scale lab work and larger industrial testing requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese