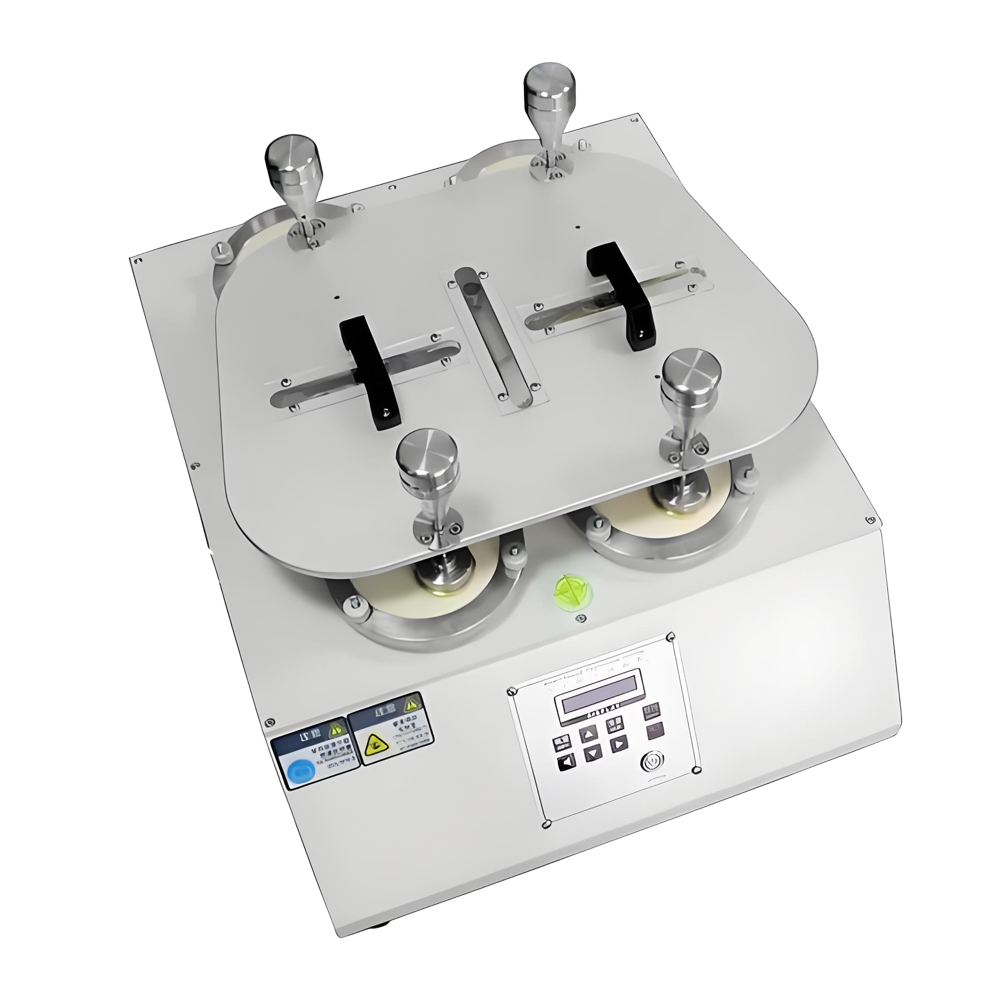

brinell hardness testing machine

138005.0 INR/Unit

Product Details:

- Display Type Dial Gauge / Optional Digital Display

- Hardness Brinell Hardness number (HB)

- Automation Grade Manual / Semi-Automatic

- Test Range 8-650 HBW

- Application Metals and Alloys Hardness Testing

- Humidity Up to 85% RH (non-condensing)

- Mounting Type Bench-mounted

- Click to view more

X

brinell hardness testing machine Price And Quantity

- 1 Unit

- 138005.0 INR/Unit

- Indoor, Dust-free

- Hardened Steel Ball 10 mm

- Supplied with calibration certificate

- Brinell microscope, test blocks, set of weights

- Eyepiece with built-in scale

- Manual mechanical

- Dead Weight lever system

- Powder Coated, Anti-Corrosive

- Overload protection

brinell hardness testing machine Product Specifications

- 8 to 650 HBW

- 1% of reading

- Up to 220 mm

- Maximum test load 3000 kgf

- 0.1 HBW

- Industrial / Laboratory

- Brinell Hardness Testing Machine

- Height up to 220 mm

- Single at a time

- Manual / Semi-Automatic

- 10C to 40C

- 220-240 V AC

- 220-240 V AC, 50 Hz

- Immediate (manual reading)

- Flexible / Adjustable

- NA / Optional USB

- Standard 10 mm ball (indentor)

- 220 mm

- Bench-mounted

- Approx. 450 kg

- Up to 85% RH (non-condensing)

- 50 Hz

- Robust construction, Stable loading, Precision Measurement

- 8-650 HBW

- Metals and Alloys Hardness Testing

- Manual / Semi-Automatic

- 130 mm

- Dial Gauge / Optional Digital Display

- Brinell Hardness number (HB)

- Indoor, Dust-free

- Hardened Steel Ball 10 mm

- Supplied with calibration certificate

- Brinell microscope, test blocks, set of weights

- Eyepiece with built-in scale

- Manual mechanical

- Dead Weight lever system

- Powder Coated, Anti-Corrosive

- Overload protection

brinell hardness testing machine Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 5 Days

- All India

Product Description

| Type | DR-C203 |

| Measuring range | 20-88HRA, 20-100HRB, 20-70HRC |

| Test force | 588, 980, 1471N (60, 100, 150kgf) |

| Max. height of test piece | 165mm |

| Distance from indenter to outer wall | 160mm |

| Rockwell scaleplate | HRA,HRB,HRC,HRD,HRE,HRF,HRG,HRH,HRK |

| Hardness measuring range | HRA:20-88 HRB:20-100 HRC:20-70 HRD:40-77 |

| HRF:60-100 HRG:30-94 HRH:80-100 HRK:40-100 | |

| Initial force | 1000kgf (98.07N) |

| Dimensions | 466 x 238 x630mm |

| Weight | Approx. 70kg |

| Accessories | Large flat anvil: 1 pc. Small flat anvil: 1 pc. V-notch anvil: 1 pc. Diamond cone indenter: 1 pc. 1/16" steel ball indenter: 1 pc. Rockwell standardized block: 5pcs. |

The Brinell hardness tester is a device used to measure the hardness of materials. Based on the principle of Brinell hardness testing, the hardness value of materials is determined by the indentation method. It is widely used for hardness testing of materials such as metals, alloys, plastics, etc., and has the characteristics of wide testing range, high accuracy, and easy operation.

Working principle of Brinell hardness tester

Testing principle

Use a hard alloy ball (or steel ball) of a certain diameter as the indenter, press it into the surface of the tested material under the specified test force, maintain it for a certain period of time, and then remove the test force.

Measure the diameter of the indentation and calculate the Brinell hardness value (HB) using the formula.

Calculation formula

HB=

D(D

D

two

d

two

)

2F

Among them:

F Test force (unit: N or kgf)

D Pressure head diameter (unit: mm

d Indentation diameter (unit: mm

Product Features

High precision measurement

Adopting high-precision sensors and measurement systems to ensure the accuracy of hardness values.

Multifunctionality

Can test various materials, such as metals, alloys, plastics, etc.

Easy to operate

Equipped with touch screen or computer control system, user-friendly interface, supports data storage and printing.

Wide range of experimental force

Different test forces (such as 9.807N, 49.03N, 980.7N, etc.) can be selected based on the hardness of the material.

Automatic loading and unloading

Using electric or hydraulic loading systems to achieve automatic loading and unloading of test force.

Safe and reliable

Equipped with overload protection, emergency stop and other safety devices to ensure safe operation.

Common problems and solutions

Unclear indentation

Check if the test force is sufficient, if the indenter is worn, and if the material surface is flat.

Large deviation in hardness value

Check whether the diameter of the indenter and the test force are accurate, and whether the measurement system is calibrated.

The device cannot load the test force

Check if the power supply, hydraulic system, or motor is working properly.

Measurement system malfunction

Restart the device, check if the sensors and control system are functioning properly, and contact the manufacturer for repairs if necessary.

Installation Guide

Venue selection

Choose a stable, level, and vibration free workbench or ground.

Power requirements

Ensure that the power supply voltage and frequency meet the equipment requirements, equipped with independent power switches and grounding devices.

Installation steps

Handling: Use a forklift or crane to transport the equipment to the designated location, taking care to avoid collisions.

Fixed: Adjust the equipment feet to ensure that the equipment is level and stable.

Connect power supply: Connect the power cord according to the instructions to ensure correct wiring.

Check the pressure head: Install the pressure head and ensure that it is securely installed.

Debugging and Calibration

After booting up, follow the instructions to set parameters and debug the system.

Use standard hardness blocks to calibrate equipment and ensure measurement accuracy.

Operation training

Train operators to ensure they are familiar with equipment operation, maintenance, and troubleshooting methods.

Precautions

Ensure that the material surface is clean and flat before testing.

Select the appropriate test force and indenter diameter based on the hardness of the material.

Regularly maintain and upkeep the equipment to ensure its long-term stable operation.

If there are any problems that cannot be solved, please contact the manufacturer's technical support in a timely manner.

The Brinell hardness tester is an important tool for material hardness testing, and correct installation and operation are key to obtaining accurate test results.

Precision Hardness Testing for Metals & Alloys

Equipped with a 10 mm hardened steel ball indenter and dead weight lever system, this machine delivers consistently reliable Brinell Hardness Number (HB) readings. Its robust build and stable loading mechanism ensure repeatable results across a broad measurement range, making it a trusted solution in both quality control and research settings.

Built for Operator Safety and Longevity

Safety is paramount: the built-in overload protection and anti-corrosive powder-coated finish combine to protect both user and instrument. With supplied calibration certificate and quality-assured accessories, the machine promises years of accurate service, even in high-usage environments.

FAQ's of brinell hardness testing machine:

Q: How does the Brinell Hardness Testing Machine operate?

A: The machine utilizes a dead weight lever system to apply force through a 10 mm hardened steel ball indenter onto your metal or alloy sample. The indentation is then measured using the built-in eyepiece scale, providing immediate hardness readings.Q: What benefits does the overload protection feature offer?

A: Overload protection safeguards both the operator and the equipment by preventing damage from excessive force, enhancing operational safety and extending the machine's lifespan.Q: When should I calibrate the Brinell Hardness Testing Machine?

A: Calibration is essential before initial use and at regularly scheduled intervals as specified in your quality assurance guidelines. The machine is delivered with a calibration certificate, ensuring immediate compliance with industrial standards.Q: Where can this testing machine be used effectively?

A: Designed for indoor, dust-free conditions, the machine is suited for laboratories and industrial settings where metals and alloys require reliable hardness testing. Its powder-coated, anti-corrosive finish makes it ideal for demanding environments.Q: What is the process for performing a hardness test?

A: Position your specimen (up to 220 mm high) securely under the indenter. Apply the load using the dead weight lever system. After holding for the prescribed duration, use the eyepiece or optional digital display to read the indentation and determine the Brinell Hardness Number (HB).Q: How is the machine supplied and what accessories are included?

A: The machine comes with a Brinell microscope, certified test blocks, a set of weights, and a calibration certificate, providing all essentials for immediate and accurate testing upon installation.Q: What are the main advantages of using this Brinell Hardness Testing Machine?

A: This equipment offers robust, precision-driven measurement, flexible test speed, easy operation, and reliable safety functions. Its versatility for both manual and semi-automatic modes makes it ideal for varied hardness testing applications in industry and laboratories.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese