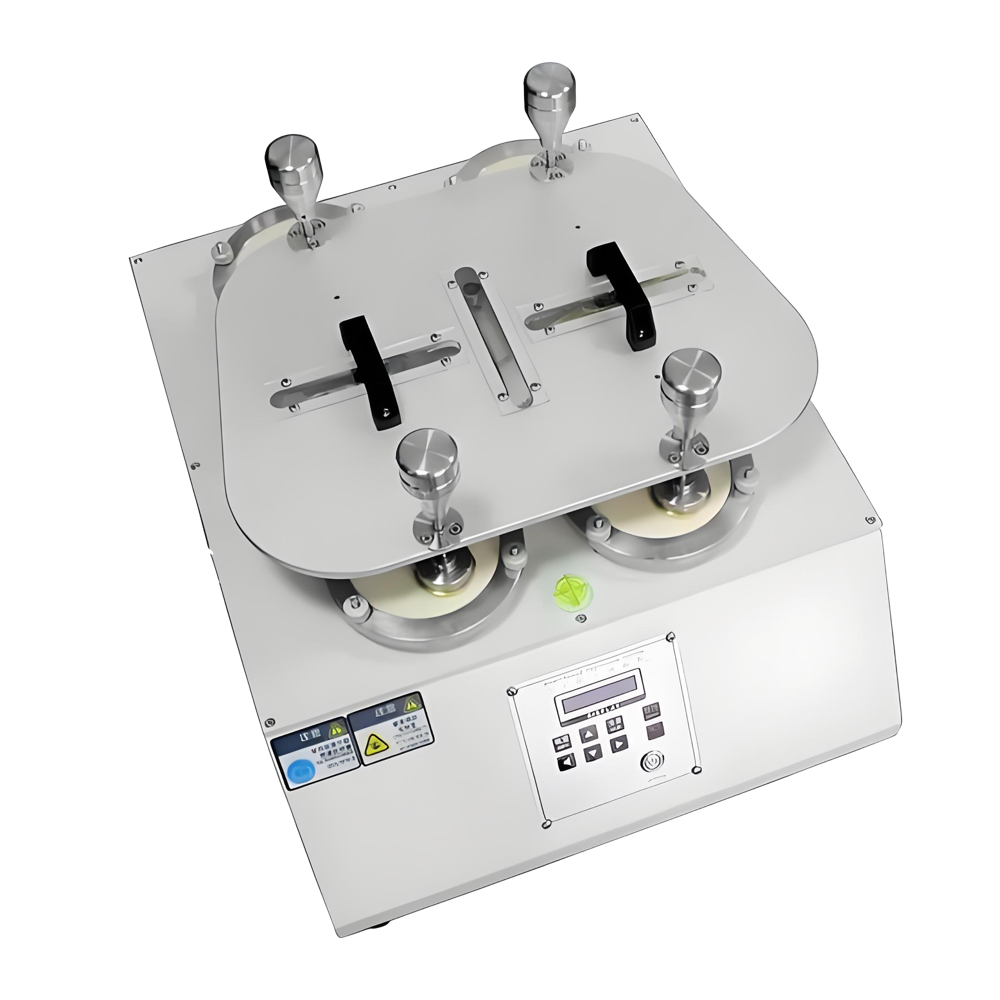

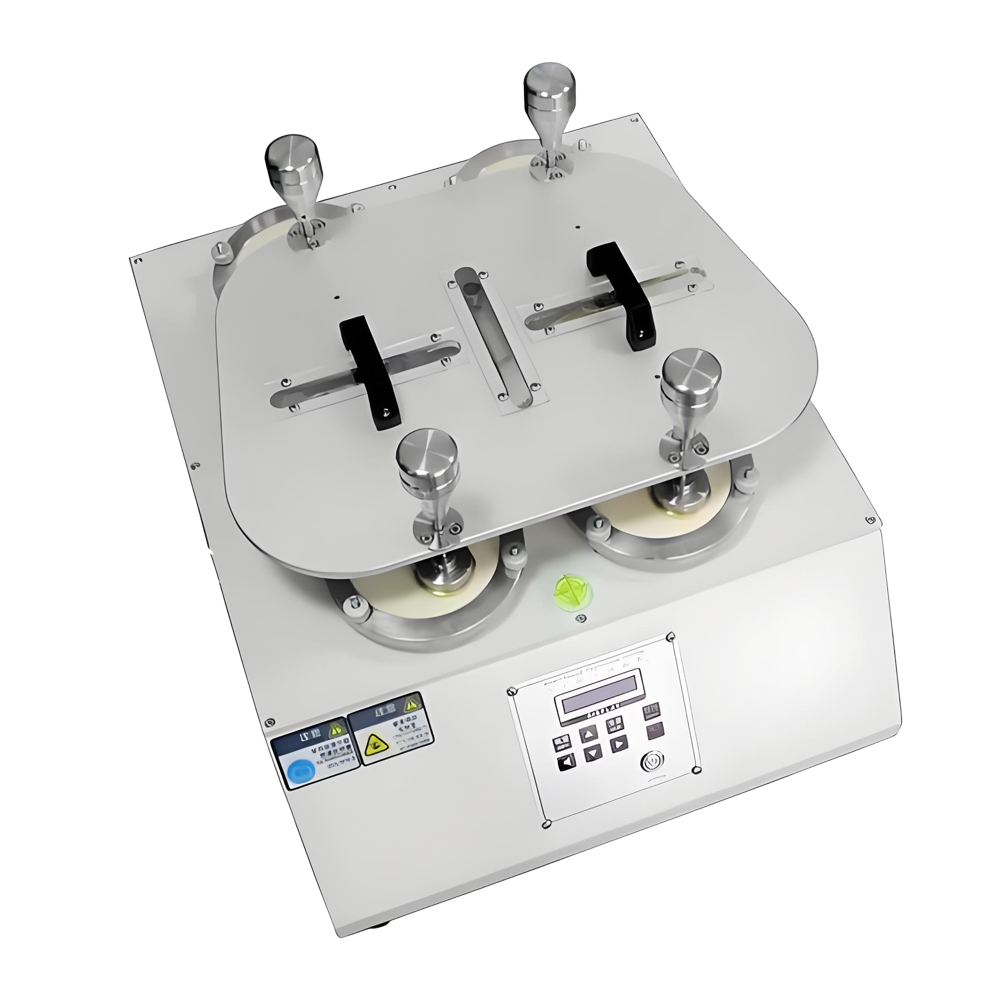

martindale pilling tester

136005.0 INR/Unit

Product Details:

- Features Programmable counter, easy specimen loading, safety cover, robust construction

- Interface Type Push-button control

- Application Determination of pilling and abrasion resistance on fabrics

- Equipment Type Textile testing instrument

- Port Size Standard specimen holder fitting

- Temperature Room temperature (20C recommended)

- Automation Grade Semi-automatic

- Click to view more

X

martindale pilling tester Price And Quantity

- 1 Unit

- 136005.0 INR/Unit

- Approx. 900 mm x 500 mm x 400 mm

- Powder-coated metal body for durability

- Quick release system

- Transparent protective cover with interlock

- Low noise, maintenance-free motor

- Complete with all specimen holders, weights, and abrasive fabrics

martindale pilling tester Product Specifications

- LCD digital display

- Approx. 400 mm

- Standard laboratory conditions (65% RH recommended)

- 099999 cycles

- Semi-automatic

- 099999 cycles

- 90 kg

- Pilling and abrasion resistance testing

- 220V AC, 50Hz

- Digital control panel

- Push-button control

- Programmable counter, easy specimen loading, safety cover, robust construction

- Room temperature (20C recommended)

- Determination of pilling and abrasion resistance on fabrics

- Textile testing instrument

- Standard specimen holder fitting

- Benchtop

- 1 cycle

- 220V

- 1 cycle

- 47.5 1 r/min

- Multiple simultaneous test positions

- 38 mm diameter (standard), larger options available

- Immediate (for cycle count and alarm)

- 4, 6, or 8 test positions (per configuration)

- N/A (not applicable)

- 50 Hz

- 60.5 mm & 24 mm

- Diameter of specimen holder: 38 mm

- Approx. 900 mm x 500 mm x 400 mm

- Powder-coated metal body for durability

- Quick release system

- Transparent protective cover with interlock

- Low noise, maintenance-free motor

- Complete with all specimen holders, weights, and abrasive fabrics

martindale pilling tester Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 6 Days

- All India

Product Description

martindale pilling test Technical parameters:

| Model | DR-J803-1 Martindale Abrasion Tester |

| Station number | 4 station, 6 station , 8 station , 9 station (custom) |

| Count display | a.Estimated counting:0~999999 times |

| b. Total counting:0~999999 times | |

| Maximum dynamic range | 240.5mm ,60.50.5mm |

| Weight of pressure thing | a.Gripper:2001g |

| b. Cloth samples hammer:3952g | |

| c. Furniture accessories sample hammer:5942g | |

| d. Stainless steel butterfly piece:2601g | |

| Effective friction diameter of grinding block | A type: 200g (1.96N) friction head 28.8-0.084mm |

| B type: 155g (1.52N) friction head 90-0.10mm | |

| The relative velocity of Gripper and the grinding station | 50-2r/min |

| Weight of pressure hammer | 238510g |

| Dimensions | 885mm600mm410mm(LWH) |

| Weight | 150kg |

| Power | Ac220V,50Hz |

The Martindale Pilling Tester is a device specifically designed to test the pilling and pilling phenomena of textile materials and fabrics under friction. It evaluates the fuzzing and pilling performance of materials by simulating the friction environment of fabrics in actual use, in order to help manufacturers understand and improve the quality and durability of fabrics.

Main functions:

one

Test the fuzzing and pilling properties of the material:

This tester simulates the friction generated by materials during wearing, use, or cleaning, and evaluates whether the surface of the material is prone to fuzzing or pilling under repeated friction. Friction during the testing process usually forms small spherical particles on the surface of the fabric (i.e. pilling phenomenon), while fuzzing refers to the looseness and exposure of fibers.

two

Standardized testing:

The Martindale pilling tester is tested according to international standards such as ISO 12945 and ASTM D3512 to ensure the scientific and reliable nature of the test results. The test results can help determine the durability, appearance retention, and service life of the fabric.

three

Simulate actual usage environment:

Simulate friction and wear under different usage conditions through repeated friction, and detect pilling and pilling of fabrics. The test mainly focuses on the durability of textiles such as fabrics, carpets, clothing, and sofa fabrics.

Testing process:

one

Prepare samples:

Prepare fabric samples of a certain size according to the testing requirements. Samples are usually cut to standard sizes and fixed on the sample rack of the testing equipment.

two

Set parameters:

Set parameters such as friction frequency, friction load, and friction speed according to experimental standards. Different standards have different requirements for these parameters, and the equipment provides corresponding adjustment functions.

three

Conduct testing:

After the test begins, the sample undergoes a certain number of frictions on the friction disc in the equipment, causing surface wear and simulating the wear situation in daily use.

four

Observe and analyze the results:

After the test is completed, check whether there are obvious pilling and fuzzing phenomena on the surface of the sample. Usually, it is necessary to observe the surface of the sample under a microscope and analyze the degree and shape of pilling.

five

Rating:

Based on the pilling and fuzzing situation, score the sample according to the testing standards. The scoring criteria usually include the number, size, distribution, and severity of pilling.

Main components:

one

Friction discs and friction blocks:

A friction disc is a component that comes into contact with the surface of a sample and undergoes repeated friction. Friction blocks are usually made of materials with a certain hardness to simulate the friction between the material and the fabric surface.

two

Loading device:

Used to adjust the frictional load applied to the sample. The size of the load affects the strength of friction, which in turn affects the degree of pilling and pilling.

three

Sample rack:

Used to fix the fabric sample to be tested, ensuring that the sample remains in a fixed position during the testing process and avoiding any deviation that may affect the test results.

four

Counter and data recording:

The counter is used to record the number of frictions and testing time, and the equipment simulates the performance of the material in long-term use based on the number of frictions.

Testing standards:

one

ISO 12945 International standards applicable to the testing of pilling and fuzzing performance of textiles. It specifies the specific methods and parameter requirements for using the Martindale pilling tester.

two

ASTM D3512 The American standard also applies to the evaluation of pilling performance of textiles. It specifies the handling method and scoring criteria for samples during the testing process.

three

BS EN 12945 The British standard, similar to ISO 12945, is suitable for testing the pilling of fabrics and materials.

Efficient and Reliable Pilling Testing

The Martindale Pilling Tester streamlines textile testing by enabling simultaneous multi-specimen analysis using its quick release holder system. Digital control increases precision, while a transparent protective cover with safety interlock safeguards users during operation, ensuring a secure workspace for textile laboratories.

User-Friendly and Durable Construction

Built with a powder-coated metal body and weighing 90 kg, this machine is engineered for lasting durability. The intuitive digital panel and easy specimen loading reduce setup time, making it accessible for both novice and experienced laboratory technicians.

FAQ's of martindale pilling tester:

Q: How do I load and secure specimens in the Martindale Pilling Tester?

A: The tester utilizes a quick release specimen holder system, allowing operators to swiftly load and secure fabric samples. Simply fit the specimen into the 38 mm diameter holder, lock it in place, and close the transparent safety cover before initiating the test cycle.Q: What safety features does this machine offer during operation?

A: Safety is ensured by a transparent protective cover equipped with an interlock mechanism. This prevents the machine from operating when the cover is open, reducing the risk of accidental contact during testing.Q: When is this instrument most beneficial for textile laboratories?

A: The tester is ideal for routine quality control or product development, where accurate and repeatable assessment of fabric pilling and abrasion resistance is essential. Its programmable counter and simultaneous testing capacity enhance laboratory efficiency.Q: What processes can the Martindale Pilling Tester perform, and on which materials?

A: This equipment is designed to evaluate the pilling and abrasion resistance of a wide range of fabrics using abrasive cycles. It accommodates various fabric types and sizes, with standard specimen diameters of 38 mm and options for larger samples.Q: Where should the Martindale Pilling Tester be installed?

A: Install the unit on a benchtop within a laboratory environment, maintaining standard conditions (65% RH, 20C room temperature) to ensure precise and consistent test results as per international testing standards.Q: How does the digital control panel and LCD display improve usage?

A: The digital panel features push-button controls and a bright LCD display, providing immediate feedback on test cycles, programmable counter settings, and cycle count accuracy to 1 cycle, simplifying operation and monitoring.Q: What are the main benefits of using this tester?

A: Key benefits include reduced operator workload through simultaneous multi-sample testing, increased data reliability using precise digital controls, enhanced durability with its robust construction, and comprehensive safety for users.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese