UL-Certified Battery Drop Test Machine

148005.0 INR/Unit

Product Details:

- Response Time <0.5 s

- Frequency 50 Hz

- Operating Voltage AC 220V

- Max Height 1000 mm

- Humidity 20%~80% RH

- Gas Pressure 0.6~0.8 MPa (Compressed Air)

- Measuring Range Drop heights up to 1000 mm

- Click to view more

X

UL-Certified Battery Drop Test Machine Price And Quantity

- 148005.0 INR/Unit

- 1 Unit

- Emergency Stop, Interlock Chamber Door

- UL 1642, IEC 62133

- Fully Enclosed Safety Chamber

- High-Strength Steel

- <70 dB

- Powder Coated

- USB Exportable, On-board Memory

UL-Certified Battery Drop Test Machine Product Specifications

- Coin to Large Size Batteries

- 1 mm

- Battery Safety and Compliance Testing

- 5C - 40C

- Single Specimen Per Test

- Semi-Automatic

- DN15 (1/2 inch)

- 300 mm

- Drop Plate Hardness HRC45

- 1 mm

- RS232, USB

- Approx. 85 kg

- Up to 10 kg specimen

- UL Compliant, Programmable Height, Safety Enclosure, Over-pressure Protection

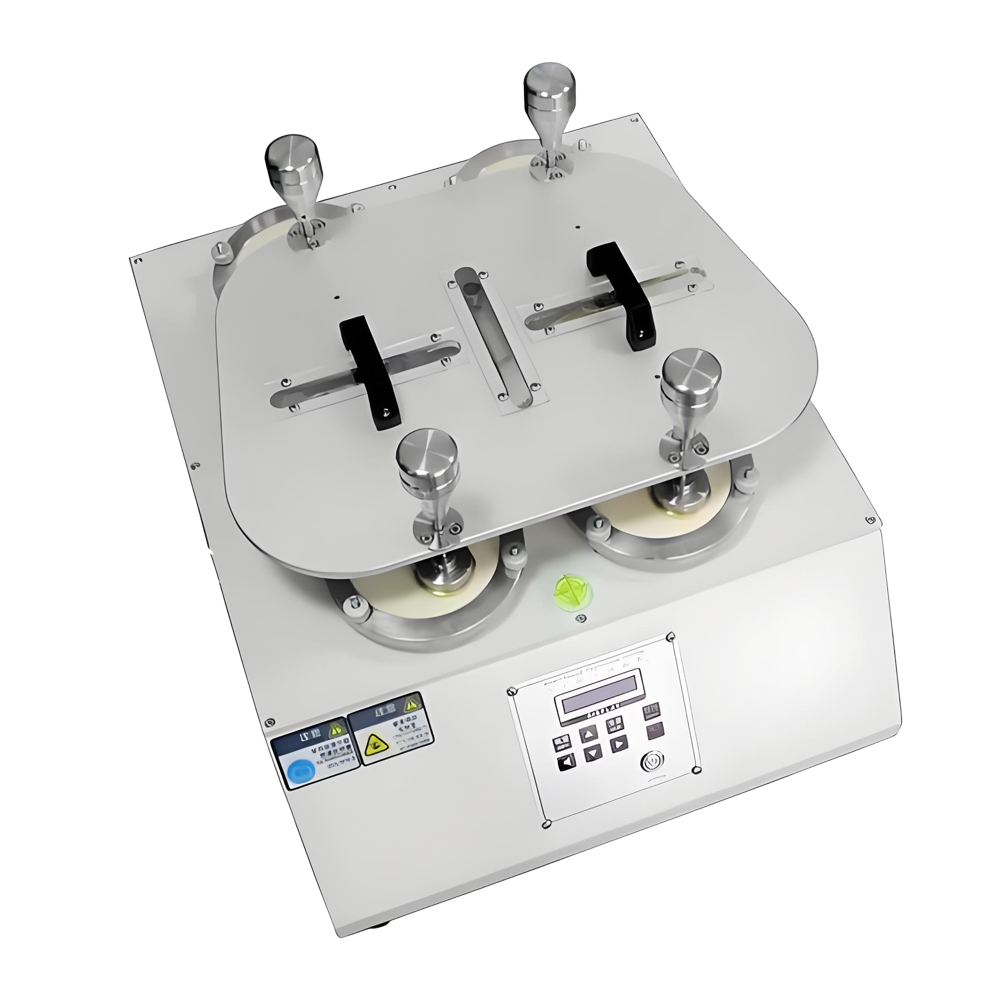

- Drop Test Machine

- Battery Mechanical Integrity Drop Test

- Digital LCD Display

- AC 220V10%, 50Hz

- Max. 200 mm x 200 mm

- 400 mm

- <0.5 s

- AC 220V

- Automatic / Manual Switchable

- 50 Hz

- 0.5~1.5 m/s (adjustable)

- 20%~80% RH

- 1000 mm

- 0.6~0.8 MPa (Compressed Air)

- Drop heights up to 1000 mm

- Floor Standing

- Emergency Stop, Interlock Chamber Door

- UL 1642, IEC 62133

- Fully Enclosed Safety Chamber

- High-Strength Steel

- <70 dB

- Powder Coated

- USB Exportable, On-board Memory

UL-Certified Battery Drop Test Machine Trade Information

- Cash in Advance (CID)

- 90 Unit Per Month

- 5 Days

- All India

Product Description

Specifications:

| Item | Description |

| Drop height | 400-1500mm (can be customized) |

| Display method | Digital display |

| Max. weight of sample | 60kg (can be customized) |

| Max. size of sample | (L*W*H) 800*800*800mm |

| Drop panel area | 1400x1200mm (material is Solid steel plate) |

| Control box dimension | (L*W*H) 350*350*1100mm |

| Deviation of drop horizon | Less than 1 |

| Machine size | (L*W*H)1400*1200*2200mm |

In the ever-evolving landscape of battery technology, ensuring the safety and reliability of batteries is paramount. The UL-Certified Battery Drop Test Machine is not just a testing equipment; its a cornerstone of quality assurance, designed to meet and exceed the rigorous safety standards established by Underwriters Laboratories (UL). This advanced machine is meticulously engineered to simulate a wide range of drop scenarios, providing comprehensive testing solutions for batteries of various types and sizes.

Key Features and Benefits:

-

UL Certification: Our Battery Drop Test Machine proudly carries the UL certification, a mark of excellence and trust in the industry. This certification ensures that the machine adheres to the highest safety and performance standards, giving you confidence in the testing results.

-

Precision Engineering: Crafted with precision, this drop test machine offers adjustable drop heights from 1 to 200cm, allowing for precise simulation of different impact forces. The robust construction and advanced sensors ensure accurate and consistent testing results, every time.

-

Versatile Testing Capabilities: Whether youre testing lithium-ion, lead-acid, or nickel-metal hydride batteries, our UL-Certified Battery Drop Test Machine is designed to handle a variety of battery types. Its versatile testing capabilities make it an indispensable tool for manufacturers, researchers, and quality control professionals.

-

Data-Driven Insights: Equipped with state-of-the-art data acquisition systems, this machine provides detailed insights into the performance of batteries under drop conditions. The comprehensive data analysis helps in identifying potential weaknesses and optimizing battery design for enhanced safety and reliability.

-

User-Friendly Interface: The machine features an intuitive user interface, making it easy to set up and operate. The user-friendly design minimizes the learning curve, allowing operators to conduct tests efficiently and effectively.

-

Compliance with International Standards: Beyond UL certification, our Battery Drop Test Machine complies with various international standards, ensuring that your products meet global safety and quality requirements.

Why Choose Our UL-Certified Battery Drop Test Machine?

- Enhanced Safety: By incorporating our drop test machine into your testing protocol, you significantly enhance the safety of your battery products, protecting both consumers and your brand reputation.

- Reliability Guaranteed: The rigorous testing capabilities of our machine ensure that only the most reliable batteries make it to the market, reducing the risk of failures and recalls.

- Competitive Advantage: With superior testing capabilities, you gain a competitive edge in the market, offering products that are trusted for their safety and performance.

- Cost-Effective Solution: Investing in our UL-Certified Battery Drop Test Machine is a cost-effective way to ensure long-term quality and compliance, saving you money on potential liabilities and recalls.

Advanced Safety and Compliance

Our battery drop test machine meets UL 1642 and IEC 62133 standards, providing a safe, enclosed chamber and robust emergency stop features. With a durable powder-coated finish, safety interlocks, and drop plate hardness HRC45, it minimizes risk during rigorous testing, ensuring secure and reliable results every time.

Precise and Versatile Testing

This equipment supports programmable drop heights from 0 to 1000 mm, accommodating a wide range of battery sizes up to 200 mm x 200 mm and 10 kg. The digital LCD display ensures precise control and real-time monitoring, while data logging features allow seamless analysis and compliance documentation.

User-Friendly and Efficient Operation

The drop test machine combines automatic and manual control modes for flexible operation. Quick-response safety mechanisms, adjustable test speed (0.5~1.5 m/s), and a semi-automatic workflow help to optimize testing throughput while keeping operator intervention minimal. USB and RS232 interfaces make data export and system integration straightforward.

FAQ's of UL-Certified Battery Drop Test Machine:

Q: How does the UL-Certified Battery Drop Test Machine ensure operator safety during testing?

A: Operator safety is maximized through a fully enclosed safety chamber, emergency stop button, and interlock-protected chamber doors. The drop chamber employs over-pressure protection and robust construction, significantly reducing exposure to hazards during battery drop tests.Q: What kinds of batteries can be tested with this machine, and what are the specimen size limitations?

A: This machine is designed for mechanical integrity drop tests on batteries ranging from coin cells to large-size batteries. It can accommodate specimens up to 200 mm x 200 mm and a maximum weight of 10 kg, ensuring versatility for various battery formats.Q: When should I use the automatic versus manual control mode during a test?

A: Automatic mode is ideal for standardized, repeatable testing and batch operations, while manual mode provides flexibility for special test conditions or when greater operator control is necessary. Users can switch modes based on testing requirements and procedural needs.Q: Where is the data recorded during tests, and how can I export or review test results?

A: Test data is automatically logged onto on-board memory, with options for USB export and RS232 connectivity. Users can review, transfer, and analyze test results conveniently, supporting efficient reporting and traceability.Q: What is the process for conducting a drop test on a battery using this machine?

A: First, secure the specimen within the chamber and set the desired drop height (up to 1000 mm). Choose control mode (automatic or manual), adjust test speed as necessary, and initiate the drop. After the test, data and digital readouts are available for evaluation and compliance documentation.Q: How does this machine meet UL 1642 and IEC 62133 compliance standards?

A: The equipment is constructed and calibrated to directly satisfy the requirements set by UL 1642 and IEC 62133, including precise drop height accuracy (1 mm), automated safety features, and robust data logging. This ensures that your battery testing processes are audit-ready and industry compliant.Q: What are the benefits of using a fully enclosed and low-noise (<70 dB) battery drop test chamber?

A: A fully enclosed chamber minimizes the risk of debris and chemical exposure during testing, while low noise levels (<70 dB) contribute to a safer, more comfortable laboratory environment, making extended testing periods less disruptive.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese