Button battery short circuit testing equipment

183005.0 INR/Unit

Product Details:

- Number of Specimens 1 specimen per batch

- Power Supply AC 220V, 50Hz

- Display Type Digital LCD

- Application Battery safety and reliability assessment

- Temperature Room temperature (10°C~35°C)

- Features Over-current protection, clear enclosure, adjustable clamp

- Specimen Size Compatible with various button battery sizes

- Click to view more

X

Button battery short circuit testing equipment Price And Quantity

- 1 Unit

- 183005.0 INR/Unit

- IEC 62133, UN38.3 battery test standards

- Programmable, 0~999 seconds

- IP20

- Internal factory calibration

- USB/RS232 to PC

- <50 dB(A)

- LED alarm for short circuit

- Automatic with safety cutoff relay

- Aluminum alloy frame with PC shield

- Clean laboratory, away from flammable gases

- Transparent enclosure for observation, over-current protection

Button battery short circuit testing equipment Product Specifications

- ~8 kg

- Digital electronic control

- Standard terminal clamps

- 220V AC

- ≤90% RH

- 0.01A

- <2 seconds

- Industrial Polycarbonate housing

- Semi-automatic

- ±1%

- No external gas required

- 180 mm

- Standard panel interface

- Button battery short circuit tester

- Lab and production testing

- 50 Hz

- Bench-top

- 0-10A

- 0-10A short circuit current

- Over-current protection, clear enclosure, adjustable clamp

- Room temperature (10°C~35°C)

- Battery safety and reliability assessment

- Single cell operation

- Adjustable based on specimen

- Compatible with various button battery sizes

- Digital LCD

- AC 220V, 50Hz

- 0-10 mm

- Steady short circuit simulation

- 1 specimen per batch

- IEC 62133, UN38.3 battery test standards

- Programmable, 0~999 seconds

- IP20

- Internal factory calibration

- USB/RS232 to PC

- <50 dB(A)

- LED alarm for short circuit

- Automatic with safety cutoff relay

- Aluminum alloy frame with PC shield

- Clean laboratory, away from flammable gases

- Transparent enclosure for observation, over-current protection

Button battery short circuit testing equipment Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 7 Days

- All India

Product Description

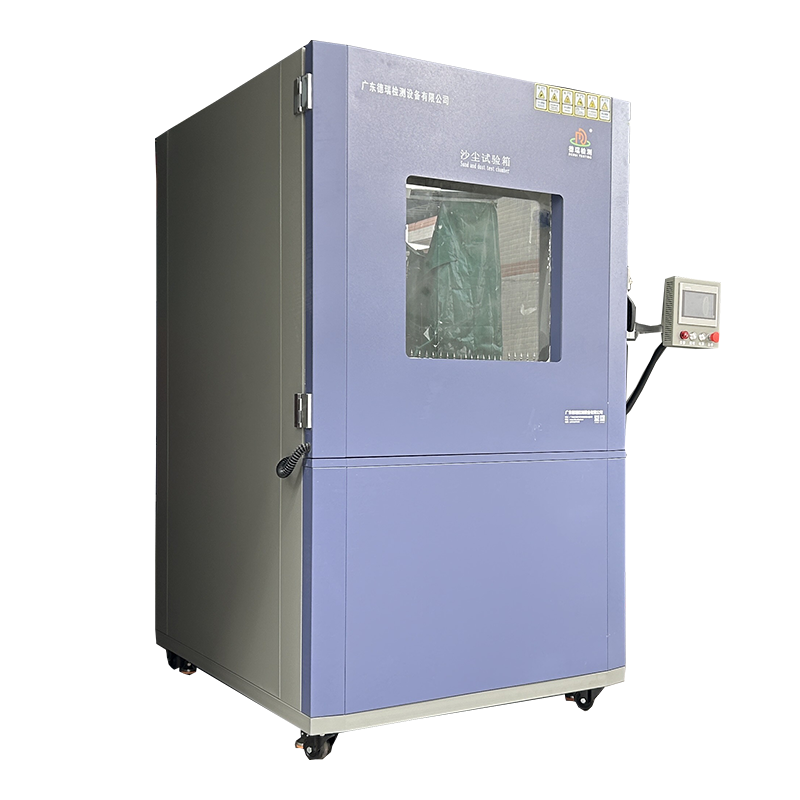

Button Cell Short Circuit Test Equipment Equipment Overview:

Coin cell short circuit test equipment is a precision test equipment specially designed to evaluate the safety performance, thermal runaway behavior and potential hazards of coin cell batteries (such as lithium manganese batteries, silver oxide batteries, zinc air batteries, etc.) under short circuit conditions. Since button batteries are usually used in small electronic devices, such as watches, hearing aids, calculators, etc., they may rapidly heat up under short-circuit conditions, leading to thermal runaway, fire or explosion. Therefore, this equipment evaluates the safety and stability of batteries under extreme conditions by simulating short-circuit failures that may occur in actual use to ensure their reliable application in small electronic devices.

2. Main Functions

- Short-circuit simulation: Create short-circuits inside or outside the battery by mechanical or electrochemical means to simulate short-circuit failures in actual use.

- Thermal runaway assessment: real-time monitoring of the temperature change of the battery during the short-circuit process, assessing its thermal runaway risk and thermal runaway behavior.

- Safety testing: Evaluate the safety performance of the battery under short-circuit conditions, including whether smoke, fire, explosion and other dangerous situations will occur.

- Data Acquisition and Analysis: Real-time acquisition of battery temperature, voltage, current and other data, and generation of detailed test reports to help analyze the thermal runaway characteristics and safety performance of the battery.

- Safety Protection: Equipped with multiple safety protection devices, such as explosion-proof box, fire extinguishing system and emergency stop device, to ensure the safety of the testing process.

- Miniature fixture design: Aiming at the small size of button batteries, special miniature fixtures are designed to ensure the accuracy and reliability of short-circuit testing.

| Model | DR-D201 |

| Inner box size | 500x500x500mm (width x depth x height); |

| Equipment dimensions | 700x800x1530mm (width x depth x height); |

| Internal material | SUS201 stainless steel plate, thickness 1.2mm, with Teflon affixed; |

| External material | 1.5mm thick cold-rolled steel plate with paint treatment; |

| Observation window | The size is 250x250mm two-layer tempered glass, the transparent window is equipped with stainless steel mesh; |

| Smoke outlet | 100mm in diameter, located at the back of the box; |

| Pressure relief port | The size of the opening is 200x200mm, located on the back side of the box. When the sample explodes, the pressure relief port will pop open to relieve the pressure; |

| Box door | The single door opens to the left, the box door is equipped with a safety limit switch, and the side is equipped with an explosion-proof chain. The device can be operated only when the box door is closed to ensure the safety of personnel; |

| Test hole | There are 2 test holes with a diameter of 50mm on the left side of the device, which are convenient for putting in the collection lines of temperature, voltage, current, etc.; |

| Lighting device | It is convenient to observe the state of the tested sample; |

| Temperature collection range | RT-1000; |

| Temperature acquisition channel | 1 channel; |

| Temperature display accuracy | 0.5; |

| Voltage acquisition range | 0-100V; |

| Voltage acquisition channel | 1 channel; |

| Voltage display accuracy | 0.5%; |

| Maximum short-circuit current | 1000A; |

| Current acquisition channel | 1 channel; |

| Current display accuracy | 0.5%; |

| The internal resistance of the device loop | 8020m; |

| Equipment movement | There are four universal casters at the bottom of the equipment, which can be moved freely; |

| Control method | PLC touch screen control; |

| Equipment weight | 85Kg |

| Power supply | AC220V;50Hz/60Hz |

Button battery short circuit testing equipment Frequently Asked Questions:

Q1: What is the maximum test current for coin cell short circuit test equipment?

A1: The maximum test current is 10A.

Q2: What are the short-circuit triggering methods?

A2: The short-circuit triggering methods include mechanical triggering and electrochemical triggering.

Q3: What are the safety measures for the equipment?

A3: The equipment is equipped with an explosion-proof box, fire extinguishing system and emergency stop device to ensure the safety of the testing process.

Q4: How to analyze the test results?

A4: By analyzing the temperature change, voltage and current data of the batteries, the risk and safety of thermal runaway is assessed and design and material improvements are made based on the results.

Q5: Is the equipment easy to operate?

A5: Yes, the equipment is equipped with a user-friendly interface with simple parameter setting and easy operation. Meanwhile, the fully automated operation reduces human intervention and improves test efficiency and repeatability of results.

Advanced Safety and Precision

The tester is housed in a strong aluminum alloy frame with a clear polycarbonate shield, ensuring both safety and unobstructed observation during testing. It includes an automatic safety cutoff relay, LED alarm indicators for short circuits, and over-current protection to minimize risks. This design provides reliable, repeatable measurements with fast response times, meeting stringent international standards.

User-Friendly Digital Control and Connectivity

Effortlessly operate the tester with its digital electronic control system, adjustable terminal clamps, and intuitive LCD display. Data transfer is efficient via USB or RS232 interfaces for streamlined report generation and comprehensive documentation. The semi-automatic nature and programmable timer (0-999 seconds) allow for flexible test sequences based on specific battery sizes and requirements.

Optimal for Laboratory and Production Use

Engineered for bench-top installation in clean laboratory settings, the tester operates quietly (<50 dB) and requires no external gas supply. Factory-calibrated for immediate use, it accommodates one specimen per batch and offers consistent, steady, short circuit simulations for rigorous battery safety validation. Its durable construction ensures long-term reliability, making it suitable for both R&D and production lines.

FAQ's of Button battery short circuit testing equipment:

Q: How does the button battery short circuit tester detect a short circuit and ensure operator safety?

A: The tester utilizes an automatic detection system paired with a safety cutoff relay, immediately ceasing operation upon detecting a short circuit. It also features over-current protection and a LED alarm to promptly alert users, while its transparent enclosure allows safe observation throughout the process.Q: What are the main steps involved in conducting a test with this equipment?

A: Simply place the button battery in the adjustable clamp, select your desired parameters via the digital control panel, and start the test. The programmable timer runs up to 999 seconds, and upon completion, data can be exported via USB or RS232. Results are displayed on the digital LCD in real-time.Q: When should this equipment be used during battery development or production?

A: This tester is ideal for both research and final production stages. It ensures each button battery meets mandatory safety standards (IEC 62133, UN38.3), identifying cells that might pose safety risks before they reach end-users.Q: Where is the optimal environment to operate this tester?

A: It should be used in a clean laboratory environment, away from flammable gases, with ambient temperatures between 10C and 35C and humidity not exceeding 90% RH. The bench-top mounting design makes it compatible with most lab setups.Q: What benefits does digital electronic control offer compared to manual testing methods?

A: Digital electronic control enhances accuracy and repeatability by automating crucial settings such as test duration and current limits. It minimizes human error, improves data consistency, and allows precise customization for different battery sizes or test criteria.Q: How is the equipment calibrated, and does it require frequent maintenance?

A: The tester is internally factory-calibrated for immediate accuracy upon installation. Minimal user maintenance is needed, beyond keeping the enclosure clean and ensuring the workspace meets safety requirements.Q: What types and sizes of button batteries are compatible with this tester?

A: The adjustable test width and standard terminal clamps make this equipment suitable for a wide range of button battery sizes, accommodating single-cell operation for diverse laboratory and production testing needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese