Cosmetic cardboard box compression test box

186005.0 INR/Unit

Product Details:

- Response Time <1 second

- Test Range 05000 N

- Temperature 10C35C

- Equipment Type Compression Test Box

- Max Height 600 mm

- Resolution 0.01 N

- Automation Grade Semi-automatic

- Click to view more

X

Cosmetic cardboard box compression test box Price And Quantity

- 1 Unit

- 186005.0 INR/Unit

- Automatic stop after fracture

- 900 mm × 700 mm

- Grey/Blue (standard)

- Stores up to 500 test results

- ISO 12048/GB T4857.4

- Over-travel and overload protection

- Windows OS compatible

- USB downloadable report

- Below 65 dB

- Precision steel

Cosmetic cardboard box compression test box Product Specifications

- Semi-automatic

- RS232/USB (optional)

- 50 Hz

- 0.01 N

- Compression Test Box

- 600 mm max

- 600 mm

- 05000 N

- Microcomputer control

- 10C35C

- Box compression strength test

- <1 second

- 10~300 mm/min adjustable

- 0.6 MPa (if pneumatic clamping is included)

- Digital LCD display

- 300 mm 300 mm (standard, customizable)

- Single specimen per test

- Standard 220 mm (customizable)

- Compression test for cosmetic cardboard boxes and packaging materials

- AC 220V 10%, 50 Hz

- 600 mm

- 3085% RH

- Table-top

- 0.5% of reading

- Automatic microcomputer data processing, Overload protection, Peak value hold

- 05000 N

- 50 kN

- Approx. 85 kg

- 220V

- Automatic stop after fracture

- 900 mm × 700 mm

- Grey/Blue (standard)

- Stores up to 500 test results

- ISO 12048/GB T4857.4

- Over-travel and overload protection

- Windows OS compatible

- USB downloadable report

- Below 65 dB

- Precision steel

Cosmetic cardboard box compression test box Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 5 Days

- All India

Product Description

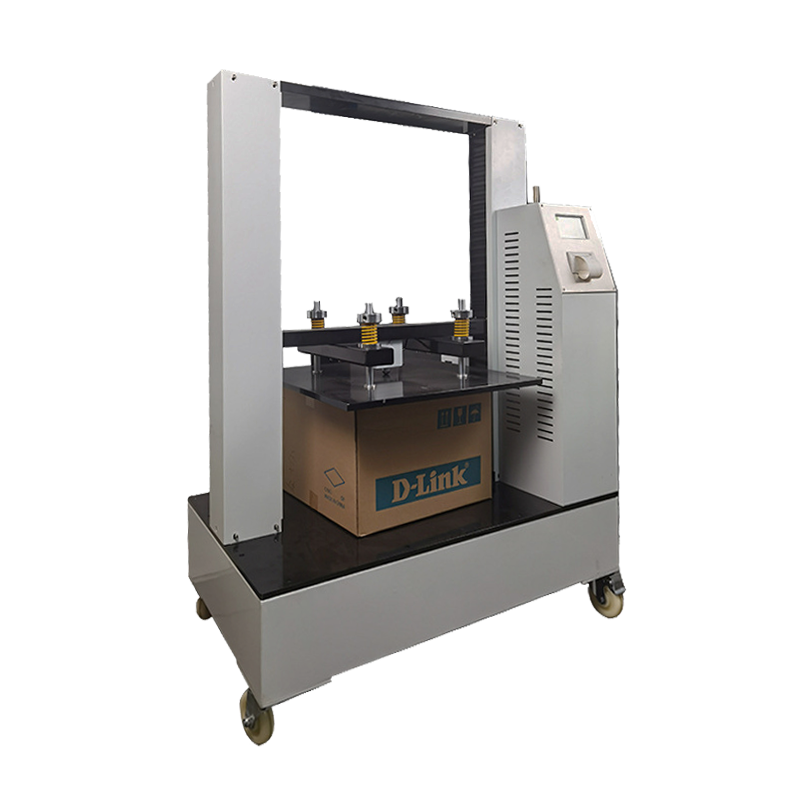

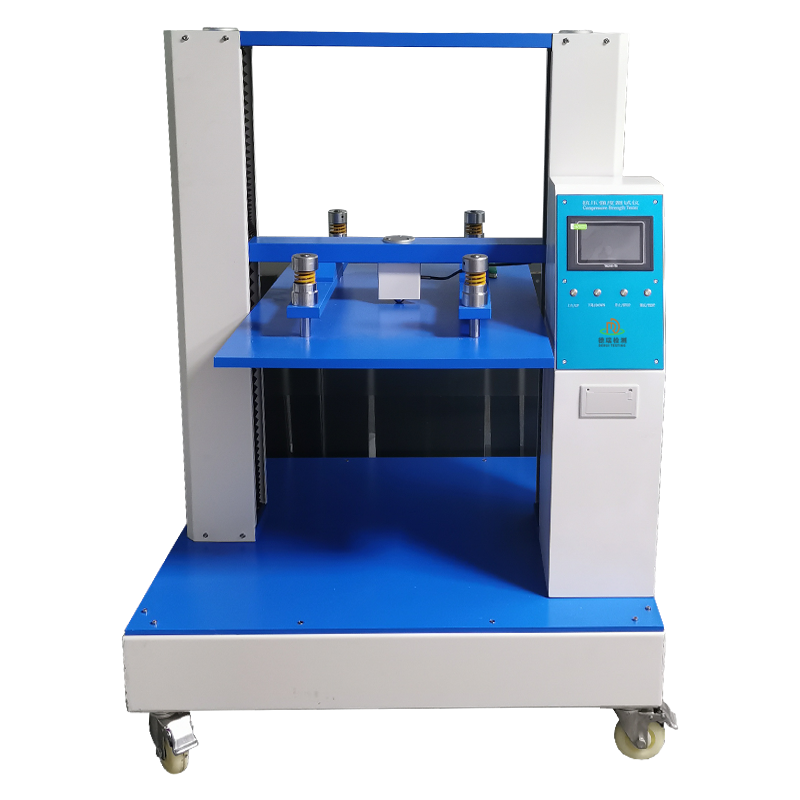

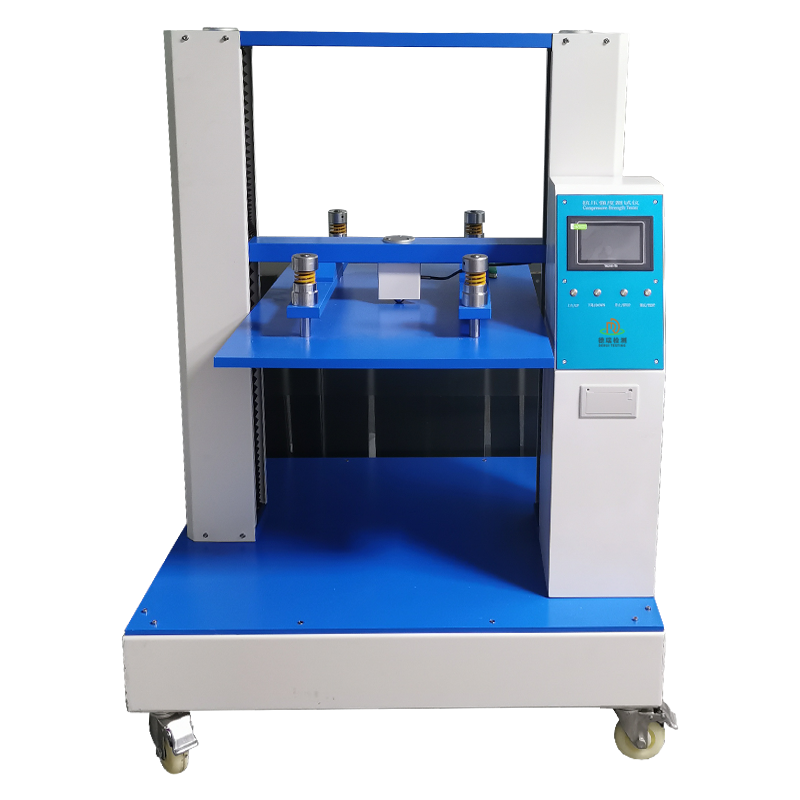

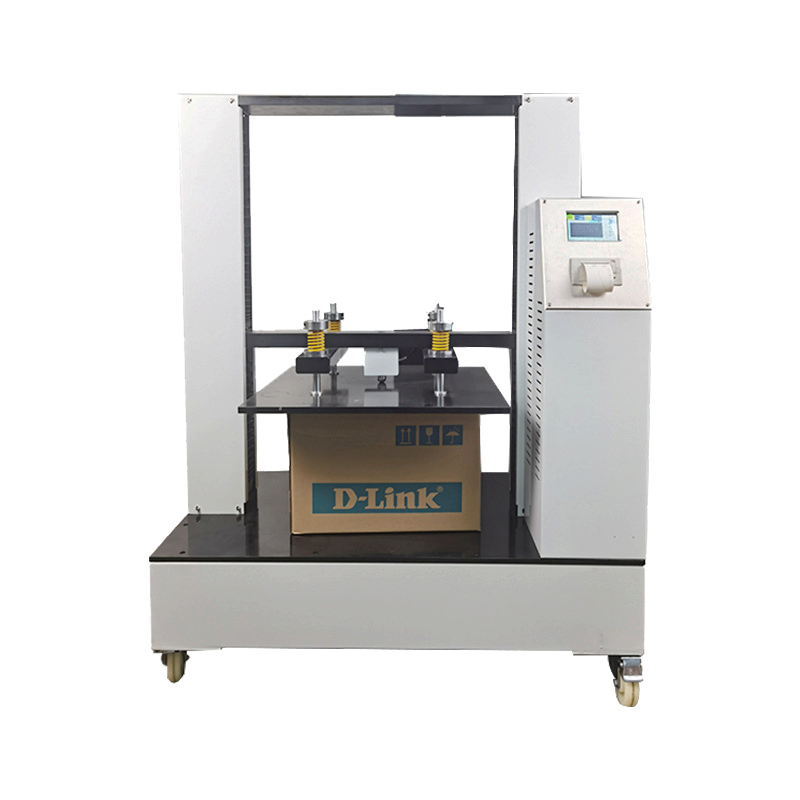

1. Equipment overview

The Cosmetic Carton Compression Chamber is a precision test equipment specially designed to evaluate the compressive strength, deformation performance and overall structural stability of cosmetic packaging cartons (e.g. corrugated cartons, color boxes, etc.) under static compression load. Since cosmetic packaging not only needs to have enough compressive capacity to withstand the pressure during transportation and stacking, but also needs to take into account the appearance of the protection and aesthetics, the tester has an important application in the cosmetic industry. The equipment ensures the safety and reliability of cosmetic packaging in various environments by simulating actual transportation, storage and stacking conditions.

2. Main Functions

Compressive strength test: Measure the maximum compressive capacity of carton in vertical direction according to ASTM D642 or other relevant standards to evaluate its load-bearing capacity during stacking, transportation and storage.

Deformation test: Record the deformation of carton under compression load, assess the degree of deformation and recovery ability, to ensure that the package can still maintain the appearance of integrity after withstanding the pressure.

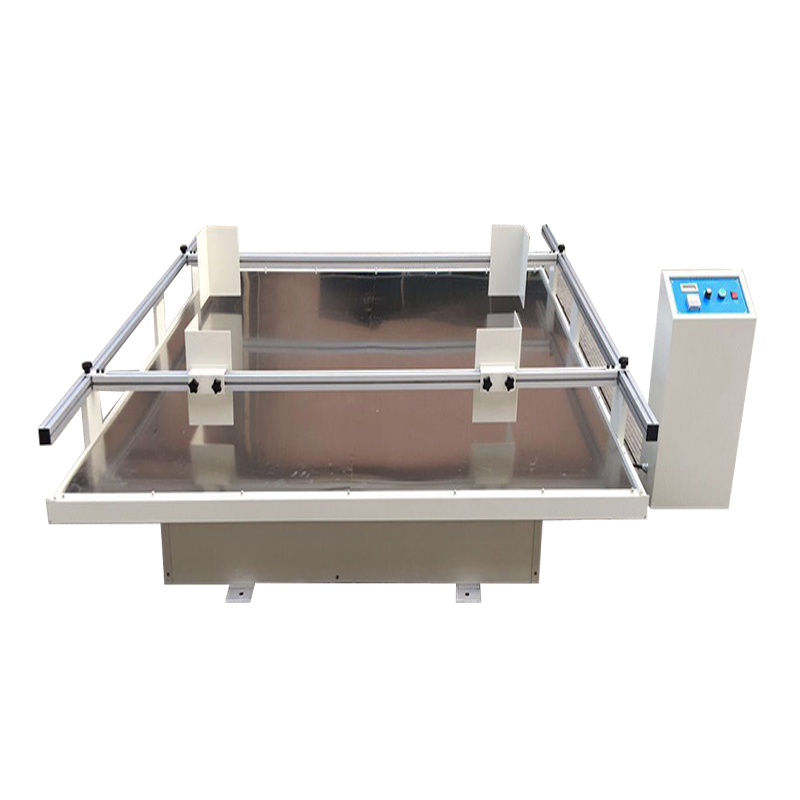

Stacking test: simulate the force of carton in actual stacking situation, assess its stacking stability and load-bearing capacity, ensure that no collapse or damage will occur when multi-layer stacking.

Cyclic compression testing: Multiple cyclic loading and unloading of cartons to assess their fatigue performance and durability, to ensure that the packaging can still maintain good compression resistance after multiple handling and transportation.

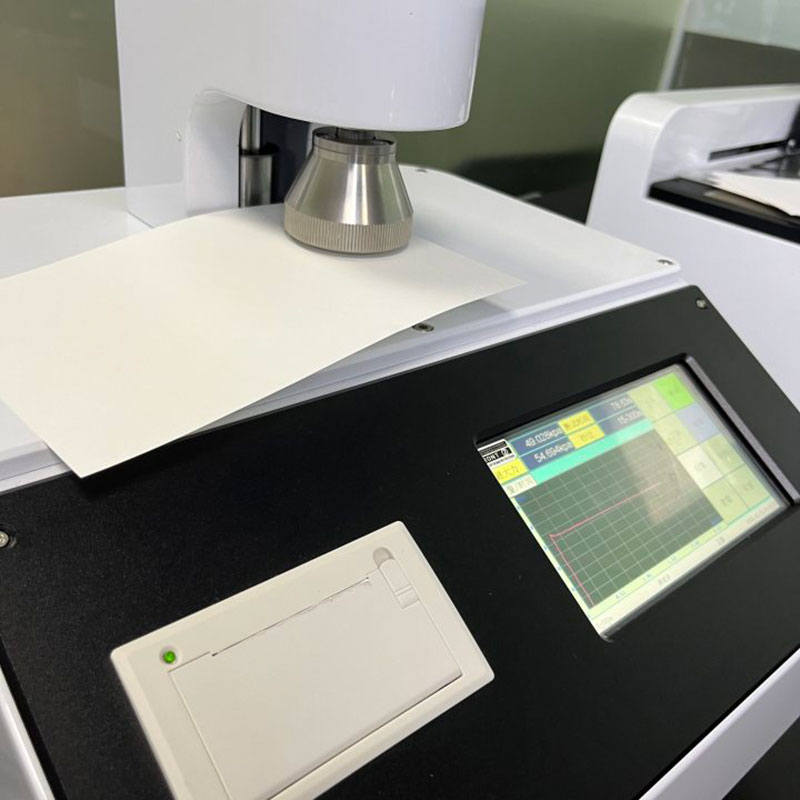

Data analysis and report generation: Built-in data analysis software can automatically generate detailed test reports, including maximum compressive strength, deformation, loading curve and other parameters, to help the quality control department carry out strict quality assessment.

3. Frequently Asked Questions

Q1: What is the test speed of Cosmetic Carton Compression Tester?

A1: The test speed is usually between 1-500mm/min, which can be adjusted according to different test requirements.

Q2: How does the equipment ensure the accuracy of the test results?

A2: The equipment adopts advanced control system and high-precision sensors, which can accurately control the parameters of compression speed, load and displacement, and ensures the safety and reliability of the testing process through multiple safety protection devices to ensure the accuracy of the test results.

Q3: Is the device easy to operate?

A3: Yes, the equipment is equipped with user-friendly interface, simple parameter setting and easy operation. Meanwhile, the fully automated operation reduces human intervention and improves test efficiency and repeatability of results.

Q4: What is included in the test report?

A4: The test report usually contains parameters such as maximum compressive strength, deformation, loading curve, etc. It also provides data analysis function, which is convenient for quality control personnel to carry out strict quality assessment.

Q5: Does the device support customized test parameters?

A5: Yes, the equipment supports the setting of different parameters such as compression speed, load range and displacement limit according to different materials and testing requirements to meet various testing requirements.

Regular maintenance is essential to ensure the long-term stability of the cosmetic carton compression tester and the accuracy of the test results. The following is a detailed description of equipment maintenance, including the need for maintenance, maintenance cycle and specific maintenance content.

1. The need for regular maintenance

- Ensure test accuracy: During the use of the equipment, the sensors, transmission components and control system may wear out or drift, regular maintenance can ensure the normal operation of these key components, thus ensuring test accuracy.

- Extend equipment life: Through regular inspection and maintenance, potential problems can be found and repaired in time, avoiding early scrapping due to excessive wear and tear or failure of the equipment, and prolonging the service life of the equipment.

- Ensure safety: Safety protection devices such as overload protection, limit protection, etc. need to be checked regularly to ensure that they can work properly in an emergency and safeguard the safety of operators.

- Compliance with quality management systems: Many quality management systems (e.g. ISO 9001) require periodic calibration and maintenance of test equipment to ensure the reliability and traceability of test results.

2. Maintenance intervals

Maintenance intervals can be determined by the frequency of use of the equipment, environmental conditions, and manufacturer's recommendations. The following is a common maintenance cycle recommendation:

-

Routine maintenance:

After each use: clean the equipment surfaces and platens to remove dust and residue.

Check the appearance: look for visible damage or abnormalities in the equipment.

-

Weekly maintenance:

Check sensors: make sure sensors are not loose or damaged.

Check drive components: Look for wear or foreign objects in drive components (e.g., screws, guide rails).

-

Monthly maintenance:

Calibration check: perform a simple calibration check to ensure the accuracy of parameters such as test force and displacement.

Lubrication maintenance: Lubricate transmission parts and movable joints to ensure smooth movement.

Safety device check: test the function of safety devices such as overload protection and limit protection.

-

Quarterly maintenance:

Comprehensive calibration: a comprehensive calibration is carried out by a professional to ensure that the equipment complies with the relevant standards.

Software update: Check and install the latest software updates to enhance equipment performance and functionality.

Internal Cleaning: Clean the interior of the equipment to remove accumulated dust and debris.

-

Annual maintenance:

Complete overhaul: perform a complete overhaul, including all mechanical and electronic components.

Replacement of wearing parts: Replace wearing parts such as seals, bearings, etc. according to wear and tear.

Performance test: Conduct a comprehensive performance test to ensure that the equipment functions properly.

3. Specific maintenance contents

- Maintenance

Cleaning:

Clean equipment surfaces, platens and control panels to remove dust, oil and residue.

Clean the interior of the equipment to remove dust and debris.

-

Lubrication:

Lubricate transmission parts (e.g., screws, guide rails) and movable joints to ensure smooth movement.

Check the oil level and quality of the lubricant and replace it if necessary.

-

Calibration:

Perform calibration of force, displacement and other parameters to ensure test accuracy.

Use standard weights or calibration instruments for calibration.

-

Check:

Check the connections of the transducers, connecting cables and control system to ensure that there is no looseness or damage.

Check that the safety protection devices (e.g. overload protection, limit protection) are working properly.

Check the appearance and structure of the device to ensure that there is no visible damage or deformation.

-

Software maintenance:

Check and install the latest software updates to enhance equipment performance and functionality.

Backup test data to ensure data security.

4. Maintenance personnel

- Routine maintenance: can be performed by the equipment operator, including cleaning, inspection and simple lubrication.

- Specialized Maintenance: Recommended to be performed by the equipment manufacturer or professional maintenance personnel, including calibration, complete overhaul and replacement of wearing parts.

5. Maintenance records

- Establish an equipment maintenance file to record the time, content and results of each maintenance.

- Regularly review the maintenance records to analyze the use of the equipment and maintenance needs, and develop a more reasonable maintenance plan.

6. Common problems and solutions

- Unstable test results: may be loose sensors or inaccurate calibration, calibration check and sensor maintenance are required.

- Abnormal operation of the equipment: it may be due to wear and tear of transmission parts or control system failure, comprehensive inspection and maintenance are required.

- Failure of safety devices: immediate shutdown is required to check the safety protection devices and replace or repair if necessary.

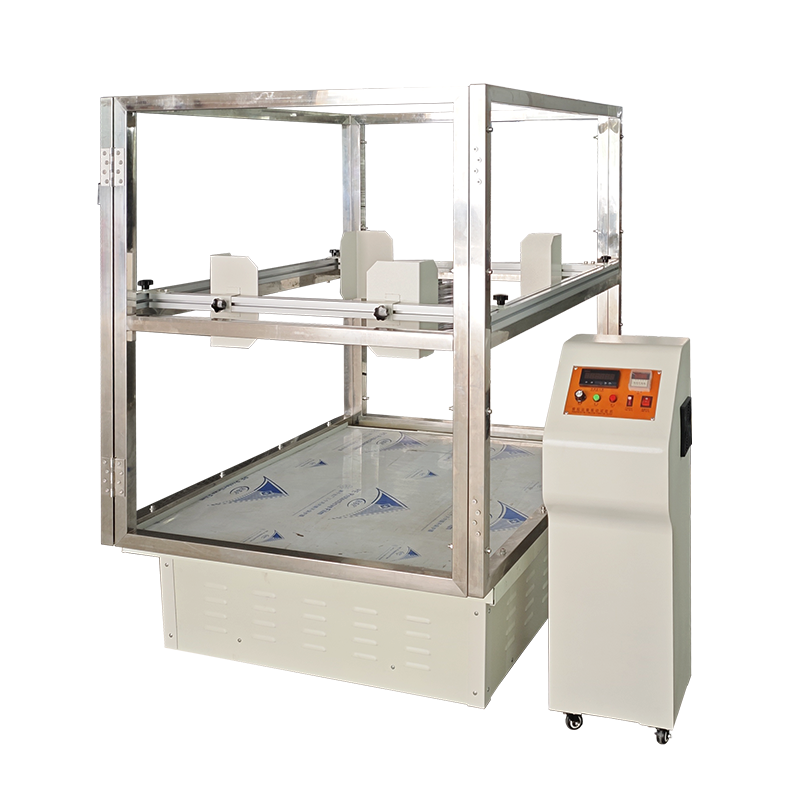

| Item | DR-B211-900 | DR-B211-1200 | DR-B211-1500 |

| Max. Force | 10KN(1000 kg ,2205lb) | 20KN(2000 kg, 4409lb) | 50KN(5000kg,11023lb) |

| Load cell | 1 load cell for highest accuracy | ||

| Control system | Dual control (Computer control with Windows mode+Touch screen control ) | ||

| Servo Motor | 400W | 750W | |

| Servo Driver | 400W | 750W | |

| Screws | Ball screws(Double ball guide rod design, high transmission accuracy, high transmission power efficiency) | ||

| Force reading | Gf, kgf, Ibf, N, KN, T etc | ||

| Load cell Resolution | 1/250,000 | ||

| Load Precision | within 0.5% | ||

| Effective test area (L x W x H) | 700x900x900mm | 1000x1200x1000mm | 1300x1500x1500mm |

| Compression Stroke | 0~900mm | 0~1000mm | 0~1500mm |

| Lift speed | 0.1~200mm/min | ||

| Software | Mtest HD-002-A(Independent R&D) | ||

| Data display | Load, displacement, speed, loading rate and elapsed time | ||

| Safety features | E-Stop Over-load protection Upper and lower limit switches Load sensor with automatic retreat | ||

| Report items | Serial number, peak value, average value, set pressure holding value, pressure holding time | ||

| Electrical Supply | 1phase, AC 220V, 500W, 50HZ | 1phase, AC 220V,550W,50HZ | 1phase, AC 220V,900W,50HZ |

| Overall Dimensions (L x W x H) | Approx.1510x1200x1645mm | Approx.1510x1200x1645mm | Approx.1865mmx1500mmx2235mm |

| Weight | Approx.350kg(772lb) | Approx.670kg(1477lb) | Approx. 1000kg(2205lb) |

| Operation Temperature and relative humidity | 10~40, 30~80% | ||

Advanced Compression Testing for Cosmetic Packaging

Engineered for professional use, this test box features automatic stroke limitation, microcomputer control, and overload protection, making it ideal for evaluating the durability of cosmetic cardboard boxes. The equipment is suitable for various box sizes, with customizable port and specimen size options. Its grey/blue design complements modern lab aesthetics, and noise levels remain below 65 dB, ensuring a comfortable working environment.

Easy Data Management and Reporting

Effortlessly manage and store test results with built-in memory capable of saving up to 500 tests. The device facilitates USB data output for quick report downloads, while its compatibility with Windows OS streamlines integration into standard laboratory workflows. Digital LCD display and rapid response time further simplify the testing process, enabling quick and accurate results.

FAQ's of Cosmetic cardboard box compression test box:

Q: How does the compression test process work with this machine?

A: The process involves placing a single specimen (usually 300 mm 300 mm) on the test platform, where the microcomputer-controlled fixture applies a compressive force up to 50 kN. The stroke automatically stops after box fracture, and the test results are digitally displayed and can be saved or exported.Q: What are the key benefits of using this compression test box for cosmetic cardboard packaging?

A: This device ensures packaging meets ISO 12048/GB T4857.4 standards, offering precise force application, automatic safety features, and quick digital result output. Its user-friendly interface, expansive memory, compact design, and adjustable test speed enhance lab productivity and test quality.Q: When should I use this compression strength tester for my products?

A: Use the compression tester during product development, quality control, or before shipment to ensure all cosmetic cardboard boxes or packaging materials meet required strength and resilience criteria, preventing product damage during transport and handling.Q: Where is this equipment typically installed and used?

A: The table-top design makes it ideal for use in laboratories, quality assurance departments, and manufacturing facilities of cosmetics exporters, manufacturers, and suppliers, especially those based in environments adhering to specified humidity and temperature ranges.Q: What is the process for exporting and managing test data?

A: Test data is automatically saved in the device's memory after each test. Users can conveniently download detailed reports to a USB drive or connect via the RS232/USB interface for further analysis or documentation using Windows-compatible software.Q: How does the safety protection feature work during testing?

A: The equipment is equipped with over-travel and overload protection, ensuring the device automatically halts testing if it detects conditions beyond safe operating limits, safeguarding both the equipment and the operator.Q: What makes this compression test box suitable for semi-automatic testing?

A: It offers automated microcomputer controls for data processing, overload protection, and automatic stop after specimen fracture, reducing user intervention while maintaining high accuracy, making the machine perfect for semi-automatic box compression testing applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese