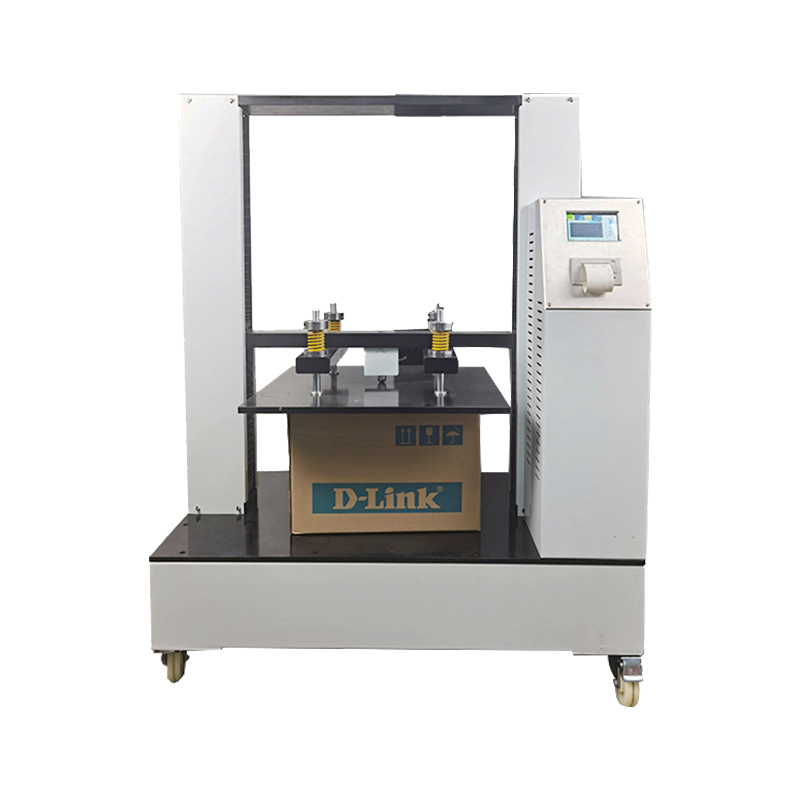

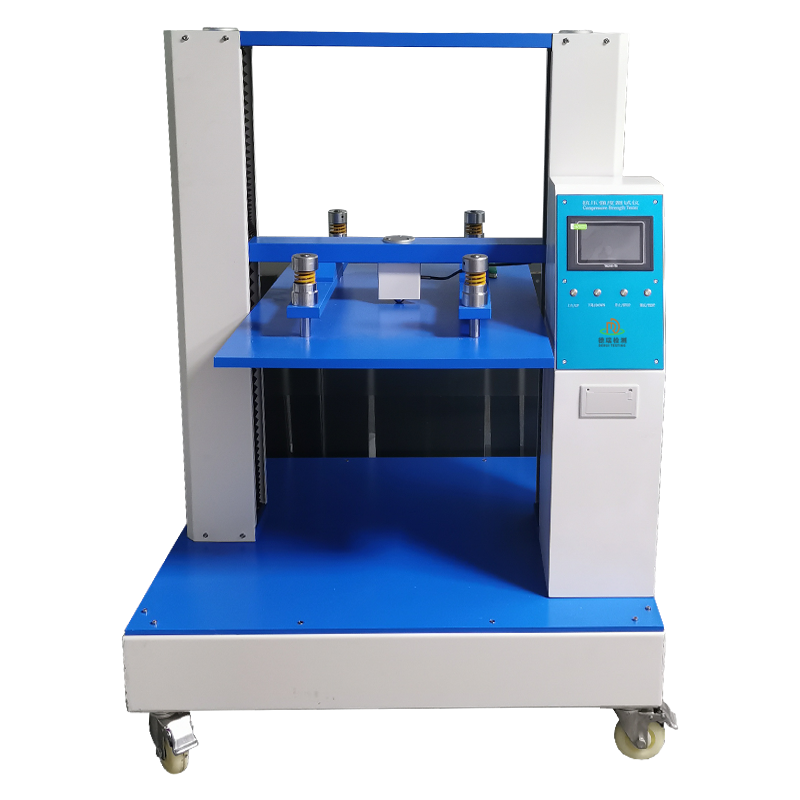

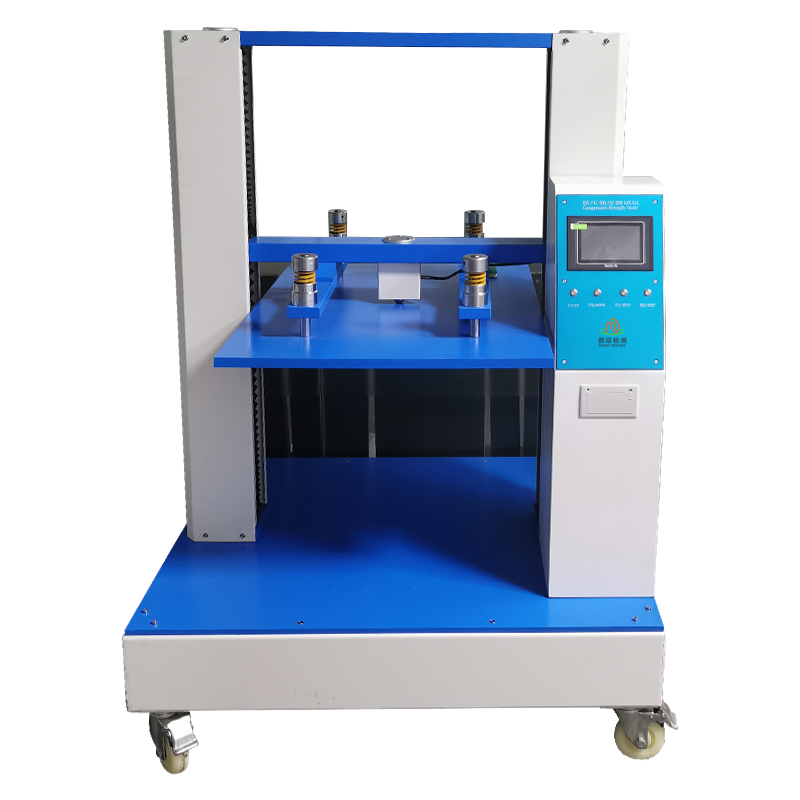

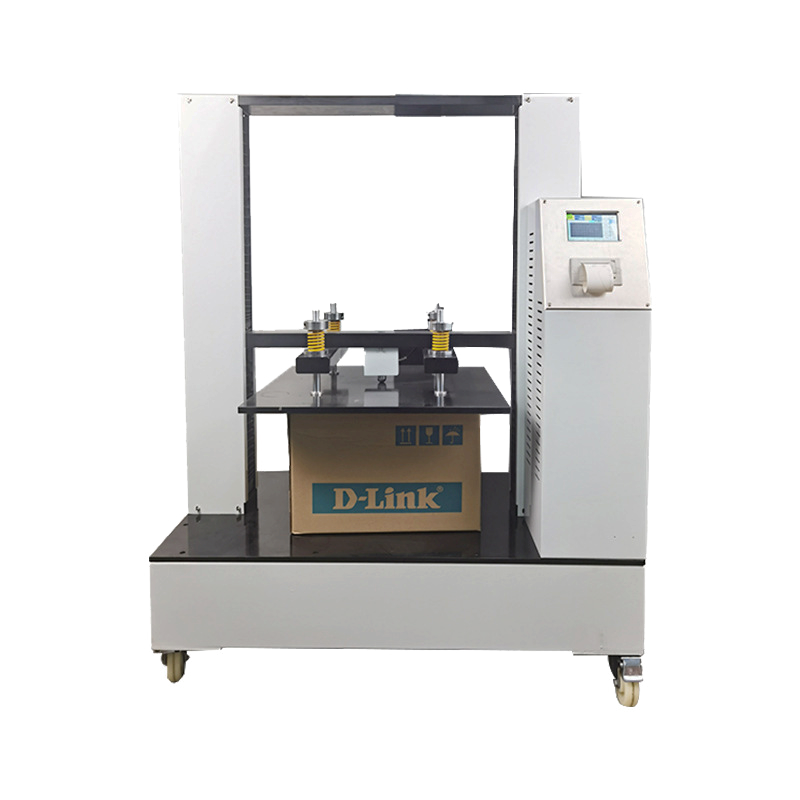

Food packaging compression testing machine

168005.0 INR/Unit

Product Details:

- Accuracy 1%

- Test Range 0-5000 N

- Response Time <1 second

- Power Supply AC 220V 50Hz

- Mounting Type Floor standing

- Gas Pressure 0.6 MPa

- Equipment Type Compression Strength Tester

- Click to view more

X

Food packaging compression testing machine Price And Quantity

- 168005.0 INR/Unit

- 1 Unit

- ASTM D642, ISO 12048

- Up to 100 test results

- kgf, lbf, N selectable

- Provided with calibration certificate

- High-precision strain gauge

- 850 x 700 x 1550 mm

- Wooden Case

- Stepper motor

- Automatic limit protection and emergency stop

- Touch screen panel

- Industrial Grey

Food packaging compression testing machine Product Specifications

- 1%

- 2 Tons

- 600 mm

- 0-5000 N

- <1 second

- AC 220V 50Hz

- 0.6 MPa

- Floor standing

- Compression Strength Tester

- 400 mm

- 1/4 inch BSP

- Industrial grade steel ram

- Approx. 110 Kg

- 20% - 90% RH

- RS232

- 600 mm

- 1 N

- Food packaging, carton, box, container compression test

- Digital LCD

- (L*W*H) Max 500 x 500 x 600 mm

- 1

- Compression strength and durability testing

- 50Hz

- 220V AC

- 0 5000 N

- Semi-Automatic

- 10-240 mm/min (adjustable)

- 5C - 40C

- High accuracy, Overload protection, Adjustable speed

- Digital (Microprocessor based)

- ASTM D642, ISO 12048

- Up to 100 test results

- kgf, lbf, N selectable

- Provided with calibration certificate

- High-precision strain gauge

- 850 x 700 x 1550 mm

- Wooden Case

- Stepper motor

- Automatic limit protection and emergency stop

- Touch screen panel

- Industrial Grey

Food packaging compression testing machine Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 10 Days

- All India

Product Description

Food Packaging Compression Tester is a precision test equipment specially designed to evaluate the compressive strength, deformation performance and overall structural stability of various types of food packaging (such as cartons, paper boxes, plastic containers, etc.) under static compression load. As food packaging not only need to withstand the pressure of the transportation and stacking process, but also need to ensure the integrity of the packaging and health and safety, so the equipment has a vital role in the food packaging industry. The equipment ensures the safety and reliability of food packaging in various environments by simulating actual transportation, storage and stacking conditions.

2. Main Functions

- Compressive strength test: Measure the maximum compressive capacity of food packaging in the vertical direction according to relevant standards (e.g. ASTM D642, GB/T 4857.4, etc.), and evaluate its load-bearing capacity during stacking, transportation and storage.

- Deformation test: Record the deformation of the package under compression load, assess the degree of deformation and recovery ability, and ensure that the package can still maintain its appearance integrity and sealing after bearing pressure.

- Stacking test: simulate the force of the package in the actual stacking situation, assess its stacking stability and load-bearing capacity, to ensure that the multi-layer stacking will not be collapsed or damaged.

- Cyclic compression test: Load and unload the package for several cycles to evaluate its fatigue performance and durability, ensuring that the package can still maintain good compression resistance after repeated handling and transportation.

- Data analysis and report generation: Built-in data analysis software can automatically generate detailed test reports, including maximum compressive strength, deformation, loading curve and other parameters, to help the quality control department carry out strict quality assessment.

Implementation process:

1.

Equipment selection and installation:

- According to the needs of the enterprise, a food packaging compression testing machine with a range of 20kN was selected.

- After the installation and commissioning of the equipment, the operator received professional training, mastered the basic operation and daily maintenance of the equipment.

2.

Test program development:

- According to the packaging specifications and transportation conditions of different products, a detailed test program was formulated.

- The tests include compressive strength test, stacking test and cyclic compression test.

3.

Test results and analysis:

- Through the test, it is found that the compressive strength of some packaging materials is insufficient, resulting in easy breakage during transportation.

- According to the test results, the enterprise optimized the packaging materials, choosing higher strength cardboard and more reasonable structural design.

4.

Effectiveness verification:

- The optimized packaging materials performed well in the subsequent tests, with compressive strength and stacking stability significantly improved.

- Customer complaints and return rates have dropped significantly, and the product market performance has improved significantly.

Operating Instructions:

1.

Equipment Preparation:

- Check the appearance of the equipment to ensure that there is no damage or abnormality.

- Confirm that the power connection is normal and the grounding is good.

2.

Specimen Preparation:

- Place the food package to be tested between the compression plates and make sure the package is placed smoothly.

- Adjust the position of the compression plate so that the specimen is located in the center of the test area.

3.

Parameter setting:

- Open the control panel and input the test parameters, including compression speed, load range, displacement limit and so on.

- According to the test standard, select the appropriate test mode (such as compressive strength test, stacking test, etc.).

4.

Test process:

- Start the equipment and begin the test.

- Observe the testing process to ensure that the equipment is running normally.

- After the test, record the test data and generate the test report.

5.

Data Processing and Analysis:

- Use the built-in data analysis software to analyze the test results in detail.

- Based on the analysis results, evaluate the compression resistance of the packaging material and make suggestions for improvement.

| Item | DR-B211-900 | DR-B211-1200 | DR-B211-1500 |

| Max. Force | 10KN(1000 kg ,2205lb) | 20KN(2000 kg, 4409lb) | 50KN(5000kg,11023lb) |

| Load cell | 1 load cell for highest accuracy | ||

| Control system | Dual control (Computer control with Windows mode+Touch screen control ) | ||

| Servo Motor | 400W | 750W | |

| Servo Driver | 400W | 750W | |

| Screws | Ball screws(Double ball guide rod design, high transmission accuracy, high transmission power efficiency) | ||

| Force reading | Gf, kgf, Ibf, N, KN, T etc | ||

| Load cell Resolution | 1/250,000 | ||

| Load Precision | within 0.5% | ||

| Effective test area (L x W x H) | 700x900x900mm | 1000x1200x1000mm | 1300x1500x1500mm |

| Compression Stroke | 0~900mm | 0~1000mm | 0~1500mm |

| Lift speed | 0.1~200mm/min | ||

| Software | Mtest HD-002-A(Independent R&D) | ||

| Data display | Load, displacement, speed, loading rate and elapsed time | ||

| Safety features | E-Stop Over-load protection Upper and lower limit switches Load sensor with automatic retreat | ||

| Report items | Serial number, peak value, average value, set pressure holding value, pressure holding time | ||

| Electrical Supply | 1phase, AC 220V, 500W, 50HZ | 1phase, AC 220V,550W,50HZ | 1phase, AC 220V,900W,50HZ |

| Overall Dimensions (L x W x H) | Approx.1510x1200x1645mm | Approx.1510x1200x1645mm | Approx.1865mmx1500mmx2235mm |

| Weight | Approx.350kg(772lb) | Approx.670kg(1477lb) | Approx. 1000kg(2205lb) |

| Operation Temperature and relative humidity | 10~40, 30~80% | ||

High-Precision Compression Testing

Achieve dependable compression strength measurements of food packaging with automated accuracy. This machine utilizes an advanced strain gauge load cell to deliver results within a 1% accuracy range, accommodating specimen sizes up to 500 x 500 x 600 mm. The digitally controlled operation and LCD display provide clear and immediate feedback for confident testing.

User-Friendly Operation & Safety

Designed with a touch screen panel, the machine's operation is straightforward, even for first-time users. Safety features such as automatic limit protection, emergency stop, and robust industrial-grade construction provide peace of mind and minimize risk during compression testing.

Comprehensive Data Management

Experience seamless traceability and data storage. The machine can store up to 100 test results and supports RS232 interface for data export. Each unit is delivered with a certified calibration, ensuring consistent and verifiable performance for quality assurance teams.

FAQ's of Food packaging compression testing machine:

Q: How does the compression testing machine ensure accuracy in measuring packaging strength?

A: The machine employs a high-precision strain gauge load cell, delivering test results with 1% accuracy and a resolution of 1 N. Calibration certification is provided to guarantee consistent and reliable measurements during every test.Q: What types of packaging can this machine test and what is the process?

A: This tester is suitable for food packaging, cartons, boxes, and containers up to 500 x 500 x 600 mm. The specimen is placed in the testing area, test parameters are selected via the touch screen, and then compression is applied through an adjustable-speed stepper motor. Data is digitally recorded for each test.Q: When should the emergency stop or limit protection features be used?

A: The automatic limit protection engages when the specimen's maximum allowable compression is reached, preventing equipment or sample damage. The emergency stop is intended for immediate manual shutdown in case of any unforeseen incidents during testing.Q: Where can test data be stored or accessed after performing tests?

A: Test results are stored internally, with a memory capacity for up to 100 test results. Data can also be exported through the RS232 interface for further analysis and documentation.Q: What are the benefits of using this machine for food packaging testing?

A: Users benefit from high-accuracy measurements, rapid digital feedback, and compliance with international testing standards (ASTM D642, ISO 12048). Its safety features and easy-to-use interface improve efficiency, while robust build quality ensures long-term durability.Q: How is the machine installed and maintained for regular usage?

A: The unit comes floor-mounted within a durable wooden case and requires an AC 220V power supply. Regular maintenance includes routine calibration checks (certificate provided), inspection of the stepper motor, and ensuring that the emergency and protection functions are operational.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese