ISTA 3A Drop Test Procedure for Packaging

158005.0 INR/Unit

Product Details:

- Number of Specimens Single specimen at a time

- Features Adjustable drop height, rugged frame, easy operation

- Power Supply 220 V AC, 50 Hz

- Test Range 1 kg - 80 kg

- Frequency 50 Hz

- Hardness Frame: Mild Steel, powder-coated

- Automation Grade Semi-automatic / Manual both available

- Click to view more

X

ISTA 3A Drop Test Procedure for Packaging Price And Quantity

- 158005.0 INR/Unit

- 1 Unit

- Interchangeable specimen holding arms

- Emergency stop, safety enclosure optional

- Powder-coated anti-rust finish

- Supplied with calibration certificate

- Base with lockable caster wheels

- Heavy-duty mild steel structure

- Electromagnetic release mechanism

- Indoor laboratory

- Flat, edge, and corner drops available

- Conforms to ISTA 3A, ASTM, and ISO standards

- Less than 70 dB during operation

ISTA 3A Drop Test Procedure for Packaging Product Specifications

- 1 mm

- 220 V AC, 50 Hz

- Instantaneous drop

- Digital height indicator

- 10C - 40C (operating)

- Floor mounted

- Up to 1000 mm

- Max. 1000 x 800 x 800 mm

- 2 mm

- Packaging drop impact testing

- Up to 1800 mm drop height

- 1800 mm

- 40% - 80% RH (operating)

- Semi-automatic / Manual both available

- 50 Hz

- Frame: Mild Steel, powder-coated

- Adjustable drop height, rugged frame, easy operation

- Single specimen at a time

- 80 Kg max

- 1 kg - 80 kg

- 220 V AC, 50 Hz

- Manual / PLC controlled

- Package drop and impact resistance testing

- Up to 1800 mm

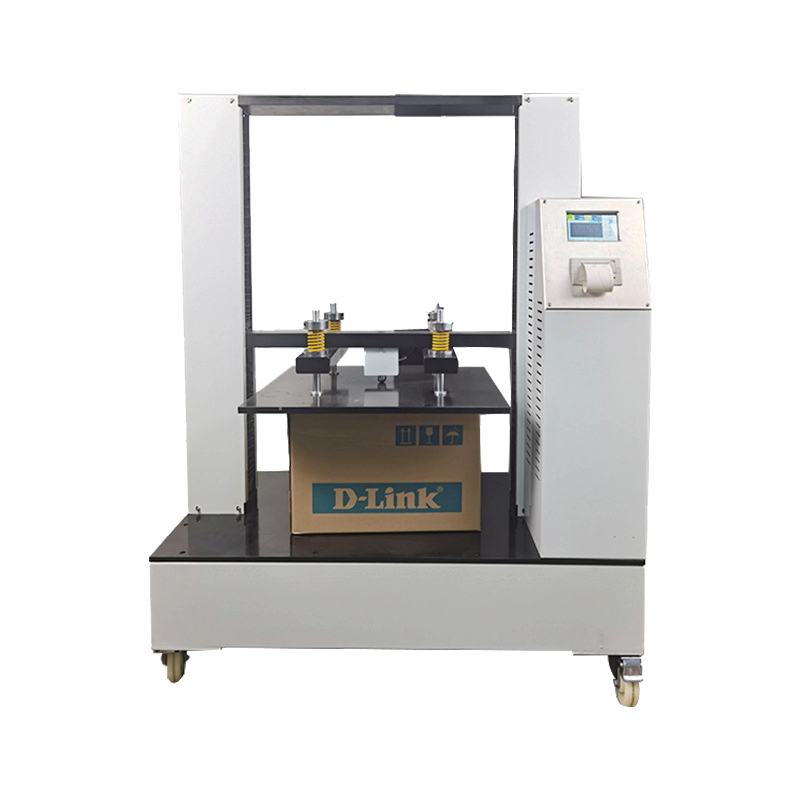

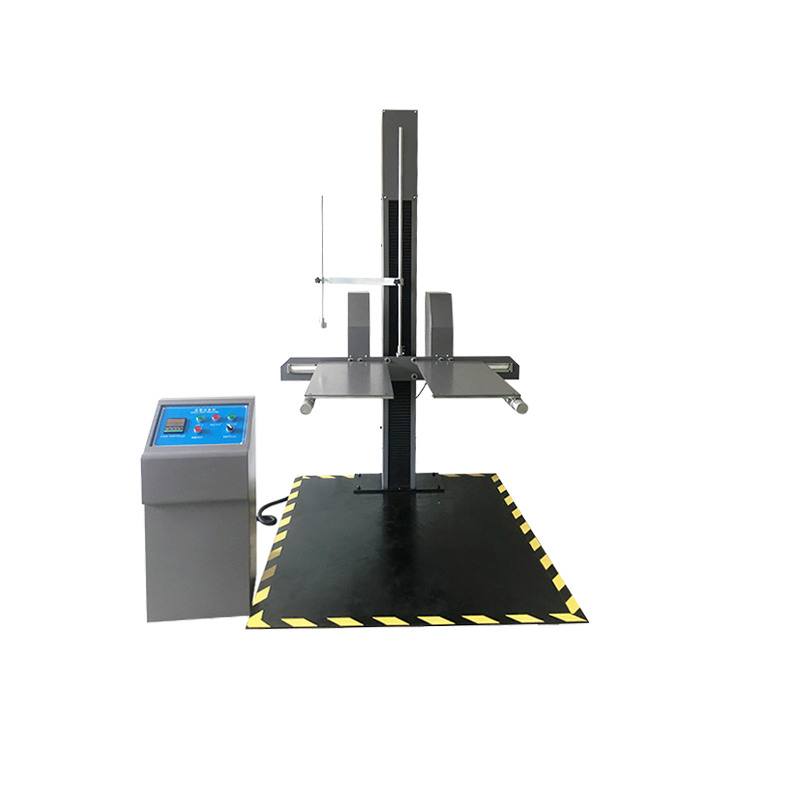

- Drop Test Machine

- Manual drop, instantaneous

- Manual / Digital

- Approx. 250 Kg

- Interchangeable specimen holding arms

- Emergency stop, safety enclosure optional

- Powder-coated anti-rust finish

- Supplied with calibration certificate

- Base with lockable caster wheels

- Heavy-duty mild steel structure

- Electromagnetic release mechanism

- Indoor laboratory

- Flat, edge, and corner drops available

- Conforms to ISTA 3A, ASTM, and ISO standards

- Less than 70 dB during operation

ISTA 3A Drop Test Procedure for Packaging Trade Information

- Cash in Advance (CID)

- 90 Unit Per Month

- 5 Days

- All India

Product Description

The ISTA 3A Drop Test Procedure for Packaging is a widely recognized testing standard used to assess the durability of packaging materials. This procedure is essential for evaluating how packaging withstands drops and impacts during shipping and handling. By simulating real-world conditions, this test helps to ensure that products arrive intact, safeguarding both the contents and the reputation of the manufacturer.

Key Functions of the ISTA 3A Drop Test Procedure

The ISTA 3A Drop Test is designed to evaluate packaging resilience under various impact scenarios. The procedure involves dropping packaged products from a predefined height onto different surfaces, mimicking the stresses they would face during transportation. This testing ensures that the packaging is robust enough to protect the contents, reducing the risk of damage, returns, or customer dissatisfaction.

Key functions of the ISTA 3A Drop Test Procedure include:

- Simulating Real-World Drops: Replicates the conditions of falls, shocks, and impacts experienced during shipping, ensuring a realistic assessment of packaging strength.

- Assessing Package Integrity: Identifies weak points in packaging that may cause product damage, allowing for corrective measures before products reach the market.

- Comprehensive Damage Assessment: The procedure provides insights into how packaging performs when subjected to different drop heights and angles.

Features of the ISTA 3A Drop Test Procedure for Packaging

-

Multiple Drop Heights and Surfaces: The test procedure incorporates various drop heights, from low to high, along with different impact surfaces to simulate the diversity of transportation conditions. This flexibility is essential for ensuring packaging durability across a range of shipping environments.

-

Standardized Testing Methodology: The ISTA 3A procedure is based on established industry standards, ensuring uniformity and reliability in testing. The use of standardized methods helps to guarantee that packaging solutions meet international requirements for product protection during transit.

-

Adaptable to Various Packaging Types: Whether for small consumer goods or larger, more fragile items, the ISTA 3A Drop Test Procedure is adaptable to test various packaging formats. This versatility makes it a valuable tool for manufacturers in multiple sectors.

-

Impact Angle and Drop Configuration: The test can be configured to simulate impacts from different angles, offering a comprehensive view of how the packaging will perform in various situations. By varying drop angles, the procedure ensures the packaging's resilience is accurately measured.

Installation and Setup of the ISTA 3A Drop Test Procedure

Setting up an ISTA 3A Drop Test system requires careful attention to detail to ensure accurate and reproducible results. Heres how to install and prepare the test system:

-

Select the Testing Equipment: Choose a drop test machine that meets the requirements for height, weight, and package size. Ensure the machine has adjustable features to accommodate various drop heights and angles.

-

Prepare the Test Area: The drop test area should be clear of obstacles and equipped with shock-absorbent surfaces to ensure that the packaging undergoes controlled impacts. Proper space allows for different drop configurations and easy handling of packages during testing.

-

Calibrate the Machine: Before running tests, calibrate the drop test machine to ensure accurate height adjustments and drop configurations. Calibration helps maintain consistency across multiple test runs.

-

Position the Packaging: Place the packaging securely in the test area, ensuring that the product is aligned with the machines drop path. Proper positioning is crucial for consistent testing results.

-

Monitor the Test: Run the test under controlled conditions, observing the packagings response to each drop. Document any signs of damage or failure to assess the packagings integrity.

Important Considerations During the ISTA 3A Drop Test Procedure

When conducting the ISTA 3A Drop Test, certain precautions should be taken to ensure the validity and effectiveness of the testing process:

-

Consistency in Setup: Ensure that the machine setup, including drop height and surface type, is consistent for each test to provide reliable and comparable results.

-

Test Multiple Samples: Run the test on several samples of packaging to assess the consistency of packaging performance across different units. This helps identify variations in packaging strength and quality.

-

Follow Standardized Guidelines: Adhering to the official ISTA 3A Drop Test Procedure guidelines is crucial to maintain the integrity of the test and ensure compliance with industry standards.

-

Evaluate Packaging Materials: Consider testing different materials, such as cardboard, foam inserts, and plastic, to understand how different types of packaging respond to impact stress. This information helps in selecting the most suitable material for specific products.

-

Record and Analyze Data: Keep detailed records of each test, including the drop heights, impact surfaces, and any observed damage. Analyzing the results will provide insights into potential weaknesses in packaging and suggest areas for improvement.

- Specifications:

Item

Description

Drop height

400-1500mm (can be customized)

Display method

Digital display

Max. weight of sample

60kg (can be customized)

Max. size of sample

(L*W*H) 800*800*800mm

Drop panel area

1400x1200mm (material is Solid steel plate)

Control box dimension

(L*W*H) 350*350*1100mm

Deviation of drop horizon

Less than 1

Machine size

(L*W*H)1400*1200*2200mm

Precision Drop Testing for Packaging Integrity

Delivering repeatable flat, edge, and corner drops, this equipment meets ISTA 3A, ASTM, and ISO standards, enabling comprehensive evaluation of package durability under real-world shipping conditions. Its flexible design allows for quick adaptation to various box sizes and materials, supporting up to 80 kg loads with a maximum drop height of 1800 mm. Control options include both manual and PLC modes, giving operators the versatility to tailor tests to their specific requirements.

Rugged Design and Enhanced Usability

Built with a powder-coated mild steel frame, the drop test machine resists corrosion and damage from frequent laboratory use. The base is fitted with lockable caster wheels for easy movement and stability. All critical electronic and mechanical components are enclosed for added safety, complemented by optional safety enclosures and an emergency stop feature. A digital height display ensures precise setup every time.

Versatile Applications for the Packaging Industry

Engineered primarily for drop impact testing of shipping cartons and containers, this machine plays a vital role in quality control and product development for manufacturers, exporters, and suppliers. Its ability to simulate diverse drop scenarios helps companies optimize protective packaging and comply with global shipping and safety regulations.

FAQ's of ISTA 3A Drop Test Procedure for Packaging:

Q: How does the ISTA 3A Drop Test Machine perform drop tests on packages?

A: The machine uses an electromagnetic release mechanism to drop packages in flat, edge, and corner orientations. Operators can precisely set the drop height manually or via PLC control, ensuring reliable and repeatable impact testing for various packaging types.Q: What are the main benefits of using this drop test equipment for package testing?

A: The key benefits include accurate measurement of package durability, compliance with international standards (ISTA 3A, ASTM, ISO), easy operation, adaptable specimen holding fixtures, and a digital height indicator for precise testing-all contributing to improved product safety during transportation.Q: When should packages be subjected to drop testing with this equipment?

A: Drop testing is recommended during product development, before mass shipping, and as part of routine quality assurance to assess and validate the protective performance of packaging under simulated distribution conditions.Q: Where is the drop test machine best suited for operation?

A: This equipment is designed for indoor laboratory settings with controlled temperature (10C - 40C) and humidity (40% - 80% RH), making it ideal for research labs, quality control departments, and packaging test facilities.Q: What is the process for conducting a package drop test with this machine?

A: To conduct a test, the user mounts the package onto the interchangeable holding arms, selects the desired drop orientation and height (up to 1800 mm), and initiates the drop via manual or PLC control. The digital height indicator assists with precise setup before each test.Q: Who can benefit most from using this drop test machine?

A: Manufacturers, exporters, packaging designers, and quality control professionals benefit significantly, as the machine provides actionable data to enhance packaging designs, reduce shipping damages, and ensure regulatory compliance.Q: How does the machine ensure safety during operation?

A: Safety features include an emergency stop, optional safety enclosure, and rugged frame construction. The base's lockable caster wheels keep the equipment stable, while the manual/PLC interface ensures controlled operation throughout the test procedure.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese