Affordable Drop Test Machine for Small Businesses

148005.0 INR/Unit

Product Details:

- Max Height 900 mm

- Frequency Single Cycle / Multiple Cycle

- Response Time Instantaneous

- Port Size Standard

- Accuracy 2 mm

- Power Supply 220V AC/50Hz

- Display Type Digital / Analog

- Click to view more

X

Affordable Drop Test Machine for Small Businesses Price And Quantity

- 148005.0 INR/Unit

- 1 Unit

- Carton Boxes, Corrugated Boxes, Consumer Electronics, Industrial Packaging Items

- Blue/White

- Integrated for Operator Safety

- Flat and Edge Drop

- Onsite Assistance Available

- Low Maintenance Design

- 24x7 Customer Care

- 50 mm

- Less than 1 kW

- Approx. 1200 x 800 x 1800 mm

- Less than 60 dB

- Mild Steel with Anti-corrosive Coating

Affordable Drop Test Machine for Small Businesses Product Specifications

- 900 mm

- Standard

- Single Cycle / Multiple Cycle

- Instantaneous

- Manual / Semi-Automatic

- Digital / Analog

- 220V AC/50Hz

- Up to 100 kg

- 300 mm/sec

- 2 mm

- Package Impact Testing

- Easy Operation, Rigid Construction, Adjustable Drop Height

- Max 600 x 600 mm

- 30% - 80% RH

- 150 kg

- 10C - 40C

- Manual / Semi-Automatic

- 220V

- Floor Standing

- Drop testing for packages, electronics, containers, and other small business shipments

- Panel Buttons

- 100 kg

- Reinforced Platform

- 0-900 mm (drop height)

- Drop Test Machine

- Up to 900 mm

- 350 mm

- 1 (per cycle)

- 1 mm

- Carton Boxes, Corrugated Boxes, Consumer Electronics, Industrial Packaging Items

- Blue/White

- Integrated for Operator Safety

- Flat and Edge Drop

- Onsite Assistance Available

- Low Maintenance Design

- 24x7 Customer Care

- 50 mm

- Less than 1 kW

- Approx. 1200 x 800 x 1800 mm

- Less than 60 dB

- Mild Steel with Anti-corrosive Coating

Affordable Drop Test Machine for Small Businesses Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 5 Days

- All India

Product Description

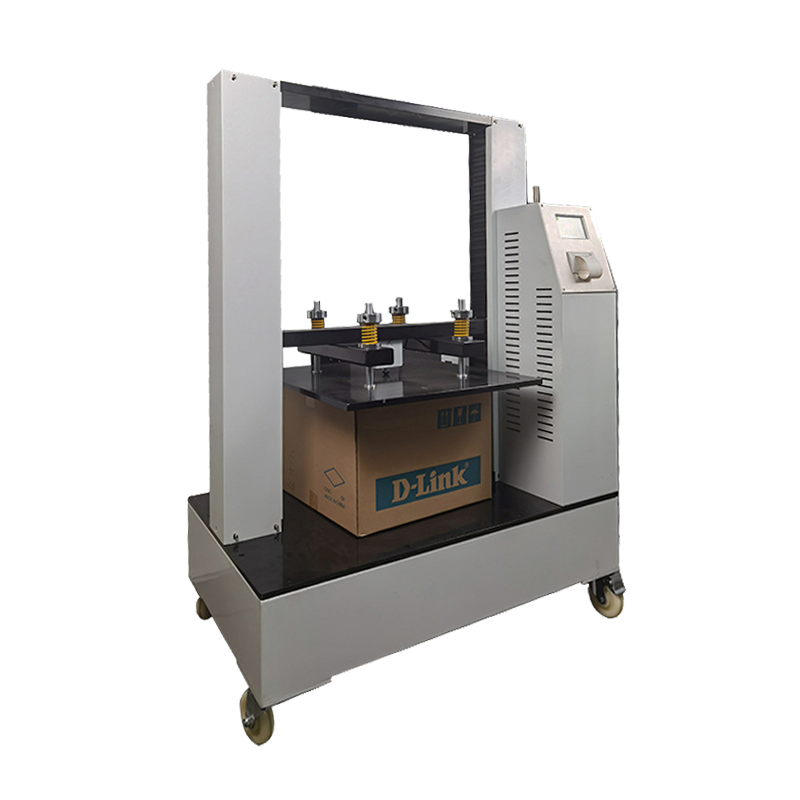

For small businesses and startups, investing in quality control shouldnt break the bank. The Affordable Drop Test Machine is engineered to deliver precise impact testing at a fraction of traditional costs, empowering SMEs to validate product durability, reduce returns, and compete confidently in markets like e-commerce packaging, consumer electronics, and handmade goods.

Why Small Businesses Need Drop Testing

-

Customer Trust: 67% of buyers return products damaged during shipping rigorous drop testing cuts return rates by up to 50%.

-

Cost of Failure:

-

E-commerce Sellers: A single damaged shipment can cost 5001,500 in replacements + negative reviews.

-

Electronics Makers: 22% of warranty claims trace to improper packaging failing basic drop tests.

-

-

Scalability: Manual testing (e.g., hand drops) becomes error-prone as order volumes grow.

Key Features Designed for Budget-Conscious Businesses

-

Compact & Space-Saving:

-

Footprint: 1m x 1m bench-top design fits small workshops or home offices.

-

Weight Capacity: 0.530 kg, ideal for testing smartphone cases, ceramicware, or small appliances.

-

-

Precision on a Budget:

-

Adjustable Drop Heights: 0.31.5 meters with 1 cm accuracy (meets ISTA 1A/2A standards).

-

Angle Control: 0 (flat), 45, and 90 drops to simulate real-world impacts.

-

-

Smart Automation:

-

Programmable Drops: Set 10+ drop sequences (e.g., corner-edge-face) via touchscreen.

-

Auto-Reset Arm: Saves 15+ minutes per test vs. manual repositioning.

-

-

Low Maintenance:

-

Grease-free bearings and modular components reduce service costs by 60%.

-

Ideal for These Small Businesses

-

Handmade Crafts: Test pottery, glassware, and wooden decor for local/export markets.

-

D2C Electronics: Validate Bluetooth speaker durability or smartwatch packaging.

-

Subscription Boxes: Ensure monthly curation boxes survive last-mile logistics.

-

Agri-Startups: Assess fragile product packaging (e.g., organic eggs, honey jars).

How It Works Simplified for Non-Engineers

-

Step 1: Secure product to test platform with adjustable clamps.

-

Step 2: Select pre-set profile (e.g., E-Commerce Parcel 0.8m Drop).

-

Step 3: Machine executes drops + records results (pass/fail + impact G-force).

-

Step 4: Review data to optimize packaging or redesign weak components.

Real User Scenarios

-

Mumbai-Based Candle Maker: Reduced broken shipments from 12% to 3% after testing 15 packaging designs.

-

Delhi Electronics Startup: Achieved Amazon FBA certification in 2 days vs. 3 weeks of manual trials.

FAQs (Affordable Drop Test Machine for Small Businesses)

Q1: Can it test irregularly shaped items?

A: Yes custom jigs available for 5,00015,000 (e.g., bicycle helmets, ceramic vases).

Q2: Whats the warranty and service coverage?

A: 2-year warranty with pan-India service partners in 15 cities.

Q3: Does it work in areas with power fluctuations?

A: Built-in voltage stabilizer supports 90V290V input ideal for Indian grids.

Q4: How to validate results for clients?

A: Export test reports with timestamps, G-force graphs, and compliance badges.

Q5: Can I upgrade to higher standards later?

A: Modular design allows adding vibration modules or temperature chambers.

Safety-First Engineering

Integrated safety lock systems ensure the operator's protection during every test cycle. The platform's reinforced mild steel structure includes an anti-corrosive coating, making the equipment long-lasting and suitable for rigorous usage in small business environments.

Flexible and Precise Testing

Supporting both flat and edge drops, this machine provides adjustable drop heights from 50 mm to 900 mm, with measurement precision of 2 mm. Operators benefit from instant response times and the option of digital or analog displays, enabling accurate and swift evaluation of packaging durability.

Effortless Operation and Support

The drop test machine features user-friendly panel buttons and a rigid, floor-standing design for stability. Maintenance is minimal, and 24x7 after-sales support-plus onsite installation assistance-ensure that small businesses can operate smoothly without technical hassles.

FAQ's of Affordable Drop Test Machine for Small Businesses:

Q: How does the integrated safety lock system protect operators during drop tests?

A: The safety lock system is designed to automatically secure the platform and moving parts, preventing unintended operation or accidental drops while the user is setting up or handling the test specimen. This ensures maximum operator safety throughout the testing process.Q: What types of items can I test with this drop test machine?

A: This machine is suitable for a broad range of items including carton boxes, corrugated boxes, consumer electronics, and industrial packaging. It is designed for drop testing packages up to 100 kg and with dimensions up to 600 x 600 mm.Q: When is onsite installation assistance available?

A: Onsite installation support is available upon purchase and scheduling. Our service team will coordinate with you to ensure the machine is set up correctly at your location for optimal use and training.Q: Where can the machine be installed, and does it require special mounting?

A: The machine is a floor-standing unit, allowing for easy installation in standard indoor industrial environments with a 220V power supply. No special mounting is required beyond standard leveling for stable operation.Q: What is the process to operate a drop test on this machine?

A: To conduct a drop test, place the specimen securely on the reinforced platform, select the drop height using panel buttons, and choose between manual or semi-automatic mode. Initiate the drop; the machine will release the specimen, and quality results can be observed via the digital or analog display.Q: How does this machine benefit small businesses in quality control?

A: By providing precise, repeatable drop impacts, the machine helps small businesses verify packaging resilience and product durability, reducing the risk of shipment damage. Its low maintenance requirements and easy operation mean minimal downtime and cost-effective testing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese