Low frequency vibration table simulation transportation test

158005.0 INR/Unit

Product Details:

- Power Supply AC 220V 50Hz

- Interface Type Standard power interface

- Gas Pressure No gas supply required

- Mounting Type Floor mounted

- Humidity 85% RH

- Test Range 0~300 times/min

- Measuring Range 025 mm amplitude

- Click to view more

X

Low frequency vibration table simulation transportation test Price And Quantity

- 158005.0 INR/Unit

- 1 Unit

- High-strength steel

- Reciprocating motion

- Approx. 1200 x 750 x 700 mm

- Overload protection, emergency stop switch

- 70 dB

- Indoor use

- Speed and time adjustable

- Control panel, user manual

Low frequency vibration table simulation transportation test Product Specifications

- 5C to 40C

- 60 kg

- Digital LED display

- AC 220V

- Simulation of road transport vibration

- 600 x 500 mm

- Approx. 120 kg

- Semi-automatic

- Immediate

- Approx. 600 mm

- Max. 600 x 500 mm

- 1~5 Hz

- Low noise, durable, easy to operate

- Digital Control

- Low Frequency Vibration Table

- 1% of set value

- 1-2 pieces per test

- Industrial grade

- 1 r/min

- Package vibration transport simulation

- AC 220V 50Hz

- Standard power interface

- No gas supply required

- Floor mounted

- 85% RH

- 600 mm

- 60-300 r/min

- 0~300 times/min

- 25 mm (fixed)

- 025 mm amplitude

- High-strength steel

- Reciprocating motion

- Approx. 1200 x 750 x 700 mm

- Overload protection, emergency stop switch

- 70 dB

- Indoor use

- Speed and time adjustable

- Control panel, user manual

Low frequency vibration table simulation transportation test Trade Information

- Cash in Advance (CID)

- 80 Unit Per Month

- 3 Days

- All India

Product Description

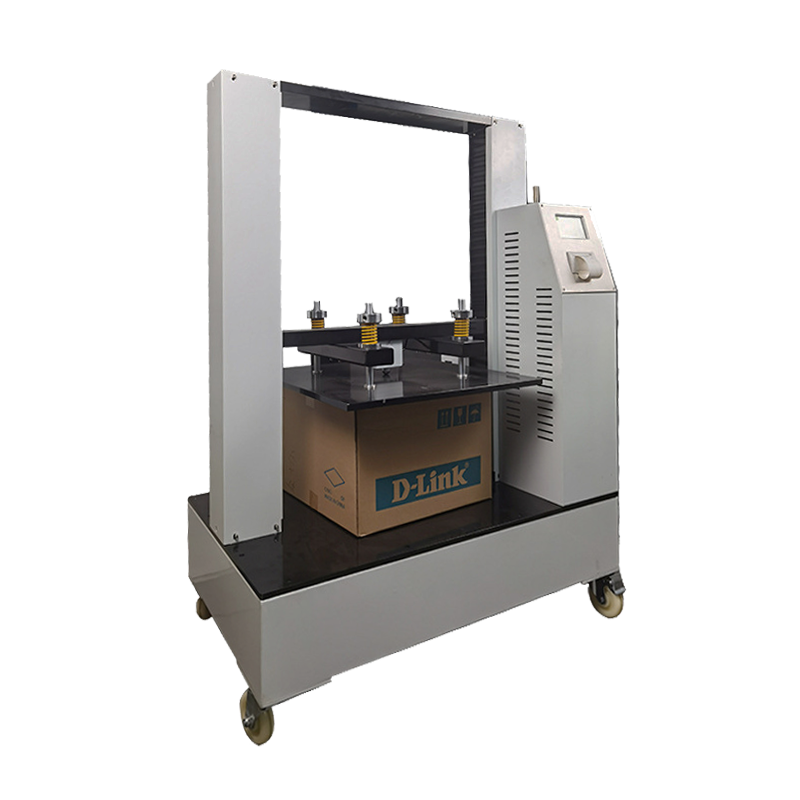

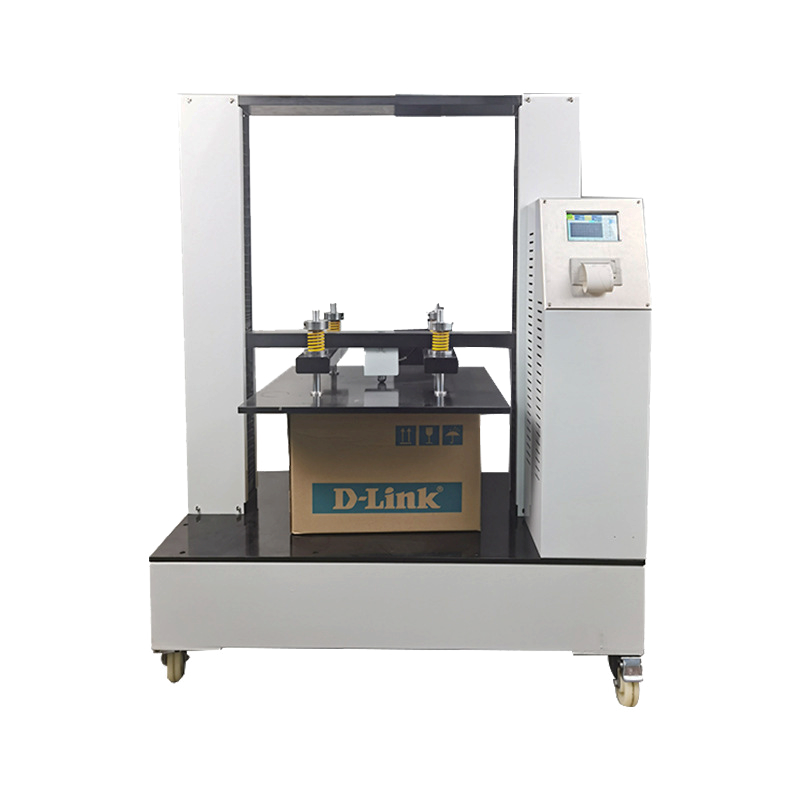

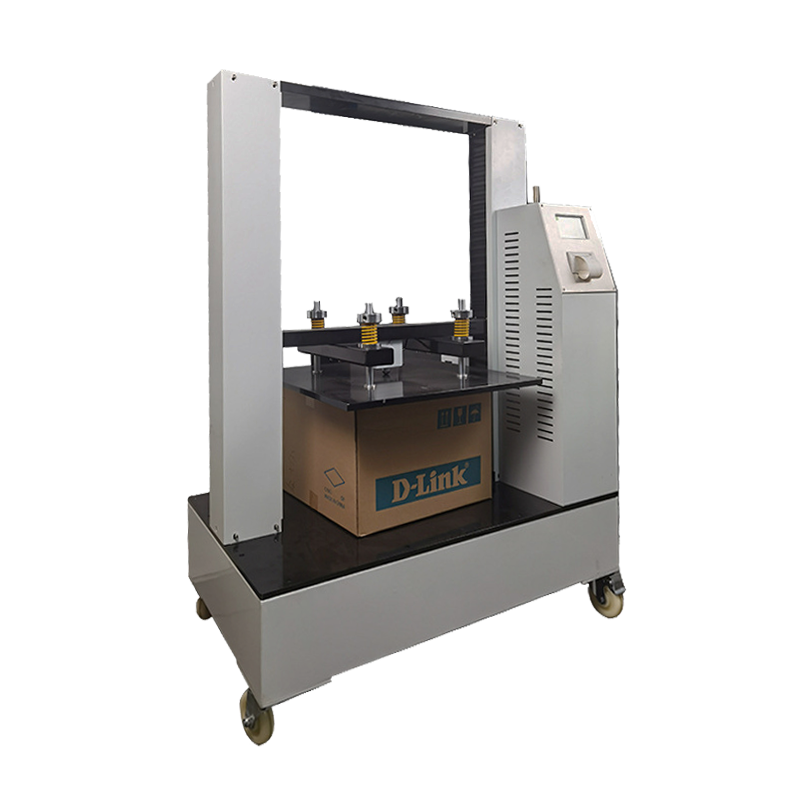

At the intersection of modern logistics and manufacturing, the transportation process of a product often becomes one of the most challenging aspects of its life cycle. As a precision test equipment, low-frequency shaker is specially designed to simulate the low-frequency vibration environment endured by products during transportation, providing an indispensable tool for product reliability testing. In this article, we will explore the functional features, application scenarios and the technical logic behind this equipment from multiple dimensions, aiming to present readers with a comprehensive and in-depth perspective.

Functional Features and Technical Analysis

1.

Accurate simulation of low-frequency vibration

The core function of a low-frequency shaker is its ability to accurately simulate low-frequency vibration. Compared with high-frequency vibration, low-frequency vibration has a more significant impact on products during transportation, especially in long-distance transportation, road bumps, loading and unloading operations, etc. Low-frequency vibration can be generated. By precisely controlling the frequency and amplitude of vibration, the device can truly reproduce various low-frequency vibration scenes during transportation, providing the closest to the actual test environment for the product.

2.

Multi-mode vibration

The device supports a variety of vibration modes, including sine waves, random waves and composite waves and other different types of vibration. Through these diverse vibration modes, users can simulate a variety of transportation conditions from smooth highways to rugged mountain roads. This multi-mode simulation capability makes the test results more representative and convincing, providing reliable data support for product design and improvement.

3.

Programmable control and automated operation

The low-frequency shaker is equipped with an advanced programmable control system, which allows users to customize the vibration parameters, such as frequency, amplitude and duration, according to different testing needs. At the same time, the automated operation function of the equipment makes the testing process more efficient and precise, reducing the errors caused by human operation. This highly automated and customizable testing process provides users with great convenience and flexibility.

4.

Real-time data monitoring and analysis

The built-in sensors and data acquisition system of the equipment can monitor various parameters during vibration in real time, such as acceleration, displacement and frequency. By analyzing and recording these data in real time, users can gain a comprehensive understanding of the product's performance in the vibration environment and discover potential problems and defects in a timely manner. This data-driven testing method provides a scientific basis for product optimization and improvement.

5.

Structural stability and durability

The mechanical structure of the low-frequency shaker is carefully designed to ensure stability and durability during long, high-intensity testing. The high rigidity frame and precision transmission system of the equipment ensure the smoothness and consistency of the vibration process, providing a strong guarantee for the accuracy of the test results.

Application Scenarios and Practical Benefits

Low-frequency shakers have a wide range of applications in many fields, and the practical benefits they bring are obvious:

- Product reliability testing

By simulating low-frequency vibration during transportation, the equipment helps manufacturers identify and resolve potential problems before the product leaves the factory. This not only improves product reliability, but also reduces returns and customer complaints due to transportation damage.

- Logistics Optimization and Cost Control

By analyzing vibration data, logistics experts can optimize packaging design and transportation solutions to better protect products. This not only improves logistics efficiency, but also reduces transportation costs. For example, in the transportation of automotive parts, simulated vibration testing can effectively reduce vibration-induced damage to parts, thereby reducing repair and replacement costs.

- Compliance and Standardization

In global trade, products are being shipped to increasingly stringent standards. Low-frequency vibration tables help companies ensure that their products meet a wide range of international and domestic transportation standards, thereby successfully passing all types of compliance reviews. For example, in the export of electronic products, simulated vibration testing ensures the safety and stability of products under different transportation conditions.

- R&D and Innovation Support

Low frequency shakers are an important tool for R&D teams. By simulating a variety of transportation conditions, R&D staff can evaluate the performance of new materials and designs to drive product innovation and development. For example, in the R&D of new packaging materials, simulated vibration testing can assess their seismic performance and durability, providing data to support the promotion and application of new materials.

Installation and Operation Points

To fully utilize the advantages of a low frequency shaker, the following installation and operation points should not be overlooked:

- Environment

The equipment should be installed in an environment away from external vibration sources to avoid external interference affecting the accuracy of test results. A stable test environment is the basis for reliable data.

- Regular Calibration and Maintenance

The equipment's sensors and drive train require regular calibration and maintenance to ensure their accuracy and reliability. This ongoing maintenance is the key to ensuring consistent test results.

- Safe Operating Procedures

Operators must follow strict safety procedures to ensure the safety of personnel and equipment during testing. This is not only for the protection of personnel, but also for the guarantee of the service life of the equipment.

- Professional training and knowledge accumulation

The operation of the equipment requires certain specialized knowledge. Providing systematic training and continuous knowledge accumulation is crucial for operators, which can help them better understand and use this precision instrument.

| Item | DR-B216 |

| Max. Test Load | 100kg |

| Frequency Range | 60-300rpm |

| Amplitude Range | 25.4mm (1 inch) |

| Simulation Speed | 25~40km/h |

| Vibration Mode | Roundtrip |

| Work Table Size | 1000*1200 mm ( L*W, can be customized ) |

| Outside dimension ( L*W*H ) | 1255*1070*660mm |

| Speed Mode | DC converter or AC Frequency Control |

| Power Capacity | 1 HP |

| Weight | 150kg |

| Power | 220V, 50 Hz |

| Speed Mode | DC converter or AC Frequency Control |

| Environmental Conditions | Temperature: 5~40C; Related Humidity <85% |

Robust Construction for Reliable Testing

Our Low Frequency Vibration Table is crafted from industrial-grade, high-strength steel to ensure durability under demanding testing conditions. This robust structure delivers consistent performance, while its floor-mounted design offers stability for various package sizes and weights. It's ideally suited for manufacturers and exporters requiring dependable transport simulation.

User-Friendly Digital Control and Safety

This equipment offers digital LED controls, making it straightforward to set and monitor speed, time, and amplitude with 1% accuracy. Built-in features such as overload protection and an emergency stop switch guarantee operational safety, allowing operators to manage tests with confidence.

Versatile Simulation for Packaging Assurance

Engineered to accommodate up to 60 kg and specimen sizes of 600 x 500 mm, the table simulates real-world road transport conditions. Ideal for package vibration testing, this semi-automatic device ensures that your products can withstand transport vibrations, minimizing shipping damage and enhancing customer satisfaction.

FAQ's of Low frequency vibration table simulation transportation test:

Q: How does the Low Frequency Vibration Table simulate road transport vibration?

A: The table uses a reciprocating motion with adjustable speed and amplitude to replicate the vibrations packages experience during road transport. This allows users to assess packaging durability and product protection under realistic transportation conditions.Q: What types of specimens can be tested with this vibration table?

A: You can test specimens up to 600 x 500 mm in size, with a maximum weight of 60 kg. The machine accommodates 1-2 pieces per test, making it ideal for testing boxes, crates, or other packaged goods.Q: When should I use this equipment for my products?

A: It's best utilized before shipping new or redesigned packaging solutions. By running transport simulation tests, you can evaluate and improve your packaging's ability to protect products during transit, reducing risk of damage and returns.Q: Where is the optimal environment for operating this vibration table?

A: The vibration table is designed for indoor use in environments with temperatures from 5C to 40C and humidity not exceeding 85% RH. It requires no gas supply, only standard AC 220V power.Q: What is the process for conducting a vibration test on this table?

A: Simply place your specimen on the table, secure it, and use the digital control panel to set your desired speed and test time. The machine's LED display shows real-time parameters, and built-in safety features help ensure safe operation throughout the test.Q: How does this equipment benefit manufacturers and exporters?

A: By simulating real-world transportation vibrations, the table helps identify potential packaging weaknesses. This enables manufacturers and exporters to make improvements, ensuring higher product integrity upon delivery and reducing claims or returns due to shipping damage.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese