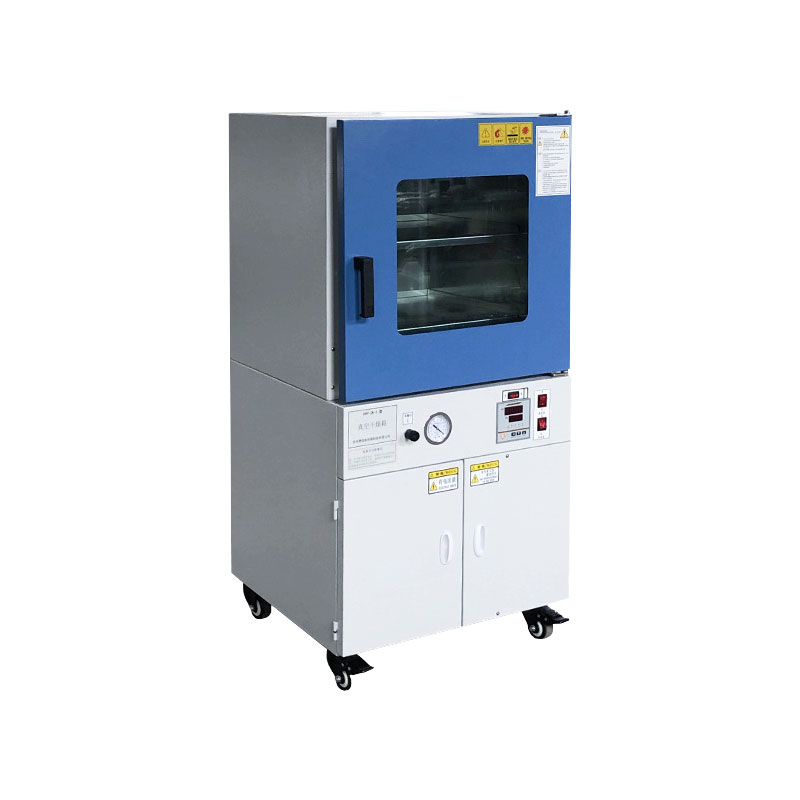

Multi-Stage Laboratory Vacuum Drying Oven for Electronic Component Testing

139805.0 INR/Unit

Product Details:

- Hardness N/A for oven

- Number of Specimens 1~4 pcs/batch

- Power Supply 220V AC, 50/60 Hz

- Accuracy 1C, 2% RH

- Mounting Type Floor Standing

- Test Range 0.1 760 mmHg

- Max Height 600 mm

- Click to view more

X

Multi-Stage Laboratory Vacuum Drying Oven for Electronic Component Testing Price And Quantity

- 139805.0 INR/Unit

- 1 Unit

- Toughened glass observation window with silicone gasket

- 2 adjustable stainless steel shelves

- <60 dB

- Overheat and overcurrent protection, auto alarm

- 0 to 9999 minutes (programmable)

- Analog and digital dual display

- High-grade stainless steel inner chamber, powder coated exterior

- 540C, non-corrosive atmosphere

- Uniform hot air circulation with forced convection

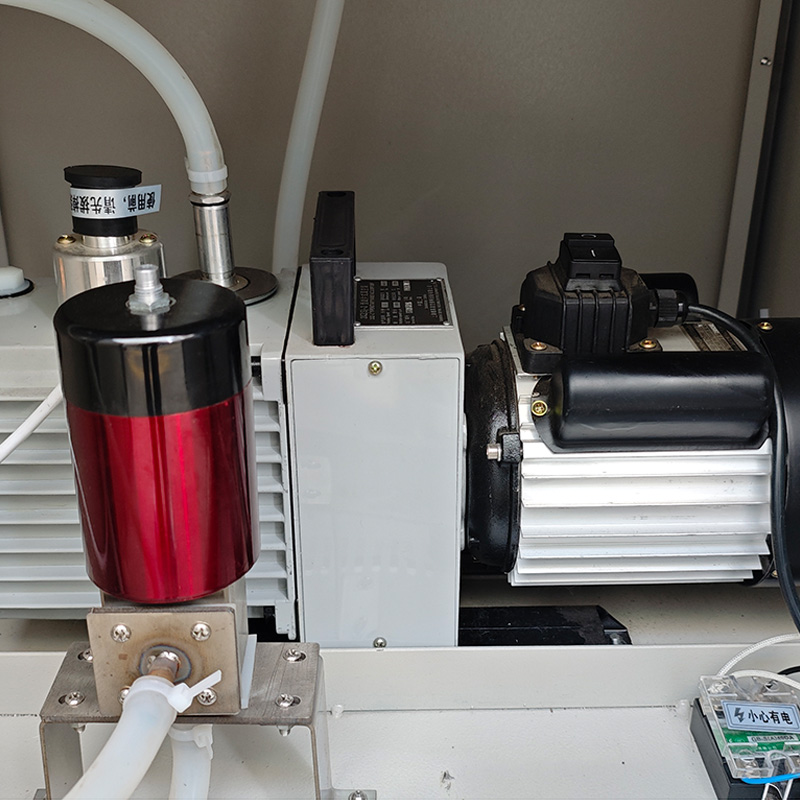

- Oil-sealed rotary vane (included)

Multi-Stage Laboratory Vacuum Drying Oven for Electronic Component Testing Product Specifications

- N/A for oven

- 300 mm

- 220V AC, 50/60 Hz

- 1~4 pcs/batch

- 1C, 2% RH

- Floor Standing

- 0.1 760 mmHg

- 600 mm

- RS232/PLC Compatible

- 0.1 760 mmHg

- 0.1C/0.1% RH

- Approx. 120 kg

- Semi-automatic

- Lab drying, moisture analysis, component reliability testing

- 220V AC

- Max 350 mm

- < 8 sec

- 52 Liters

- Electronic Component Testing

- Vacuum Drying Oven

- Room temperature to 200C

- Multi-stage programmable cycles, Vacuum & gas purge, Overtemperature protection

- Digital PID Controller

- Up to 200 x 200 x 100 mm

- DN25 (inlet/outlet)

- 50/60 Hz

- 0.1~0.9 MPa

- Digital LCD

- 10%~85% RH (ambient)

- Adjustable, up to 5 cycles/min

- Toughened glass observation window with silicone gasket

- 2 adjustable stainless steel shelves

- <60 dB

- Overheat and overcurrent protection, auto alarm

- 0 to 9999 minutes (programmable)

- Analog and digital dual display

- High-grade stainless steel inner chamber, powder coated exterior

- 540C, non-corrosive atmosphere

- Uniform hot air circulation with forced convection

- Oil-sealed rotary vane (included)

Multi-Stage Laboratory Vacuum Drying Oven for Electronic Component Testing Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 10 Days

- All India

Product Description

Engineered to meet the rigorous demands of modern electronics manufacturing, multi-stage laboratory vacuum drying ovens address critical challenges in moisture removal and thermal stabilization for advanced component testing. These systems combine precision vacuum control with programmable thermal regimes to ensure compliance with industry standards for IC packaging, MEMS fabrication, and aerospace-grade electronics.

Operational Mechanics & Key Features

1. Adaptive Multi-Stage Drying Protocols

Programmable sequences with 8 independent phases allow customized ramp/soak profiles (0.1C/min to 5C/min), critical for preventing delamination in multi-layer PCBs and BGA components.

Stage-specific vacuum control (510 Torr to ambient) prevents outgassing damage to conformal coatings during transition cycles.

2. ESD-Safe Processing Environment

Faraday cage-integrated chamber (surface resistivity <10 /sq) with grounded shelving eliminates static charge accumulation on sensitive semiconductors.

Nitrogen purge capability maintains <10 ppm O levels during cooling phases to prevent oxidation of exposed metallic contacts.

3. Non-Destructive Moisture Extraction

Hybrid vacuum-convection technology achieves 15% faster moisture removal vs. standard models (per IPC J-STD-033 Class 5 criteria), maintaining 50 ppm residual moisture in hermetically sealed packages.

Real-time mass loss monitoring via microbalance integration (0.1 mg resolution) enables closed-loop humidity control.

4. Thermal Gradient Mitigation

Triple-redundant PID controllers maintain 0.8C uniformity across 45 ft workspace, essential for batch processing of mixed-component assemblies.

Recirculating HEPA filtration (ISO Class 5 equivalent) prevents particulate contamination during vapor evacuation.

Performance Validation

Materials Compatibility Testing

Verified operational stability across:

Temperature: 40C (pre-cooling) to 200C (bake-out)

Relative humidity: 2% to 98% RH (simulated conditioning mode)

Vacuum endurance: 72+ hours continuous operation at 110 Torr

Data Integrity Assurance

21 CFR Part 11-compliant audit trails document all process variables (temperature/vacuum/time) with cryptographic timestamping.

RS-485 and Ethernet/IP outputs enable direct integration with MIL-STD-461 test setups.

Critical Applications

1. Pre-Conditioning for MIL-STD-883 Testing

Prepares moisture-sensitive devices (MSD Level 2A-3) for thermal shock (Method 1011.9) and steady-state life testing (Method 1005.8).

2. Wafer-Level Packaging

Multi-stage dehydration sequences prevent stiction in MEMS structures during critical point drying (CPD) phases.

3. Automotive Electronics Certification

AEC-Q200 compliant drying protocols for capacitors and inductors, featuring IATF 16949-aligned process documentation.

Safety & Compliance Architecture

Redundant pressure relief valves (ASME Section VIII Div.1 certified)

Automatic leak detection (110 cc/sec He sensitivity) with visual/audible alerts

UL 61010-1/CSA C22.2 No. 61010-1 certified electrical systems

ROHS 3 (Directive 2015/863) compliant construction materials

customized support

OEM, ODM

place of origin

Guangdong, China

power

3500W

Voltage

380V

warranty

1 Year

brand name

Derui

Temperature range

RT to 300'C

Display accuracy

0. 1

Uniformity

1%

Material

SUS#304 Stanless steel

Temperature controller

LED digital display

Power

14kw

Power supply

380V

Precision Multi-Stage Drying for Sensitive Components

Designed for precise moisture removal and reliability testing, the oven provides highly accurate temperature and humidity control. Its multi-stage programmable cycles enable complex testing procedures vital for electronic component quality assurance. This advanced technology ensures uniform drying and thorough analysis, making it suitable for demanding laboratory applications.

Superior Build and Enhanced Safety Features

Housed in robust high-grade stainless steel, the oven features an oil-sealed rotary vane pump and a vacuum-tight chamber. Safety is prioritized with dependable overheat and overcurrent protection, as well as automatic alarms. The toughened glass window allows convenient sample inspection without disturbing internal conditions.

User-Friendly Operation and Flexible Testing

The digital LCD interface and PID control offer easy programming of test cycles, temperature, and vacuum parameters. Dual vacuum gauge displays guarantee real-time monitoring, while adjustable shelves accommodate various specimen sizes. Connectivity through RS232/PLC provides seamless integration into laboratory workflows, facilitating smooth, semi-automatic operation.

FAQs of Multi-Stage Laboratory Vacuum Drying Oven for Electronic Component Testing:

Q: How does the multi-stage vacuum drying process work in this oven?

A: The oven utilizes a programmable digital PID controller that enables multi-stage drying cycles. Uniform hot air circulation combined with forced convection ensures consistent drying, while the vacuum and gas purge cycles quickly and efficiently remove moisture from electronic components, guaranteeing precise and repeatable results.Q: What components are suitable for testing in this vacuum drying oven?

A: This oven is specifically designed for electronic component testing, moisture analysis, and reliability assessments. It can accommodate specimen sizes up to 200 x 200 x 100 mm and process 1 to 4 pieces per batch, making it ideal for semiconductors, circuit boards, and various sensitive electronic parts.Q: When should I use the programmable timer feature?

A: The timer, programmable from 0 to 9999 minutes, should be used whenever precise drying durations are required. This ensures that the oven runs for the exact amount of time needed for each test or drying stage, improving accuracy and repeatability in laboratory testing procedures.Q: Where can this vacuum drying oven be installed?

A: The oven is designed for laboratory environments such as research institutions, electronics testing centers, and quality control labs. It is a floor-standing model suited for controlled indoor environments with temperatures between 540C and non-corrosive atmospheres.Q: What is the process for adjusting shelf height and loading specimens?

A: The oven comes with two adjustable stainless steel shelves that can be repositioned easily to accommodate different specimen heights. Simply open the toughened glass observation door, adjust the shelves to the desired height, and load the specimens. Ensure proper spacing for efficient hot air circulation around each sample.Q: How does the oven enhance safety during operation?

A: It incorporates several safety features, including overheat and overcurrent protection, automatic alarms, and a toughened glass observation window with a silicone gasket. These ensure safe operation by preventing overheating, electrical faults, and maintaining a secure vacuum environment.Q: What are the main benefits of using this oven for electronic component testing?

A: Key benefits include rapid and uniform drying, high accuracy (1C, 2% RH), programmable multi-stage cycles, real-time dual vacuum gauge monitoring, energy efficiency, and robust safety systems. These features together help achieve consistent, reliable test results for critical electronic components.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese