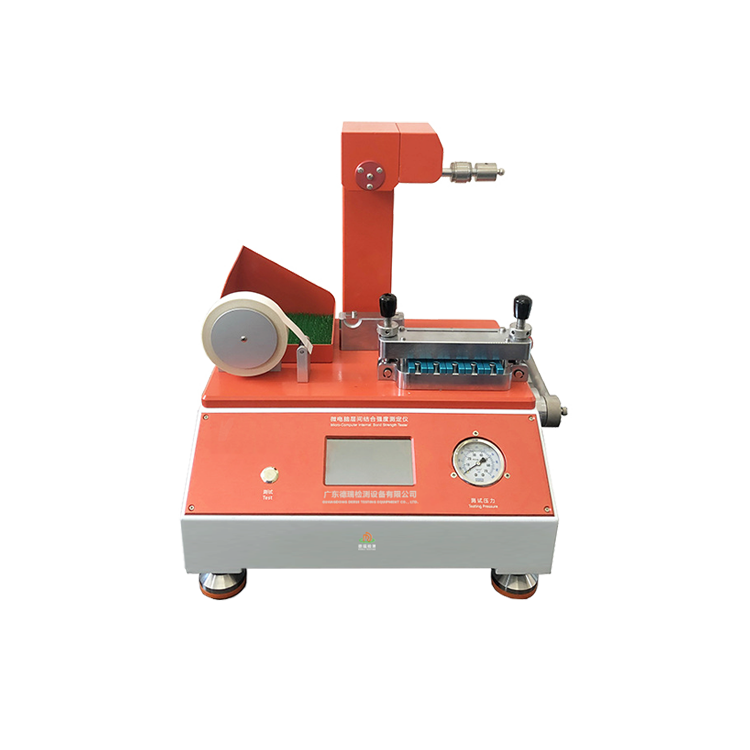

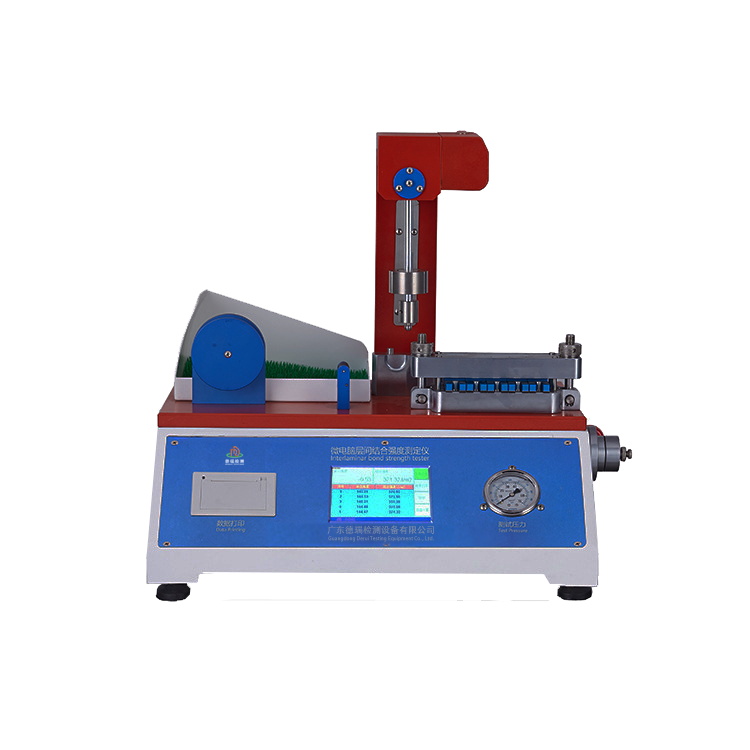

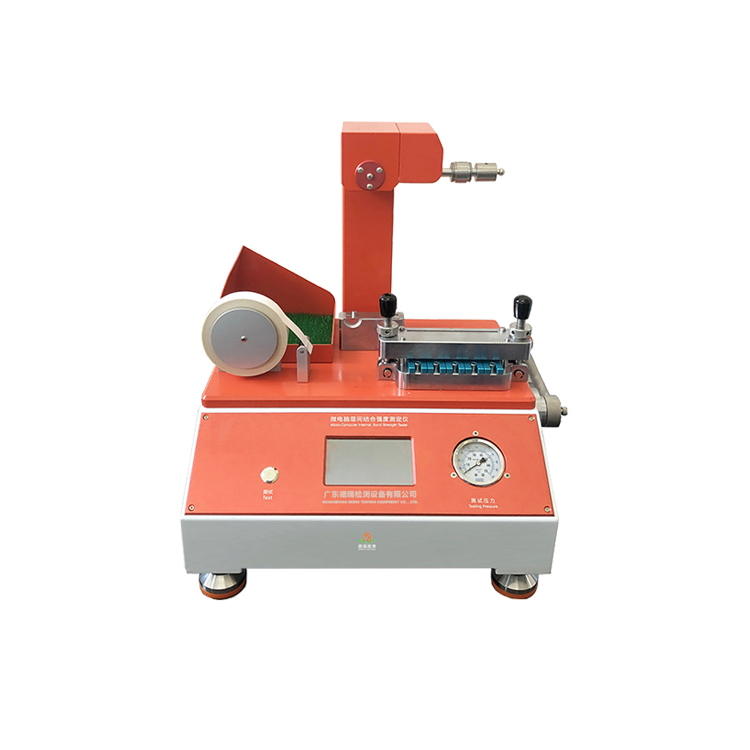

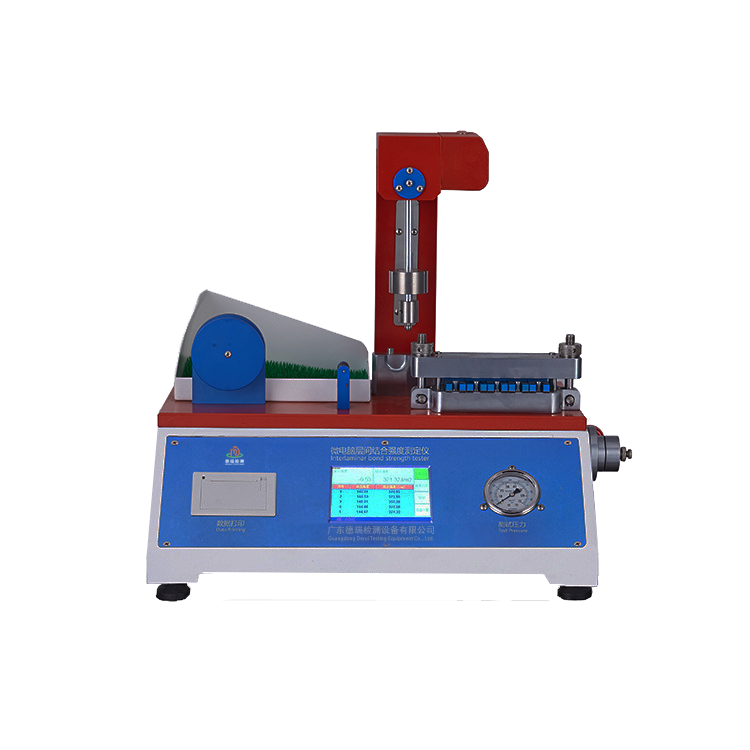

High-Precision Cardboard Interlayer Bonding Tester for Packaging Industry

138005.0 INR/Unit

Product Details:

- Accuracy 1% FS

- Application Bonding strength test for corrugated/cardboard packaging materials

- Interface Type RS232/USB

- Hardness Industrial grade construction

- Operating Voltage 220V

- Equipment Type High-Precision Cardboard Interlayer Bonding Tester

- Max Height 420 mm

- Click to view more

X

High-Precision Cardboard Interlayer Bonding Tester for Packaging Industry Price And Quantity

- 1 Unit

- 138005.0 INR/Unit

- 100 W (typical)

- Motor overload, over-travel, and emergency stop

- Clamping jaws, calibration weight, user manual

- Automatic and manual

- 580 mm x 380 mm x 420 mm (L x W x H)

- Eco-friendly design

- English/Chinese selectable

- <55 dB

- Up to 100 test results

- USB download and direct printing support

- 304 Stainless Steel

High-Precision Cardboard Interlayer Bonding Tester for Packaging Industry Product Specifications

- Industrial grade construction

- RS232/USB

- 1000 N

- Touch screen & Microcomputer control

- 220V

- High-Precision Cardboard Interlayer Bonding Tester

- 420 mm

- 1% FS

- Bonding strength test for corrugated/cardboard packaging materials

- Up to 50 mm

- High precision, automatic data processing, user friendly interface, real-time curve display

- 101000 N

- 2 ms

- 5 mm/min (adjustable)

- Digital LCD Touch Screen

- 62 kg

- Benchtop

- 0.01 N

- Semi-automatic

- 1

- 25 mm x 100 mm (W x L)

- 01000 N

- 0.6 MPa (if pneumatic specimen clamping)

- Standard ISO fixture

- Paper, cardboard, packaging industry bonding strength measurement

- AC 220V 10%, 50Hz

- 20%85% RH (non-condensing)

- 50 Hz

- 10C40C

- 25 mm

- 100 W (typical)

- Motor overload, over-travel, and emergency stop

- Clamping jaws, calibration weight, user manual

- Automatic and manual

- 580 mm x 380 mm x 420 mm (L x W x H)

- Eco-friendly design

- English/Chinese selectable

- <55 dB

- Up to 100 test results

- USB download and direct printing support

- 304 Stainless Steel

High-Precision Cardboard Interlayer Bonding Tester for Packaging Industry Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 10 Days

- All India

Product Description

The cardboard interlayer bonding tester is suitable for the interlayer adhesion test of paper for base paper industrial packaging, and the total energy required to divide the internal fibers of the sample into two layers along the Z-shaped direction is measured by pendulum impact, and the interlayer bonding strength can be used to detect the interlayer adhesion strength test of sheet materials such as paper composite materials and film packaging composites at the same time.

It is suitable for paper mills, scientific research institutes and quality inspection departments.

According to the standard:

GB/T 34444 Determination of interlayer peel strength of paper and cardboard

TAPPI T569 Internal Binding Strength - Scott Type

ISO 16260 Paper and Cardboard. Determination of internal bond strength.

GB/T 34444 Determination of interlayer peel strength of paper and cardboard

TAPPI T569 Internal Binding Strength - Scott Type

ISO 16260 Paper and Cardboard. Determination of internal bond strength.

Technical parameters:

1. Sampling size and quantity: 25.4mm130mm; 5 sets of square specimens

2. Sample size: 25.4mm25.4mm

3. Maximum sampling thickness: 5mm

4. Commonly used sample pressure: (68020) kpa or (123434) kpa,

5. Specimen clamping force: 0~460N (adjustable)

6. Sample pressure range: 0~100kg/cm(0~1000psi)

7. First-level pressure area: 12.72cm

8. Parallel positioning of the specimen seat: R=0.410

9. Pressure-to-arm ratio: 231.08:0.8

10. Release mode: fully automatic release

11. Impact angle: The standard impact energy release angle is 90

12. Resolution: 0.001lbf/in, 8000 pulse high-precision encoder with data acquisition and resolution ability

13. The viscosity of double-sided tape to stainless steel is greater than: 486N/m

14. Measuring range: A: (0~500)J/M2; B file: (500~1000) J/M2

C file: (1000~1500) J/M2

15. Self-approval: special level 5 calibration tool set (optional)

16. Indication error: A file: 0.5J/m2; B file: 1J/m2

17. Unit: J/M2, lbf/in interchange

18. Human-machine interface: 7IN touch screen control, real-time display of test data, impact angle, etc

19. Software: You can choose computer connection software, office file processing documents, terminal A4 printing

20. Printout: modular all-in-one thermal printer

21. Dimensions: 550m 420cm660mm

22. Weight: 75KG

1. Sampling size and quantity: 25.4mm130mm; 5 sets of square specimens

2. Sample size: 25.4mm25.4mm

3. Maximum sampling thickness: 5mm

4. Commonly used sample pressure: (68020) kpa or (123434) kpa,

5. Specimen clamping force: 0~460N (adjustable)

6. Sample pressure range: 0~100kg/cm(0~1000psi)

7. First-level pressure area: 12.72cm

8. Parallel positioning of the specimen seat: R=0.410

9. Pressure-to-arm ratio: 231.08:0.8

10. Release mode: fully automatic release

11. Impact angle: The standard impact energy release angle is 90

12. Resolution: 0.001lbf/in, 8000 pulse high-precision encoder with data acquisition and resolution ability

13. The viscosity of double-sided tape to stainless steel is greater than: 486N/m

14. Measuring range: A: (0~500)J/M2; B file: (500~1000) J/M2

C file: (1000~1500) J/M2

15. Self-approval: special level 5 calibration tool set (optional)

16. Indication error: A file: 0.5J/m2; B file: 1J/m2

17. Unit: J/M2, lbf/in interchange

18. Human-machine interface: 7IN touch screen control, real-time display of test data, impact angle, etc

19. Software: You can choose computer connection software, office file processing documents, terminal A4 printing

20. Printout: modular all-in-one thermal printer

21. Dimensions: 550m 420cm660mm

22. Weight: 75KG

Scope of application:

Applicable to the interlayer adhesion of insulating paper: the interlayer adhesion strength test of electrical cardboard and electrical insulating cardboard

It is suitable for the interlayer peeling force of bobbin paper: the strength test of interlayer adhesion force of paper tube paper, bobbin paper and kraft paper

Applicable to the interlayer adhesion of gray cardboard: the strength test of the interlayer adhesion of various gray cardboard, cardboard and composite cardboard

Suitable for interlayer adhesion of cardboard: test the strength of interlayer adhesion of kraft cardboard, white card and whiteboard paper

It is suitable for the interlayer peeling force of packaging boxes: the strength test of interlayer adhesion force of color boxes, ciga rette boxes and packaging boxes

Applicable to others: other industrial paper that needs to be processed for interlayer adhesion strength test

Applicable to the interlayer adhesion of insulating paper: the interlayer adhesion strength test of electrical cardboard and electrical insulating cardboard

It is suitable for the interlayer peeling force of bobbin paper: the strength test of interlayer adhesion force of paper tube paper, bobbin paper and kraft paper

Applicable to the interlayer adhesion of gray cardboard: the strength test of the interlayer adhesion of various gray cardboard, cardboard and composite cardboard

Suitable for interlayer adhesion of cardboard: test the strength of interlayer adhesion of kraft cardboard, white card and whiteboard paper

It is suitable for the interlayer peeling force of packaging boxes: the strength test of interlayer adhesion force of color boxes, ciga rette boxes and packaging boxes

Applicable to others: other industrial paper that needs to be processed for interlayer adhesion strength test

Advanced Testing Features for Reliable Results

This tester delivers superior measurement accuracy, supported by a 0.01 N resolution and a fast response time ( 2 ms). The automatic data processing system and real-time curve display empower users to make informed decisions quickly, while memory storage for up to 100 results allows for convenient record-keeping and data management.

User-Friendly with Enhanced Safety and Accessibility

Equipped with a digital LCD touch screen and dual language (English/Chinese) support, operation is seamless for diverse operators. The machine boasts comprehensive safety features, including motor overload, over-travel, and emergency stop functions, ensuring safe use in busy manufacturing environments.

Robust Design, Flexible Operation

Constructed with industrial-grade materials, including 304 stainless steel fixtures, this benchtop tester supports both automatic and manual calibration. Its eco-friendly construction, low power consumption (100 W typical), and standard ISO fixture compatibility make it suitable for a wide range of packaging material tests in varying conditions.

FAQ's of High-Precision Cardboard Interlayer Bonding Tester for Packaging Industry:

Q: How do I store and retrieve test results using this bonding tester?

A: You can save up to 100 test results directly in the machine's memory. Data can easily be exported via USB or printed using the direct print option, allowing for seamless record keeping and analysis.Q: What types of cardboard and packaging materials can the tester measure?

A: The tester is designed for bonding strength measurement of corrugated and cardboard materials, making it suitable for various packaging products in paper, corrugated, and board industries.Q: When should I perform calibration, and what are the calibration options?

A: Calibration should be performed regularly according to your quality control protocol or whenever accuracy is in question. The device supports both automatic and manual calibration modes for precise and adaptable operation.Q: Where can this benchtop bonding tester be installed?

A: With its compact size (580 x 380 x 420 mm) and benchtop mounting design, the equipment fits easily into laboratory spaces and factory testing areas. It requires an AC 220V 10% power supply and operates optimally in temperatures of 10C-40C with 20-85% RH humidity.Q: What safety features are included to protect operators and the machine?

A: The tester incorporates motor overload protection, over-travel prevention, and an emergency stop mechanism. These features ensure both operator safety and the longevity of the equipment during intensive use.Q: How does the touch screen and microcomputer control improve the testing process?

A: The intuitive digital LCD touch screen, combined with microcomputer controls, simplifies operation and test setup. Users can quickly adjust parameters, view results in real-time, and access data, enhancing workflow efficiency and reducing the potential for error.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese