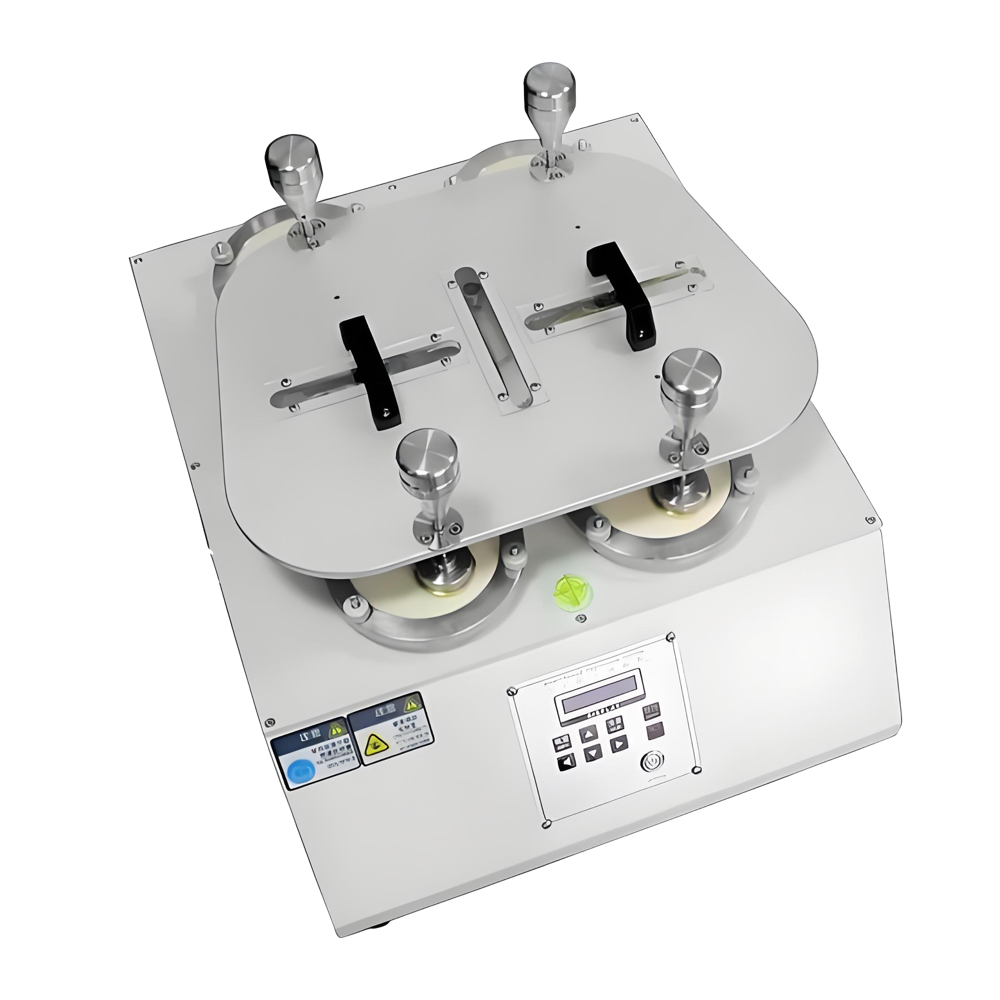

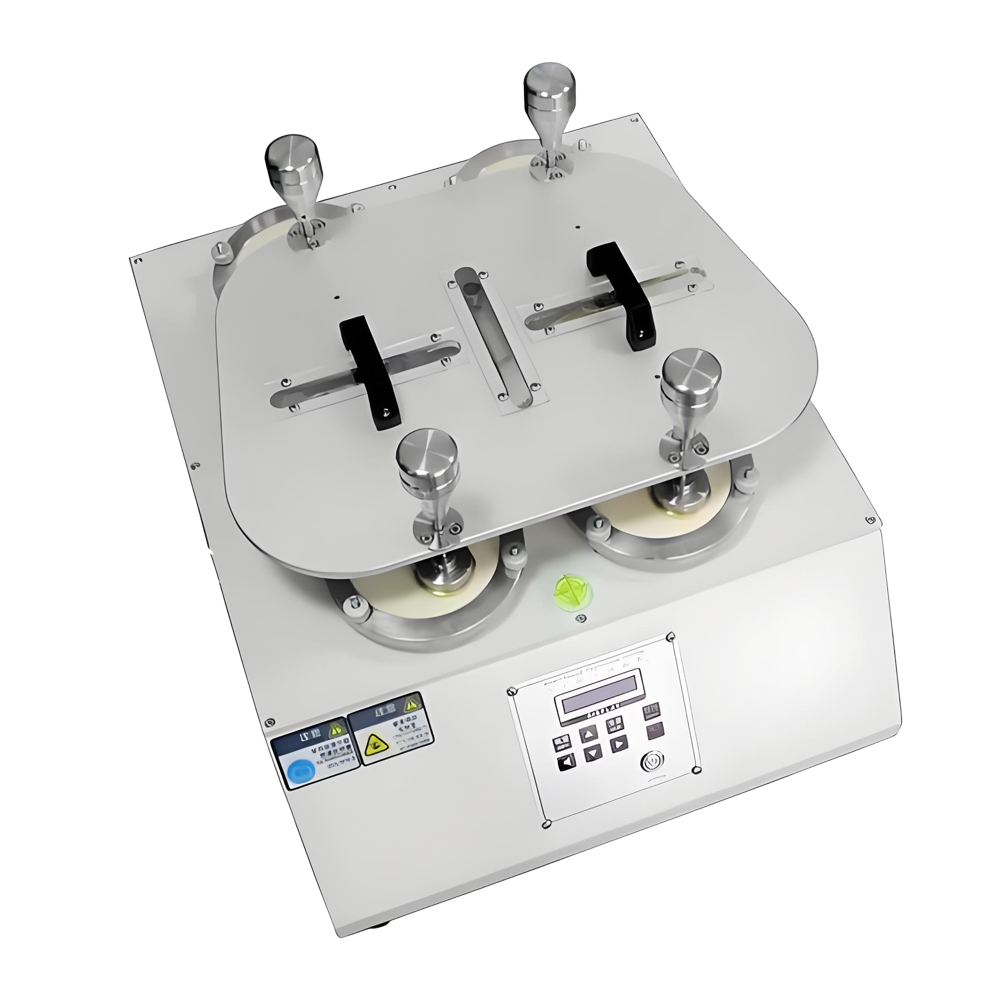

abrasion testing machine for glazed tiles

148005.0 INR/Unit

Product Details:

- Temperature 10C to 40C

- Mounting Type Floor standing

- Accuracy 1 cycle

- Features Corrosion resistant, easy sample mounting, adjustable stroke, robust structure

- Measuring Range 0 1000 cycles

- Response Time Instantaneous

- Port Size 1/4 inch

- Click to view more

X

abrasion testing machine for glazed tiles Price And Quantity

- 1 Unit

- 148005.0 INR/Unit

- Digital, configurable up to 9999 sec

- Conforms to IS 13630 / ISO 10545-7

- Standard Abrasive Powder Aluminum Oxide

- 750 mm x 400 mm x 400 mm

- Mild Steel with Powder Coating

- <70 dB

- Removable and interchangeable

- Overload protection, Emergency stop

abrasion testing machine for glazed tiles Product Specifications

- 0 1000 cycles

- Up to 95% RH

- Push-button and Digital Display

- Approx. 60 kg

- 1 at a time

- 230 V AC

- Abrasion Testing Machine for Glazed Tiles

- 100 mm x 100 mm

- 300 10 rpm

- 1 cycle

- Floor standing

- Manual or Digital Control

- 10C to 40C

- Instantaneous

- 0 1000 cycles

- 1/4 inch

- Corrosion resistant, easy sample mounting, adjustable stroke, robust structure

- 3 kg (Abrasive Load)

- 400 mm

- Laboratory, Quality Control

- 230 V AC, 50 Hz

- 1 cycle

- 50 Hz

- 50 mm

- Digital LCD

- Glazed tile surface abrasion resistance test

- Semi-automatic

- Up to 7 Mohs (Tile suitability)

- 200 mm

- Digital, configurable up to 9999 sec

- Conforms to IS 13630 / ISO 10545-7

- Standard Abrasive Powder Aluminum Oxide

- 750 mm x 400 mm x 400 mm

- Mild Steel with Powder Coating

- <70 dB

- Removable and interchangeable

- Overload protection, Emergency stop

abrasion testing machine for glazed tiles Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 7 Days

- All India

Product Description

| Item | DR-J803 |

| Stations | 6 Stations |

| Interface | LCD display |

| Count display | Projected Count: 0 ~ 999 999 times; |

| Cumulative count: 0 ~ 99 9999 times | |

| Maximum stroke | 24 0.5mm, 60.5 0.5mm |

| Loading | a. Holder:2001g |

| b. Dress material counter weight: 3952g | |

| c. Furnishings/Leather material counter weight: 5942g | |

| d. Stainless steel butterfly slice: 2601g | |

| Abrasion chunk effective rub diameter | A model: 200g(1.96N,9KPa) , abrasion head 28.8 -0.084mm |

| B model: 155g(1.52N,12KPa) , abrasion head 90 -0.10mm | |

| Pace speed of the holder | 50-2r/min |

| Sample loading pressure hammer | 238510g |

| consumables | Baize 6, Testing Cotton 6 |

| Diameter of abrasion fabric | 140mm |

| Diameter of Specimen | 38mm |

| Power | AC 220V/50Hz |

| Overall dimension | 50cmx60cmx32cm(LWH) |

| Weight | 76 KG |

product overview

The glazed tile wear tester is a high-precision testing equipment specifically designed to test the wear resistance of glazed tiles. By simulating the wear process in actual use, this equipment can accurately evaluate the surface wear resistance of glazed tiles, ensuring that they meet relevant industry standards and quality requirements.

Product Features

one

Wear resistance test

Conduct wear tests on the surface of glazed tiles by rotating the grinding disc or friction wheel, simulating the actual wear situation during use.

Can test the wear resistance of glazed tiles under different pressure, speed, and time conditions.

two

Multiple testing modes

Supports multiple testing modes such as dry grinding and wet grinding to meet different testing needs.

Test parameters can be customized according to customer needs, such as speed, pressure, testing time, etc.

three

High precision measurement

Adopting high-precision sensors and control systems to ensure the accuracy and repeatability of test results.

Real time recording of wear and tear, providing detailed testing data and analysis reports.

four

User friendly design

Equipped with a touch screen operation interface, the operation is simple and intuitive, making it easy for users to quickly get started.

Built in multiple testing programs, supporting one click start and automatic stop functions.

five

Durable and sturdy

Adopting high-strength materials and precision machining processes to ensure the stability and durability of the equipment during long-term use.

Suitable for laboratory and industrial production environments.

application area

Building materials industry: used to test the wear resistance of glazed tiles, ceramic tiles and other materials.

Quality inspection agency: provides wear resistance testing services that meet industry standards for building materials products.

R&D laboratory: used for researching and developing the wear resistance of new materials.

Compliant with standards

GB/T 3810.7 "Test methods for ceramic tiles - Part 7: Determination of wear resistance of glazed tiles"

ISO 10545-7 "Ceramic tiles - Part 7: Determination of wear resistance of glazed tiles"

Other relevant international and industry standards

Advanced Testing Accuracy

Engineered for high-precision testing, this machine delivers consistent results with an accuracy of 1 cycle and a measurement range up to 1,000 cycles. The digital LCD ensures instant and clear readouts, while push-button controls simplify operation for laboratory technicians and quality control professionals.

Enhanced Safety and Durability

Built with user safety and durability in mind, this abrasion tester incorporates overload protection and an emergency stop feature. Its powder-coated mild steel body resists corrosion and wear, ensuring dependable operation and a long service life, even under rigorous laboratory use.

Flexible and User-Friendly Operation

Designed for ease of use, the sample holder is fully removable and interchangeable, accommodating standard tile specimens (100 mm x 100 mm). The adjustable stroke and intuitive controls allow both manual and digital operation, making it suitable for diverse abrasion resistance testing applications.

FAQ's of abrasion testing machine for glazed tiles:

Q: How does the abrasion testing machine assess glazed tile resistance?

A: The machine evaluates the abrasion resistance of glazed tiles by subjecting them to cycles of rubbing with standard aluminum oxide powder. The tile specimen is securely held, and the abrasive is applied in a controlled motion at 300 10 rpm, allowing precise measurement up to 1,000 test cycles.Q: What types of tiles can be tested with this equipment?

A: This machine is suitable for glazed tiles up to 100 mm x 100 mm and with surface hardness up to 7 Mohs, following IS 13630 and ISO 10545-7 standards. It is mainly used for laboratory and quality control applications in tile manufacturing industries.Q: When should I use the emergency stop feature?

A: The emergency stop button should be pressed immediately in case of any unsafe operating conditions, unexpected malfunctions, or if the specimen or machine exhibits abnormal behavior that could risk damage or injury.Q: Where is the abrasion testing machine typically installed?

A: Due to its dimensions (750 x 400 x 400 mm) and weight (approximately 60 kg), the machine is designed for floor-standing installation within laboratories, manufacturing facilities, or quality control departments.Q: What is the typical process for operating the tester?

A: Begin by securely mounting the tile specimen using the removable holder. Set your desired test parameters with the digital timer and choose the operation mode (manual or digital). After loading the appropriate abrasive powder, start the test. Results are displayed instantly on the LCD upon completion.Q: How does the machine benefit tile manufacturers and exporters?

A: With its high accuracy, digital controls, and adherence to international standards, the machine enables manufacturers and exporters to reliably certify glazed tile durability, ensuring product quality and compliance for domestic and international markets.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese