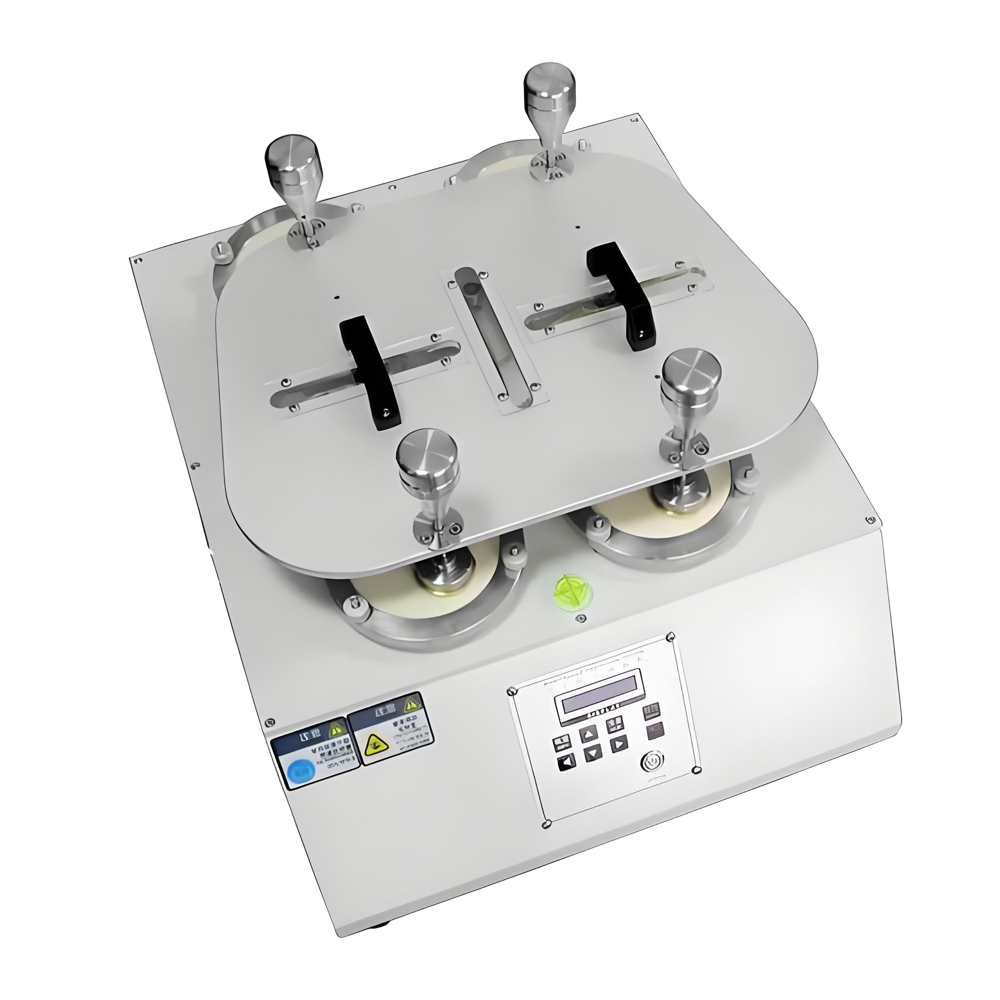

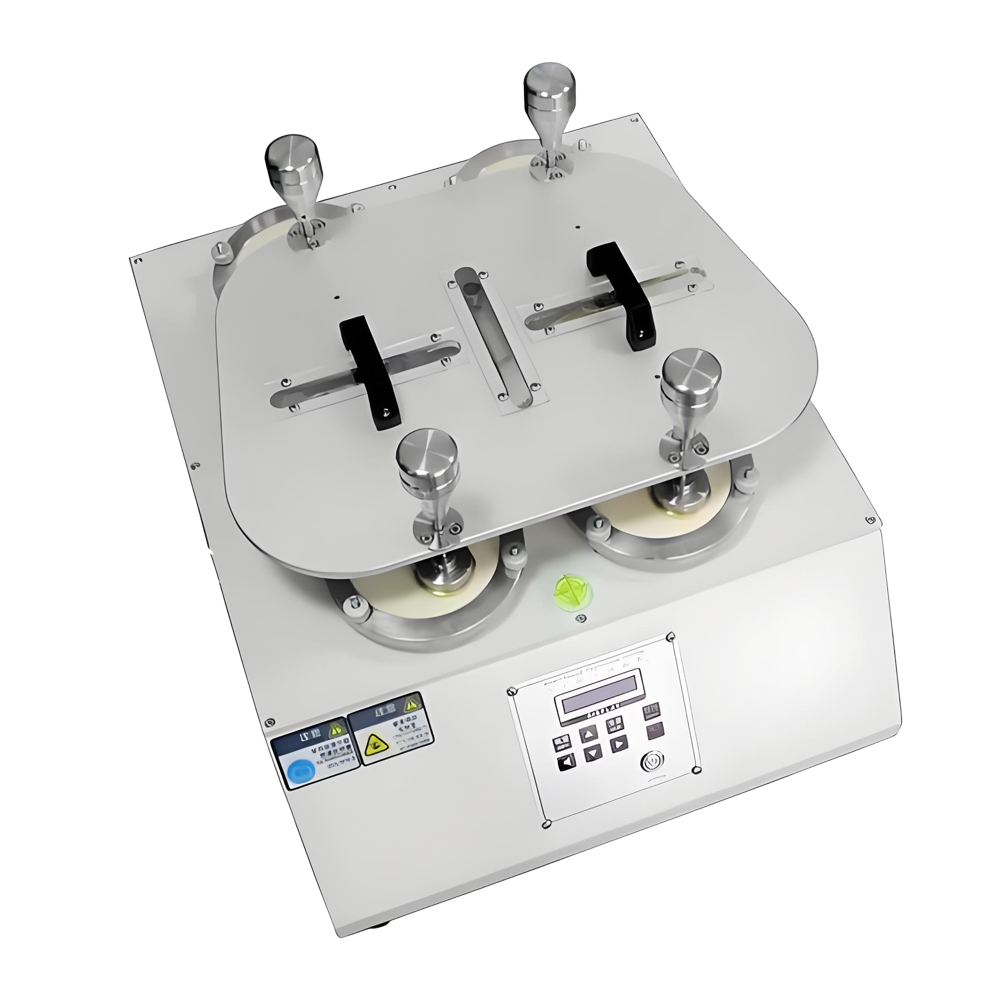

martindale abrasion testing machine

155005.0 INR/Unit

Product Details:

- Specimen Size 38 mm, 90 mm (as per ISODIN/BS/AATCC standards)

- Application Textile, fabric, non-woven, leather wear and abrasion resistance test

- Frequency 50 Hz

- Accuracy 1 cycle

- Display Type LCD digital display

- Power Supply AC 220V 10%, 50Hz

- Temperature 15C - 35C (recommended)

- Click to view more

X

martindale abrasion testing machine Price And Quantity

- 1 Unit

- 155005.0 INR/Unit

- Automatic stop on completion or abnormal operation

- Sample holders, abrasive fabric, weights, user manual, spanner

- 9 kPa or 12 kPa (as per fabric type)

- ISO 12947-1/2/3/4, EN 530, ASTM D4966, ASTM D4970, BS 5690, DIN 53863, JIS L1096

- <65 dB(A)

- Digital programmable timer

- Stainless steel

- High precision geared motor drive

martindale abrasion testing machine Product Specifications

- 24 0.5 mm (standard), 60.5 0.5 mm (optional)

- Textile, fabric, non-woven, leather wear and abrasion resistance test

- 50 Hz

- 38 mm, 90 mm (as per ISODIN/BS/AATCC standards)

- Approximately 80 kg

- LCD digital display

- 1 cycle

- AC 220V 10%, 50Hz

- Digital / programmable control panel

- 15C - 35C (recommended)

- Conforms to Martindale test requirements

- 4, 6, or 8 heads (interchangeable depending on model)

- Standard test plate size per sample: 120 mm

- Touch control panel

- 40% - 70% RH (recommended)

- 47.5 5 rpm

- Tabletop

- 1 999,999 cycles

- Programmable preset counts, cycle counter, easy holder change, emergency stop, digital display

- Semi-automatic/Digital

- Martindale Abrasion & Pilling Tester

- Sample thickness up to 25 mm

- Up to 999,999 cycles

- Immediate (real-time counting)

- 220V AC

- No direct width; suitable for standard Martindale specimens

- Up to 8 test holders

- Not required for operation

- 1 cycle

- For determining wear and pilling resistance of textiles

- Automatic stop on completion or abnormal operation

- Sample holders, abrasive fabric, weights, user manual, spanner

- 9 kPa or 12 kPa (as per fabric type)

- ISO 12947-1/2/3/4, EN 530, ASTM D4966, ASTM D4970, BS 5690, DIN 53863, JIS L1096

- <65 dB(A)

- Digital programmable timer

- Stainless steel

- High precision geared motor drive

martindale abrasion testing machine Trade Information

- Cash in Advance (CID)

- 90 Unit Per Month

- 5 Days

- All India

Product Description

martindale abrasion testing machine Technical parameters:

| Model | DR-J803-1 Martindale Abrasion Tester |

| Station number | 4 station , 6 station , 8 station , 9 station (custom) |

| Count display | a. Estimated counting:0~999999 times |

| b. Total counting:0~999999 times | |

| Maximum dynamic range | 240.5mm ,60.50.5mm |

| Weight of pressure thing | a.Gripper:2001g |

| b. Cloth samples hammer:3952g | |

| c. Furniture accessories sample hammer:5942g | |

| d. Stainless steel butterfly piece:2601g | |

| Effective friction diameter of grinding block | A type: 200g (1.96N) friction head 28.8-0.084mm |

| B type: 155g (1.52N) friction head 90-0.10mm | |

| The relative velocity of Gripper and the grinding station | 50-2r/min |

| Weight of pressure hammer | 238510g |

| Dimensions | 885mm600mm410mm(LWH) |

| Weight | 150kg |

| Power | Ac220V,50Hz |

The Martindale abrasion tester is mainly used to test the wear resistance of fabrics or other materials under friction. The following are its main application areas:

one

Textile industry:

Evaluate the wear resistance of clothing fabrics, home textile products, curtains, tablecloths, and other fabrics, especially during daily use and cleaning processes.

Through testing, ensure the wear resistance of the fabric after prolonged wearing or use.

two

Carpet and flooring materials:

Carpets, floor coverings, and other flooring materials often face friction and wear, and their durability and wear resistance are tested to ensure the quality stability of the product after long-term use.

three

Footwear industry:

Fabric and leather materials such as shoe uppers and insoles require friction resistance, and the Martindale abrasion tester can evaluate their durability to ensure the durability of footwear products.

four

Furniture industry:

The fabrics and leather materials of furniture such as sofas and chair cushions are prone to wear and tear during use. This test evaluates the wear resistance of the fabrics and improves the quality of the products.

five

Automotive interior materials:

Materials such as car seats and floor mats are often subject to friction, and using the Martindale abrasion tester can help evaluate the durability and service life of the materials.

six

Industrial fabrics and filter materials:

Industrial fabrics, filter cloths, tooling fabrics, etc. also face the challenge of long-term friction and wear. Testing their wear resistance can help improve the efficiency of product use.

Product selection of Martindale abrasion tester

When choosing a Martindale abrasion tester, the following aspects need to be considered:

one

Testing standards and requirements:

Different application areas may require compliance with different international standards, such as ISO 12947, ASTM D4966, EN 530, etc. It is particularly important to choose standards that are suitable for your product requirements.

two

Sample size and testing area:

Select the appropriate testing machine based on the size and type of the sample. For example, some tests require larger or smaller sample areas, or higher loads and speeds.

three

Load regulation range:

Different materials may require different loads for testing, and choosing a testing machine with a wide range of load adjustment can adapt to testing more materials.

four

Friction disc material and surface texture:

The material and surface characteristics of the friction disc will affect the test results. Common friction disc materials include natural rubber, leather, etc. Friction discs of different materials are suitable for different types of testing.

five

Automation and data analysis functions:

Some modern testing machines have automated testing functions and data analysis systems, which can help more accurately record and analyze test results, improve efficiency and accuracy.

six

Accuracy and stability of testing:

Choose equipment with high precision and stable performance to ensure the reliability of test results. It is recommended to choose equipment with well-known brands and good after-sales service.

frequently asked questions

one

Why is the wear result of the sample unstable?

Possible reasons:

Improper sample preparation: The sample may not have been cut, cleaned, or dried according to standard requirements, affecting the test results.

Friction disc wear: Friction discs may wear out after prolonged use, resulting in uneven friction force.

Uneven load: Uneven load or non-compliance with standard requirements may affect the results.

Solution:

Ensure that sample preparation is carried out in accordance with standard requirements.

Regularly inspect and replace friction discs.

Accurately adjust the test load to ensure consistency.

two

How to determine if the friction disc needs to be replaced?

Possible signs:

Obvious wear or damage on the surface.

The test results show significant deviations.

The surface of the friction disc becomes smooth, losing its expected friction performance.

Solution:

Regularly inspect the friction disc to ensure there is no excessive wear on its surface, and replace it at regular intervals.

three

How to control and set test parameters?

Possible issues:

Users may not be clear on how to choose the appropriate load, friction speed, friction frequency, etc.

Solution:

Carefully read the equipment manual and select appropriate parameters according to the testing standards.

Reasonably set testing conditions based on the type of sample and actual needs.

four

What are the criteria for determining sample damage?

Reason for the problem:

Different standards for sample damage may affect the evaluation results.

Solution:

According to relevant testing standards such as ISO 12947, ASTM D4966, etc., clarify the definition and standards of damage. Generally speaking, when a fabric shows obvious holes, color changes, or fiber shedding, it is considered damaged.

five

How to ensure the accuracy of test data?

Possible issues:

The test data shows fluctuations or inconsistencies.

Solution:

Regularly calibrate equipment to ensure its accuracy and stability.

Maintain all components of the equipment to ensure stable testing processes.

six

How to deal with errors that occur during the testing process?

Reason for the problem:

Test errors may be caused by improper operation, equipment aging, environmental factors (such as temperature and humidity changes), etc.

Solution:

Standardize operations to ensure that the equipment is in good condition.

Regularly calibrate equipment and ensure a stable testing environment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese