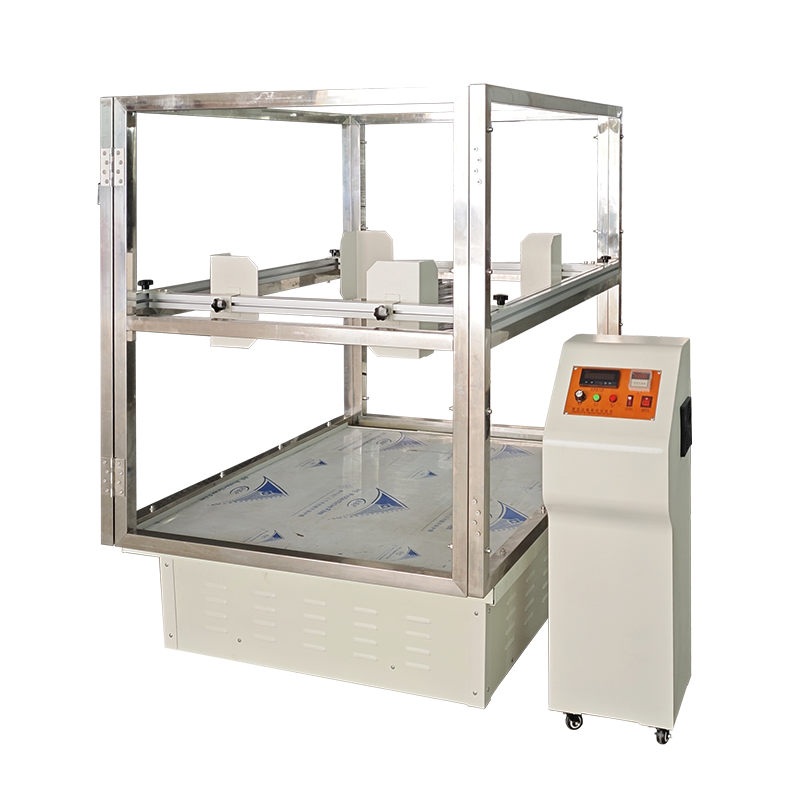

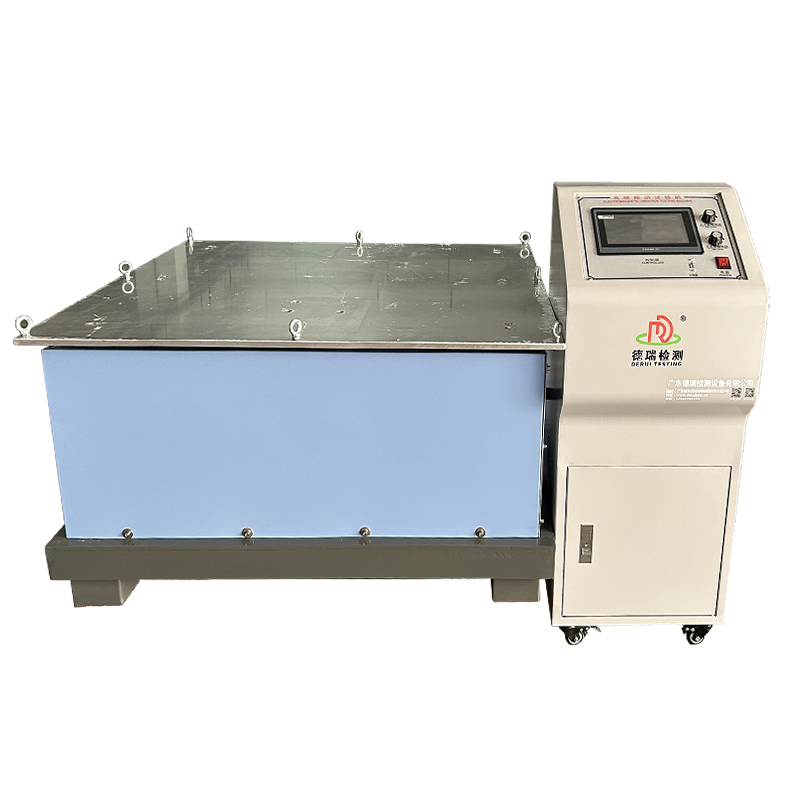

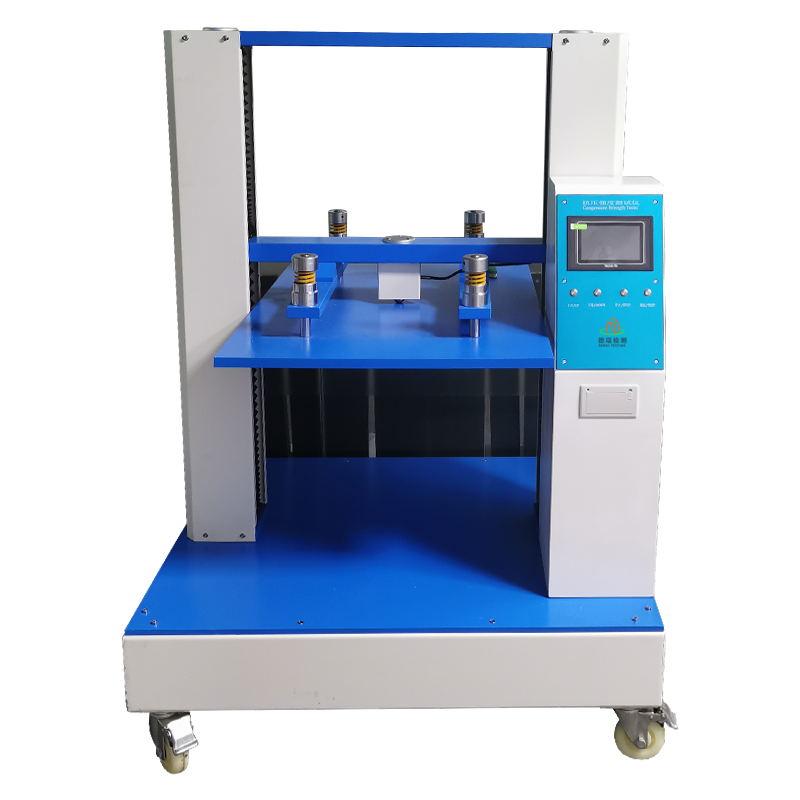

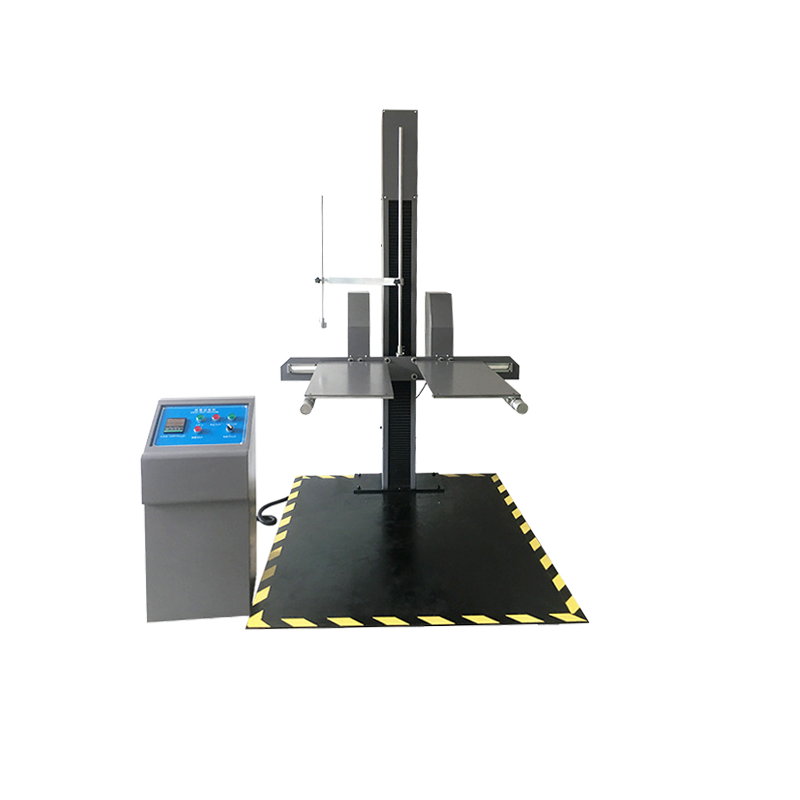

Industrial Random Vibration Tester for Transportation Simulation

138005.0 INR/Unit

Product Details:

- Test Range 1-100 Hz

- Resolution 0.1 Hz

- Hardness 453 HRC

- Temperature 5C - 40C

- Operating Voltage 220-240V

- Accuracy 5%

- Equipment Type Industrial Random Vibration Tester

- Click to view more

X

Industrial Random Vibration Tester for Transportation Simulation Price And Quantity

- 138005.0 INR/Unit

- 1 Unit

- IEC 60068-2-6

- Integrated

- Random and Sine

- 75 dB

- Steel

- USB Data Data Logger

Industrial Random Vibration Tester for Transportation Simulation Product Specifications

- 150-300 rpm

- 1-100 Hz

- 453 HRC

- 0.1 Hz

- 25 mm

- 220-240V

- Simulate transportation vibration for packaged goods

- 5C - 40C

- 5%

- 800 mm

- Industrial Random Vibration Tester

- Programmable vibration waveform, Overload protection

- Transportation Simulation

- RS232

- 1 - 100 Hz

- 250 kg

- LCD Digital Display

- Floor-mounted

- Digital Touch Screen

- 8 mm

- 1800 mm

- 0-50 mm

- Automatic

- 220V, 50Hz

- Max 1200 x 1000 mm

- 180 kg

- Up to 2

- 20% - 90% RH

- 0.6 Mpa

- < 3 sec

- IEC 60068-2-6

- Integrated

- Random and Sine

- 75 dB

- Steel

- USB Data Data Logger

Industrial Random Vibration Tester for Transportation Simulation Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 5 Days

- All India

Product Description

| Item | DR-B216 |

| Max. Test Load | 100kg |

| Frequency Range | 60-300rpm |

| Amplitude Range | 25.4mm (1 inch) |

| Simulation Speed | 25~40km/h |

| Vibration Mode | Roundtrip |

| Work Table Size | 1000*1200 mm ( L*W, can be customized ) |

| Outside dimension ( L*W*H ) | 1255*1070*660mm |

| Speed Mode | DC converter or AC Frequency Control |

| Power Capacity | 1 HP |

| Weight | 150kg |

| Power | 220V, 50 Hz |

| Speed Mode | DC converter or AC Frequency Control |

| Environmental Conditions | Temperature: 5~40C; Related Humidity <85% |

The Random Vibration Tester for Transportation Simulation replicates real-world transit stresses to predict how products and packaging withstand road, rail, and air freight vibrations. Compliant with ISTA 3A, ASTM D4169, and BIS IS 16046, this system helps manufacturers reduce shipment damages by 4060% while optimizing packaging costs.

Why Transportation Vibration Testing is Non-Negotiable

-

Damage Statistics:

-

Indian Logistics: 32% of goods sustain transit damage due to poor packaging costing SMEs 1530 lakh annually.

-

Common Failures: Loose PCB components, cracked glassware, and collapsed corrugated boxes.

-

-

Regulatory Compliance:

-

E-commerce Mandates: Amazon FBA, Flipkart Advantage require ISTA 3A testing for fragile items.

-

Export Standards: IEC 60068-2-64 compliance is mandatory for EU/US automotive parts exports.

-

Core Features Tailored for Indian Logistics

-

Real-World Simulation Modes:

-

Road Freight: Random vibration profiles (5500 Hz) mimicking truck movement on NH-44 highways.

-

Rail Transport: Low-frequency shocks (110 Hz) simulating rail track irregularities.

-

Air Cargo: High-frequency vibrations (502000 Hz) for aircraft cargo hold conditions.

-

-

Budget-Friendly Automation:

-

Pre-Loaded ISTA Profiles: 1-click testing for Series 3A (parcel), 3E (large shipments).

-

Adaptive Control: Self-adjusting PID algorithms maintain 0.5 Grms accuracy without manual tuning.

-

-

Space-Efficient Design:

-

Compact Footprint: 1.2m x 1.5m bench-top model fits small labs or factory floors.

-

Payload Flexibility: Test items from 5 kg (electronics) to 200 kg (industrial machinery).

-

Step-by-Step Testing Workflow

-

Setup: Secure package to platform with ISO 2247-compliant restraints.

-

Profile Selection: Choose Mumbai-Pune Truck Route or Delhi-Chennai Rail.

-

Automated Test:

-

1-hour vibration + 15-minute shock pulses (simulating potholes).

-

-

Analysis:

-

Review SRS (Shock Response Spectrum) graphs to pinpoint weak points.

-

Generate ISTA-compliant reports for client/certification submissions.

-

Industry-Specific Applications

-

Pharma & Vaccines: Validate cold chain packaging for temperature-sensitive drugs.

-

Automotive Spares: Test ECU modules and sensor durability in Tata/Mahindra supply chains.

-

Handicrafts Export: Ensure marble statues survive 6G vibrations during sea freight.

-

E-Commerce Sellers: Certify smartphone boxes for last-mile delivery abuse.

Technical Specifications

-

Frequency Range: 52000 Hz (extendable to 5000 Hz for aerospace).

-

Control Accuracy: 0.5 Grms (meets MIL-STD-810G Method 514.7).

-

Data Output: CSV time-history files compatible with Ansys/LabVIEW.

-

Power: 230V/50Hz with surge protection for unstable grids.

FAQs (Random Vibration Tester for Transportation Simulation)

Q1: How does random vibration differ from sinusoidal testing?

A: Random vibration mimics real-world chaos (e.g., potholes, engine rumble), while sine tests focus on fixed frequencies.

Q2: Can we test monsoon-affected road conditions?

A: Yes custom profiles replicate wet road vibrations with 38 Hz dominant frequencies.

Q3: Whats the ROI for small packaging businesses?

A: Typical payback in 9 months via reduced damages and lower insurance premiums.

Q4: How to validate tester accuracy without NABL labs?

A: Use included calibration weights and free ISTA 3A reference samples.

Q5: Is training provided for first-time users?

A: Yes 2-hour onsite workshop covers setup, testing, and report generation.

Comprehensive Vibration Simulation

This tester supports both random and sine vibration modes to thoroughly replicate actual transportation conditions for packaging. By offering a wide test frequency range (1-100 Hz) and programmable waveform capabilities, the equipment delivers accurate and reliable simulation, helping assess the durability of packaged products during shipment.

User-Friendly and Precise Operation

Operated via a digital LCD touch screen, the system features a fast response time of less than 3 seconds. Detailed data is easily captured through the USB data logger, offering convenient extractable records for analysis. Notably, the tester is equipped with overload protection and automated digital controls for ease of use and increased safety.

Ergonomic and Durable Construction

Built with a rugged steel platform and an integrated shock absorption system, the vibration tester can handle weights up to 250 kg. The floor-mounted design ensures stability, while the unit operates efficiently within a wide temperature (5C - 40C) and humidity range (20% - 90% RH), making it ideal for various lab environments.

FAQ's of Industrial Random Vibration Tester for Transportation Simulation:

Q: How does the tester simulate transportation vibrations for packaged goods?

A: This tester utilizes both random and sine vibration modes within a frequency range of 1-100 Hz to replicate the stresses experienced during transportation. The programmable vibration waveform feature allows for tailored vibration scenarios, closely matching real-world conditions encountered by packed goods during transit.Q: What is the process for operating the vibration tester and recording data?

A: Operation involves placing the specimen on the steel test platform, configuring settings via the digital touch screen, and initiating the test. All vibration data is automatically recorded by the USB data logger for easy retrieval and analysis. The interface is designed for straightforward programming and quick response, maximizing user efficiency.Q: When should I use this tester for my products?

A: Utilize the vibration tester during the development or quality assurance process of packaged products, before large-scale transportation or shipping. Early identification of packaging weaknesses helps prevent goods damage during distribution, protecting product integrity from factory to end-user.Q: Where can the Industrial Random Vibration Tester be installed?

A: This equipment is floor-mounted and suitable for installation in laboratories, quality control areas, or packaging research facilities. Its design allows for stable operation on solid floors and is adaptable to various environmental conditions common in industrial settings.Q: What are the main benefits of using this vibration tester?

A: Key benefits include improved accuracy in packaging durability assessment, enhanced product safety, and adherence to international safety standards (IEC 60068-2-6). Automatic operation, efficient data logging, and programmable testing profiles streamline the quality assurance process and reduce the risk of shipping-related product failures.Q: How does the tester ensure operator and specimen safety during tests?

A: The system features integrated overload protection and conforms to IEC 60068-2-6 safety standards. The robust steel design and shock absorption mechanisms ensure that both the operator and tested specimens are protected from excessive forces or accidental damage throughout testing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese