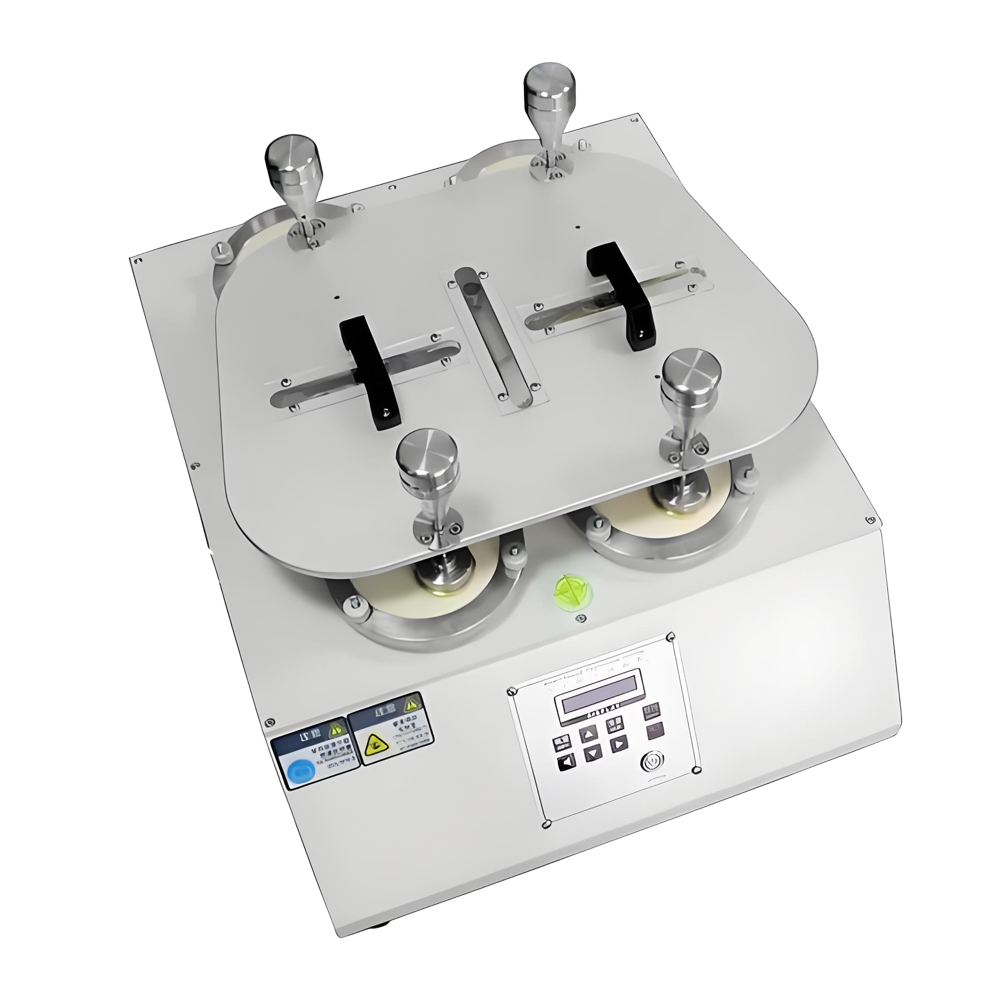

brinell hardness testing machine

141005.0 INR/Unit

Product Details:

- Max Height 380 mm

- Port Size Standard test port - 10 mm ball

- Test Range 8-650 HBW

- Number of Specimens Single specimen per test

- Application Hardness Test on Metallurgical and Engineering Materials

- Resolution 0.1 HBW

- Mounting Type Floor mounted

- Click to view more

X

brinell hardness testing machine Price And Quantity

- 141005.0 INR/Unit

- 1 Unit

- Scratch Resistant Powder Coating

- Test Table, Allen Key set, Standard Test Block, Instruction Manual

- Cast Iron

- 150 mm

- 10 to 15 sec adjustable

- Overload and Over-travel protection

- 2.5 mm and 5 mm ball available

brinell hardness testing machine Product Specifications

- 0.1 HBW

- Floor mounted

- 450 kg (approx.)

- 380 mm

- Standard test port - 10 mm ball

- Manual/Automatic (Depending on the model)

- 8-650 HBW

- Up to 200 mm

- Single specimen per test

- Hardness Test on Metallurgical and Engineering Materials

- 180 mm

- 220V AC, 50Hz

- 90% RH (non-condensing)

- 10C to 35C

- Brinell Hardness Testing Machine

- Sturdy construction, precise loading, large workspace, low maintenance

- Brinell: 8-650 HBW

- 50 Hz

- Manual/Semi-automatic/Automatic (Model dependent)

- 220 Volt

- 8-650 HBW

- Up to 3000 kgf (Test load)

- 1% of reading

- Analog/Optional Digital Output

- Optional digital/RS232

- <2 seconds

- Metallurgical labs, production, quality control

- Variable, user-controlled

- Up to 380 mm height

- Scratch Resistant Powder Coating

- Test Table, Allen Key set, Standard Test Block, Instruction Manual

- Cast Iron

- 150 mm

- 10 to 15 sec adjustable

- Overload and Over-travel protection

- 2.5 mm and 5 mm ball available

brinell hardness testing machine Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 6 Days

- All India

Product Description

| Type | DR-C203 |

| Measuring range | 20-88HRA, 20-100HRB, 20-70HRC |

| Test force | 588, 980, 1471N (60, 100, 150kgf) |

| Max. height of test piece | 165mm |

| Distance from indenter to outer wall | 160mm |

| Rockwell scaleplate | HRA,HRB,HRC,HRD,HRE,HRF,HRG,HRH,HRK |

| Hardness measuring range | HRA:20-88 HRB:20-100 HRC:20-70 HRD:40-77 |

| HRF:60-100 HRG:30-94 HRH:80-100 HRK:40-100 | |

| Initial force | 1000kgf (98.07N) |

| Dimensions | 466 x 238 x630mm |

| Weight | Approx. 70kg |

| Accessories | Large flat anvil: 1 pc. Small flat anvil: 1 pc. V-notch anvil: 1 pc. Diamond cone indenter: 1 pc. 1/16" steel ball indenter: 1 pc. Rockwell standardized block: 5pcs. |

Performance characteristics of Brinell hardness tester

High precision measurement

Adopting high-precision sensors and measurement systems to ensure the accuracy of hardness values.

Multifunctionality

Can test various materials, such as metals, alloys, plastics, ceramics, etc.

Wide range of experimental force

Supports multiple testing forces (such as 9.807N, 49.03N, 980.7N, etc.), suitable for materials of different hardness.

Easy to operate

Equipped with touch screen or computer control system, user-friendly interface, supports data storage and printing.

Automatic loading and unloading

Using electric or hydraulic loading systems to achieve automatic loading and unloading of test force.

Safe and reliable

Equipped with overload protection, emergency stop and other safety devices to ensure safe operation.

Data management

Support the storage, analysis, and printing of test data, and generate test reports.

Strong durability

Adopting high-strength materials and precision manufacturing processes to ensure long-term stable operation of the equipment.

Select key points

Testing requirements

Select the appropriate test force and indenter diameter based on the type and hardness range of the test material.

Accuracy requirements

Choose high-precision sensors and measurement systems to ensure the accuracy of test results.

Degree of automation

Select manual, semi-automatic, or fully automatic equipment according to requirements to improve testing efficiency.

Equipment size

Choose a testing machine of appropriate size based on the size of the test sample.

Brand and after-sales service

Choose well-known brands to ensure equipment quality and after-sales service.

Budget

Choose cost-effective equipment based on budget, balancing performance and cost.

Additional features

Choose whether it has data storage, printing, remote control and other functions according to the requirements.

Working conditions

Environmental requirements

Temperature: 10 C to 35 C, to avoid extreme temperatures affecting test accuracy.

Humidity: Relative humidity 80%, to avoid equipment failure caused by humid environments.

Vibration: Avoid strong vibrations and impacts to ensure stable operation of the equipment.

Power supply: Ensure that the power supply voltage and frequency meet the equipment requirements, equipped with independent power switches and grounding devices.

Operational requirements

Sample preparation: Before testing, ensure that the surface of the sample is clean, flat, and free of obvious defects.

Selection of indenter: Choose the appropriate indenter diameter and test force based on the hardness of the material.

Operating standards: Strictly follow the equipment manual and testing standards to avoid equipment damage or test failure caused by misoperation.

Maintenance requirements

Regular calibration: Use standard hardness blocks to regularly calibrate equipment to ensure measurement accuracy.

Cleaning and maintenance: Regularly clean the pressure head, measurement system, and equipment surface to keep the equipment clean.

Lubrication maintenance: Regularly lubricate mechanical components to ensure smooth operation of the equipment.

Precautions

Check the equipment status before testing to ensure that all components are working properly.

Avoid human interference during the testing process to ensure the accuracy of the test results.

In case of equipment failure or testing abnormalities, promptly contact the manufacturer's technical support.

The selection of Brinell hardness testing machine and optimization of working conditions are key to ensuring the accuracy of test results and long-term stable operation of the equipment.

Advanced Hardness Testing for Metallurgical Applications

Engineered for versatility and dependable performance, this Brinell Hardness Testing Machine suits a wide range of metallurgical and engineering material assessments. Adjustable dwell times, variable test speeds, and selectable indenter sizes ensure adaptability for diverse sample requirements, from research labs to manufacturing floors.

Robust Design and Enhanced Safety

A sturdy cast iron frame paired with scratch-resistant powder coating delivers exceptional durability. Overload and over-travel protections provide peace of mind during operation, while accessories such as a test table, Allen keys, and standard test block support precise and consistent hardness evaluation.

Flexible Operation and Accurate Results

Offering both manual and automatic control modes, this machine can be customized to user preferences. Its measuring range of 8-650 HBW, 1% accuracy, and optional digital output cater to quality control needs. A large workspace and adjustable settings further enhance ease of use and efficiency.

FAQs of brinell hardness testing machine:

Q: How does the Brinell Hardness Testing Machine ensure accurate hardness measurements?

A: The machine achieves high accuracy through precise loading mechanisms, a robust indenter system (2.5 mm and 5 mm ball diameters), and a measuring range of 8-650 HBW with 1% accuracy. Adjustable dwell time and variable test speed also help optimize conditions for reliable readings.Q: What materials can be tested with this machine?

A: This equipment is designed for hardness testing of a variety of metallurgical and engineering materials, making it suitable for laboratory research, production, and quality control applications across metals and alloys.Q: When is overload and over-travel protection activated?

A: Overload and over-travel protections activate automatically during test cycles if unusual force or excessive travel is detected, safeguarding both the machine and specimen from potential damage.Q: Where should this Brinell Hardness Testing Machine be installed?

A: The machine is floor-mounted and should be placed in environments with temperatures between 10C and 35C and humidity levels not exceeding 90% RH (non-condensing). Its robust design supports stable operation in laboratories or industrial settings.Q: What is the process for conducting a hardness test on this machine?

A: After preparing the specimen and selecting the appropriate indenter, the user secures the sample on the test table, adjusts the settings (dwell time, test speed, and load), and initiates the test in either manual or automatic mode. Hardness readings are displayed within 2 seconds.Q: How is the testing machine beneficial for quality control?

A: The machine offers precise and repeatable hardness measurements, adjustable for specific testing needs. Its robust construction, wide measuring range, and reliable safety features help ensure consistent quality verification in production and inspection environments.Q: What accessories are supplied with the Brinell Hardness Testing Machine?

A: The standard package includes a test table, Allen key set, standard test block, and instruction manual, equipping users for immediate setup and accurate operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese