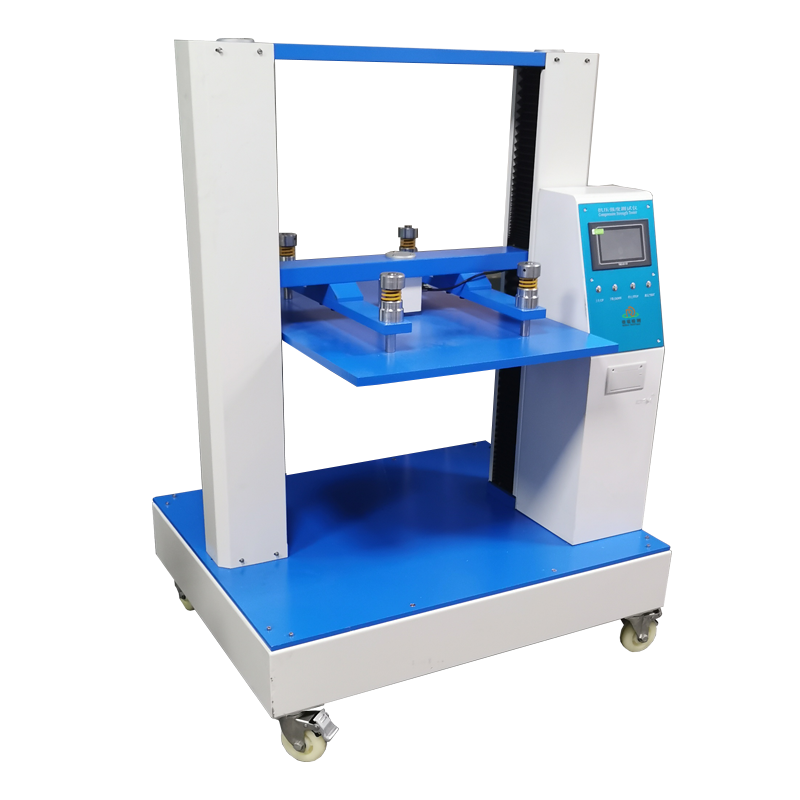

Compression testing machine for electronic product packaging

198065.0 INR/Unit

Product Details:

- Power Supply AC 220V 10%, 50 Hz

- Automation Grade Semi-Automatic

- Port Size Standard Compression Platform

- Specimen Size Max 600 x 600 mm

- Equipment Type Compression Testing Machine

- Frequency 50 Hz

- Resolution 1 N

- Click to view more

X

Compression testing machine for electronic product packaging Price And Quantity

- 1 Unit

- 198065.0 INR/Unit

- English/Multilingual

- Overload, Over-travel, Emergency stop

- Windows Compatible Control Software

- Alloy steel, anti-rust coated

- Auto/Manual Calibration

- GB/T, ASTM D642, ISO 12048

- CSV, Excel, USB

- Low, easy access panel

- Industrial gray

- High-precision load cell

- 100 Hz

- Approx. 800 x 700 mm

- <65 dB

Compression testing machine for electronic product packaging Product Specifications

- Floor-standing

- 50 kN

- 10% - 90% RH

- Overload protection, Data storage, Real-time curve display

- Compression testing for packaging and products

- 210 kg

- Digital (LCD/Touch Screen)

- 0 - 50 kN

- 220 V

- 1% of reading

- 0 - 50 kN

- 1

- 10-300 mm/min adjustable

- Electronic Product Packaging Strength Test

- USB/RS232

- 0C - 40C

- 600 mm

- 600 mm

- None (Electric Drive)

- 2 ms

- 1 N

- 50 Hz

- Compression Testing Machine

- Semi-Automatic

- Standard Compression Platform

- Microcomputer Control / Touch Screen

- Max 600 x 600 mm

- 0-600 mm

- AC 220V 10%, 50 Hz

- English/Multilingual

- Overload, Over-travel, Emergency stop

- Windows Compatible Control Software

- Alloy steel, anti-rust coated

- Auto/Manual Calibration

- GB/T, ASTM D642, ISO 12048

- CSV, Excel, USB

- Low, easy access panel

- Industrial gray

- High-precision load cell

- 100 Hz

- Approx. 800 x 700 mm

- <65 dB

Compression testing machine for electronic product packaging Trade Information

- Cash in Advance (CID)

- 90 Unit Per Month

- 5 Days

- All India

Product Description

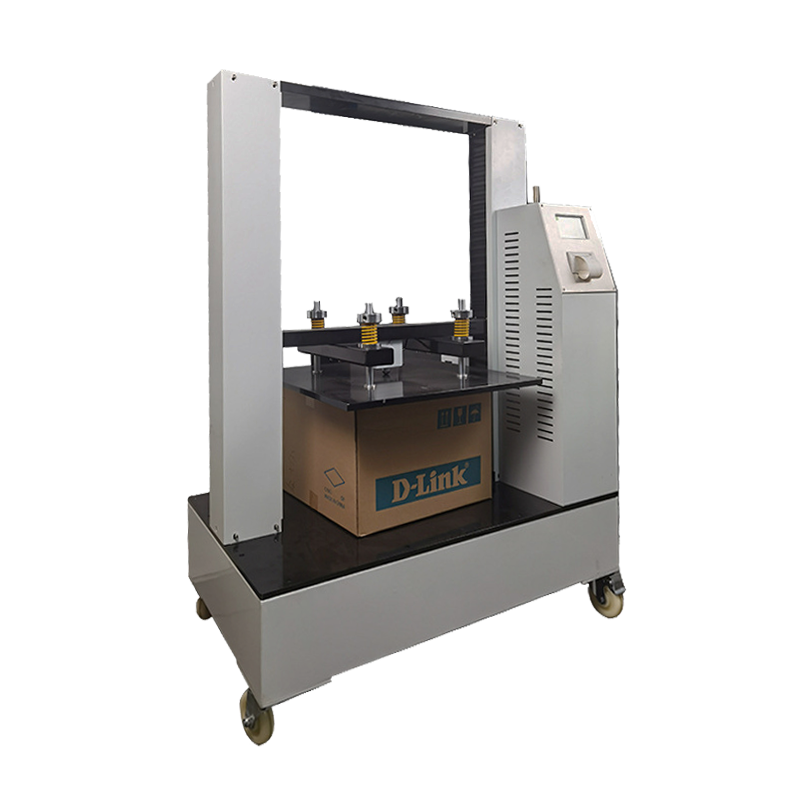

The Servo Motor Driven Compression Tester is an advanced compression test equipment that utilizes a high-precision servo motor as the drive system, and is mainly used to evaluate the compressive strength, deformation performance and overall structural stability of various materials and products (e.g., cardboard boxes, plastic containers, metal packaging, etc.) under static compression loads. The servo motor drive system provides precise speed control and position control, giving the equipment a significant advantage in terms of testing accuracy, stability and repeatability. The equipment is widely used in the packaging material manufacturing industry, automotive industry, electronics industry and quality control departments to ensure the safety and reliability of products during actual use and transportation.

2. Main Functions

Compressive strength test: According to relevant standards (such as ASTM D642, ISO 12048, etc.), measure the maximum compressive capacity of the material or product in the vertical direction, and evaluate its load-bearing capacity in the process of stacking, transportation and storage.

Deformation Test: Records the deformation of a material or product under compressive load, assesses the degree of deformation and recovery ability, and ensures that it maintains its structural integrity and appearance after being subjected to pressure.

Stacking Test: Simulate the force under actual stacking situation, evaluate its stacking stability and load-bearing capacity, and ensure that no collapse or damage will occur when multiple layers are stacked.

Cyclic compression test: Load and unload the material or product several times cyclically to evaluate its fatigue performance and durability, and ensure that it still maintains good compression resistance after repeated handling and transportation.

High-precision Position Control: The servo motor drive system realizes precise position control of the compression process, ensuring the stability and repeatability of the testing process.

Data analysis and report generation: Built-in data analysis software can automatically generate detailed test reports, including maximum compressive strength, deformation, loading curve and other parameters, which helps the quality control department to carry out strict quality assessment.

Compliance Requirements for Packaging Compression Testers for Electronic Products

In the context of today's rapid development of the electronics industry, it is particularly important to ensure the safety and stability of electronic products during transportation and storage. For this reason, the compliance requirements of the electronic product packaging compression tester has become the focus of industry attention. The following is a detailed analysis of this area:

First, the domestic standards and industry norms

GB/T 4857 series of standards: as China's authoritative standards in the field of packaging and transportation, GB/T 4857 series covers a full range of test methods from compression to stacking. These standards provide rigorous testing guidelines for packaging of electronic products to ensure their stable performance in various environments.

GB/Z 41305.2-2022: Aiming at the special requirements for electronic equipment during storage and handling, this standard specifies in detail the conditions for vibration and shock tests. These requirements are also applicable to the packaging of electronic products, providing a strong guarantee for their safety performance in complex environments.

Second, international standards and global vision

ASTM D642: As an internationally recognized standard for packaging compressive strength testing, ASTM D642 provides a scientific test method for the global packaging industry. By simulating the real transportation environment, the standard helps enterprises and organizations to accurately assess the compressive performance of packaging, thus reducing the damage rate of products and improving logistics efficiency.

ISTA series of standards: The ISTA standards, developed by the International Safe Transportation Association, cover a wide range of test items such as vibration, drop and stacking. These standards are designed to comprehensively assess the performance of packaging in the transportation process to ensure the safe circulation of electronic products around the world.

Third, the test equipment and accurate methods

Compression Tester: As the core testing equipment, the compression tester accurately tests the compressive strength of packaging samples by applying uniform pressure and recording the pressure value. Its flat and hard metal platen design ensures the uniform distribution of pressure, which guarantees the accuracy of the test results.

Heat Seal Tester: For heat seal strength testing of plastic film packaging bags, the heat seal tester simulates the three elements of pressure, temperature and time of the packaging production line. Through this equipment, companies can ensure that mass-produced bags with stable heat sealing performance, thus ensuring the safe packaging of electronic products.

Fourth, the sample preparation and strict steps

In terms of sample preparation, according to the actual size and shape of the package to determine the sample size, and to ensure that at least five samples to take the average value as the final result. This step ensures the representativeness and reliability of the test.

For the test procedure, the sample is placed on the lower platen of the compression tester, the tester is activated to apply vertical pressure and the maximum pressure value at yielding or rupture of the sample is recorded. This process strictly follows the standard operating procedures, ensuring the accuracy and traceability of the test data.

V. Data Recording and Detailed Reporting

Complete documentation of test data is an important part of compliance requirements. Detailed data including sample size, test conditions and test results provide strong support for subsequent analysis and improvement. Meanwhile, clear and detailed test reports also provide valuable reference for enterprises.

| Item | DR-B211-900 | DR-B211-1200 | DR-B211-1500 |

| Max. Force | 10KN(1000 kg ,2205lb) | 20KN(2000 kg, 4409lb) | 50KN(5000kg,11023lb) |

| Load cell | 1 load cell for highest accuracy | ||

| Control system | Dual control (Computer control with Windows mode+Touch screen control ) | ||

| Servo Motor | 400W | 750W | |

| Servo Driver | 400W | 750W | |

| Screws | Ball screws(Double ball guide rod design, high transmission accuracy, high transmission power efficiency) | ||

| Force reading | Gf, kgf, Ibf, N, KN, T etc | ||

| Load cell Resolution | 1/250,000 | ||

| Load Precision | within 0.5% | ||

| Effective test area (L x W x H) | 700x900x900mm | 1000x1200x1000mm | 1300x1500x1500mm |

| Compression Stroke | 0~900mm | 0~1000mm | 0~1500mm |

| Lift speed | 0.1~200mm/min | ||

| Software | Mtest HD-002-A(Independent R&D) | ||

| Data display | Load, displacement, speed, loading rate and elapsed time | ||

| Safety features | E-Stop Over-load protection Upper and lower limit switches Load sensor with automatic retreat | ||

| Report items | Serial number, peak value, average value, set pressure holding value, pressure holding time | ||

| Electrical Supply | 1phase, AC 220V, 500W, 50HZ | 1phase, AC 220V,550W,50HZ | 1phase, AC 220V,900W,50HZ |

| Overall Dimensions (L x W x H) | Approx.1510x1200x1645mm | Approx.1510x1200x1645mm | Approx.1865mmx1500mmx2235mm |

| Weight | Approx.350kg(772lb) | Approx.670kg(1477lb) | Approx. 1000kg(2205lb) |

| Operation Temperature and relative humidity | 10~40, 30~80% | ||

High-precision Electronic Packaging Testing

Utilizing a state-of-the-art load cell, this machine provides accurate compression force data for electronic product packaging. With testing standards such as GB/T, ASTM D642, and ISO 12048 supported, users are assured of reliable and consistent results. The digital display and touch screen interface allow for intuitive operation and real-time curve monitoring.

Robust and Reliable Construction

Featuring a compression plate made of anti-rust coated alloy steel, this machine guarantees durability and longevity. The compact 800 x 700 mm footprint allows convenient placement in testing facilities, while the easy-access panel and low maintenance requirements minimize downtime and ensure continuous operation.

Seamless Data Management and Safety Features

All test data can be exported in CSV, Excel, or through a USB interface, simplifying analysis and record-keeping. Overload, over-travel, and emergency stop protections safeguard both operator and equipment, while multilingual capabilities support global operations.

FAQ's of Compression testing machine for electronic product packaging:

Q: How does the compression testing machine ensure data accuracy for electronic product packaging?

A: Equipped with a high-precision load cell, the machine offers measurement accuracy within 1% of reading and a fine resolution of 1 N. It features both automatic and manual calibration modes, ensuring consistent and valid data for all packaging strength assessments.Q: What is the process for exporting test results from the machine?

A: Test results are instantly recorded and can be exported via USB, or in CSV and Excel formats. The Windows-compatible control software allows for seamless data management and real-time curve display, simplifying further analysis and documentation.Q: When should the system's calibration be performed, and how is it carried out?

A: Calibration is typically recommended before routine operation, after major maintenance, or periodically as specified by internal quality protocols. The system offers both automatic and manual calibration processes, accessible directly via the touch screen interface.Q: Where is the optimal location to install this compression testing machine?

A: Its floor-standing design with an 800 x 700 mm footprint allows placement in most laboratory or production environments. Ensure installation on a stable, level surface within an ambient temperature of 0C to 40C and humidity between 10% and 90% RH.Q: What packaging and product types can be tested with this equipment?

A: Designed for electronic product packaging, the machine accommodates single specimens up to 600 x 600 mm in size with a maximum height of 600 mm, supporting a test range up to 50 kN.Q: How does the machine improve safety during operation?

A: Safety is prioritized through multiple protective systems, including overload, over-travel, and an emergency stop function. These features help prevent accidental damage to the specimen or machine, ensuring safe usage for operators.Q: What are the benefits of using this machine for electronic packaging testing?

A: Users gain reliable strength evaluation, efficient data handling, and compliance with international standards. The machine's robust build, automation features, and easy maintenance contribute to long-term performance and operational convenience.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese