digital brinell hardness testing machine

158005.0 INR/Unit

Product Details:

- Measuring Range 8-650 HBW

- Interface Type RS232/USB

- Number of Specimens Multiple

- Accuracy 1%

- Max Height 300 mm (specimen)

- Hardness Brinell (HBW)

- Features Automatic loading/unloading, Digital display, Data storage

- Click to view more

X

digital brinell hardness testing machine Price And Quantity

- 1 Unit

- 158005.0 INR/Unit

- < 500 W

- Up to 500 results

- USB/Printer

- Included

- Machined or polished

- 10 mm Hardened Steel Ball

- 1015 secs adjustable

- LED Illumination

- Digital Brinell Hardness Testing Machine

- Cast Iron

- Yes

digital brinell hardness testing machine Product Specifications

- 8-650 HBW

- 1%

- Multiple

- RS232/USB

- Automatic loading/unloading, Digital display, Data storage

- Brinell (HBW)

- 300 mm (specimen)

- Industrial

- 220 V AC, 50 Hz

- Metals and Alloys Hardness Testing

- Up to 180 mm

- Instant

- Standard

- 50 Hz

- 0.5 mm/s

- 85% RH

- 250 kgf, 500 kgf, 750 kgf, 1000 kgf units

- Automatic

- 220 V

- Digital LCD Display

- Bench-Top

- 10C to 40C

- 8-650 HBW

- Up to 200 mm

- 0.1 HBW

- Digital/Automatic

- Approx. 200 kg

- Up to 300 mm height

- < 500 W

- Up to 500 results

- USB/Printer

- Included

- Machined or polished

- 10 mm Hardened Steel Ball

- 1015 secs adjustable

- LED Illumination

- Digital Brinell Hardness Testing Machine

- Cast Iron

- Yes

digital brinell hardness testing machine Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 7 Days

- All India

Product Description

| Type | DR-C203 |

| Measuring range | 20-88HRA, 20-100HRB, 20-70HRC |

| Test force | 588, 980, 1471N (60, 100, 150kgf) |

| Max. height of test piece | 165mm |

| Distance from indenter to outer wall | 160mm |

| Rockwell scaleplate | HRA,HRB,HRC,HRD,HRE,HRF,HRG,HRH,HRK |

| Hardness measuring range | HRA:20-88 HRB:20-100 HRC:20-70 HRD:40-77 |

| HRF:60-100 HRG:30-94 HRH:80-100 HRK:40-100 | |

| Initial force | 1000kgf (98.07N) |

| Dimensions | 466 x 238 x630mm |

| Weight | Approx. 70kg |

| Accessories | Large flat anvil: 1 pc. Small flat anvil: 1 pc. V-notch anvil: 1 pc. Diamond cone indenter: 1 pc. 1/16" steel ball indenter: 1 pc. Rockwell standardized block: 5pcs. |

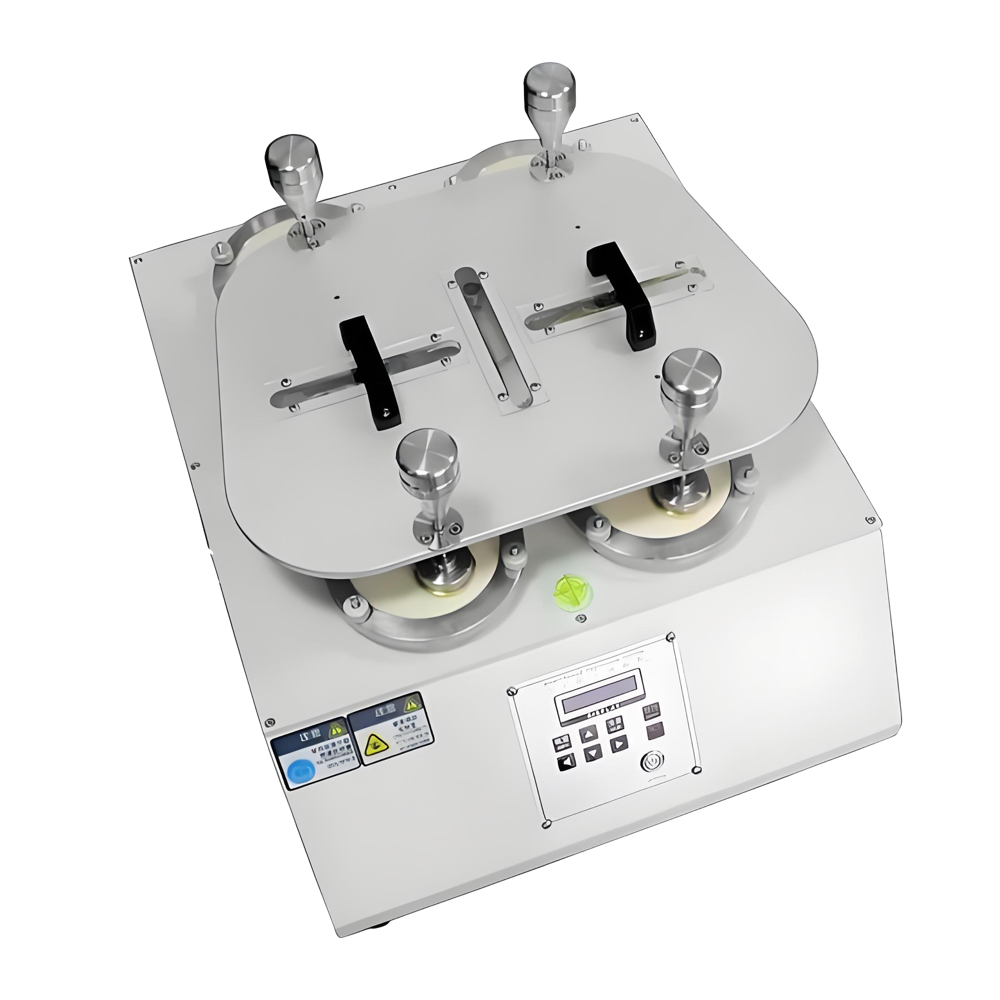

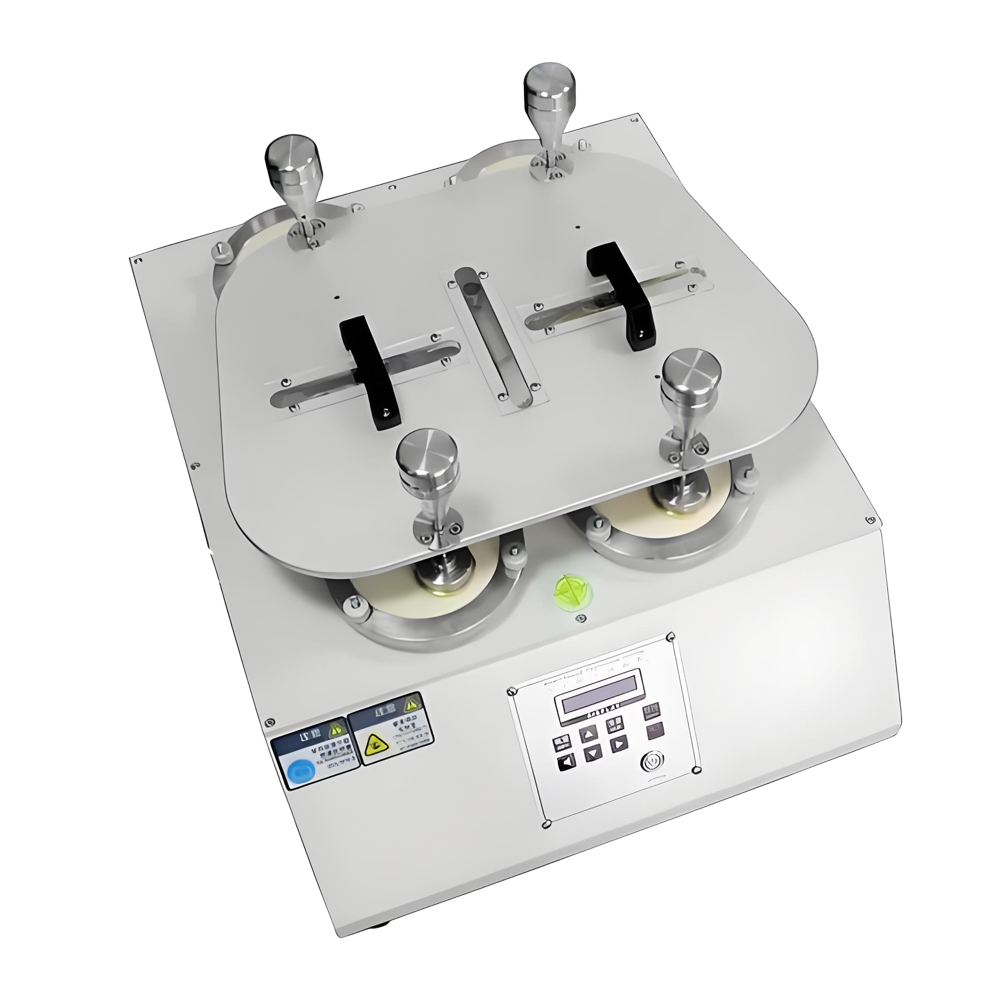

The digital Brinell hardness tester is an instrument used to measure the hardness of metal materials. It adopts the Brinell hardness test method, which applies a hard sphere of known diameter on the surface of the material, presses it into the material surface under a certain load, and then measures the diameter of the indentation to calculate the Brinell hardness value of the material.

Main features:

one

High precision measurement: Digital Brinell hardness testing machines are usually equipped with high-precision sensors and digital display systems, which can provide accurate measurement results.

two

Automated operation: Modern digital Brinell hardness testing machines typically have automatic loading, unloading, and measurement functions, reducing human operational errors.

three

Data processing capability: These devices are typically equipped with data processing software that can automatically calculate hardness values and generate test reports.

four

Multiple load options: Different loads and indenter diameters can be selected according to different materials and testing requirements.

five

User friendly interface: Most digital Brinell hardness testing machines are equipped with touch screens or computer interfaces for easy operation.

working principle:

one

Prepare the sample: Polish the surface of the metal material to be tested flat to ensure the accuracy of the measurement results.

two

Loading: Select the appropriate load and indenter diameter on the testing machine and apply them to the surface of the material.

three

Indentation measurement: The indenter presses a circular indentation on the surface of the material and measures the diameter of the indentation using a microscope or built-in measurement system.

four

Calculate hardness: Use the Brinell hardness formula to calculate the hardness value based on the indentation diameter and load.

Brinell hardness formula:

=two

(

two

two

)

Among them:

It is the Brinell hardness value

It is the applied load (kilogram force)

It is the diameter of the indenter (in millimeters)

The diameter of the indentation (in millimeters)

Application areas:

The digital Brinell hardness tester is widely used for quality control, research and development, and hardness testing in the production process of metal materials. It is suitable for various metal materials such as steel, aluminum alloy, copper alloy, etc.

If you have specific needs or questions, such as choosing appropriate equipment or operating methods, I can provide more details and I will do my best to assist you.

Advanced Digital Hardness Testing

Equipped with digital/automatic control and a user-friendly LCD display, this Brinell hardness tester is engineered to deliver fast, consistent, and highly accurate results. The machine handles specimens up to 300 mm in height and 200 mm in width, accommodating a wide test range and ensuring versatility for industrial applications.

User-Focused Design and Control

The machine offers convenient automatic loading/unloading and digital controls for seamless operation. Test data is easily exported via USB or RS232, and up to 500 results can be stored in memory. Safety interlocks and low power consumption enhance both safety and efficiency during extended industrial use.

FAQ's of digital brinell hardness testing machine:

Q: How does the digital Brinell hardness testing machine operate?

A: The machine works automatically by loading the specimen, applying force with a 10 mm hardened steel ball indenter, and holding it for an adjustable dwell time between 10-15 seconds. The hardness value is then measured digitally and displayed instantly on the LCD screen.Q: What benefits does the LED illumination provide during testing?

A: The integrated LED illumination enhances visibility during the test, ensuring precise observation of the indentation. This supports accurate measurement and reliable hardness readings, even on machined or polished surfaces.Q: When is the digital Brinell hardness tester most effectively used?

A: This machine is best used for testing the hardness of metals and alloys in industrial environments where high precision, repeatability, and data traceability are required. It is suitable for exporters, manufacturers, and suppliers handling a variety of specimen sizes.Q: Where can the test results be accessed or stored?

A: Test results are shown immediately on the digital LCD display and stored in the system's memory for up to 500 tests. Data can also be exported directly to a USB drive or printer, ensuring convenient record-keeping and analysis.Q: What are the main advantages of the automatic loading and unloading feature?

A: Automatic loading and unloading reduce manual effort, minimize the risk of user error, and speed up the overall testing process, making high-throughput industrial testing more efficient and consistent.Q: Which types of specimens and applications can this machine handle?

A: The tester is designed for metals and alloys, accommodating specimens up to 300 mm in height and 200 mm in width, making it ideal for quality control, research, and production in various industrial sectors.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese