Horse racing simulation transportation vibration table

138005.0 INR/Unit

Product Details:

- Specimen Size Max. 1200 x 800 mm

- Features Programmable, automatic stop, overload protection

- Max Height 1200 mm

- Accuracy 0.01 g

- Frequency 35 Hz (adjustable)

- Operating Voltage 220V

- Number of Specimens Up to 4 pieces

- Click to view more

X

Horse racing simulation transportation vibration table Price And Quantity

- 1 Unit

- 138005.0 INR/Unit

- Precision induction motor

- Free from corrosive gases or dust

- Emergency stop switch, overload protection

- 60 dB

- Customizable continuous or interval

- High-strength anti-vibration steel

- Horizontal synchronous vibration

- PC data export, run log storage

Horse racing simulation transportation vibration table Product Specifications

- Standard 25 mm air inlet

- LED digital display

- 800 mm

- 5C40C

- Platform: 505 Shore A

- Package integrity and vibration resistance testing

- AC 220V/50Hz

- Floor standing

- Simulate transportation vibration for packaging reliability

- Approx. 330 kg

- 1 s

- 25 mm (2 mm)

- 0.50.7 MPa

- 0.001 g

- Horse racing simulation transportation vibration table

- RS232/USB

- Automatic

- 05 g acceleration (adjustable)

- Up to 4 pieces

- 100300 r/min (adjustable)

- 20%80% RH

- Dynamic vibration simulation

- 0.01 g

- 1200 mm

- Digital Touch Control Panel

- Programmable, automatic stop, overload protection

- Max. 1200 x 800 mm

- 220V

- 35 Hz (adjustable)

- Up to 100 kg

- Precision induction motor

- Free from corrosive gases or dust

- Emergency stop switch, overload protection

- 60 dB

- Customizable continuous or interval

- High-strength anti-vibration steel

- Horizontal synchronous vibration

- PC data export, run log storage

Horse racing simulation transportation vibration table Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 5 Days

- All India

Product Description

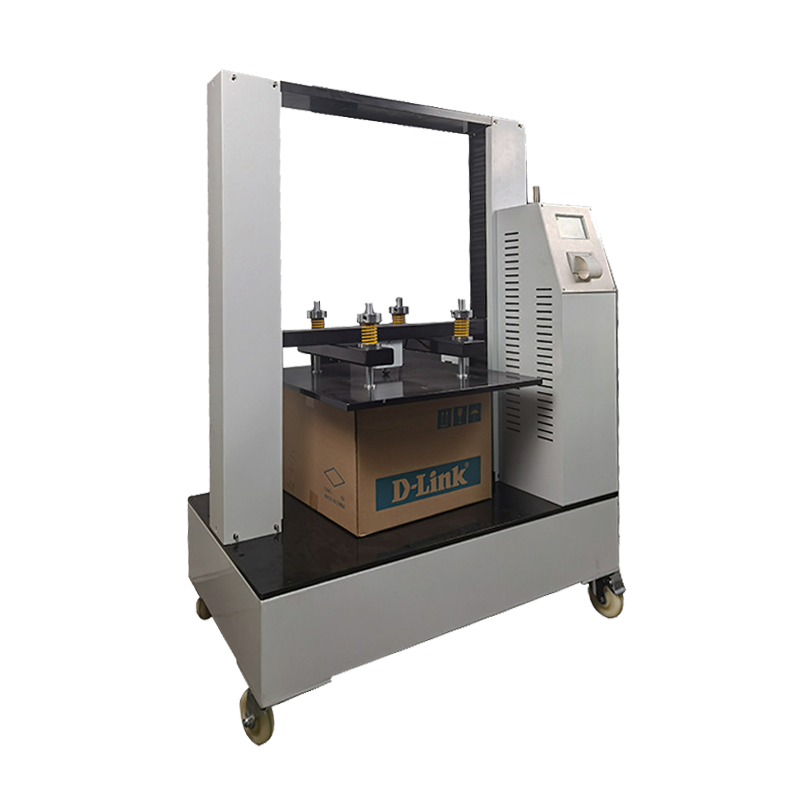

With the advancement of globalization, the transportation of various products gradually crosses geographical regions and faces different transportation environments. In order to ensure the safety and durability of goods during transportation, simulated transportation shakers, as a high-precision testing equipment, are being widely used in various industries. Today, we're highlighting an innovative transportation simulation shaker - the Prancing Horse - designed to simulate the vibration environments commonly encountered during transportation, with the aim of providing companies with a more accurate and efficient vibration testing solution.

Functionality of the Prancing Horse Transportation Shaker

The Running Shaker, also known as a Running Shaker, is a high-end transportation simulation de vice designed to simulate the vibration conditions encountered during the actual transportation of goods. It provides a very practical tool for companies to ensure that their products perform well in different modes of transportation by vibration testing them at various frequencies and accelerations. Below are the core features of the Running Simulated Transportation Shaker:

Multi-band support for simulated transportation vibration

The Running Shaker is capable of simulating a wide range of vibration bands from low to high frequencies, providing comprehensive coverage of the vibration environments that may be encountered in different modes of transportation, including road, air, and sea transportation. By setting up different vibration modes, companies can accurately understand the impact of different frequency bands on their products, and thus develop more scientific transportation solutions.

Acceleration adjustment and precise control

The dev ice supports precise adjustment of vibration acceleration, users can adjust the amplitude of vibration according to the test requirements, simulating the real transportation vibration situation. The wide range of acceleration adjustments meets the needs of most standard transportation environments, and is also suitable for extreme testing of some special products.

Continuous vibration test mode

Running simulation transportation shaker with continuous, stable vibration test function. It can be operated for long periods of time to simulate the vibration shocks that may occur over a long period of time during real transportation. This is especially important for products that require high durability testing, and can help companies identify problems and make improvements in advance.

Intelligent automatic control system

The equipment is equipped with an intelligent control system, which can automatically adjust the vibration frequency, acceleration, vibration amplitude and other parameters. This fully automatic operation not only enhances the testing efficiency, but also minimizes human errors and improves the accuracy and consistency of the test.

Real-time data recording and report generation

The Running Simulation Transportation Shaker integrates advanced data recording and analysis functions, enabling real-time recording of parameters during testing, such as acceleration, vibration amplitude, frequency, etc. The system generates a detailed report on the test results. Detailed test reports are generated through the built-in system, making it easy for companies to analyze data and assess quality.

Product Advantages of Running Simulation Transportation Shaker

Compared with traditional vibration test equipment, the running simulation transportation shaker has several unique advantages that make it occupy an important position in various industries. Below are the key benefits:

Improved quality and reliability of transported products

During actual transportation, products inevitably experience vibration shocks. These vibrations can have an impact on the product's structure, packaging, and internal components, leading to damage or functional failure. By using a running simulation transportation shaker for advance testing, companies can find potential problems with their products during transportation and make improvements in a timely manner to ensure that the products are intact under all types of vibration conditions during transportation, improving product quality and customer satisfaction.

Improve production efficiency and save costs

Traditional testing methods often rely on actual transportation, which is time consuming and costly. With a running simulation shaker, companies can complete efficient vibration testing in a short period of time and simulate different vibration conditions through precise adjustments, greatly reducing product development cycles and lowering potential risks for later logistics and transportation.

Highly flexible and adjustable

The acceleration, vibration frequency and amplitude of the running simulation transportation shaker can be flexibly adjusted according to the testing requirements, supporting a wide range of different product testing needs. Whether it's fragile electronic equipment, heavy machinery and equipment, or small consumer goods, all can be accurately simulated on the equipment to meet the testing needs of a variety of complex transportation environments.

Powerful data analysis

Simulation shakers not only perform efficient vibration testing, but also record key data during testing in real time, such as vibration intensity and frequency changes, to generate detailed reports. These data are very helpful for product design optimization and quality control, and can provide reliable data support for companies to help them make more scientific decisions.

Adapt to a wide range of applications

Running simulation transportation shakers are applicable to a wide range of applications. Whether it is electronic products, automotive components, aerospace parts, or general consumer goods, the equipment can be used for comprehensive transportation vibration testing. It is particularly suitable for products that require a high degree of durability, such as high-precision instruments and mechanical equipment.

Application Areas of Running Simulation Transportation Shakers

Electronics Industry

For consumer electronics, safety in packaging and transportation is of paramount importance. With a running simulation shaker, companies can test the performance of cell phones, TVs, computers and other products in different modes of transportation to ensure that they can be transported without damage.

Automobiles and Automotive Parts

Automakers and automotive suppliers often need to ensure that their products can withstand vibration during transportation. Running simulation transportation shakers help test the durability of automotive parts and ensure their reliability during transportation.

Aerospace Products

Aerospace products are often subjected to severe vibration during transportation. Horse-drawn simulation shakers provide high-precision simulation of these products to ensure that they can withstand the vibrations and shocks that may be encountered during transportation.

Consumer Goods and Commodities

A wide range of consumer goods, such as household appliances, furniture, toys, etc., can be damaged or rendered dysfunctional by vibration during transportation. Running simulated transportation shakers help companies reduce transportation losses and improve customer experience by testing product packaging.

| Item | DR-B216 |

| Max. Test Load | 100kg |

| Frequency Range | 60-300rpm |

| Amplitude Range | 25.4mm (1 inch) |

| Simulation Speed | 25~40km/h |

| Vibration Mode | Roundtrip |

| Work Table Size | 1000*1200 mm ( L*W, can be customized ) |

| Outside dimension ( L*W*H ) | 1255*1070*660mm |

| Speed Mode | DC converter or AC Frequency Control |

| Power Capacity | 1 HP |

| Weight | 150kg |

| Power | 220V, 50 Hz |

| Speed Mode | DC converter or AC Frequency Control |

| Environmental Conditions | Temperature: 5~40C; Related Humidity <85% |

Advanced Precision and Safety Features

The vibration table is equipped with a precision induction motor for consistent performance and uses a high-strength anti-vibration steel platform to guarantee durability. Advanced safety mechanisms, including an emergency stop switch and overload protection, provide secure operation during every test cycle.

Flexible Simulation and Testing Modes

With both continuous and interval cycle settings, horizontal synchronous vibration, and a test speed of 100-300 r/min (fully adjustable), users can easily configure simulations to match specific transportation scenarios. The digital touch control panel, programmable operations, and automatic stop allow for seamless, hands-free usage.

Comprehensive Data Management and Connectivity

Featuring PC software support, run log storage, and data export capability via RS232/USB, users gain full oversight of testing data. The LED digital display, adjustable acceleration range (0-5 g), and high response time (1 s) ensure precise, real-time monitoring of results.

FAQ's of Horse racing simulation transportation vibration table:

Q: How does the horse racing simulation transportation vibration table operate for package testing?

A: The vibration table uses a precision induction motor to generate horizontal synchronous vibrations, simulating real-world transportation conditions. Its digital touch control panel allows users to customize cycle mode, test speed, and vibration frequency, ensuring adaptability for various package sizes and types.Q: What types of specimens and packaging can be tested on this equipment?

A: This table accommodates up to four specimens with a maximum size of 1200 x 800 mm and a total weight of 100 kg. It's ideal for evaluating packaging integrity and vibration resistance for a range of products transported in competitive and commercial environments.Q: When should I use the customizable cycle modes during testing?

A: Customizable modes-such as continuous or interval-should be selected based on the specific transportation scenario being simulated. For example, use continuous mode for steady transport conditions or interval mode to mimic stops and starts during shipping.Q: Where can I access the test results and how are they managed?

A: Test results are displayed in real-time on the LED digital screen and recorded via the system's run log feature. Additionally, data can be exported to a PC using the RS232/USB interface, facilitating comprehensive result management and analysis.Q: What is the process for ensuring operator safety during operation?

A: Operator safety is ensured through an emergency stop switch and overload protection system, allowing for immediate halting of operations if necessary. The equipment also operates at a noise level of 60 dB for a safe and comfortable work environment.Q: How does using this vibration table benefit packaging reliability?

A: By simulating the dynamic vibrations encountered in transportation, this table helps identify potential weaknesses in packaging or products, enabling improvements before distribution. This results in reduced damages, higher customer satisfaction, and minimized return rates.Q: What are the recommended ambient and installation requirements for the machine?

A: The table should be operated in environments free from corrosive gases and dust, within a humidity of 20%-80% RH and temperature of 5C-40C. It is designed for floor mounting and requires a standard AC 220V/50Hz power supply.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese