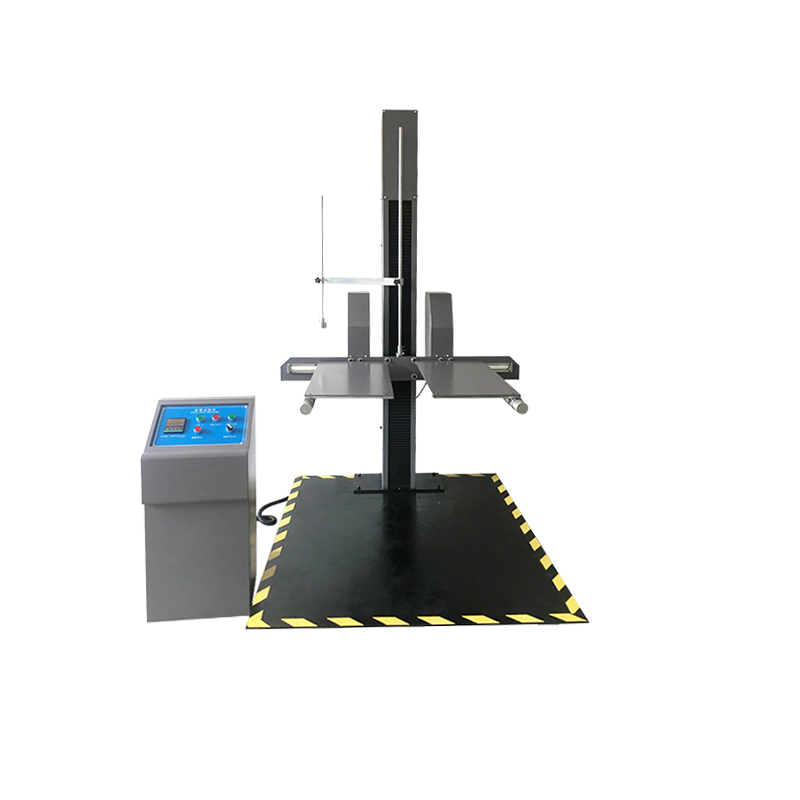

Drop Test Machine MIL-STD-810G Compliance

158055.0 INR/Unit

Product Details:

- Number of Specimens Single Specimen per Test

- Automation Grade Semi-Automatic

- Measuring Range 01500 mm

- Interface Type Digital Panel

- Frequency Single Test Cycle or Programmable

- Specimen Size Maximum 8008001000 mm

- Max Height 1500 mm

- Click to view more

X

Drop Test Machine MIL-STD-810G Compliance Price And Quantity

- 158055.0 INR/Unit

- 1 Unit

- Precision Machined Steel

- Electromagnetic Clamp

- Powder Coated

- Emergency Stop, Interlock Door

- MIL-STD-810G

- 1200 mm 1000 mm 2000 mm

- 65 dB

Drop Test Machine MIL-STD-810G Compliance Product Specifications

- Single Test Cycle or Programmable

- Digital Panel

- Standard Free Fall

- 01500 mm

- Semi-Automatic

- Shock/Impact Test

- Single Specimen per Test

- Adjustable Drop Height, Safety Lock, Sturdy Construction, Swivel Arm

- 1 mm

- 500 mm 500 mm

- 0-1500 mm Drop Height

- AC 220V, 50 Hz

- 1500 mm

- Maximum 8008001000 mm

- Approx. 500 kg

- Surface Plate HRC 45

- Up to 100 kg

- 1 mm

- Instantaneous

- 20% - 80% RH

- 220V AC

- Drop Test Machine

- Floor Standing

- 0-1500 mm Adjustable

- Manual & PLC Controlled

- 0C - 40C

- 0.5-0.7 MPa

- Digital

- MIL-STD-810G Drop Test for Package/Equipment

- Standard 1/4 Pneumatic Port

- Precision Machined Steel

- Electromagnetic Clamp

- Powder Coated

- Emergency Stop, Interlock Door

- MIL-STD-810G

- 1200 mm 1000 mm 2000 mm

- 65 dB

Drop Test Machine MIL-STD-810G Compliance Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 5 Days

- All India

Product Description

Specifications:

| Item | Description |

| Drop height | 400-1500mm (can be customized) |

| Display method | Digital display |

| Max. weight of sample | 60kg (can be customized) |

| Max. size of sample | (L*W*H) 800*800*800mm |

| Drop panel area | 1400x1200mm (material is Solid steel plate) |

| Control box dimension | (L*W*H) 350*350*1100mm |

| Deviation of drop horizon | Less than 1 |

| Machine size | (L*W*H)1400*1200*2200mm |

FAQs: Drop Test Machine MIL-STD-810G Compliance

Q1: What is MIL-STD-810G compliance for a drop test machine?A1: MIL-STD-810G compliance for a drop test machine indicates that the equipment adheres to the rigorous standards set by the U.S. Department of Defense for testing the durability and reliability of products under various environmental conditions, including drop impacts.

Q2: Why is MIL-STD-810G compliance important for drop testing?A2: MIL-STD-810G compliance is crucial for drop testing as it ensures that the products are tested against standardized, real-world scenarios, providing accurate and reliable data on their ability to withstand drops and impacts, thereby enhancing product quality and reliability.

Q3: How does the Drop Test Machine ensure MIL-STD-810G compliance?A3: The Drop Test Machine ensures MIL-STD-810G compliance by precisely simulating the drop heights, angles, and surfaces specified in the standard, allowing for accurate replication of the test conditions required for compliance.

Q4: Can the Drop Test Machine be used for testing products other than military equipment?A4: Yes, the Drop Test Machine with MIL-STD-810G compliance is versatile and can be used for testing a wide range of products, including consumer electronics, industrial equipment, and packaging, to ensure their durability and reliability.

Q5: What are the key features of a MIL-STD-810G compliant Drop Test Machine?A5: Key features of a MIL-STD-810G compliant Drop Test Machine include adjustable drop heights, precise impact surface materials, automated test procedures, and data recording capabilities, all designed to meet the stringent requirements of the standard.

Q6: How does MIL-STD-810G compliance benefit product manufacturers?A6: MIL-STD-810G compliance benefits product manufacturers by providing a standardized testing methodology that ensures product durability, reduces the risk of failure in the field, and enhances customer satisfaction and brand reputation.

Q7: Is the Drop Test Machine easy to operate for MIL-STD-810G testing?A7: Yes, the Drop Test Machine is designed with user-friendliness in mind, featuring intuitive controls and automated procedures that simplify the process of conducting MIL-STD-810G compliant drop tests.

Q8: Can the Drop Test Machine be customized for specific MIL-STD-810G test requirements?A8: Absolutely, the Drop Test Machine can be customized to meet specific MIL-STD-810G test requirements, including adjustments for drop height, impact surface, and test parameters, ensuring tailored testing for various product types.

Introduction:

In the relentless pursuit of product superiority, the adherence to stringent testing standards is indispensable. At TradeIndia, we pride ourselves on offering drop test machines that not only meet but exceed the requirements of the MIL-STD-810G compliance standard. This elite certification is a beacon of durability and environmental endurance, setting a gold standard for product testing across various industries. Our commitment to providing MIL-STD-810G certified drop test machines underscores our dedication to empowering businesses with the most rigorous and reliable testing solutions available.

The Pinnacle of Environmental Testing with MIL-STD-810G:

-

Unparalleled Environmental Resistance Evaluation: The MIL-STD-810G standard is renowned for its exhaustive suite of tests designed to assess a product's ability to withstand extreme environmental conditions. Our drop test machines are engineered to precisely replicate these conditions, subjecting your products to the ultimate test of resilience and ensuring they meet the highest standards of durability.

-

Fortifying Product Longevity and Performance: Achieving MIL-STD-810G compliance is a testament to a product's robustness and readiness to perform under pressure. By employing our certified drop test machines, manufacturers can confidently attest to their products' durability, thereby reducing the risk of failures in real-world applications and minimizing associated costs.

-

Fostering Global Confidence and Market Expansion: Products that bear the mark of MIL-STD-810G compliance are revered worldwide for their exceptional quality and reliability. This global recognition opens doors to broader markets, enhances consumer trust, and positions your offerings as benchmarks of excellence within your industry.

Advanced Features of Our MIL-STD-810G Certified Drop Test Machines:

-

Precision-Crafted Impact Simulations: Our machines leverage cutting-edge technology to recreate the exact impact forces and environmental stresses prescribed by the MIL-STD-810G standard. This level of accuracy guarantees that your products undergo the most authentic and challenging tests, preparing them for any scenario.

-

Flexible and Customized Testing Scenarios: Recognizing the diverse testing needs of various products, our drop test machines offer adaptable configurations. This versatility allows you to fine-tune your testing environment to closely mimic the specific conditions your products are likely to encounter, ensuring comprehensive and targeted durability assessments.

-

Intuitive Operation and Sophisticated Analytics: Designed for ease of use, our machines boast user-friendly interfaces that simplify the testing process. Coupled with advanced data analysis tools, these features enable swift and insightful evaluation of test results, streamlining the path to product improvement and innovation.

-

Durable and Reliable Construction: Crafted from premium materials and built to endure the toughest testing regimens, our drop test machines embody the very durability they are designed to assess. This ensures uninterrupted testing operations and enduring performance, making them a valuable asset to your quality control arsenal.

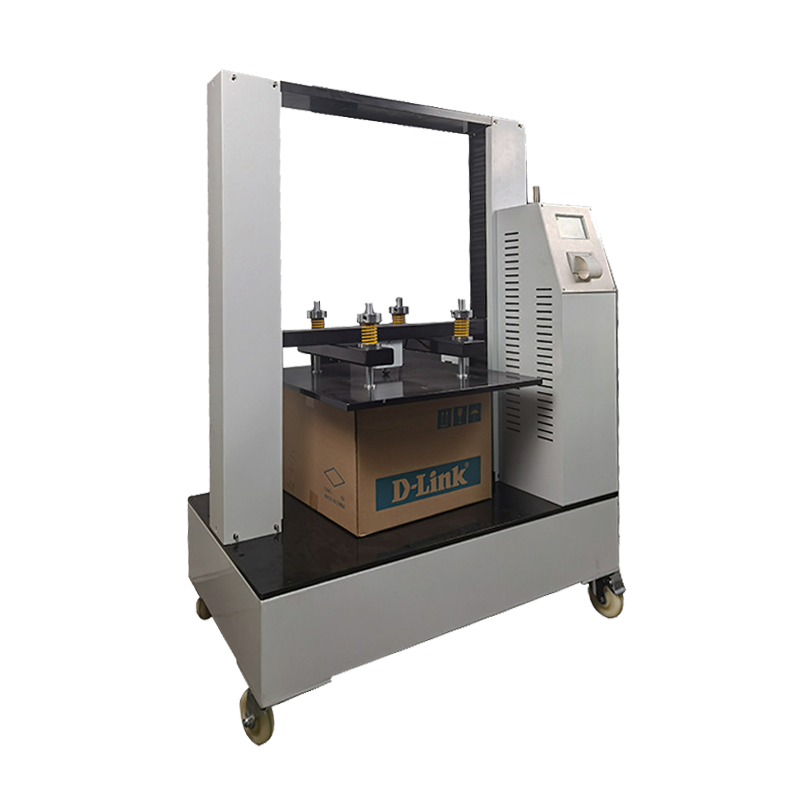

Precision Testing for Compliance and Safety

Designed for MIL-STD-810G standards, this machine enables manufacturers to evaluate products under exacting drop and impact test conditions. The precision-machined steel platform, combined with advanced safety features like an emergency stop and interlock door, ensures reliable, secure, and repeatable results for single specimens. Operators can conduct tests with instantaneous digital readouts and adjustable parameters for maximum flexibility.

Advanced Features for Versatile Applications

With a test capacity of up to 100 kg and adjustable drop strokes up to 1500 mm, the Drop Test Machine accommodates a range of specimen sizes. Control is effortless via manual or PLC modes, with digital panel display for precise parameter adjustments. The electromagnetic clamp lets you release samples at the exact desired drop height, while a sturdy, powder-coated frame guarantees stability and longevity.

Streamlined Operation and Safety at Every Step

Ease of use is central to the design, thanks to adjustable test heights, clear digital displays, and automation options. The equipment operates within a low noise threshold, ensuring a comfortable working environment. Operators benefit from advanced safety features and ergonomic mounting, making it ideal for busy labs or production lines requiring reliable shock and impact testing.

FAQ's of Drop Test Machine MIL-STD-810G Compliance:

Q: How does the Drop Test Machine ensure compliance with MIL-STD-810G during testing?

A: The Drop Test Machine is specifically engineered to meet the rigorous requirements of MIL-STD-810G, utilizing an electromagnetic clamp for precise specimen release and adjustable drop heights. This ensures consistent, accurate free-fall impacts as prescribed by the standard.Q: What safety features are incorporated in the Drop Test Machine?

A: Key safety features include an emergency stop button, an interlock door to prevent accidental access during operation, and a sturdy construction to ensure operator protection throughout the testing process.Q: When should I use the Drop Test Machine for my product evaluation?

A: The machine is ideal for verifying package or equipment durability during prototype development, pre-shipment testing, or quality assurance checks to ensure products meet military or industrial drop-impact standards.Q: Where is the Drop Test Machine typically installed and used?

A: This floor-standing machine is designed for use in quality control labs or manufacturing facilities, particularly by exporters and suppliers in India needing equipment that complies with international standards.Q: What is the process of conducting a drop test using this equipment?

A: Place the single test specimen (up to 100 kg and 8008001000 mm) on the precision-engineered drop platform. Adjust the drop height (up to 1500 mm) as required, set test parameters on the digital control panel, then release the sample using the electromagnetic clamp. Data is captured instantaneously for analysis.Q: How can the adjustable drop height and digital display benefit my testing procedures?

A: Adjustable drop height allows you to precisely match test conditions to product requirements, while the digital display ensures real-time monitoring and accurate, measurable results on every test cycle.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese