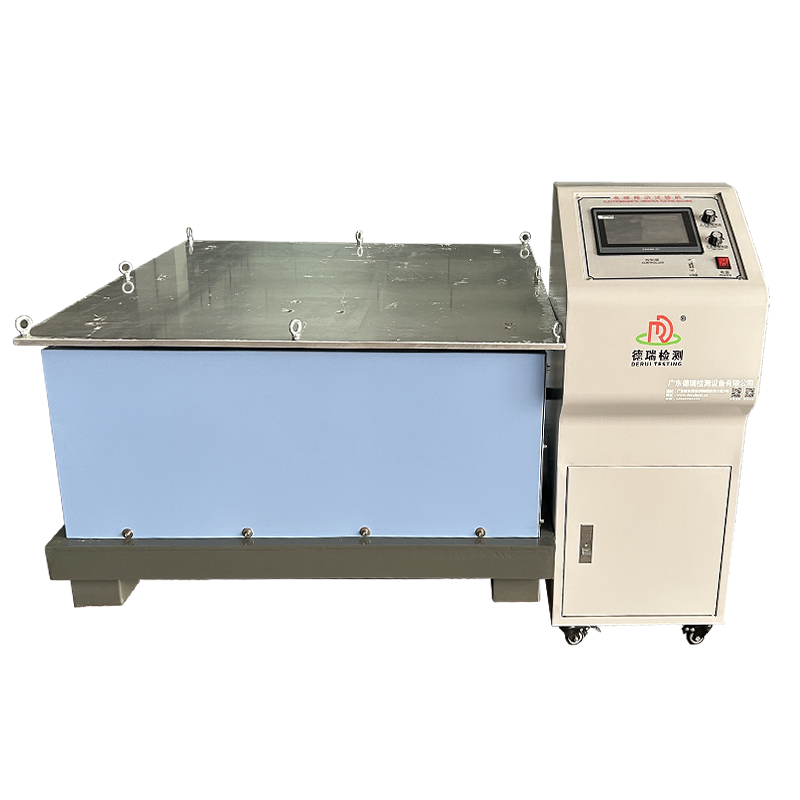

Electromagnetic three-axis vibration test bench

138005.0 INR/Unit

Product Details:

- Frequency 1~100 Hz (adjustable)

- Application Environmental simulation, reliability testing, vibration resistance assessment

- Automation Grade Automatic

- Power Supply AC 220V 10%, 50/60Hz

- Humidity 20%-90% RH (non-condensing)

- Port Size Standard Interface

- Equipment Type Electromagnetic Vibration Test Bench

- Click to view more

X

Electromagnetic three-axis vibration test bench Price And Quantity

- 138005.0 INR/Unit

- 1 Unit

- Windows compatible, remote monitoring enabled

- Up to 3000 N

- Industrial blue/grey standard

- X, Y, Z (independent or simultaneous)

- Supports up to 1000 test records

- LAN, USB, RS232

- 65 dB

- Over-load, over-current, over-temperature

- 0-50 mm

- Air-cooled

Electromagnetic three-axis vibration test bench Product Specifications

- Floor mount

- 0~100 Hz frequency range

- 400 mm

- Test bench platform: 45 HRC

- Three-axis vibration (XYZ)

- Three-axis simultaneous vibration, programmable profiles, overload protection

- 2%

- Up to 300 x 300 mm

- Digital touchscreen display

- 1-6 (adjustable)

- 220V

- 0.5~0.7 MPa (if pneumatic type)

- Up to 200 mm/s

- RS232/USB

- 600 mm

- Approx. 350 kg

- Digital Programmable Control

- Electromagnetic Vibration Test Bench

- 60 kg max. loading

- 0-50 mm

- Automatic

- Environmental simulation, reliability testing, vibration resistance assessment

- 1~100 Hz (adjustable)

- Standard Interface

- 20%-90% RH (non-condensing)

- AC 220V 10%, 50/60Hz

- 1 ms

- 0.01 Hz

- Electronic components, automotive parts, packaged products

- 5C ~ 40C

- Windows compatible, remote monitoring enabled

- Up to 3000 N

- Industrial blue/grey standard

- X, Y, Z (independent or simultaneous)

- Supports up to 1000 test records

- LAN, USB, RS232

- 65 dB

- Over-load, over-current, over-temperature

- 0-50 mm

- Air-cooled

Electromagnetic three-axis vibration test bench Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 3 Days

- All India

Product Description

| Item | DR-B216 |

| Max. Test Load | 100kg |

| Frequency Range | 60-300rpm |

| Amplitude Range | 25.4mm (1 inch) |

| Simulation Speed | 25~40km/h |

| Vibration Mode | Roundtrip |

| Work Table Size | 1000*1200 mm ( L*W, can be customized ) |

| Outside dimension ( L*W*H ) | 1255*1070*660mm |

| Speed Mode | DC converter or AC Frequency Control |

| Power Capacity | 1 HP |

| Weight | 150kg |

| Power | 220V, 50 Hz |

| Speed Mode | DC converter or AC Frequency Control |

| Environmental Conditions | Temperature: 5~40C; Related Humidity <85% |

With the continuous progress of science and technology, electromagnetic triaxial vibration test bench has become one of the indispensable and important equipments in modern engineering experiments. It plays an extremely important role in product development and quality control by simulating the vibration environment to help enterprises, scientific research institutions and other units to carry out precision vibration testing, especially in product development and quality control. Today, we will discuss the features, advantages and FAQs of electromagnetic triaxial vibration test bench.

Working Principle of Electromagnetic Triaxial Vibration Test Bench

Electromagnetic triaxial vibration test bench utilizes the electromagnetic principle to generate triaxial vibration through the interaction of electric current and magnetic field. It is capable of simulating a wide range of vibration conditions that may be encountered by products in transportation, use and natural environments, and provides composite vibration testing in different directions, including but not limited to horizontal, vertical and oscillating vibration. This test method is crucial for vibration testing in many fields such as electronics, aviation, automotive, and building materials.

Core Advantages of Electromagnetic Triaxial Vibration Test Bench

Accurate Vibration Simulation

Electromagnetic triaxial vibration test benches use advanced control technology to precisely adjust vibration frequency, amplitude, acceleration and other parameters to ensure highly accurate test results. Whether it is low-frequency or high-frequency vibration, the test bench can realize precise control.

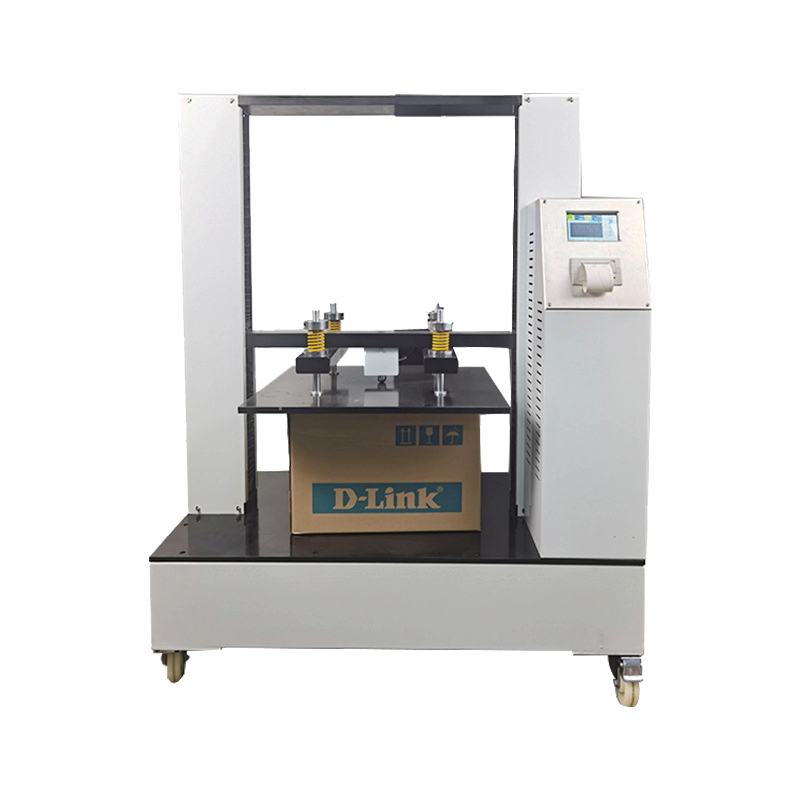

Three-axis composite vibration function

One of the best features of the device is that it has a triaxial compound vibration function, which can simultaneously apply vibration to the object under test in three directions (X, Y, Z). This allows it to more realistically simulate the complex vibration conditions in the actual working environment, and is particularly suitable for vibration testing of high-precision, high-demand products.

Wide applicability

Electromagnetic triaxial vibration test stands are used in many fields, such as aerospace, automobile manufacturing, electronic equipment, building materials, etc., and are suitable for a variety of experiments and tests. Whether it is a small and light precision instrument or a large mechanical device, it can provide comprehensive vibration test support.

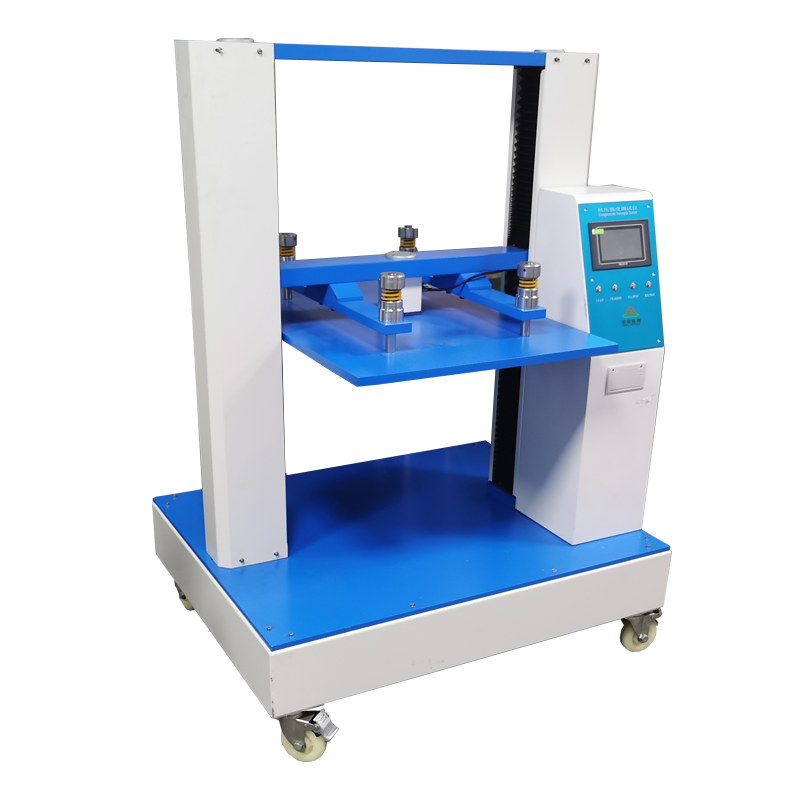

Easy to operate, accurate data

The control system of the test bench is designed to be very easy to use, so that even people with no professional operating experience can quickly get started. Equipped with high-precision sensors and data acquisition systems, the equipment is able to collect and analyze test data in real time and generate detailed test reports, helping users to quickly obtain accurate experimental results.

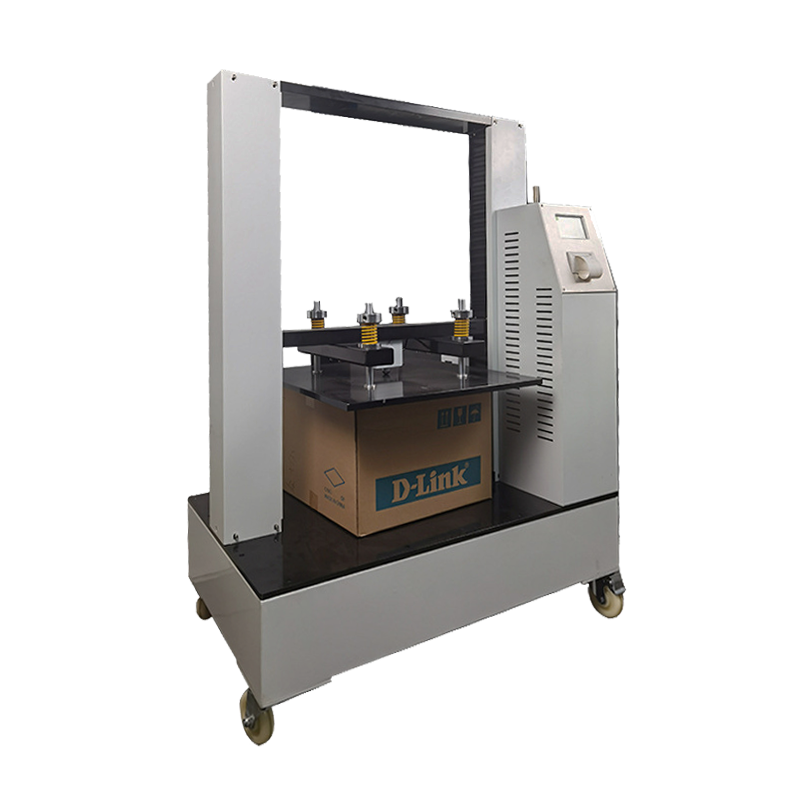

High Stability and Durability

Electromagnetic triaxial vibration test bench adopts high-quality materials and high-strength structural design, with good stability and the ability to work under high load for a long time. Even under long time and strong load vibration test conditions, the equipment is still able to operate stably and ensure test accuracy.

Application areas of electromagnetic triaxial vibration test bench

Aerospace

In the aerospace industry, electromagnetic triaxial vibration test benches are widely used in the vibration testing of aircraft, satellites, spacecraft, etc., to ensure the stability of the performance of these products in complex vibration environments.

Automobile manufacturing industry

Automobiles will encounter different frequencies and strengths of vibration during driving, electromagnetic triaxial vibration test bench can simulate the vibration environment of automobiles in driving, collision, etc., to help automobile enterprises to improve the anti-vibration ability of their products.

Electronic equipment field

As electronic equipment continues to move towards miniaturization and high performance, the impact of vibration on equipment is also increasing. Electromagnetic triaxial vibration test bench can simulate the vibration situation in various real environments, providing strong support for the seismic capacity test of electronic equipment.

Building Materials and Structures Testing

For building materials and structures, vibration testing is an important means of evaluating their seismic performance. Electromagnetic triaxial vibration tester can provide accurate vibration test data for construction projects, help relevant units to optimize building design and improve seismic performance.

Frequently Asked Questions

Q1: What is the main function of an electromagnetic triaxial vibration test bench?

A1: The electromagnetic triaxial vibration test bench is mainly used to simulate the multi-axial vibration environment that the products may encounter in transportation, use and natural environment, and to ensure the reliability and stability of the products in practical applications by testing their seismic capacity.

Q2: What types of vibration can be simulated?

A2: The electromagnetic triaxial vibration test bench can simulate compound vibration in three axes, including horizontal, vertical and oscillating vibration, which can accurately simulate the complex vibration conditions in the actual working environment.

Q3: What industries is the Electromagnetic Triaxial Vibration Test Bench applicable to?

A3: This equipment is widely used in aerospace, automobile manufacturing, electronic equipment, construction materials and other fields, especially suitable for vibration-sensitive products for high-precision testing.

Q4: Are the test results of the electromagnetic triaxial vibration test stand accurate?

A4: Yes, the electromagnetic triaxial vibration test bench adopts high-precision sensors and advanced control technology to ensure high accuracy and repeatability of vibration testing, which can provide users with reliable experimental data.

Q5: How to choose a suitable electromagnetic triaxial vibration test bench?

A5: When selecting an electromagnetic triaxial vibration test stand, you need to choose the right model of equipment based on specific testing needs (e.g., vibration frequency, acceleration, size of the test object, etc.). In addition, factors such as equipment stability, data processing capability and after-sales service should also be considered.

Versatile Three-Axis Vibration Testing

Experience comprehensive testing with independent or simultaneous vibration along X, Y, and Z axes, covering a frequency range of 1 to 100 Hz and an excitation force up to 3000 N. The bench supports testing of up to six specimens simultaneously, with a max load capacity of 60 kg and precise control over test parameters, making it ideal for evaluating structural integrity and product reliability.

User-Friendly Controls & Advanced Safety

Operate with ease using the digital touchscreen display and programmable controls, compatible with Windows systems. The bench incorporates essential protection features including over-load, over-current, and over-temperature safeguards, ensuring both operator safety and equipment longevity during rigorous testing cycles.

Robust Design & Flexible Installation

Crafted in industrial blue/grey, the robust platform features 45 HRC hardness and accommodates specimens up to 300 x 300 mm. The air-cooled, floor-mounted design is ideal for modern laboratories, requiring standard AC 220V power and supporting gas pressure input for pneumatic versions. Automation and remote monitoring add to operational efficiency.

FAQ's of Electromagnetic three-axis vibration test bench:

Q: How does the Electromagnetic Three-Axis Vibration Test Bench operate?

A: The test bench uses electromagnetic vibration technology to deliver programmable vibrations along the X, Y, and Z axes independently or simultaneously. Operators set test profiles using the digital touchscreen interface, allowing precise control of frequency, displacement, and test duration.Q: What types of products can be tested with this bench?

A: This equipment is suitable for electronic components, automotive parts, and packaged products, accommodating specimen sizes up to 300 x 300 mm and weights up to 60 kg. It is widely used for environmental simulation, reliability testing, and vibration resistance assessments.Q: When should I use the simultaneous vibration mode?

A: Simultaneous three-axis vibration is ideal when you need to simulate real-world conditions where products experience multidirectional forces, such as in transportation or vehicle environments. This helps ensure comprehensive durability and reliability assessments.Q: Where is the optimal environment to install the test bench?

A: Install the bench in a laboratory or industrial environment with ambient temperatures between 5C and 40C and humidity levels between 20% and 90% RH (non-condensing). A standard AC 220V power supply is required, along with a stable, flat floor for mounting.Q: What is the process for retrieving test data from the machine?

A: Test results are stored digitally, supporting up to 1000 records. Data can be exported through LAN, USB, or RS232 connections, enabling efficient integration with your quality assurance reporting systems.Q: How does the machine ensure safe operation during testing?

A: The test bench is equipped with multiple protective features, including over-load, over-current, and over-temperature protection. These safeguards automatically intervene to prevent equipment damage or hazardous situations during rigorous testing cycles.Q: What are the benefits of remote monitoring and programmable profiles?

A: Remote monitoring allows users to oversee and control tests from a distance, improving safety and workflow efficiency. Programmable profiles enable repeatable, consistent testing scenarios, enhancing test precision and facilitating easy process automation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese